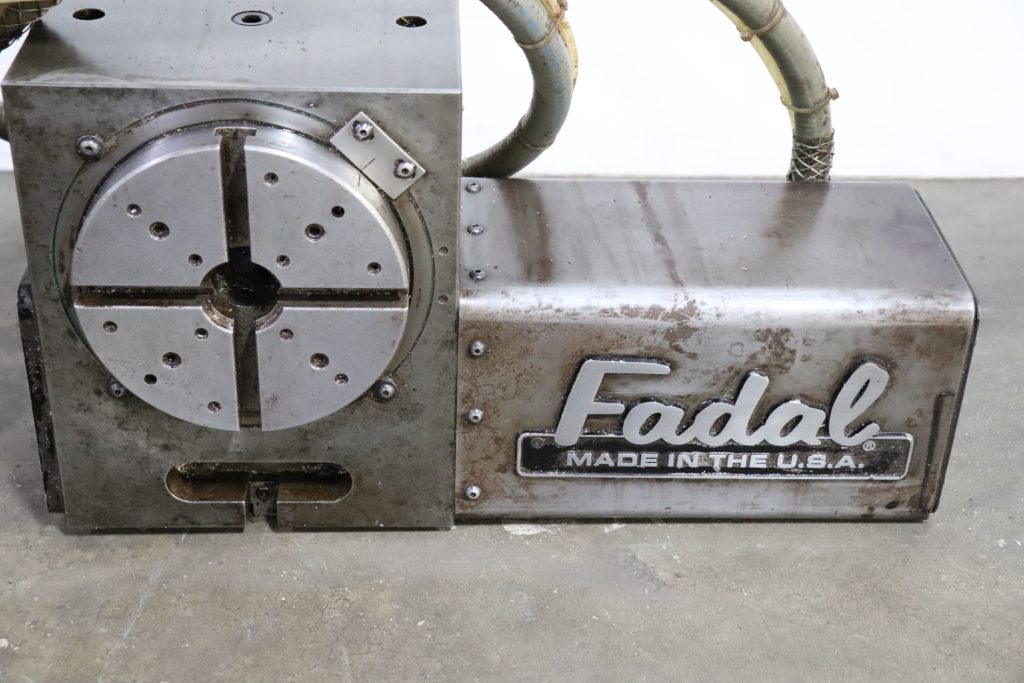

fadal 4th axis cnc rotary table brands

Index Designs is an all-American company. Their founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. Index Designs entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Thier products are completely manufactured in our Chatsworth, California facility. Index Designs uses state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines.

All CategoriesRoot CatalogDefault CategoryAmplifier Power SuppliesAmplifiers, AC & DCFeatured AmplifiersAxis, Rotary & Turret MotorsBallscrews, Assemblies & Parts1) Ballscrew Only2) Ballscrew Assemblies4) Ballscrew Covers5) Ballscrew NutsBearings & KitsBelts & Belt GuidesBreakers & FusesBrushes, DC MotorCables & Wire HarnessesChain & Sprocket KitsChiller UnitCircuit Boards1010 Axis/Spindle1020 Clock Boards1030 Cmptr. Interface1040 Mill Interface1050 M Function1060 Mother Boards1090 Keyboards1100 Power Distribution1400 CPU Boards1420 Video Boards1460 Memory Expansion1550 Chiller Boards1610 Software Modules1900 Pendant InterfaceAll Other CNC BoardsUpgrade KitsCouplersCylindersDoor PartsDow Frost, Epoxy, GreaseDrawbar & Spindle PartsElectrical PartsEncoders, Resolvers & Tach.Eproms & SoftwareFansGibs & StrapsHardware, Misc. PartsHydraulic ActuatorIdler PartsKeyboardsLights and LampsLinear GuidesLube & Plumbing PartsMonitorsMPG Remote & PartsO-RingsOrientation PartsPower SuppliesPulleysPumps & Pump PartsRegulatorsRelaysRotary HeadsRotary Parts & KitsSealsSensors & SwitchesService ToolsSpindle DrivesSpindle Motors & PartsSpindles, New & RemanTool Changer PartsTransformersTurcite Kits & EpoxyValvesWay Covers & WipersUSB Mass StorageSprings1330 Dual Arm (DATC)New ArrivalsWaycoversLoad MeterTension Idler PartsLCD DisplaysSpecial OfferReman, Circuit Boards3) Bearing MountsFadal DecalFadal DecalScalesItsfadalpartsMotor MountsWay Lube CarriersHoses & Tubing

Fadal CNC 88 Control, 4th Axis Drive and Interface, Fadal VH-65 Rotary Table, Coolant System, 20 Station Automatic Tool Changer, Cat 40 Spindle Taper, 10,000 Max Spindle RPM

Fadal VMC 6535 VHT 3-Axis CNC Vertical Machining Center with Fanuc 18iMB Control, 10,000 RPM VHT Spindle, Hennig Chip Conveyor, 24 Station Side Mount Tool Changer

Fadal VH-65 4th Axis Rotary Table, 7,500 RPM, BT40, 21 ATC. This 2000 Fadal VMC 2016L vertical machining center includes Expanded Memory 384KB and high speed CPU with graphics.

Fadal VH65 4th Axis Rotary Table, 7,500 RPM, BT40, 21 ATC. This 1999 Fadal VMC 2016L vertical machining center has an upgraded LCD screen and high speed CPU with graphics!

Are you looking for an accessory to boost the precision of your modern machining centers? CNC rotary tables provide a versatile tool in expanding the capabilities of your machines. They allow for precision positioning during 4 and even 5 axis cutting operations, thereby transforming 3-axis machinery into CNC machines with heightened accuracy. CNC rotary tables are a cost-effective solution to perform complicated machining tasks, with additional benefits such as increased productivity, efficient use of labor and materials, and better quality control.

Additionally, CNC rotary tables can be used independently to mount other components on a table, including trim attachments and chucks for drilling applications. CNC rotary tables offer considerable advantages that promote their usefulness in a variety of industrial settings.

Looking to sell your CNC Rotary Table? Simply fill out the sell your machine form and we will get back to you with a quote. Interested in one of our used machines for sale? Simply click the “Get Quote” button and a sales representative will contact you shortly.

A normal CNC milling machine has three axes: the X, Y and Z axis. From the front of a machine, the X-axis is left to right, the Y is front to back and the Z is up and down. The workpiece is stationary on a bed and the cutter does all the moving (unless there is a T-slot bed).3 Axis CNC Mill4 Axis CNC Mill5 Axis CNC Mill

This configuration can mill slots, drill holes and face off parts with the cutter in the vertical direction only.Generally, the 4th axis rotates around the X-axis (which moves left to right). This allows you to make holes and slots in the front and back of the workpiece. The cutter can rotate around the part which is fixed on a table. The fourth axis is called the A axis.When the A axis is at zero, a fifth axis would be perpendicular to the Z axis. The cutter can be rotated 90 degrees towards to the front of the machine and moved to allow for milling around the sides of the workpiece. The 5th axis is called the C axis.

When deciding on the type of used 4 axis mills to purchase, key factors to consider will be part complexity, part mix and the average number of parts to be run per setup.

Primary Industry: Is your shop dedicated to a single manufacturing field like automotive, aerospace, mold & die, medical device or oil? The different industries have different demands for torque, speed and precision. For example, medical devices frequently require smaller, high-precision parts. Aerospace demands difficult to machine materials and many large parts. This would indicate that you need a 4 axis CNC mill with enough power to handle tough materials.

Physical Size: You"ll want to consider the physical size of your used CNC 4 axis machine. This will be dictated by the size of parts to be machined in diameter, length, X, Y and Z travel, as well as any other axis travel in degrees. Then you"ll need to determine the rigidity and horsepower requirements by thinking about the types of materials that you will be machining.

Built to order: Keep in mind that some multi-axis machines are better than others for particular applications. It is helpful to learn if a particular used CNC machine was used in a similar application before. Often 4 axis CNC machines are built to order per a specific customers needs. When you buy used, you"re looking for the closest fit from existing machines.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

11" 4th Axis Index Design Rotary Table (Glentek AC motor) for FADAL VMC . Made in the USA! The Index Designs VH11 is a rotary table that is compatible with Old Legacy Fadal VMCs (Calmotion 4th Axis kit). This rotary is high performance with an accuracy of +/-15 arc-seconds and a brake torque of 450 ft-lbs. Made in the USA! The Index Designs VH11 is a rotary table that is compatible with Old Legacy Fadal VMCs (Calmotion 4th Axis kit). This rotary is high performance with an accuracy of +/-15 arc-seconds and a brake torque of 450 ft-lbs. This particular model is equipped with a Glentek AC motor with a cable to the bulkhead. Available in different configurations (Legacy Fadal AC or DC motors, Fanuc motors, Mitsubishi, Yaskawa), VMC must be 4th Axis ready. Does not include any axis cards, amps, or internal cabinet wiring. Specs : Accuracy = +/- 15 Arc-seconds Brake torque = 450 ft-lbs Brake type = pneumatic Repeat-ability = 10 arc-seconds Gear Ratio = 120:1 Spindle Diameter = 11" (280mm) Center line = 6.750"

8613371530291

8613371530291