drilling rig rotary table sizes brands

Cameron rotary tables range from 27 1/2 in to 60 1/2 in and feature a large oil capacity that adds to the unit"s durability. The rotary table includes a forged-steel fabricated housing and a heat-treated forged-steel turntable. Each rotary table is supplied with spiral-bevel, induction-hardened gears and two independent ratchet-type locks, with lever access from the top to lock the table in position.

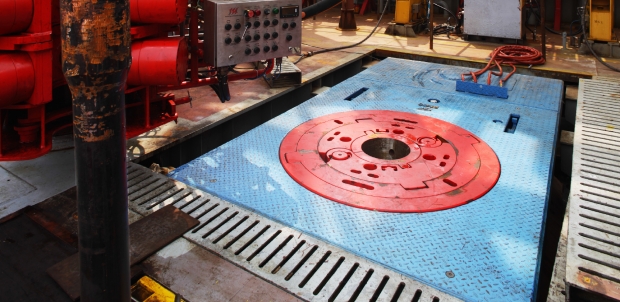

The C-375 Rotary Table by National Oilwell Varco is used for onshore and offshore drilling. Most conductor, riser, and wellhead elements will pass through the C-375 Rotary Table 37-1/2″ table opening.

Armco produces a full line of NATIONAL Rotaries notable for dependability, safety and efficiency, and suitable for any drilling requirement from shallow to the deepest wells. Construction features of NATIONAL Rotaries are developments of nearly half a century of constant design improvement.

Throughout every region in the world and across every area of drilling and production, our family of companies has provided the technical expertise, advanced equipment, and operational support necessary for success—now and in the future.

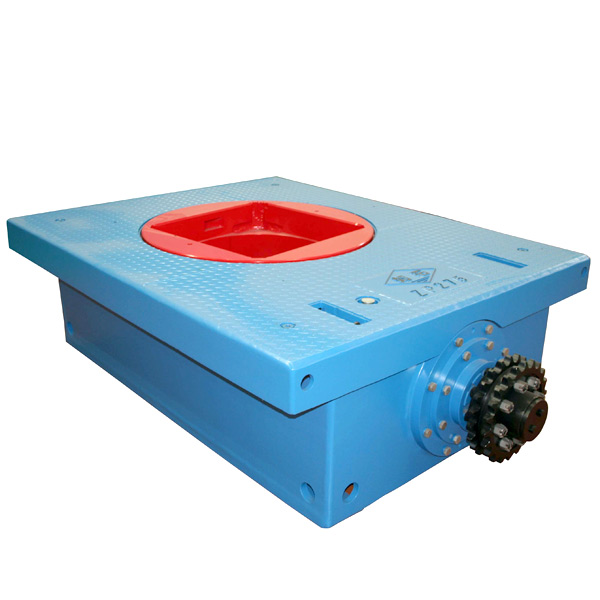

TSC RT series rotary table is provided with high reliability and serviceability. The rotary table structure has been designed to provide maximum strength to ensure larger load, increased safety and well-fit between bearings and gears. The table assembly was greatly simplified so it can be installed into the rotary housing and is easy to maintain. The RT series can be designed to meet the requirements of various drilling operations and work environments.

The Hacker International HTD Rotating System is designed and built as an efficient and economical compliment to drilling rigs utilizing a top drive drilling system. Whether a rig build or a retrofit to an existing rig, the Hacker HTD can be designed to fit any application, any size, and is engineered for the most rugged drilling conditions. Hacker International is world renowned for its custom built rotary tables which are being utilized on every continent in the world. We pride ourselves in our innovative designs and our ability to solve specific needs of our customers in each custom rotating system we build.

The new HTD units are available in sizes 49.5”, 37.5”, 27.5”, 22.5”, 20.5”, and the ever popular 17.5”. Custom built units are also available for 15”, 12.5” and 10.5” rotating systems. Hacker also sells any type of bushings required to satisfy our customers’ needs.

With a maximum torque of 25k ft. lbs., a rotating speed of 135 rpm’s and with a static load rating of 1250 tons, our 27.5” table is a brute able to withstand harsh drilling conditions but easily controlled by the movement of a joy stick. These high torque variable speed features make this rotating system the perfect complement to your top drive system.

All of our tables are equipped with precision machined spiral bevel gears and heavy duty main thrust bearings to provide long lasting durability. The dual locking system utilizes ratcheting lock pawls that engage the rim of the table assembly. This enables the table to be locked in a single direction or both directions. The entire pinion shaft assembly uses a sealed cascade lubrication system from a large oil reservoir.

All Hacker Rotating Systems are field-proven, efficient and reliable giving our customers many years of reliable service. And if repairs are needed for any of your drilling rig components don’t hesitate to call us 24/7. Our fully staffed component repair facility and fabrication shop has a 30 ton lifting capacity with 25 feet under hook clearance.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

Jiangsu Xinxiang share Co., Ltd was founded in 1994, its predecessor was established in 1955, it‘s located in high-tech industrial concentration zone of Nantong City, Jiangsu Province; near to a new developing international deep-water port Yangkou Port which commitment to ship 200,000 tons goods; world famous modern city Shanghai is only 2.5 hours away from it by car; company registered capital is 60,000,000 RMB, the total assets is 119.85 million RMB, it covers an area of 160,000 square meters and currently over 500 employees. Jiangsu Xinxiang Share Co., Ltd is "self-import and export enterprise", "private technology enterprises in Jiangsu Province", "high-tech enterprises in Jiangsu Province", it is top ten companies of the first national large and medium-sized industrial enterprises in independent innovation capacity of the industry; it accessed to API7, 7K, 8A, 8C, and has the right to use the logo, and also passed the ISO9001:2000 quality system certification in the earlier stage within the same industry.

Explore the various drilling rig parts rotary table products available for wholesale at Alibaba.com. Get a drilling rig parts rotary table for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some drilling rig parts rotary table options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

drilling rig parts rotary table options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a drilling rig parts rotary table that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. Chinese wholesalers provide you with customization options and great after-sales services.

Forum offers a wide variety of safety clamps designed to fit tubulars up to 43 inches. Gripping pressure remains uniform around pipes to prevent crushing thin-walled pipes or gouging their surfaces. Adding or removing segments adjusts the gripping diameters by approximately one inch per segment, providing flexible options that accommodate numerous pipe sizes.

Depending on the size of your drilling pipes, Forum offers clamp types C, T, CXL and AMP to ensure a perfect fit while making-up or breaking-out the string.

KINGWELL Rotary Table Features & Benefits: Rotary table is effective device used in drilling rig which conforms to API spec 7K. Kingwell can offer a full range of table from 17 ½ to 60 ½. These tables are able to stand the worst drilling conditions with fabricated frame, heavy duty main thrust bearing and precision machined spiral bevel gear. That is why our table is in superior strength, toughness and durability 1. Gear and pinion are made of alloy steel2. Split main bushing is steel cast. Kelly drive and slip drive are available for choose.3. Match with API standard casing bushing and special lifting tool4. Spiral bevel gear ensures a strong load capacity, steady operation and a long service life.5. Efficient lubrication and reliable sealing.6. Fabricated frame which ensures a strong rigidity and high precision.7. Higher load, smaller overall size and lighter weight.

Unfortunately they too suffer from "cheapitis". Indian made tools fall into two definate classes of good and not so good. The problem being that there is little or no consistency from model, size or brand. Bison and some of the other vendors like Grizzly do have a decent quality offering, but they are not sub 100 dollar items. You definately want the largest table that your mill will accomodate because you also need room to be able to clamp and secure the piece you are working on. I am not familiar with the dimensions of your lathe/mill but you want to try to keep the quill retracted as close to the head as possible to impprove stiffness and reduce chatter, but you do not want to crowd the head too much either. I would also opt for the horz/verticle mounting options to increase the tools use and versatility. The sub 100 dollar units seem to be rough, have a good bit of looseness and have been found to even still have casting dirt still in the cavities. This is especially prevalent in the cheapest offerings from places like CDCO and Shars. So I would suggest a bit more shopping with an eye toward making one slightly more expensive purchase rather than having to revuild/repair a smaller unit that you will ultimately replace or relegate to the "spare parts" dungeon. I have not bught one myself yet, but I have been following a number of threads outlining the woes of others who failed too remember the old adage of :Ya gets what ya pays for, and nothing more" Hope this helps and is not intended to discourage just inform and to help you become aware of the pitfalls with rotary tables in general.

Unfortunately they too suffer from "cheapitis". Indian made tools fall into two definate classes of good and not so good. The problem being that there is little or no consistency from model, size or brand. Bison and some of the other vendors like Grizzly do have a decent quality offering, but they are not sub 100 dollar items. You definately want the largest table that your mill will accomodate because you also need room to be able to clamp and secure the piece you are working on. I am not familiar with the dimensions of your lathe/mill but you want to try to keep the quill retracted as close to the head as possible to impprove stiffness and reduce chatter, but you do not want to crowd the head too much either. I would also opt for the horz/verticle mounting options to increase the tools use and versatility. The sub 100 dollar units seem to be rough, have a good bit of looseness and have been found to even still have casting dirt still in the cavities. This is especially prevalent in the cheapest offerings from places like CDCO and Shars. So I would suggest a bit more shopping with an eye toward making one slightly more expensive purchase rather than having to revuild/repair a smaller unit that you will ultimately replace or relegate to the "spare parts" dungeon. I have not bught one myself yet, but I have been following a number of threads outlining the woes of others who failed too remember the old adage of "Ya gets what ya pays for, and nothing more" Hope this helps and is not intended to discourage just inform and to help you become aware of the pitfalls with rotary tables in general.

8613371530291

8613371530291