fadal rotary table quotation

All CategoriesRoot CatalogDefault CategoryAmplifier Power SuppliesAmplifiers, AC & DCFeatured AmplifiersAxis, Rotary & Turret MotorsBallscrews, Assemblies & Parts1) Ballscrew Only2) Ballscrew Assemblies4) Ballscrew Covers5) Ballscrew NutsBearings & KitsBelts & Belt GuidesBreakers & FusesBrushes, DC MotorCables & Wire HarnessesChain & Sprocket KitsChiller UnitCircuit Boards1010 Axis/Spindle1020 Clock Boards1030 Cmptr. Interface1040 Mill Interface1050 M Function1060 Mother Boards1090 Keyboards1100 Power Distribution1400 CPU Boards1420 Video Boards1460 Memory Expansion1550 Chiller Boards1610 Software Modules1900 Pendant InterfaceAll Other CNC BoardsUpgrade KitsCouplersCylindersDoor PartsDow Frost, Epoxy, GreaseDrawbar & Spindle PartsElectrical PartsEncoders, Resolvers & Tach.Eproms & SoftwareFansGibs & StrapsHardware, Misc. PartsHydraulic ActuatorIdler PartsKeyboardsLights and LampsLinear GuidesLube & Plumbing PartsMonitorsMPG Remote & PartsO-RingsOrientation PartsPower SuppliesPulleysPumps & Pump PartsRegulatorsRelaysRotary HeadsRotary Parts & KitsSealsSensors & SwitchesService ToolsSpindle DrivesSpindle Motors & PartsSpindles, New & RemanTool Changer PartsTransformersTurcite Kits & EpoxyValvesWay Covers & WipersUSB Mass StorageSprings1330 Dual Arm (DATC)New ArrivalsWaycoversLoad MeterTension Idler PartsLCD DisplaysSpecial OfferReman, Circuit Boards3) Bearing MountsFadal DecalFadal DecalScalesItsfadalpartsMotor MountsWay Lube CarriersHoses & Tubing

Your rotary unit is repaired, reassembled and run in for 10 hours. It is then re-inspected, all final adjustments and calibrations are performed to the original manufactures specification.

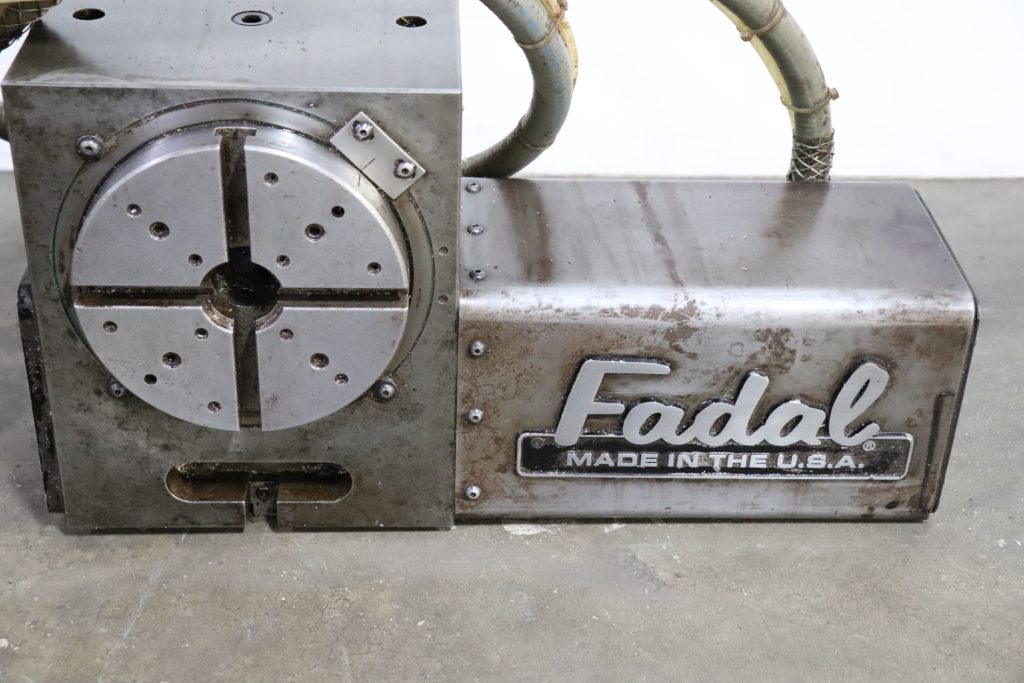

The original Fadal rotary heads are still one of the best overall designed attachments for the Fadal machine. While there are many imported rotary heads that might "look good" on the outside, it"s the inside that really counts. The simple fact is the Fadal rotary tables were specifically designed to take a crash and keep on working.

Many different rotary heads were made throughout the years of production. A 4th or 5th rotary axis was one of the most popular machine options. In the early 90"s we started shipping all machines "4th axis ready" which means the machine has all the wiring necessary. You basically only needed an amplifier and a axis controller card with software. Contact us if you thinking of adding a 4th axis, we offer all the necessary components.

As you"ll see below, we are the most qualified to repair your rotary table. Having been there from the beginning, we know exactly what your table needs to bring it up to original specifications.

The very first rotary table sold that was sold on the VMC45 in 1981. It was designed and manufactured by Fadal for the VMC45, it never realized full production after production the VMC45 was stopped.

Troyke Mfg. Co. -Afterwards, with the introduction of the VMC40 in 1984, we began offering the TROYKE rotary products as a 4th axis option. The table had an interesting full contact bearing surface using Turcite between the faceplate and the casting with radial bearings support for the faceplate spindle. Few of theses units still remain in the field today. If needed, we can provide complete service for these units.

Soon after 1987, we started adapting many of the popular Japanese rotary tables. Some customers would send us their tables and we adapt our motors and 4th axis interface to them. Eventually we started adding the Tsudakoma, Tecnara and Nikken rotary tables as a direct option to all machines

TR65 - The TR65 (Tilt/Rotate, 6.5" dia. faceplate) had a unique clutch system build into the trunion for the B-axis. One of the biggest problems with 5-axis programming was that is was easier to crash than to program. And a B-axis crash usually resulted in the customer having to return the unit for repair. With this unique design, if the Z-axis crashed into the part, instead of damaging the gears it would simply slip the trunion clutch. The CNC knows the exact position of the B-axis because of the rotary scale feedback that is directly attached to the trunion and not the motor. The addition of the trunion clutch was so important because it virtually eliminated the disruption of operation for a service call.

Index Designs is an all-American company. Their founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. Index Designs entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Thier products are completely manufactured in our Chatsworth, California facility. Index Designs uses state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines.

Increase efficiency and production of your CNC machine with our Dual VH-8. Perfect for making 2 parts at a time thus reducing the number of tool changes and allowing the operator more time to complete other tasks. The standard configuration places the motor at the side or we also offer the option to wrap the motor around the back to save space, reduce overall length and eliminate possible machine interferences. The Dual VH-8 has twin 8.25" spindles (210mm) with dual tapered roller bearings supporting the front and back of each spindle. The VH-8 worm wheel is helically cut and throated for increased surface contact between the wheel and worm. This provides longevity and helps maintain the accuracy of the rotary table over time. There are optional 8" 3-Jaw chucks and adapter plates available as well as a 5C nose pieces with either manual or air collet closers for your workholding needs.

The Index Designs Dual VH-8 is a true 4th-axis rotary table with two platters,complete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

Increase productivity and reduce setup time with the TR-8, 4th- and 5th-axis rotary table by eliminating second and third operations. In a single set-up, achieve multi-sided machining capability as well as the ability to tackle tough complex shapes and difficult to reach angles. Both housings were based on our VH8 and still come packed with the same quality. Both spindles and worms have dual bearings. Each worm wheel is helically cut and throated for greater surface contact between the wheel and worm. The B axis housing uses a stronger motor to make up for the extra weight of tilting the A axis housing and maintain accuracy.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th and 5th axis drive needed.

Fadal VMC 6535 VHT 3-Axis CNC Vertical Machining Center with Fanuc 18iMB Control, 10,000 RPM VHT Spindle, Hennig Chip Conveyor, 24 Station Side Mount Tool Changer

Fadal VH-65 4th Axis Rotary Table, 7,500 RPM, BT40, 21 ATC. This 2000 Fadal VMC 2016L vertical machining center includes Expanded Memory 384KB and high speed CPU with graphics.

Fadal VH65 4th Axis Rotary Table, 7,500 RPM, BT40, 21 ATC. This 1999 Fadal VMC 2016L vertical machining center has an upgraded LCD screen and high speed CPU with graphics!

Fadal CNC 32MP Control, 4th Axis Drive and INterface, Fadal VH65 Programmable Rotary Table, 28" Extended Z Axis Travel, 20 Station Automatic Tool Changer, Hydrosweep Chip Removal System, Coolant System, Rigid Tapping, Expanded memory to 166k, High Speed CPU, Thru Spindle Coolant, Servo Turret, Baldor 15HT High Torque Spindle Drive, Machine Manuals

Fadal CNC 32MP Control, 4th Axis Drive and INterface, Fadal VH65 Programmable Rotary Table, 28" Extended Z Axis Travel, 20 Station Automatic Tool Changer, Hydrosweep Chip Removal System, Coolant System, Rigid Tapping, Expanded memory to 166k, High Speed CPU, Thru Spindle Coolant, Servo Turret, Baldor 15HT High Torque Spindle Drive, Machine Manuals

Fadal CNC 88 Control, 4th Axis Drive and Interface, Fadal VH-65 Rotary Table, Coolant System, 20 Station Automatic Tool Changer, Cat 40 Spindle Taper, 10,000 Max Spindle RPM

Pre-owned FADAL VMC4020FX 2008 Vertical Machining Center. This Vertical Machining Center has average cutting time and is equipped with a CNC control. Extended 28" Z Axis This CNC Machine is currently located in USA. This FADAL Vertical Machining Center is available for a limited time. Get a quote today on this VMC4020FX before it"s gone.

Specializing in Fadal CNC rebuilding, We disassemble the machine complete and inspect each and every part, checking the machine and base ways for wear, flatness and alignment. We are world wide and taking a major leap forward in rebuilding rigid box way constructed machines. In the rebuilding process minimizing friction between to way surfaces ensures effective advanced performances at a high feed rate. In re-scraping a machine or rebuilding the ways to a new machine tolerance we are ensuring the customer that there machine is performing to the highest level of speed and accuracy that the machine is designed for.

Fadal VH165 4th Axis Rotary Table 6" Diameter DC Motor VMC 15, 4020, 3016, 6030. VH165 In extremely clean condition. Center Height: 6.5" Swing Clearance: 12.95" Weight: 165 lbs Thru-Hole Diameter: 1.25" Face Plate Diameter: 6" Load Capcity: 180 lbs. Motor: DC ***Cash or check payment only. Payment must be cleared before shipping. Shipping is not included and is the responsibility of the customer, however we can provide a quote. Ask for more details. Sold as is where is. Located in Chatsworth, California and available for viewing/demoing. Please contact [phone removed by eBay] for any questions or additional information. M&M CNC is based in Los Angeles, California and has 15 years of experience in machine service and remanufacturing. They are the only company to be Fadal certified for the remanufacturing of Fadal machines. *Fadal Machines also for sale: VMC 4020, VMC 20, VMC 40, 3016

8613371530291

8613371530291