haas 5 axis rotary table made in china

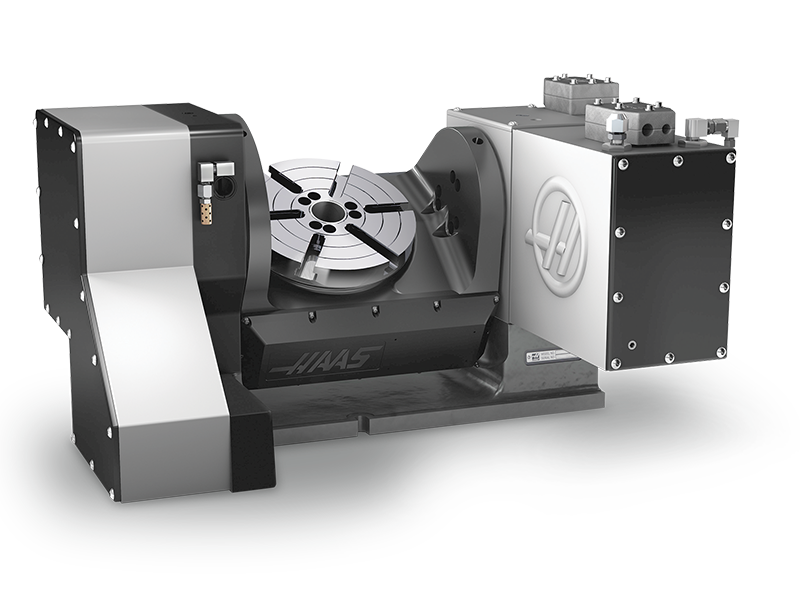

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility than its predecessor. We’ve completely redesigned the TRT160 to create a much more compact and versatile 5-axis solution for smaller mills, including Haas Mini Mills and Toolroom Mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Europe and America: the best selling brands in the Chinese market are Haas and Lehmann. Haas is mainly configured on its machine tools, other brands of machine tools are rarely installed. Lehmann is positioned at the high end and mainly cooperates with some high-end machine tools. In addition, it is also used in some occasions with high accuracy requirements, but the demand is small

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

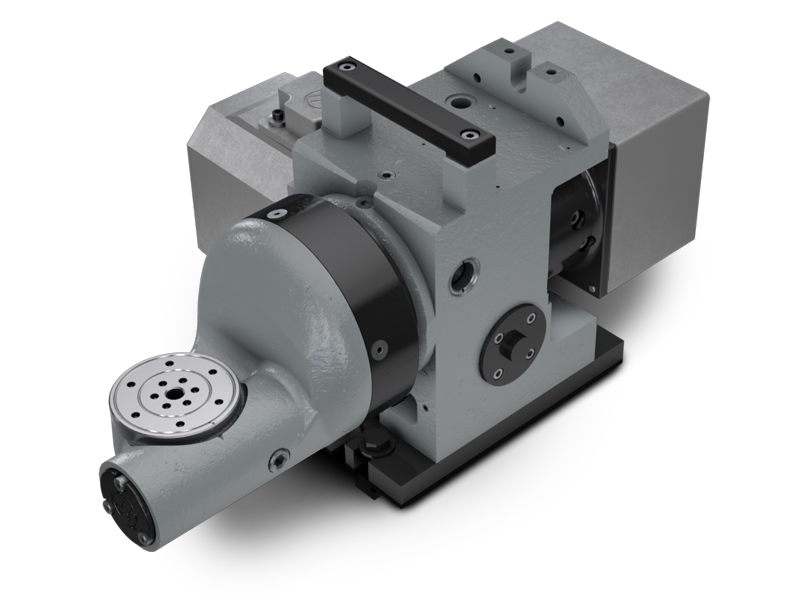

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

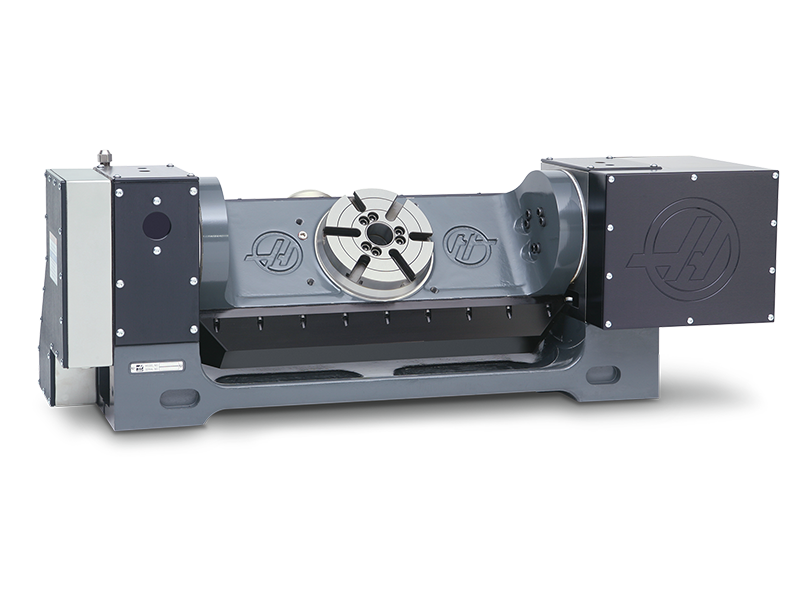

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

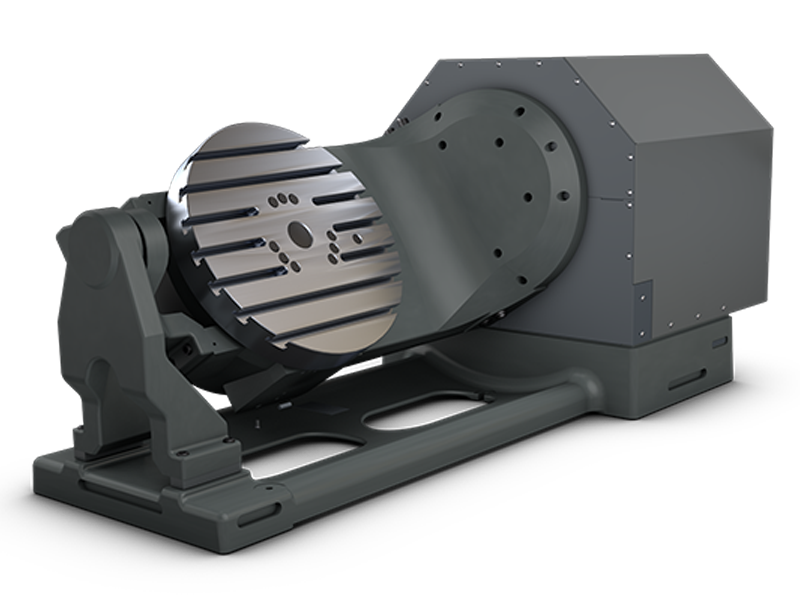

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

One of the most obvious advantages of a 3 axis machine might require several different set-ups and more than five hours to complete, its 5 axis counterpart can complete the part in just a couple operations that take less than two hours from start to finish.

Some jobs are very complex profiled. Such as turbine impellers. Such jobs have features like curved vanes having back turns. So the tool cannot be positioned even by four axes to reach every nook and corner of the job. To machine such a job, a 5 Axes machine is required. A 5 axes machine has 3 regular axes of VMC machine as well as 2 rotary axes for most complex job machining, so people also call it a 5 axis machining center.

5 axis machining involves all the axes of 4 axis machining, with an additional rotational axis. 5 axis milling machines are the best CNC milling machines available today, capable of creating precise and intricate parts for artificial bones, aerospace products, titanium pieces, oil and gas machine parts, car molds, medical, architectural, and military products. The 5th axis in 5 axis milling machine is around the B-axis, which rotates around the Y-axis in the X-Y-Z plane. This multidimensional rotation and tool movement allows for B-axis unparalleled precision, finish and speed in the production of a piece. 5 axis machining can create very complex parts, which is why it is so important for high level uses, such as aerospace applications.

Some people mistakenly think five-axis technology is only for the most complex parts. While it certainly excels at that, a significant majority of the applications are simply used to enable the machining of five sides of a workpiece in a single setup. With three-axis machining, jobs might require two, three or more setups to get at all the features of the part.

With the done-in-one approach, those additional setups are eliminated in addition to the potential for error each time you reposition a part. The justification for a 5 axis machine on these grounds is simple, with dramatic reductions in total setup, machine time and reduced fixturing.

Another inherent advantage of 5 axis machining is it can use shorter tools because the tool/tool holder combination can be tipped away from otherwise interfering surfaces or features on the workpiece. This is particularly important in die and mold work where the use of toolholder extensions is common to reach deep cavity surfaces. A shorter tool results in less vibration, allowing for heavier or faster cutting, better surface finish and longer tool life.

5 axis CNC milling machines are different from 4 axis CNC milling machines. There are several types of 5 axis CNC milling machines. Their mechanical structures are different. Different types of 5 axis machining centers have their own advantages. Let"s take a look at their differences.

The simplest and least expensive way to get at five sides of a part is with a 3+2 machine configuration. For small to medium machines, that typically means a 5 axis machining center with a tilting rotary table to position the part. This, of course, can be accomplished with an auxiliary 2 axis table on a standard 3 axis machining center. But a machine with an integrated tilt table offers better machining performance and is easier to set up and program.

In fact, the 3+2 5-axis CNC milling machine only adds a 5-axis CNC rotary table on the 3 axis CNC milling machine. This method is less cost-effective and can be modified by almost all 3 axis CNC machines.

The rotary axes in trunnion-style 5 axis CNC milling machine are expressed via the movement of the table, whereas swivel-rotate-style machines express their rotary axes by swiveling the spindle. Both styles have their own unique advantages. For instance, trunnion-style machines offer larger work volumes, since there’s no need to compensate for the space taken up by the swiveling spindle. On the other hand, swivel-rotate-style machines can support heavier parts, since the table is always horizontal.

swivel head-type 5 axis CNC milling machine has the following advantages:Heavier Parts: Because the table is stationary, the swivel head/rotary table machines are used with heavier parts.

Versatility. You can add a vise for greater versatility because of the large table size. Use the extra space to finish the sixth side of the part or do 3-axis work.

If you choose the 3+2 type 5 axis machining center, the biggest cost difference is the 5 axis CNC rotary table. The cost of the 5 axis CNC rotary table of different sizes is very different, and there is a big price difference between different 5 axis CNC controllers. These affect the cost of the 3+2 type 5 axis CNC milling machine.

It should be noted that the 5 axis CNC milling machine is a very expensive investment and requires very professional CNC skills. If you are a 5 axis machining amateur, you can choose the desktop mini 5 axis CNC milling machine, such as Pocket NC V2.

You can also consider buying a small 5 axis CNC milling machine. TAICNC"s 3+2 type small 5 axis CNC milling machine is also very economical and practical. Below is our small 5-axis machining center video:

The 5 axis machining center made in China has cost advantages and is precise and stable. Below is a demonstration video of a 5 axis machining center made in China. You can contact us if you have any needs.

For example, if the parts are small to medium size, with today’s technology, a tilting-table-type machine is going to be the best bet. If the parts are large and heavy, an articulating head—possibly on a gantry-style machine or a horizontal machining center—may be the only option. This consideration alone will narrow your choices and help you compare features of various machine models within the required range.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new 5 axis rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement 5 axis rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new 5 axis rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

To enable the 4th and 5th axis code, set the right machine configuration for the ABC axis for the specific machine being used. The machine configuration can be found in the onOpen() function:

Range: Specifies the angular range for the axis in degrees as a 2-element array ("[-120, 120]"). You can also specify a single number to create an axis for an aggregate.

Resolution: Specifies the resolution. In degrees for rotational actuator. The default is 0. Note: If there"s only need for a 4 axis setup, delete the other axis beginning with "var bAxis” and “var cAxis” or disable them by typing two slashes “//” in front of the line that needs to be disabled.

This line creates a new machine configuration as defined previously by using the given variables for each axis (in that case: aAxis, cAxis). Only use the variables inside the parenthesis. If an axis has been removed or disabled earlier for a 4 axis machine setup, remember to remove the disabled axis variable here as well.

Like any other machining process, 5-axis CNC machining refers to manufacturing progress that removing material from a workpiece by using the high-speed CNC machine, which is called a 5-axis CNC machine or 5-axis milling machine.

There are many CNC machines in the manufacturing industry, the most common type is a 3-axis machine. This type of basic machine normally moves a tool on three primary axes as below.

5-axis milling machine, on the other hand, can drive two more additional axes which we normally call A and B. By having these two additional axes, the 5-axis machine can drive the cutting tool to reach a more multidirectional approach, and machine very complex parts easily.

First, we can sort it by configurations. There are three categories: Head/Head 5-axis Machines, Table/Head 5-axis Machines, and Table/Table 5-axis Machines.

Next, we can sort it by size. There are small 5 axis CNC machines, large 5 axis CNC machines, desktop 5 axis CNC machines, compact 5 axis CNC machines, and more.

Thirdly, we can sort it by function. There are 5 axis CNC grinder, 5 axis CNC router, 5 axis laser cutting machine, 5 axis laser engraver, high speed 5 axis CNC machining, and more.

Lastly, we can also sort them to be cheap machine and expensive machine. The expensive machines normally come with high precision such as Haas 5 axis CNC machining from the USA and Mazak 5 axis CNC machining from Japan.

3+2-axis machine, refers to a traditional three axes machine, adding rotary tables to its two fixed axes (normally from A and B). With 3+2 axes operation, the angle of the cutting tool does not change as the table rotates, the part is in a fixed orientation. Therefore, 3+2-axis is also known as positional five-axis machining.

Simultaneous 5-axis machining, on the other hand, the three linear axes and the two additional rotational axes can be controlled to move at the same time. Therefore, the cutting tool can keep continuous contact with the workpiece at any angle.

Comparing both ways, we can see that Simultaneous 5-axis machining is a higher precision cutting process than the 3+2 machining method. It is allowed to reach hard-to-reach areas and creates perfect cuts to offer a better surface finish quality.

3 axis machining can only operate the X-axis, Y-axis, and Z-axis. The workpiece is fixed in position with moving during machining progress, this limits the cutting tool approaches.

5 axis machining, on the other hand, there are two more axes. This machine can rotate around both X-axis and Y-axis, so the workpiece can be turned to any angle. Therefore, this allows a wilder cutting range and can produce more complicated geometry features.

For example, it is difficult to mill the undercut feature with 3 axis machining. However, the 5 axis machining can easily finish this job with a single-step machining mold.

During the 5-axis machining, we can turn the cutter close to the workpiece surface, so it is possible to use a shorter cutting tool. With a shorter cutting tool, the feeding and speed can be higher, all this leads to faster material removal at last.

As we know, there are many types of cutters including flat end mill, bull nose end mill, ball end mill, and more. Among them, the flat end mill produces a flat-bottom cut that is the most efficient for material removal.In 5 axis machining, we can use a flat end mill cutter frequently, this also leads to higher cutting efficiency.

During the three-axis machining, the complex fixture is often required for workpiece fixing. Besides, a lot of parts machining will need more than one setup, one setup takes one type of fixture. Each fixture takes cost, more fixture takes more cost.

Five-axis machining has a strong capability to make complex shapes in a single setup with a simple fixing fixture. Thus, it can save a lot of costs from the workpiece fixture.

Unlike traditional machining ways, 5 axis machine can drive the cutter to any face of the workpiece including the bottom surface. This makes sure all cutting work can be done during a single setup.

5 axis machining can achieve smaller cuts due to its multiple movements, this helps to get contoured geometry on the surface and leads to a higher quality finish.

As a 5-Axis CNC machine is not a cheap machine, not every shop can afford one. Having the 5-Axis machining capability, it can help you to get more trust from your customer. Thus, you can run faster than your competitor and be more competitive in the market.

Compared with the ordinary 3-axis machine, the cost for a five-axis CNC milling machine is much higher. Besides, there is also a high maintenance fee along with the machine.

The 5-axis machining movement is more complex than other simple CNC machines. To run the machining efficiently and correctly, a lot of parameters have to be calculated carefully. This will need experienced programming engineering for the job, this leads to an additional high cost.

Since the 5-axis milling is complex, it will ask for a higher requirement for the operator who operates the machine. Normally, a higher experienced operator always comes with a higher salary, this adds up to the total machining cost.

Thirdly, when the CNC machined part asks for high precision for some features. Compare with 3 axis milling, 5 axis milling is a better option due to its single setup advantage.

Next, when there is an urgent requirement for delivery, you need to increase production efficiency to reduce production time. With a single set-up and fewer clamping fixtures, a 5-axis machine can be a better choice.

5 axis CNC machining is a special process, it’s machining cost is also higher. As for the specific cost figure per hour, it is hard to tell as it depends on several parameters. Among them, there are two major parameters: machine maintenance cost and management cost.

The XR20 rotary axis calibrator works in conjunction with XL-80 and XM-60 laser systems providing highly accurate, repeatable rotary axis calibration for stages, jigs and machine tools.

It consists of an integrated angular retroreflector mounted on a precision servo-controlled axis. The angular position of the axis, and the optics relative to the main body housing, is controlled by a very high accuracy encoder system with the scale directly machined on the main bearing.

FeaturesHigh accuracy- ±1 arc second using the XL-80 laser or ±1.2 arc second using the XM-60 multi-axis calibrator. (See error budget and uncertainty calculation below for further details).

A mounting ring adaptor plate enables the XR20 rotary axis calibrator to be fitted to rotary tables with unsuitable centre recesses. It can also be used to secure the XR20 rotary axis calibrator to the chuck (lathe) adaptor and custom mounts.

CARTO software suite is used for capturing data, analysis and rotary measurement using the XL-80 laser or XM-60 multi-axis calibrator. CARTO is made up of three applications:Capture to collect laser measurement data.

Off-axis rotary measurement mode in the CARTO software suite provides a single source for testing off-axis measurement using the XR20 rotary axis calibrator and XL-80 laser system. This streamlines the measurement of rotary positioning accuracy for 5-axis machine tools, where the XR20 rotary axis calibrator cannot always be mounted on the centre of rotation.

Off-axis rotary measurement application in the CARTO software suite allows the XR20 rotary axis calibrator to be used to measure the rotary positioning accuracy of an axis, even when the XR20 isn"t mounted on the centre of rotation (pivot point) of that axis. This extends the capability of XR20 to many five axis machine tools.

The mounting of the XR20 rotary axis calibrator relative to the axis under test is vital for accurate measurement. Renishaw has developed the XR20 90° bracket to remove complexity of manufacture for the user. This accessory is manufactured to extremely fine tolerances required to achieve accuracy of testing.

Flexible fixturing options are provided by removable magnetic feet and a variety of through holes for direct bolt attachment. The bracket is useful for meeting the mounting requirements of "off-axis" rotary measurements and resolving "on-axis" mounting difficulties on trunion type machines.

The mounting of the XR20 relative to the axis under test is vital for accurate measurement. Renishaw has developed the XR20 90 deg bracket to remove complexity of manufacture for the user.

The Renishaw XR20 rotary axis calibrator uses Bluetooth® wireless technology. In some territories the level of regulation varies. This table indicates the relevant standards or licensing authority that XR20 complies with, for indicated territories and the corresponding registration number, where applicable.[183kB]

8613371530291

8613371530291