haas cnc rotary table factory

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Haas HRT160SS is a high-speed 4-axis rotary table, with a cycloidal drive that provides a maximum speed of 500° per second. That’s nearly four times the speed of the standard HRT160. The compact size and high speed of the HRT160SS make it the perfect complement to the Haas DT-1 Drill/Tap Centre and moreover other high-speed Haas machines. The cycloidal rotary drive system provides a great combination of speed, accuracy, and durability.

Requires a Haas mill with 4th-axis drive and NGC software version 100.21.000.1150 or later. Stand-alone operation requires a Haas SCOL rotary control box with software version 26.22 or higher.

High-speed 4-axis rotary table – 160 mm (6.3″) Super-Speed Servo Rotary Table with 500 deg/sec indexing. Requires Haas mill with 4th-axis drive. Mills built before 1/1/2011 require software version 17.06C or later; mills built after 1/1/2011 require software version 18.01A or later. Not available for stand-alone operation.

The cycloidal rotary drive system was designed for machine tools and robotics. The drive provides a great combination of speed, accuracy, and durability. The rugged design provides long service life, with little or no maintenance. By the same token the cycloidal rotary drive can be back driven to absorb energy from an impact. Furthermore, the shock-load capacity is 5 times the rated torque of the gearbox. Should damage occur the entire gearbox is a simple drop-in replacement.

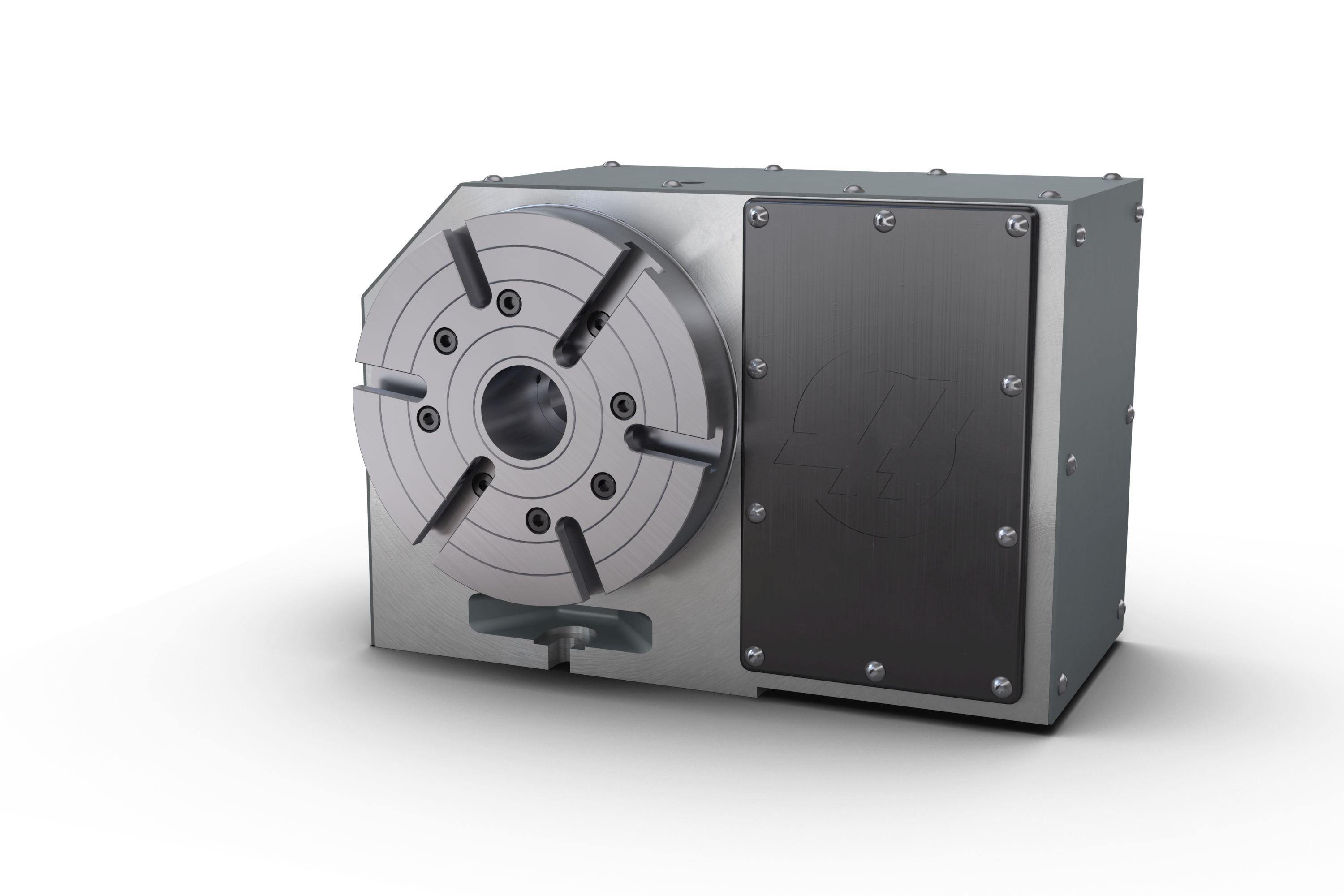

... heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive to deliver a true 4th-axis ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary control box for ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HRT160SS is a high-speed cycloidal drive rotary table that provides a maximum speed of 500° per second – nearly four times the speed of the standard HRT160. The compact size and high speed of the ...

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

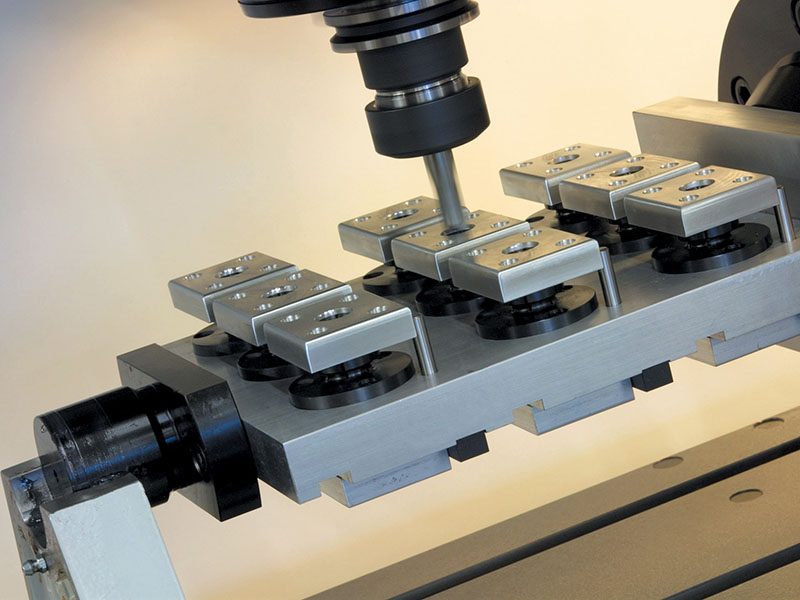

... fixtures, the HRT series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

The Haas HRT210HT rotary table uses a high-torque servomotor to provide 385 ft-lb (522 Nm) of spindle torque for heavy cutting – that’s 83% more torque than our standard HRT210. This rugged, heavy-duty ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

We offer quick turnaround and since all repairs and maintenance are performed locally, it reduces your down time. We diagnose, rebuild and repair each machine to restore it to optimal performance. All services are performed by knowledgeable, courteous, local Haas factory-certified service technicians to ensure that your CNC rotary table repair service is done according to manufacturer standards.

Productivity offers rotary table preventive maintenance that includes motor checks, backlash adjustments, flushing and replacement of lubricant and replacement of O-rings and seals. We also offer full service electronic repair of servo control units and cables.

As CNC machine tool technology has evolved it’s possible to do more operations better, faster and at lower cost than ever before. These advances also mean that there are more machine components and accessories to monitor and maintain. Often overlooked are rotary or trunnion tables that reduce setup and cycle times and, in many applications, enable the machining of complex parts.

Properly functioning rotaries and trunnions are essential to making accurate parts, and like other critical machine components should be checked regularly for signs of wear or damage. The most obvious tipoff that something is wrong with the rotary device is that you experience difficulty setting up a part, or begin producing out-of-tolerance parts. However there are 3 simple checks that, if done regularly, can help keep your rotary tables and trunnions in peak working order:

Check the oil sight glass for discolored or cloudy conditions. This may indicate that a seal has failed and coolant, dirt or other debris is in the lubrication system. Contaminated oil cannot properly protect the inner workings of the rotary device and can cause thousands of dollars in damage.

If you find that your Haas made rotary devices need maintenance or repair, contact your Torrance, CA Haas Factory Outlet for quick and reliable service. Since 1986 Haas has built and sold over 55,000 rotaries and trunnions for Haas and other machine tools, and provides comprehensive service on all 35 models.

Most jobs are turned around in 7 to 10 business days and include a thorough inspection to determine what components need attention to bring the rotary device back to factory specifications. This process includes:

Your Torrance, CA HFO technical service professionals will be happy to discuss your specific rotary device needs and can provide rentals or loaners to help minimize the impact on your production schedules. Learn more by calling Gabriel Monroy, 310-381-0750 Ext. 17526. Or email: gmonroy@haasfactoryoutlet.com. Visit www.haasfactoryoutlet.com for all the local Haas news.

Haas Factory Outlet – A Division of Timco is a distributor for Haas Automation, the largest machine tool builder in the United States. Haas Automation manufactures a full line of CNC vertical and horizontal machining centers, CNC lathes, rotary tables, mini mills, super mini mills and 5C indexers. Haas machine tools and rotary products are built to deliver high accuracy, repeatability and durability.

Timco Machine Tools, Inc. was established in 1986 with the primary goal and a strong commitment to not only offer the finest machine tools available but also back them with some of the best support in the machine tool industry. With over three collective decades in the machine tool business, Timco’s staff has the knowledge, equipment and resources to help our customers determine their needs and the commitment to service the selected product. We have been selling Haas machines for over a decade and have over 4000 machines in Oklahoma.

Timco’s service personnel are continually going through comprehensive training to keep up with the ever-changing technology of today’s machine tool market. We currently employ seven Haas Certified service engineers.

To provide the most thorough local sales, service, and support in the industry, Haas Automation, Inc., the largest machine tool builder in America, has established a nationwide network of Haas Factory Outlets (HFOs). These locally owned and operated HFOs provide dedicated sales, service, and training exclusively for Haas products, while delivering a consistent, professional corporate image and high-quality experience for the customer at the local level.

Currently, nearly 70 HFOs have opened throughout the United States, Canada, and Mexico. Under the HFO program, Haas distributors around North America – and around the world – are setting up facilities dedicated solely to the Haas product line. These facilities feature demonstration areas equipped with the latest Haas machine tools – VMCs, HMCs, lathes, and rotary products – as well as fully dedicated Haas service departments and training centers.

“We want to provide the best of both sales and service,” says Gene Haas, President of Haas Automation. “Our HFOs are independently owned and operated to provide the local attention our customers deserve. They offer a professional atmosphere where end users can test-drive Haas products and see the latest technology. Customers can expect the same high level of service from each and every outlet, regardless of location. Each HFO will still be unique, though, because it retains the local know-how and relationships that have been built up over the years by the local distributor.”

The largest tool builder in the world, Haas Automation, is an evolving line of American made, accurate and durable machining products, puts us in the position to offer our customers reliability, technology and value. Our alliance with Haas Automation is defined not only by its machining centers but by its outstanding service and applications. As a factory direct distributor, we carry replacement parts for next day delivery and a fleet of fully stocked service trucks providing installation and ongoing service. Our Application Engineers have the experience to help you select the best Haas product for your application provide turnkey solutions and training.

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

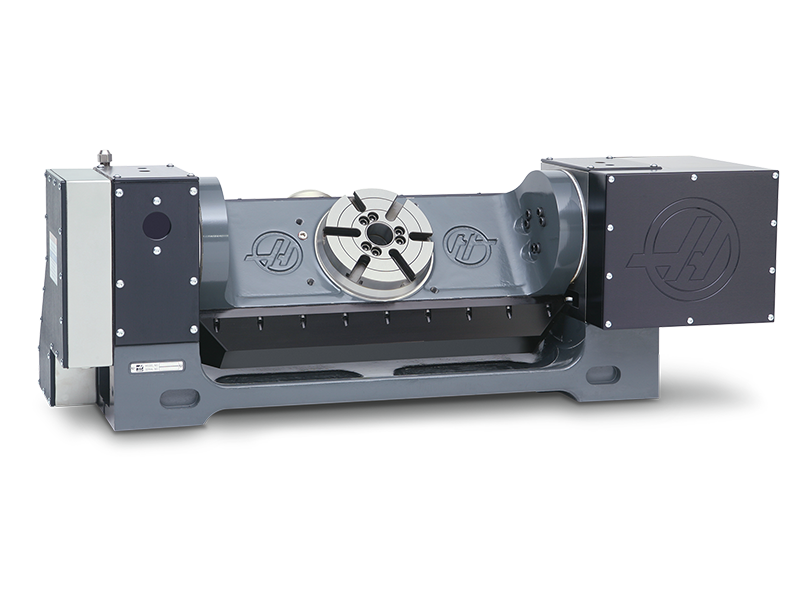

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

8613371530291

8613371530291