golden sun rotary table factory

GSA TECHNOLOGY CO., LTD. established in 1978, from time to time, our growing of devotion work stable, keeping in mind of honesty, faith, profession and innovation, nonstop communication and promotion of critical quality procedure, ensure every products could meet high quality of duration and precision.

GANRO makes every rotary table based on this concept from every single part to a complete rotary table. Even a small screw will decide if a machining center can achieve the most profitable function.

From 1978, Golden Sun Industrial Co., ltd. maintains quality and value in making rotary tables utilizing advanced technologies, GANRO Industrial Corp, was established in 2008 to meet the high standard and demands from our customers all over the world. The spirit of pursuing perfection of Golden Sun is fully passed on to GANRO.

GANRO is convinced that a perfect work isn’t made without a foundation. As everyone knows that German and Japanese manufacturers keep most strict standards to make rotary tables. Their standards and attitudes to make rotary tables are GANRO’s motive power that keeps GANRO walking forward.

CNC Indexing & Feeding Technologies is proud to carry TJR Precision Technology rotary tables. All of TJR’s rotary tables incorporate a range of features that give them an edge over competitors, and the dual lead worm gear is at the top of the list. How Does A Dual Lead Worm Gear Work? With the dual […]

CNC Indexing & Feeding Technologies is proud to offer the best the industry has to offer in our complete line of Ganro Industrial Corp. rotary tables. While parts of a rotary table may seem the same no matter what brand you choose, the true test of quality lies in the equipment design. Ganro has been developing […]

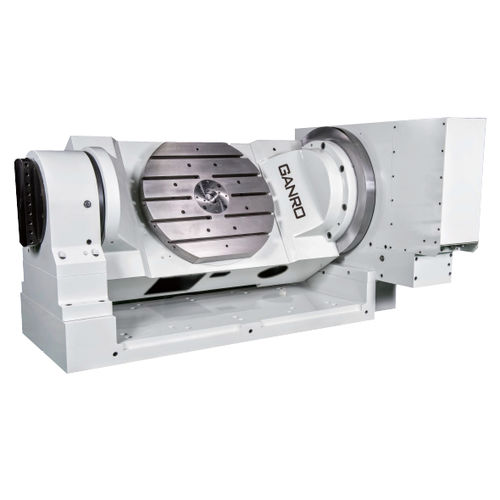

Ganro Industrial Corporation offers large rotary tables in their standard DR series configuration. The large rotary tables are available in a range of 1000mm (40”) to 2500mm (98”) in faceplate diameter. They can be utilized as a full rotating axis incorporated into a machine’s control or as indexers with Ganro’s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions to give manufacturers maximum flexibility. These large rotary tables and indexers utilize a hydraulic brake system to reach high clamping torques. All Ganro DR Series rotary tables and indexers use Ganro’s core technology of a double lead worm shaft and worm wheel system for high precision and reduced backlash. Ganro rotary tables are assembled using cross cylindrical roller bearings with high rotation accuracy capable of bearing heavy loads in every direction.

As the exclusive importer and dealer of Ganro products in the United States, CNC Indexing & Feeding Technologies stocks the most popular Ganro rotary table models, accessories and spare parts. We have certified service technicians for installation and repair of all Ganro and Golden Sun rotary table and indexer models. Please contact us today to learn how adding a Ganro rotary table or indexer can help improve your manufacturing process.

Manufacturers across the globe are always looking for reliable workholding devices to accommodate their manufacturing indexing and rotating requirements. CNC Indexing & Feeding Technologies has been proud to represent the complete Ganro Industrial Corp. (Golden Sun) product line of workholding rotary tables and indexers. Ganro has been producing a wide variety of workholding products to accommodate manufacturers for over 30 years. To help a company decide which table is best for its applications, it is beneficial to understand the proper use and capability of each workholding device. CNC Indexing and Feeding Technologies offers various Ganro workholding products.

Standard Rotary Tables: The sizes range from 120mm (4.72") to 800mm (31.49") in faceplate diameter and can be used as a full rotating axis incorporated into a machine"s control or as indexers with Ganro"s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions and have large thru-holes to give manufacturers maximum flexibility.

Large rotary tables: The large rotary tables are available in a range of 1000mm (40") to 2500mm (98") in faceplate diameter. They can be used as a full rotating axis incorporated into a machine"s control or as indexers with Ganro"s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions.

Rear Motor Mount: Ganro manufactures two of the most popular sized rotary tables with a rear mounted motor for smaller vertical machining centers. The rear motor mount rotary table design is available in the standard 170mm (6.69") and 250mm (9.84") faceplate diameters. As with other Ganro rotary tables, they can be used as a full rotating axis incorporated into a machine"s control or as an indexer with Ganro"s M-Mate AC servo controller.

CNC Indexing offers three types of Ganro standard rotary tables to accommodate a wide range of 4- and 5-axis manufacturing requirements. The standard tilt rotary table is a trunnion design with faceplate diameters ranging from 320mm (12.59") to 800mm (31.49"). This style is created to give manufacturers ample room for workholding and workpiece while providing clearance for the machine"s spindle and tool.

Compact Tilt: The compact tilt rotary table design comes in faceplate sizes of 150mm (5.90"), 200mm (7.87") and 250mm (9.84") and is ideal for smaller machining centers and smaller workpieces.

Manual Tilt: The manual tilt table is designed with a full 4th axis (rotating axis) and a manual tilting axis. It is available in sizes from 200mm (7.87") to 630mm (24.80") and is ideal if a tilting axis is only occasionally required.

Horizontal Rotary Table: This rotary table design is available with table tops ranging from 400mm (15.74") to 2500mm (98.42") square. Ganro"s horizontal CNC rotary tables can be used in various areas of manufacturing but are ideal for horizontal boring mill applications.

Horizontal Index Tables: CNC Indexing offers two types of Ganro horizontal index tables for both manual and automated manufacturing processes. Both series of precision horizontal index tables use a two piece Hirth coupling design that provides superior indexing accuracy while maintaining high rigidity during heavy cutting.

CNC Index Table: The CNC Index Tables are clamped and unclamped with hydraulics and are designed to be incorporated into a machine"s CNC control or operated with Ganro"s M-Mate AC servo control system.

Manual Index Tables: The Manual Index Tables are clamped and unclamped pneumatically or hydraulically. Once unclamped the series is manually indexed to the desired degree and securely clamped into position.

Face Gear Rotary Tables: The Face Gear Rotary Tables are manufactured with a three piece Hirth coupling design to avoid lifting during rotation. The use of a Hirth coupling allows for the mounting of heavy loads while offering high rigidity and high accuracy. These tables are primarily used in applications incorporating a strong tailstock and a tombstone or fixture plate. It can be integrated into a machine"s control or operated through Ganro"s AC servo controller.

The index tables are available in four faceplate sizes (250mm, 320mm, 400mm and 500mm). Ganro rotary tables can provide a solution for rotating and indexing small workpieces to large workpieces, for vertical and horizontal applications, for 4-axis and 5-axis work and for manual and automated applications. Ganro products give manufacturers the capability of improving the manufacturing process by accessing multiple workpiece faces in one clamping. This improves workpiece accuracy and reduces manufacturing cycle times.

8613371530291

8613371530291