fanuc ddr rotary table manufacturer

Designed to enhance the productivity of your FANUC ROBODRILL across an enormous range of applications, FANUC’s range of options give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBODRILL. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

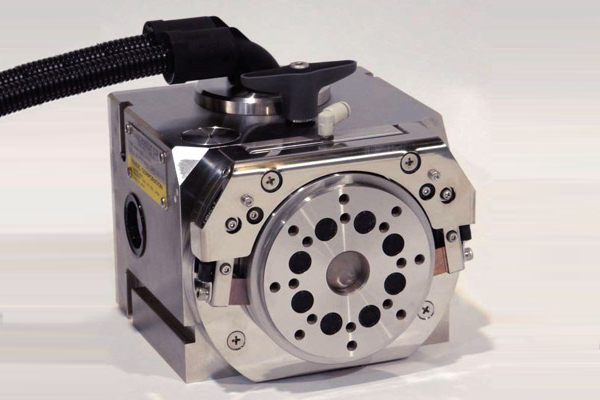

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDR makes the perfect additional axis for your ROBODRILL. It"s direct drive and non-backlash structure enabling high speed and high precision machining. Benefits include an extremely fast indexing and clamping speeds. Extremely precise and reliable, the DDR offers the best value for your money.

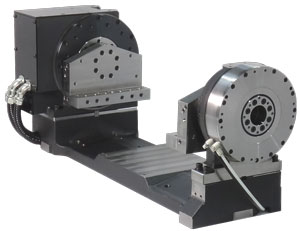

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets. Its improved rigidity ensures even higher degrees of machining accuracy. All you need to do is add the fixture plate. The DDR-T"s practical design ensures that the existing X-axis travel remains the same as on the 3-axis design.

FANUC ROBODRILL offers a wide variety of spindle options in order to meet the optimum performance standards to a customer"s requirements and application.

Dynamic Industrial Corporation is establish in the year2014. We are the leading Manufacturer and Supplier of SPM Machines, Maintenance Related Services & Spare Parts incluning Imports Items, Stockiest of Lubrication Grease Cartriges Daikin, Lube / Fanuc Batteries & Fan / Encoders / MPG Pendants. We are Specialist in Spindle, Ballscrew, Servo/PQ Valves & All CNC/VMC/Diecasting Machine Parts Repairing/Supplies. We are Specialist in Fanuc & Siemens Conrol Parts Repairing like Servo Drives/Other Control Cards. We provide the complete Maintenance Solutions under one Roof. Our Technically Skill Team had experience in Maintenance field More than 18 years

The new generation ROBODRILL vertical machining centre promises unrivalled quality and precision at great hourly rates. With an unbeatable tool change time of 0.7 seconds and a turret capable of handling tools weighing 4 kg, the new advanced versions are both the fastest and strongest 5-axis CNC machines on the market. Advanced or standard, every ROBODRILL vertical machining centre is a real high-speed all-rounder offering incredible performance and unbeatable efficiency.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 7fffe68e5176872a08a9b8b55ab248e9 63.210.148.230 02/01/2023 09:03 PM UTC

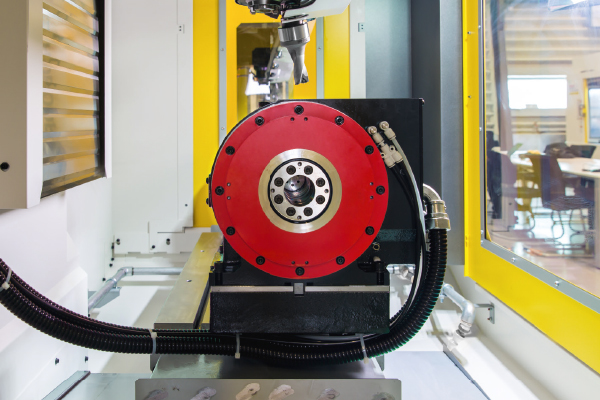

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

FANUC RoboDrill vertical machining center is available with FANUC DDR/B rotary fourth-axis, which eliminates positioning delays of traditional rotary tables. Capable of 200 rpm speeds, axis can unclamp, rotate 180°, and reclamp in less than 0.3 sec and has 220 lb part-loading and 369 lb-ft torque capacities. Axis offers virtually backlash-free operation; has direct-drive motor with no gears; and, if bumped, can be tuned to original specifications.

SUDBURY, MA - The new FANUC DDR/B from Methods Machine Tools is a rotary 4th-axis designed specifically to complement the speed and versatility of the FANUC RoboDrill vertical machining center. By eliminating the positioning delays of traditional rotary tables, it dramatically reduces part cycle times.

A true milling 4th axis, the DDR/B can unclamp, rotate 180°, and reclamp in less than 0.3 seconds. Capable of 200 rpm, it has a part-loading capacity of 220 pounds and 369 foot-pounds of torque, enough to handle even the most difficult applications. Virtually backlash-free, it has a direct-drive motor with no gears to wear out or break. If bumped, it can be easily tuned to original specifications.

With its unique combination of speed, strength, and reliability, the DDR/B is ideal for small-volume shops or OEMs making millions of parts. And, priced at thousands of dollars less than comparable 4th-axis tables, it is an exceptional value.

The RoboDrill VMC, available in three sizes with a 14- or 21-station tool changer and a 10,000 rpm "Big Plus" spindle, provides milling performance unmatched in a 30-taper machine. It also offers high-speed drilling, tapping, deburring, and chamfering; rigid tapping to 8000 rpm; peck tapping for blind holes; and high-speed reverse tapping (up to 20 times faster than infeed). With feedrates to 2362 ipm, rapid traverses to 2125 ipm, accelerations (in the X, Y, and Z axes) to 1.5 G, and 1.6-second tool changes (chip-to-chip), it is typically 30-50% faster than standard machining centers. With precision-enhancing thermal compensation and HRV control, the RoboDrill boasts positioning accuracy of 0.0002" and repeatability of ± 0.000080". Its sophisticated Fanuc 31i-A5 Nano CNC has an optional 1000-block "look-ahead" and a 0.4 ms block-processing speed, ensuring exceptional surface finishes over contours.

Methods Machine Tools, Inc., has been a supplier of precision machine tools and accessories for 50 years. Methods is the exclusive North American source for FANUC RoboDrill vertical machining centers, providing installation, parts, service, and training through a nationwide network of dealers. For more information, contact: John Crean, RoboDrill Product Manager, Methods Machine Tools, Inc., 64 Union Avenue, Sudbury, MA 01776, TEL: (978) 443-5388, FAX: (978) 440-9405, www.methodsmachine.com.

Table Model • Several options available for motor mounting position, including right side, left side, back and top • Highest weight load capacity in its class Table Model • Compact design • Suitable for a wide range of applications from small machines with simple indexing to full CNC integration for production application • Excellent full 5 axis contouring capabilities • Compact design Table Model • Suitable for a wide range of applications from small machines with simple indexing to full CNC integration for production application Table Model NIKKEN KOSAKUSHO EUROPE LTD - PRECISION HOUSE -...

The Perfect Solution for Your Manufacturing Needs Nikken’s Rotary Tables are known worldwide for their longivity, rigidity and quality. Our range of rotary tables are designed and built to provide extreme accuracy and to increase your work productivity. Fanuc Robodrill is an intelligent high-speed CNC drill with versatility which offers application solutions to meet a wide variety of machining needs. Nikken’s Rotary Tables seamlessly become part of the machine to create the perfect solution for each and every manufacturing requirement. The result is simple: maximum productivity and...

8613371530291

8613371530291