golden sun rotary table pricelist

CNC Tilting Rotary Tables are two axes (4th & 5th Axes) units and can rotate the component in two axes making a machine capable of accessing the areas which can not be reached with only 3 axes. Tilting tables can also interpolate with machine axes to generate profile such as impellers. Using Tilting Rotary Table a standard 3 axes machine can be converted into a 5 axes machine.

CNC Indexing & Feeding Technologies is proud to carry TJR Precision Technology rotary tables. All of TJR’s rotary tables incorporate a range of features that give them an edge over competitors, and the dual lead worm gear is at the top of the list. How Does A Dual Lead Worm Gear Work? With the dual […]

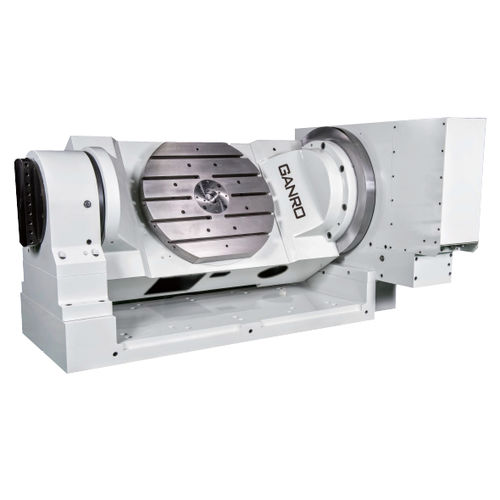

CNC Indexing & Feeding Technologies is proud to offer the best the industry has to offer in our complete line of Ganro Industrial Corp. rotary tables. While parts of a rotary table may seem the same no matter what brand you choose, the true test of quality lies in the equipment design. Ganro has been developing […]

Clamping table, clamping angle, dividing head, dividing head, rotary table, milling machine table, clamping angle with three-jaw chuck, clamping angle with lathe chuck

Clamping table, clamping angle, dividing head, dividing head, rotary table, milling machine table, clamping angle with three-jaw chuck, clamping angle with lathe chuck

Clamping table, clamping angle, dividing head, dividing head, rotary table, milling machine table, clamping angle with three-jaw chuck, clamping angle with lathe chuck

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Compact precision small rotary table, suitable for single part or small series production in laser welding precision mechanics. A horizontal or vertical assembly is possible.

It is particularly suitable as a 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, slot milling, or for use on a tool or surface grinding machine.

Nomura Model B-85BT-2 Horizontal Boring Mill Table Type.3.35" Spindle Dia. 40" Vert, 20" spdl Travel, 40" Cross Travel, Rapid Traverse, 35.5" x 39" Rotary T Slot Table, Pendant Control, DRO

2. To drain the A axis unscrew the drain port [4] at the bottom of the rotary. The rotary likely will be to be suspended in the air to do this. Rotary units are heavy so take appropriate safety measures while draining the oil. Clean off the oil remaining on the rotary and replace the screw. Both rotaries have two screws on the bottom.

4. To drain the B axis tilt axis to 90° and unscrew the drain port [3]. Only one side has a drain port check for it before tilting the rotary. Once the rotary is empty screw the port plug back in.

TJR Precision Technology, a known manufacturer of Rotary tables, is found in 2009. Since its establishment, we have focused on the R&D and manufacturing of high-precision key components for CNC machine tools, such as CNC Rotary Table, Rotary Table, index Table, and other accessories with high precision and stability. Our products are mainly used in the aerospace industry, high-tech electronics industry, automotive component manufacturing, multi-faceted spiral processing industry and various industrial machinery. We have the best research and development team that integrates the applications of machine centers and Rotary tables, and have the strictest quality control to ensure the highest quality. We also have the most active customer service to make the Rotary Table work in the optimal condition....

TANSHING ACCURATE INDUSTRIAL CO., LTD. is one of the Rotary Table and index Table manufacturer. We have passed the ISO9001 quality system certification. We insist on the concept of "Quality first, prestige important", and after continuous innovation and development, the products have been widely used in many fields. Not only the products sold well in the world"s market, but also have enjoyed a good reputation in the markets. We offers the customers with Rotary Table of excellent quality and best service, hope to build a new brilliant with you in the future.

Spintop has been specialized precision Rotary Tables for more than two decades. Our CNC/NC Rotary tables are designed with many different size apertures, Table diameters, and mounting options to provide the ideal solution for your industrial automation application. Our products are widely used in industrial robots, fiberoptics and photonics, vision systems, machine tools, semiconductor equipment, medical component laser machining, electronic manufacturing, and other high-performance industrial automation applications. Welcome to visit our showroom to view relative products: CNC Rotary Table, Double Axis Tilting CNC Rotary Table and Tailstock Rotary Table, NC Rotary Tables and more. If you need the further details of our Rotary tables, please kindly contact us at any time.

Found in 2000, Ocean Techologies Co., Ltd. is one of leading manufacturers and supplier of drilling EDM and EDM parts such as wire EDM, Rotary Table, PNC drilling EDM, ceramic guide, and so on. Also, we obtained CE certificated. In 2005, we sold over 200 sets machines worldwide. After years" efforts, we have become one of the leading manufacturers in this field. To meet the severe competition and to serve the customers more. We are strict to our quality of product standard in order to make customer have good right. Besides, we also provide excellent service to our customer. We guarantee we must make you satisfy with our product and service. Welcome to visit our website and hope you could get the products which you are interested in or more information.

On a manufacturing area of 12,000 square meters, HOSEA PRECISION has been focusing on producing high precision Rotary tables that meet the quality standards in western markets. Our Rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers. More and more manufacturers across Europe cooperate with us and make use of our 5 axis Rotary tables, Rotary Table and other products. With a Hosea Rotary Table you always know what you get: a quality product that was manufactured in a quality production process - from start to finish. With this attitude and as a member of the Taiwan Machine Center Alliance, we continue to provide the best products for the high-tech machine tool industry of today and the future.

Multiplas Enginery Co.,Ltd. was established in 1988 and is the professional injection molding machines and Rotary Table manufacturer in Taiwan. We believe that our professional experience and reasonable prices will help you in your market bring much more business for you. Your suggestion always welcome, and we are looking forward to cooperating with you and a mutually profitable relationship. If you are interested our products, contact us, we will offer you the best price and superior high quality. We wish to have a long term business relationship with you.

Pan Uni Technique Co., Ltd. is a factory specializing in Rotary Table, plastic welding machines, PP case sealing machines, folding machines, plastic forming machines and so on. Recently, with the speedy technology advances, keen competitive markets and strict quality standards, the materials for plastic products have been keeping on innovating and developing. To keep up with the trends, we replace the human-manipulated machines with advanced and wholly automatic machinery and make strict demand on processing quality and figure examination. Only making relentless efforts on the fields of technique and production management can we meet the customers" need. If you want to get more information about our products, please feel free to contact with us.

Saynen manufactures CNC Rotary tables for machining centers with rich experiences, vast industry knoledge and expertise. Based on our nearly 50-year experience in this field, we can produce high-precision Rotary tables. All our products can be used in both vertical & horizontal directions to accommodate the requirements of various machining facilities. To ensure our quality, we developed an inspection system with the Mechanical Industry Research Lab at Industrial Technology Research Institute. Due to the mentioned experience and new investment, we are able to produce major parts in house, under strict QA system in order to best control the quality. We deeply believe that our Rotary tables can compete with those similar products made in Japan, USA, Germany and so on. Contact us for more!

Kinn Shang Hoo Iron Works has spent 40 years of experiment and research to manufacture food processing machinery, adopt automatic machines to reduce cost and lower the price for the customers. Our food machinery including meat mincer, Rotary Table, oven, meat slicer machine, mixing & seasoning machine, boiler, smasher, dryer and shaping machine. Due to our consistent high product quality and reasonable price structures, our products have won popularity among clients around the world. Now express heartfelt thanks to the supports. We will increase output to reduce the machines’ cost and as soon as possible to improve the quality of products. To supply a reasonable price for customers. Thanks for comments.

In the CNC Rotary Table industry, Exact Machinery is a national-wide famous provider who specializes in the design, production and sale of a variety of Rotary tables. All tables can be position in horizontal and vertical used. Each model with a standard-size tabletop fitted with or without T slots and a precision center pilot hole for alignment and clamping of the fixture or piece parts. With our years of experience and technical know-how, we are confident that we have the ability to supply CNC Rotary tables available to suit most applications in the metal cutting industries. We also provide lots of different Rotary tables for special application such as with pallet changer system by request. Please feel free to inquiry us to get more information.

GANRO make every Rotary Table based on this conception from every single part to a complete Rotary Table. Even a small screw will decide if a machine center can achieve the most profitable function.

From 1978, Golden Sun Industrial Co., ltd. holds the spirit of the devil’s in the detail to make Rotary tables released in the market. With the advanced technology, GANRO Industrial Corp. was established in 2008 to meet the high standard and demands from our customers over the world. The spirit of pursuing perfection of Golden Sun is fully passed on to GANRO. We stand on solid ground and innovate more...

TJR Precision Technology co., Ltd. is a professional manufacturer of CNC Rotary tables (the 4th and 5th axis). The main products are CNC Rotary Table, CNC index Table, and other accessories with high precision and stability.

We have the best research and development team that integrates the applications of machine centers and Rotary tables, and have thestrictest quality control to ensure the highest quality. We also have the most active customer service to make the Rotary Table work in the optimal condition.

GSA TECHNOLOGY CO., LTD. established in 1978, from time to time, our growing of devotion work stable, keeping in mind of honesty, faith, profession and innovation, nonstop communication and promotion of critical quality procedure, ensure every products could meet high quality of duration and precision.

detron Machine Co., Ltd. is a professional manufacturer of CNC Rotary tables. With the company"s policy of sincerity, practicality, professionalism and perseverance, we have dedicated ourselves to technological R&D and innovation. This is combined with our rigorous quality control system to ensure each Rotary Table from detron will present outstanding quality. In addition, we have also invited several machine tool design engineers to join together with our R&D team. This joint force enables us to achieve the best possible integration between the machine tool and the Rotary Table, therefore maximizing the Rotary Table performance. The outstanding quality of detron CNC Rotary tables is competitive with imported products and this is the major reason why detron CNC Rotary tables have been recognized...

MATSUMOTO MACHINE CO., LTD. is a manufacturer and sales of peripheral equipment for machine tools, Hydraulic chuck and 2 to 9 jaws and/or long stroke special chucking systems High speed High accuracy NC Rotary Table.

NCT tables are designed with axial - radial bearings to provide excellent load and thrust capabilites. The hydraulic clamp produces a massive holding power and the housings withstand any twisting or flexing. The large center bore series provides for added flexibility when adding work holding devices.

CNC Rotary tables are attachments for machining centers. It is known as the 5th axes in Taiwan. A good 4th axis must basically possess the characteristics of “indexing accuracy” and “repeated accuracy.” In order to achieve high accuracy, the 4th axes must have good warm gears and warm sets, as well as precision construction. Based on our nearly 50-year experience in producing high-precision gears, we are able to produce high-precision warm gears and warm sets. In addition, we specially purchased a CNC boring machining center from Toshiba, Japan to produce high-precision construction. Also, to ensure our quality, we developed an inspection software with the Mechanical Industry Research Lab (MIRL) at Industrial Technology Research Institute (ITRI). Due to the mentioned experience and new investment,...

1. Five face or multiple direction processing 3 axis cnc machine plus this two axis nc Rotary Table, it is able to do 4-axis or 5axis stimulate processing.

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

* With the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

Golden Sun Industrial Co., which focuses on producing key machine-tool components such as index tables and rotary tables, said it would upward adjust product prices by 5% up to 10% in the foreseeable future.

Kao Ming general manager Shih-yu Chang said the upward adjustment in product prices is inevitable as the last price increase was over three years ago, despite steadily rising prices of imported raw materials over the same period of time. He noted that the prices for cast iron rose 45% from NT$32 (US$0.99 at US$1:NT$32.3) per kilogram in April last year to the current NT$45 (US$1.39). It is expected the prices for cast iron would be raised again sometime in March, when the quotations for such stock will break the NT$50 (US$1.54)-per-kilogram mark.

Faced with spiraling prices of cast iron, the Industrial Development Bureau (IDB) under the Ministry of Economic Affairs recently convened domestic machine-tool and cast-iron suppliers to come up with effective ways to overcome the hurdle, which may be a means to stay profitable. Leading domestic producers of cast iron, including Ying Chieh Casting Co., Chia Sheng Co. and Yuan Run Fong Cast Iron Co., said they are doing everything within their power to source ample raw materials to ensure the steady production of cast iron until the end of the second quarter of this year.

8613371530291

8613371530291