edm rotary table quotation

This indexing unit with collet chuck is specially designed for use on wire-EDM machines provided. Through the mounting holes mounting on hole pattern 40 mm and 50 mm by M8 srews is possible.

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or ...

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

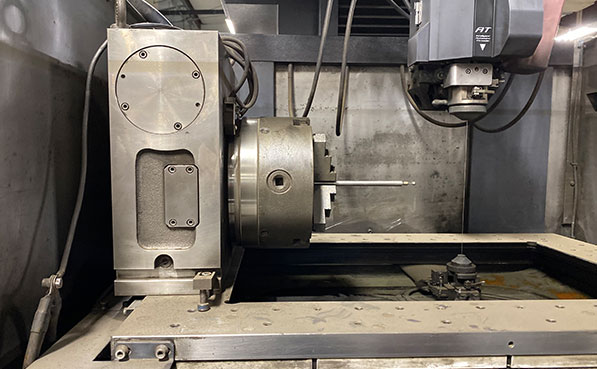

The MMK Matsumoto Corp. MDW series single axis EDM rotary table is specifically designed for wire EDM applications. MDW series indexers are protected from the EDM environment, fully sealed, air purged and impervious to debris, oil and water.

These EDM rotary tables can be mounded on the A-axis or B-axis. The table’s internal structure is completely isolated from the electric current, and the unit is equipped with current-collecting brushes, which help to effectively distribute electricity charge.

Matsumoto MDW series EDM rotary tables are built from stainless still and can be fully submersed in oil or water. The tables feature an OTT (German) worm gear system with optional power chuck, tailstock, and additional brushes for enhanced performance.

Anyway, to answer your questions, I looked up the Hirschmann table you referenced and it looks to me like it"s a spinner and indexer, not a turn while burn table.

Hirschmann must have a similar provision to integrate their turn while burn capable tables to whatever machines they are going to be run on...I don"t think you can just buy one and bolt it to a machine without the interface kit to mate it to the control.

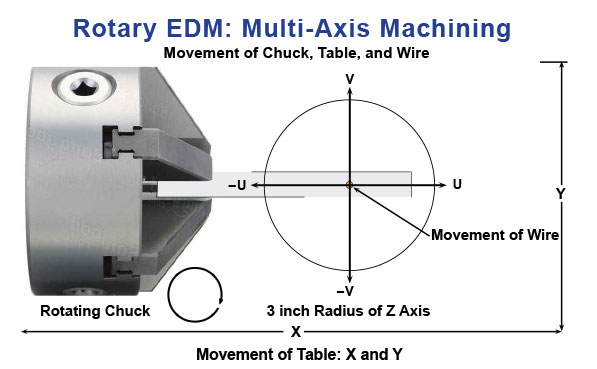

Turn while burn requires that the controller governs the rotary motion; this is because the rate of rotation has to be driven by the spark gap conditions in conjunction with the axis motion of the rest of the machine whether it"s X or Y or U or V.

It was faked by tilting the wire to an angle other than the thread helix angle with the U axis, then driving a fine pitch helix with B and X (B is the rotary axis on my machine).

You can imagine just how many passes that would take (a LOT), and you will always have a 0.005" radius at the junction of each flank and the root, which may or may not be acceptable depending on the application.

The robust geared rotary tables of the 500 series are extremely flexible to use and, thanks to the combiFLEX® modular system, can be converted or extended at any time to meet new machining tasks. The rotary tables are not only suitable for positioning operation, but can also be used for short simultaneous machining operations. The preloaded gear and the powerful bearings allow high long-term accuracies as well as large spindle loads. The maximum clamping force of up to 7,000 Nm leaves hardly anything to be desired.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

The high-speed generating LN2WH Control uses a Windows platform. The system was designed to provide a user-friendly environment for the operator and still have the high-level functionality that is required in today’s demanding world. The control is network capable, which will allow for NC sharing, remote monitoring and messaging via LAN (option). The LN2WH Control automatically generates cutting conditions, offsets, corner control settings, wire speed, wire tension and other data necessary for proper operation. This is especially helpful to novice EDM operators, since no prior knowledge of EDM is necessary to achieve excellent results.

Where wire EDM is concerned, accuracy has traditionally come at the cost of speed. That’s why FANUC has developed a next generation ROBOCUT wire-cutting machine. The α-CiB series comprises three versatile all-around machines, including the first model with an 800 mm table. With incredibly long mean times between failures, low maintenance, longevity and excellent uptimes, these future-proof spark erosion machines are designed to save time and drive down unit costs while ensuring outstanding accuracy and cutting efficiency.

ROBOCUT’s Smart Positioning function gets you started faster by cutting the time it takes the wire EDM machine to measure geometrical references on the workpiece.

ROBOCUT is available with a CCR rotary table. This lightweight universal rotary table comes with high-resolution glass scales and, for maximum concentricity, provides optimum travel between the U and V axes.

Depending on the model, ROBOCUT’s U and V axes can be traversed 90 mm beyond the table. This enables smaller workpieces to be machined without the need for expensive clamping devices.

We believe that our wealth of experience and our passion for quality makes Midland Engineering the best choice when it comes to the repair of your rotary table. We understand the need for a quality assured repair service with a focus on keeping downtime to a minimum.

Burn Time Counter – Auto stop feature in which a maximum time is preprogrammed into the burn command. If the EDM process is not accomplished in this given time, the EDM process will discontinue.

Micro-Pulse Technology – is specifically designed for low recast and little or no detectable micro cracking in aerospace as well as semiconductor industries during fast hole EDM process.

Depth Finder – For blind hole applications where a specific depth needs to be met in the target material. Sample measurements are taken during the drilling process to calculate tool and material wear. These calculations make it possible for the EDM process to be stopped at a specific depth.

High-speed EDM Drill 20 Model has an integrated rotary spindle. The X, Y, and Z axes are motor powered and controlled by a Windows-based CNC HMI control. The cast-iron, compact, open-front frame guarantees stability. The data input is quick and simple.

Technology settings are selected automatically by material electrode / piece, piece height, and electrode diameter with a few commands. Options allow you to go to .004 -.12 electrode range (fine hole drilling option is -.004 - .012 inches). This is suitable for drilling start holes on lead frames and high-speed stamping molds.

It’s a sensible complement to any wire EDM product. Filtration system and DI unit are standard with this model. There is an AC Cam Drill option. An on-board programming system allows you to define multiple hole positions as well as import DXF / IGES / TXT / files. Get all of this at the most competitive price in the class.

Makino EDMs stand apart with the intuitive Hyper-i control system, a streamlined and efficient interface that helps you get work done faster. A large high definition 24” touch screen functions like a smart device (phone/tablet), allowing operators of all skill levels to benefit from its inviting and familiar operation that substantially reduces training requirements. The Hyper-i control further elevates an operator’s capability with several integrated advanced functions, such as hyper-linked digital manuals and video tutorials, E-Tech Doctor, and EZ-Cut that deliver higher levels of productivity to the operator’s fingertips.

With pinpoint sub-micron precision and outstanding surface finish, these are ideal for small electronics and micromachining applications. Built on the EDAC-1 machine platform, the machine can perform ultra-high precision ram EDM operations as well as small hole drilling.

With a focus on high-precision small hole drilling and excellent edge quality, these also have the flexibility to execute standard ram EDM operations.

8613371530291

8613371530291