fanuc ddr rotary table quotation

Designed to enhance the productivity of your FANUC ROBODRILL across an enormous range of applications, FANUC’s range of options give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBODRILL. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDR makes the perfect additional axis for your ROBODRILL. It"s direct drive and non-backlash structure enabling high speed and high precision machining. Benefits include an extremely fast indexing and clamping speeds. Extremely precise and reliable, the DDR offers the best value for your money.

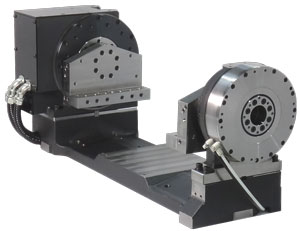

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets. Its improved rigidity ensures even higher degrees of machining accuracy. All you need to do is add the fixture plate. The DDR-T"s practical design ensures that the existing X-axis travel remains the same as on the 3-axis design.

FANUC ROBODRILL offers a wide variety of spindle options in order to meet the optimum performance standards to a customer"s requirements and application.

Dynamic Industrial Corporation is establish in the year2014. We are the leading Manufacturer and Supplier of SPM Machines, Maintenance Related Services & Spare Parts incluning Imports Items, Stockiest of Lubrication Grease Cartriges Daikin, Lube / Fanuc Batteries & Fan / Encoders / MPG Pendants. We are Specialist in Spindle, Ballscrew, Servo/PQ Valves & All CNC/VMC/Diecasting Machine Parts Repairing/Supplies. We are Specialist in Fanuc & Siemens Conrol Parts Repairing like Servo Drives/Other Control Cards. We provide the complete Maintenance Solutions under one Roof. Our Technically Skill Team had experience in Maintenance field More than 18 years

A: We are a supplier ofthe most completeFanuc parts in China. There are more than 10,000 pieces of Fanuc parts in stock available. We’ll arrange the delivery after you order. Warmly welcome you to vist our company.

IntelLiDrives manufactures a large selection of rotary tables including direct-drive tables that use brushless torque rotary servo motors, as well as precision motorized worm-gear and belt-driven rotary actuators. These rotary stages are available with many different size apertures, table diameters, and mounting options to provide the ideal solution for your industrial automation application. IntelLiDrives rotary tables are used in industrial robots, fiberoptics and photonics, vision systems, machine tools, assembly, semiconductor equipment, medical component laser machining, electronic manufacturing, and other high-performance industrial automation applications.

Direct drive (DDR) rotary tables eliminate backlash and provide a stiff mechanical system for highly dynamic applications. Integrated with precision bearings and ring encoders, these rotary tables provide ultimate performance in rotary indexing applications

Motorized rotary tables incorporate an aluminum housing with bearing and precision ground worm or pinion gear drive. Multiple choices of gear reduction are available. Features no backdrive with minimum backlash.Supplied with stepper motors or brushless servo motor/encoder combination

High speed, large aperture and low profile motorized belt driven rotating actuators. Cost effective alternative to direct drive rotary servo tables. Supplied with NEMA23 stepper or brushless servo motors with encoders

Rotary tables incorporate ABSOLUTE RING ENCODERS with industry standard SSI, BISS-C and Fanuc interfaces. Absolute positioning information is maintained during power-down. No homing required upon power-up

Low profile rotation stages 22 to 42 mm. Light-weight and compact, these rotary actuators are best suited for integration with XY tables to minimize system stack-up height and errors

Direct drive air bearing rotation stages with axial and radial air bearings. Frictionless and maintenance-free rotary tables best suitable for cleanroom environments

Rotary tables with protection against ingress of water and particles. IP65,IP66and IP67 rated. Direct drive rotary servo tables and motorized actuators

Low profile and small footprint (40 mm to 115 mm) rotary stages. Designed for the confines of laboratory and production environment. Available in vaccum compatible versions

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

Direct Drive (DDR)rotary tables with absolute encoders provide superior angular positioning and are designed to eliminate backlash, friction and wear problems associated with worm, gear and belt drives.Low maintenance and high throughput characteristics of the Direct Drive stage yields the lowest total cost of ownership.

Rotary tables PSR300MHS-ABS and ACR-250HT-ABS are industry first direct drive rotary table that incorporates ABSOLUTE ring encoder with industry standard interfaces like SSI, BISS-C, FANUC

The motor and contactless absolute ring encoder are directly coupled to eliminate coupling backlash. The low inertia and zero backlash make these rotary tables the ideal solution in applications requiring position retention upon power-up.

FANUC RoboDrill vertical machining center is available with FANUC DDR/B rotary fourth-axis, which eliminates positioning delays of traditional rotary tables. Capable of 200 rpm speeds, axis can unclamp, rotate 180°, and reclamp in less than 0.3 sec and has 220 lb part-loading and 369 lb-ft torque capacities. Axis offers virtually backlash-free operation; has direct-drive motor with no gears; and, if bumped, can be tuned to original specifications.

SUDBURY, MA - The new FANUC DDR/B from Methods Machine Tools is a rotary 4th-axis designed specifically to complement the speed and versatility of the FANUC RoboDrill vertical machining center. By eliminating the positioning delays of traditional rotary tables, it dramatically reduces part cycle times.

A true milling 4th axis, the DDR/B can unclamp, rotate 180°, and reclamp in less than 0.3 seconds. Capable of 200 rpm, it has a part-loading capacity of 220 pounds and 369 foot-pounds of torque, enough to handle even the most difficult applications. Virtually backlash-free, it has a direct-drive motor with no gears to wear out or break. If bumped, it can be easily tuned to original specifications.

With its unique combination of speed, strength, and reliability, the DDR/B is ideal for small-volume shops or OEMs making millions of parts. And, priced at thousands of dollars less than comparable 4th-axis tables, it is an exceptional value.

The RoboDrill VMC, available in three sizes with a 14- or 21-station tool changer and a 10,000 rpm "Big Plus" spindle, provides milling performance unmatched in a 30-taper machine. It also offers high-speed drilling, tapping, deburring, and chamfering; rigid tapping to 8000 rpm; peck tapping for blind holes; and high-speed reverse tapping (up to 20 times faster than infeed). With feedrates to 2362 ipm, rapid traverses to 2125 ipm, accelerations (in the X, Y, and Z axes) to 1.5 G, and 1.6-second tool changes (chip-to-chip), it is typically 30-50% faster than standard machining centers. With precision-enhancing thermal compensation and HRV control, the RoboDrill boasts positioning accuracy of 0.0002" and repeatability of ± 0.000080". Its sophisticated Fanuc 31i-A5 Nano CNC has an optional 1000-block "look-ahead" and a 0.4 ms block-processing speed, ensuring exceptional surface finishes over contours.

Methods Machine Tools, Inc., has been a supplier of precision machine tools and accessories for 50 years. Methods is the exclusive North American source for FANUC RoboDrill vertical machining centers, providing installation, parts, service, and training through a nationwide network of dealers. For more information, contact: John Crean, RoboDrill Product Manager, Methods Machine Tools, Inc., 64 Union Avenue, Sudbury, MA 01776, TEL: (978) 443-5388, FAX: (978) 440-9405, www.methodsmachine.com.

DD technology for linear motors and rotary tables has matured in recent years. It has significantly improved the overall performance of machine tools, which has enabled corresponding improvements in the quality, speed and efficiency of production machining. These benefits help manufacturers to reduce machining times and to drive down costs.

Haozhi builds direct-drive rotary (DDR) tables and linear motors with integrated high-performance optical encoder systems from Renishaw, which give Haozhi products a substantial competitive advantage.

“Haozhi initially focused on producing machine tool motor spindles and, after many years of hard work, we are now the global market leaders. We have launched a wide range of spindle products aimed at different industries — including the world"s fastest motor spindle that operates at up to 400 krpm with a rotational accuracy of 6 µm. We also manufacture machine tool rotary tables and linear motors, and are developing gear reducers and robotic joint products to cater for the rapidly growing robotics market. We export primarily to Southeast Asia and a number of European countries.”

We first came across Renishaw"s advanced metrology products more than a decade ago and have enjoyed working with them ever since. When we decided to begin developing rotary tables, we chose their optical encoders without any hesitation as we have the utmost confidence in Renishaw"s products.

Rotary tables are usually deployed as either a fourth or fifth axis on CNC machining centres for precision light manufacturing, such as the machining of mobile phone and tablet cases. Alternatively, rotary tables are used in indexing table modules for automated production lines.

Many everyday consumer products require parts that have been precision machined on rotary tables with excellent accuracy and motion control performance in order to produce the smooth surfaces required.

The error budget of a motion control system, such as a rotary table, is affected by factors related to the machine structure, individual mechanical components, transmission mechanisms and position encoders.

Mechanical resonance is one of the most common problems designers face when trying to maximize either the command response or dynamic stiffness of traditional rotary tables driven by worm gears. One particular concern is the inertia mismatch between the load and the motor.

DDR tables eliminate many of the mechanical resonances associated with traditional rotary tables and enable the design of high-performance systems which are optimised for the speed and torque requirements of the application.

For Haozhi, encoders are one of the most critical components in their motion control products. Important encoder errors for rotary motors include sub-divisional error (SDE), jitter, installation error (which includes scale eccentricity), scale graduation error and the compliance of the coupling between the motor and the encoder rotary scale.

“We first came across Renishaw"s advanced metrology products more than a decade ago and have enjoyed working with them ever since. When we decided to begin developing rotary tables, we chose their optical encoders without any hesitation as we have the utmost confidence in Renishaw"s products. Our experience has shown that their optical encoders are easy to install and that our engineers are able to assemble them quickly.

Mr Lei continues: “In terms of compatibility and the diversity of the product range — there are definite advantages to Renishaw encoders. Many controller manufacturers out there offer a huge variety of available communications protocols: RESOLUTE absolute optical encoders support most mainstream industrial comms protocols including FANUC, Mitsubishi, Siemens DRIVE-CLiQ and BiSS®. Furthermore, the encoder readhead and ring dimensions are always the same irrespective of the serial protocol output option which eliminates the need to modify our structural designs.”

“In order to make a good job of quality control, we use Renishaw XL-80 laser interferometers with XR20-W rotary axis calibrators to test all our linear motors and rotary tables. The accuracy, ease of use and reliability of the testing equipment were decisive factors.”

By integrating Renishaw"s RESOLUTE absolute optical encoder system into its CNC rotary tables, Haozhi has further assured the accuracy, reliability and superior motion control performance of its products.

Haozhi rotary tables offer positioning accuracy of ±10 arc seconds, repeatable precision of ±2 arc seconds and a wide range of torques and speeds. While Haozhi linear motors offer a bidirectional positioning accuracy of ±2 µm, a continuous thrust range of 0.2–4.0 kN, and a peak thrust range of 1–12 kN.

The core of Haozhi"s main business is advanced machine tool spindles, rotary tables and DD linear motors which are integrated into OEM manufacturing equipment and robotics applications. It became a listed company on the Shenzhen Stock Exchange"s Growth Enterprise Market (GEM) in 2016.

To repair a motorized Fanuc spindle can be a more in-depth process when it comes to sensors, encoders, proximity switches, thermistors and various other electronics. Motor City Machine Tool owns highly advanced equipment to test all aspects of your direct drive spindle to ensure it functions to the OEM specification. Our technicians balance all spindle components dynamically and statically. We are able to balance spindles so they are able to operate precisely for a long time.

Refilled and bled the hydraulic system for the brakes with the mori tech on friday, pressure switch lit up like it was supposed to when we were done, so assumed it had just worked some more air bubbles up and we left it at that. Come in this morning after the weekend, and no pressure. I guess it must have an internal leak somewhere still. Those mori DDRTs have an inner and outer housing, so if the hydraulic system for the brakes is leaking, you will almost never see it outside the unit. Uses an air over oil system with the brakes, so a few bubbles can cause major problems.

8613371530291

8613371530291