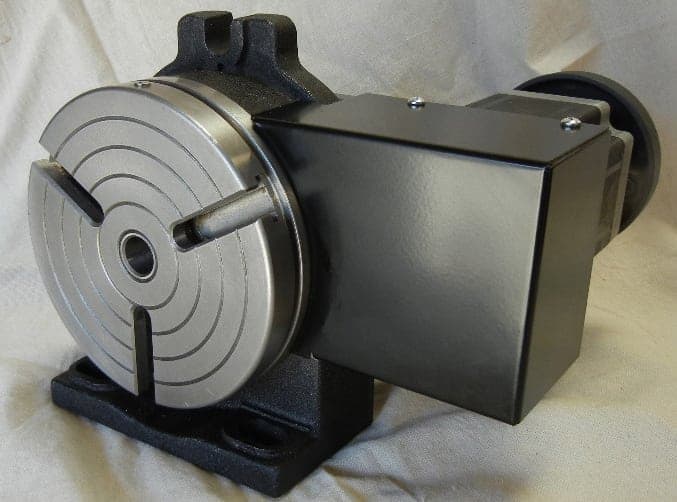

fourth axis rotary table in stock

All CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

A rotary table is a workbench, designed to cut wood, metal, and other surfaces with a built-in tablebench, to make work easier. It is so compact and easy to use as a 4th axis tablebench, so that the work can be harder.

There are many types of rotary tables depending on your client"s needs. The rotary table is also called a rotary table, if it is a client"s design or a business, it can be compared to other rotary tables depending on the client"s needs. A rotary table is also called a rotary table, which allows users to cut many projects at once and have a different finish compared to the original rotary table.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

Martin Trunnion Tables offers complete 4th axis packages for Samchully rotary tables. Ready to be mounted into your machine, your Stallion Trunnion Table will already be attached to your Samchully rotary table and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis CNC machining. Scroll down for examples and package options! Don"t hesitate to reach out to us to discuss your manufacturing needs. Our applications engineers are always happy to help!

This 4th axis rotary table system can be added to any of our machines, even if you already have your machine. Just send us the electronics panel and we can add the electronics for you. Includes all necessary electronics installed inside the machine with a plug on the front console. Wired, installed, and completely ready to run.

4th axis programming can be done with a 3 axis CAD program by converting the Y axis to A axis in the post processor. Just make the Y dimension of your drawing the same dimension as the cylindrical circumference of your work piece.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

Benefiting from TJR’s proven knowledge and experience, TJR provides diverse transmission mechanisms such as 1. Driven by Worm & Worm Gear, 2. Driven by Roller Gear Cam, 3. Driven by Direct Drive Motor to meet various needs. If you are looking for the 4th axis rotary tables cooperation partner, please feel free to check out 4 axis rotary table here and get in touch with TJR.

All CategoriesRoot CatalogDefault CategoryAmplifier Power SuppliesAmplifiers, AC & DCFeatured AmplifiersAxis, Rotary & Turret MotorsBallscrews, Assemblies & Parts1) Ballscrew Only2) Ballscrew Assemblies4) Ballscrew Covers5) Ballscrew NutsBearings & KitsBelts & Belt GuidesBreakers & FusesBrushes, DC MotorCables & Wire HarnessesChain & Sprocket KitsChiller UnitCircuit Boards1010 Axis/Spindle1020 Clock Boards1030 Cmptr. Interface1040 Mill Interface1050 M Function1060 Mother Boards1090 Keyboards1100 Power Distribution1400 CPU Boards1420 Video Boards1460 Memory Expansion1550 Chiller Boards1610 Software Modules1900 Pendant InterfaceAll Other CNC BoardsUpgrade KitsCouplersCylindersDoor PartsDow Frost, Epoxy, GreaseDrawbar & Spindle PartsElectrical PartsEncoders, Resolvers & Tach.Eproms & SoftwareFansGibs & StrapsHardware, Misc. PartsHydraulic ActuatorIdler PartsKeyboardsLights and LampsLinear GuidesLube & Plumbing PartsMonitorsMPG Remote & PartsO-RingsOrientation PartsPower SuppliesPulleysPumps & Pump PartsRegulatorsRelaysRotary HeadsRotary Parts & KitsSealsSensors & SwitchesService ToolsSpindle DrivesSpindle Motors & PartsSpindles, New & RemanTool Changer PartsTransformersTurcite Kits & EpoxyValvesWay Covers & WipersUSB Mass StorageSprings1330 Dual Arm (DATC)New ArrivalsWaycoversLoad MeterTension Idler PartsLCD DisplaysSpecial OfferReman, Circuit Boards3) Bearing MountsFadal DecalFadal DecalScalesItsfadalpartsMotor MountsWay Lube CarriersHoses & Tubing

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

Index Designs rotary tables can be connected to nearly any type of CNC or manual machine using one of three conventional interface methods outlined below. The first one requires the CNC machine be 4th axis ready. The other two require the use of the Index Designs single axis control box.

By far, the most popular interface option is true 4th axis servo control. This allows for use in either indexing or continuous mode. This provides the most integrated control method by using an amplifier built into the host machine. The A axis rotary table is programmed and controlled along with X, Y and Z axis commands. This method of integration is the most flexible as it allows either indexing for simple point to point part positioning or very sophisticated synchronous contouring for creating complex surfaces that are otherwise very difficult or impossible to produce.

The programmable single axis control box can store a series of moves within the memory and have those moves incremented one by one with the closure of an M-function from the host machine. A pulse from the host machine commands the control box to move the 4th axis to the next position from within the program. Upon completion of each move, the control box signals back with a cycle complete pulse so the host machine knows the 4th axis is in position and can proceed with the next operation. A spare M-function is required on the host machine and interfaced with a simple 4 wire connection with two wires used for cycle start and the other two for cycle finish. The single axis control box comes with 15’ of cable and a 4 pin DIN connector that plugs into the back of the controller. .

Serial control of a 4th axis can be achieved by having the host machine send move and feed information via a standard RS-232 connection. Many CNC’s have the ability to accommodate print statements within their programs which send move data out the control’s serial port. The Index Designs Programmable Control Box reads these instructions and positions the 4th axis accordingly. An M-function interface is required to coordinate cycle start and finish of these moves so the CNC and Control Box are in sync with each other.

CNC rotary table is a device used to assist the workpiece in multi angle machining on the machining center. One-time clamping and multi-faceted machining can ensure the position accuracy between workpiece features and improve the use efficiency of the machine tool. In contrast, the standard machining center has only three axes x, y and Z. after adding four axes, it can process workpieces with complex features, such as blades, cams, etc.

If the work piece is made of aluminum, copper materials, and the machining cutting force is small, you can choose harmonic gear, DD motor type rotary table, or choose worm or roller cam structure, and use pneumatic brake.

If the parts are made of cast iron, steel and other materials, it is recommended to select the rotary table with worm or roller cam structure, and judge whether to add hydraulic brake according to the cutting force.

(1). Worm, roller cam and DD motor rotary tables have different accuracy and retention life.which should be determined according to the workpiece accuracy

(2).If accuracy specified in mm, check for the diameter at which the accuracy is required.Convert Indexing Accuracy of the Rotary Table specified in arcsec to mm at the diameter where the operation is to be carried out,(A = Tan Ө x R),Ө = Indexing Accuracy (Ex: +/- 15” (30”sec)),R = Radius at which the operation to be carried out ,A = Accuracy in μ

(2) Confirm the total load that the machine tool can bear, and then add up the weight of the preselected rotary table, tail stock, L-Block, medium plate (bridge plate), base plate, work piece, fixture and so on,

After moving the Y-axis of the machine tool to the origin, measure the distance from the center of the worktable to the metal plate of the moving door of the machine tool, check the size from the center of the disk surface of the indexing plate to the tail end of the motor cover, and judge whether the motor cover will interfere with the metal plate of the machine tool. If there is interference, change the motor cover

The rotary table is generally composed of several parts as shown in the figure below: ① rotary table house, ② motor of the fourth axis, ③ cable with sheath, ④ cable without sheath, and ⑤ driver. In addition to the five major hardware, the interface must be reserved for the fourth axis on the machine tool.

(2).If the machine tool does not have interfaces reserved for the fourth axis, but wants to add the fourth axis later, please ask the machine tool manufacturer to open the interface or select the single axis controller, but the single axis control system cannot be linked with any axis of the X, Y and Z axes of the machine tool. Only after the rotation of the fourth axis is completed, the other three axes can operate.

when purchasing rotary table and disc tail stock, and designing the cradle type fixture, when eccentric machining is caused by the force arm (A) exceeding the disc surface (the higher the cushion is, the longer the force arm A is, which is not the load of mechanical common sense), it will seriously wear the rotary table reducer. Please be careful

8613371530291

8613371530291