fadal vh65 rotary table supplier

All CategoriesRoot CatalogDefault CategoryAmplifier Power SuppliesAmplifiers, AC & DCFeatured AmplifiersAxis, Rotary & Turret MotorsBallscrews, Assemblies & Parts1) Ballscrew Only2) Ballscrew Assemblies4) Ballscrew Covers5) Ballscrew NutsBearings & KitsBelts & Belt GuidesBreakers & FusesBrushes, DC MotorCables & Wire HarnessesChain & Sprocket KitsChiller UnitCircuit Boards1010 Axis/Spindle1020 Clock Boards1030 Cmptr. Interface1040 Mill Interface1050 M Function1060 Mother Boards1090 Keyboards1100 Power Distribution1400 CPU Boards1420 Video Boards1460 Memory Expansion1550 Chiller Boards1610 Software Modules1900 Pendant InterfaceAll Other CNC BoardsUpgrade KitsCouplersCylindersDoor PartsDow Frost, Epoxy, GreaseDrawbar & Spindle PartsElectrical PartsEncoders, Resolvers & Tach.Eproms & SoftwareFansGibs & StrapsHardware, Misc. PartsHydraulic ActuatorIdler PartsKeyboardsLights and LampsLinear GuidesLube & Plumbing PartsMonitorsMPG Remote & PartsO-RingsOrientation PartsPower SuppliesPulleysPumps & Pump PartsRegulatorsRelaysRotary HeadsRotary Parts & KitsSealsSensors & SwitchesService ToolsSpindle DrivesSpindle Motors & PartsSpindles, New & RemanTool Changer PartsTransformersTurcite Kits & EpoxyValvesWay Covers & WipersUSB Mass StorageSprings1330 Dual Arm (DATC)New ArrivalsWaycoversLoad MeterTension Idler PartsLCD DisplaysSpecial OfferReman, Circuit Boards3) Bearing MountsFadal DecalFadal DecalScalesItsfadalpartsMotor MountsWay Lube CarriersHoses & Tubing

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

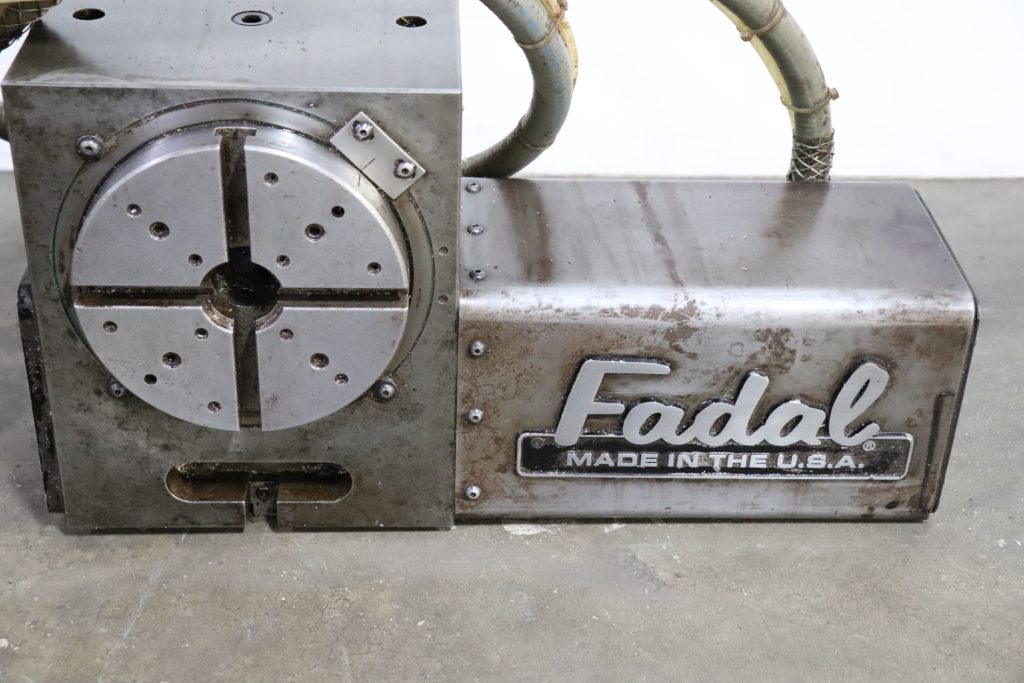

Fadal Part Number HDW-0224Genuine Fadal OEM hardware. The HDW-0224 is a Lip Seal that is used to seal the Face Plate of the Fadal TR65 and VH65 Rotary Table.

1) Diagnose - Direct help in determining if you really do need to replace the part. Based on experience having worked as part of the engineering team that originally designed the Fadal machine, our knowledge helps us determine if there"s other elements in the system that need to be addressed before replacing the part.

4) Support - With the combination of our Fadal Engineering background and direct interaction with suppliers engineers, you are getting the absolute best product support possible at installation and beyond.

If you use a drive with a built in dc supply and you run it from 110v ac mains, you will end up with 150 volts of dc, that is a 90 volt motor, you will have to scale the input signal by by about 40%. the drive you select will have to be able to tolerate 150v of dc. AMC drives are sized by current /voltage. A 25a20 will push up to 25 amps of 200v dc. On a dc brush motor( and this may apply to brushless also, I don’t know) , motor speed is relative to voltage. If you call Fadal or Rotary Design( they are what is left of the Fadal brothers), they can give you a pin out for the cannon plug on the end of the cable . The plug isnt cheap....

Increase efficiency and production of your CNC machine with our Dual VH-8. Perfect for making 2 parts at a time thus reducing the number of tool changes and allowing the operator more time to complete other tasks. The standard configuration places the motor at the side or we also offer the option to wrap the motor around the back to save space, reduce overall length and eliminate possible machine interferences. The Dual VH-8 has twin 8.25" spindles (210mm) with dual tapered roller bearings supporting the front and back of each spindle. The VH-8 worm wheel is helically cut and throated for increased surface contact between the wheel and worm. This provides longevity and helps maintain the accuracy of the rotary table over time. There are optional 8" 3-Jaw chucks and adapter plates available as well as a 5C nose pieces with either manual or air collet closers for your workholding needs.

The Index Designs Dual VH-8 is a true 4th-axis rotary table with two platters,complete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

The big deal is that my VH-65 has the older style MTR-0002, which is a stubby sized (for the rotary) DC motor that has an encoder on it instead of a tach and resolver. This setup is used with the fadal "servo controller model 1" which is an indexer controller box. The indexer box communicates with the CNC88 control using a contact that it closes to let the machine know the index move is complete. The CNC88 sends a signal (also just a relay contact) to the indexer via M-Code (M20) to tell the indexer to execute the next move. The moves are programmed on the indexer or sent to the indexer over rs232.

I suspect that this indexer setup is quite rare and that FADAL went to full 4th axis" only shortly after the indexer box and strange VH-65 with an encoder was released. I have not seen or heard of another person with the indexer box.

Another issue is that the previous owner of my machine / rotary table said that "there is a problem with the brake on the VH-65". This is second hand info that I got from the machine tool dealer that I bought the machine from. I have not tried the brake at all yet. It could easily be a problem with the solenoid on the indexer box, rather than a real mechanical problem with the VH-65 brake itself. The brake mechanics are buried deep in the rotary table, and I"d have to pull it fully apart I think to get to the brake to inspect it and/or replace parts. I"m going to try and use it with my new solenoid and M60 on the CNC88 prior to going to that extreme. Regardless, anyone ever have an air brake problem on their VH-65? What happened and how did you fix it?

Another potential issue is that I will not be using an axis inhibitor board. This is on some advice from a 20+ year factory service technician that told me that the inhibitor is really for AC machines, and that DC machines don"t need it. The intent of the inhibitor is to shut down the rotary table"s motor when its at rest to stop it heating up - which could ware on your amp, and on the motor. we will see what happens.

8613371530291

8613371530291