haas rotary table accessories free sample

The system of rotary/indexer and Servo Control unit is defined as a semi-fourth axis. This means that the table cannot do simultaneous interpolation with other axes. Linear moves or spirals are generated by having an axis of the mill move at the same time the rotary table moves. Refer to “Simultaneous Rotation and Milling” on page 31 for details. This method requires a host machine capable of closing a relay (or switch). Most CNC machine tools are equipped with spare M codes, which can be used to close a relay. Indexing commands are stored only in the Servo Control program memory. Each pulse of the host machine relay triggers the Servo Control to index to its next programmed position. After finishing the index, the Servo Control signals that it has finished and is ready for the next pulse.This method can be used with machine tools that have no controls.

The first part is the model number of the rotary unit [1]. This can be found on the serial plate of the unit. Some Rotary units have a dash in there name, that dash may or may not be in the included in the file name.

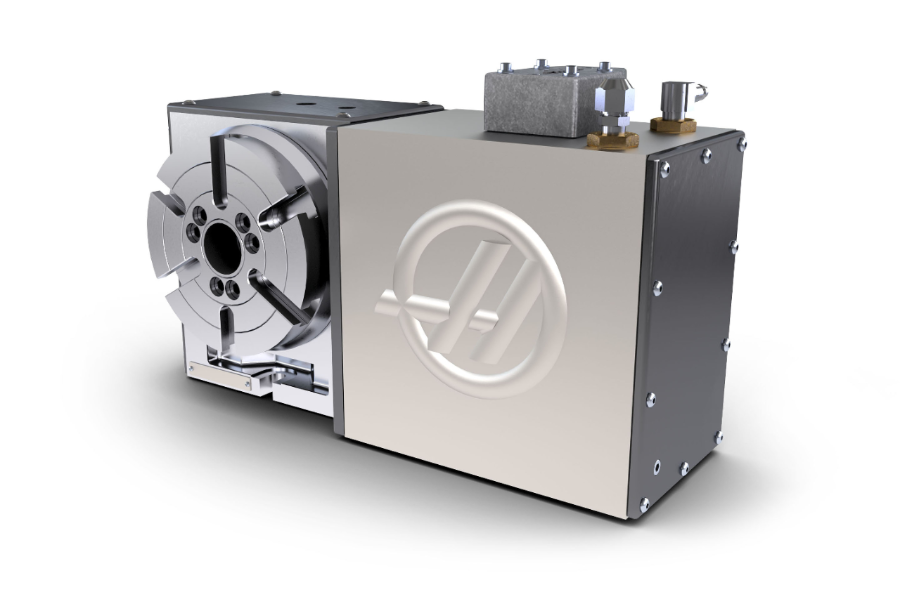

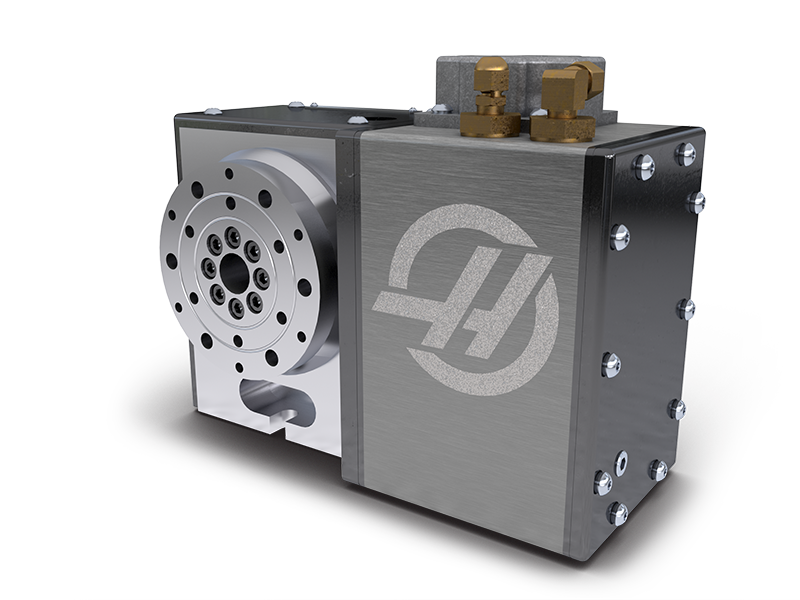

The fastest way to increase the productivity of your Haas mill is to add a Haas single or dual-axis rotary product. You can reduce or totally eliminate multiple setups, and easily handle machining multi-sided parts.

With a full line of Haas rotary products, including many specialised units designed for maximum productivity, Haas continues to lead the way to higher productivity through automation.

All Haas rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4-axis or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy to use. It’s possible to install a Haas rotary on other makes of mill as we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable.

Adding a rotary axis to your CNC mill is the fastest way to boost throughput and increase accuracy. Because Haas began as a rotary table manufacturer in the 1980s, we are able to provide the simplest and most cost-effective entry into 4-axis and 5-axis machining available.

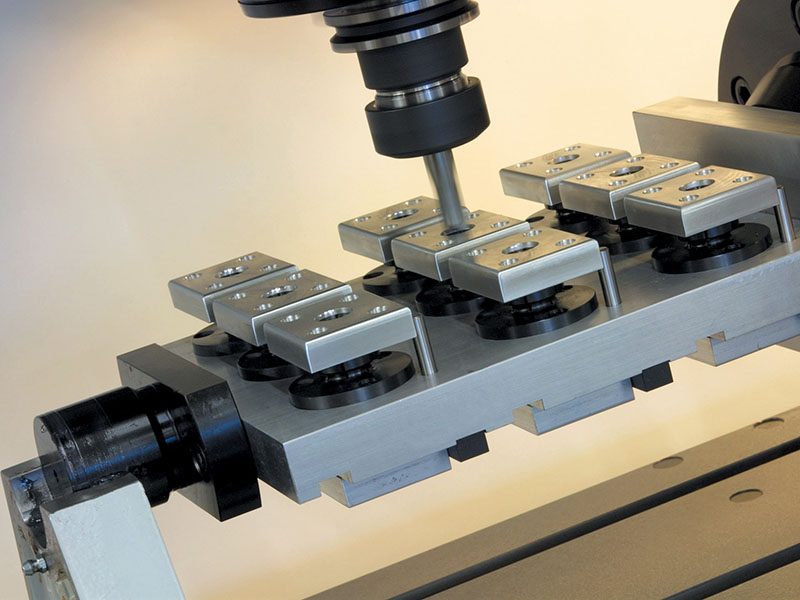

Haas offers a wide selection workholding solutions for your 4-axis and 5-axis clamping needs, from compact air-collet closers to quick-change fixture plates to manual scroll chucks.

Constructed of heavy-duty materials and designed for dependable day-in, day-out operation, Haas rotary products are the benchmark by which all others are measured. We manufacture all critical components in-house at our state-of-the-art California facility. At the core of every Haas rotary table is a large-diameter, aluminium-bronze worm gear meshing with a ground alloy steel worm (hardened to 60 Rc) submerged in a synthetic oil bath.

Sherline has taken their accurate and reliable 4″ rotary table into the 21st century with the addition of Computer Numeric Control. Clock-makers or anyone with a need to cut gears or other complicated radially symmetrical patterns will find this accessory takes all the headaches out of repetitive indexing operations.

The rotary table comes with clamps and T-nuts for attaching it to the T-slots of a Sherline mill table. In addition, there are two options available for mounting the table in the vertical position or at other angles:

Right-Angle Attachment—This plate holds the table in the vertical position with a center height of 2.7″. A right-angle tailstock is also available to support long stock held on center in the rotary table.

Tilting-Angle Table—This table holds the rotary table and can be fixed at any angle from 0° to 90°. In the 90° position, the rotary table center is also at the 2.7″ height, which allows the right-angle tailstock to be used with it.

After entering the number of steps per revolution (or the number of degrees per step) on a simple numeric keypad, the table advances quickly and precisely to the next position at the touch of a single advance key. If an error is made, previous positions can be accurately recalled by hitting another button. Basic resolution is 28,800 steps per revolution, ±0.006° per step. This allows the accurate machining of items like gears with odd numbers of teeth. Computations are made internally to a high degree of accuracy to avoid cumulative errors.

Are you considering the purchase of a CNC machine and want to know whether to chooseHaasorMazak? Both are popular manufacturers and have their own loyal followers. As you will see, we compare the companies, machines construction, CNC controls, service and training. Both companies have their own strengths and serve their markets very well. In the end, you’ll have to evaluate each machine company’s strengths as compared with your needs. We encourage you to keep in mind your needs for machine service and training, types of materials that you’ll be machining, tolerances that you’ll need and part complexity requirements as you read through this guide. We also recommend that you call your local support technicians for both Mazak and Haas to evaluate the kind of local support that is available before you make your final decision.

Haas is a manufacturer of four main product lines: vertical machining centers (VMCs), horizontal machining centers (HMCs),CNC lathesand rotary tables as well as 5-axis CNC’s and other specialty machines. All products are made in Oxnard, California in a large modern machine tool shop with most of their machines being made on their own equipment. They have been known for making economical and reliable machine tools since 1988, when they introduced their first VMC, called the VF-1. This machine was introduced for a price under $50,000 and solidified their position as CNC manufacturer for the small job shop. Today they have an extensive line of machines of all sizes and applications.

Haas CNC are made with cast-iron construction which provides ten times more damping capacity as compared to steel. The castings are analyzed for flaws in reinforced with numerous heavy ribs to resist flex and damp vibration. They add bulk and ribbing to the headstock and tailstock of the Haas lathes for stability, repeatability and cutting accuracy. Haas machines are built to be economical but still solid. However, they are not considered the most heavy-duty. For applications machining aluminum and softer materials or lower production job shops, the Haas is often the CNC of choice.

Mazak has been building machines and innovating for over 100 years and has a reputation for designing and supplying high-quality, innovative and customer-friendly machines. No matter what your machining needs, there’s a good chance that there’s a used Mazak that will be a good fit for your application. Mazak builds heavy-duty CNC’s with solid cast iron bases that they machine in their own plants. They use heavy-gage external steel housing, which sets them apart from most of their competitors including Haas. Mazak CNC’s are known for solid construction and engineering – they are considered top quality CNC’s and new go for as much as 40% more than similar Haas machines. For tight-tolerance work, especially machining tougher materials, many prefer the Mazak.

The Haas control is considered one of the easiest to operate. Even models going to back to the year 2000 had Haas-only features like “Word Processor Editing” to help operators easily make changes. They carried features like one-touch, multi-function jog-handle and quick code programming even on early milling machines. Haas provides a robust dependable control that is integrated with the Haas CNC machine. They do not rely on third-party NC suppliers. Haas CNC’s have dedicated keypads with a full array of keys including a complete alphanumeric keypad with all common functions clearly labeled for operator use. Operators don’t need to remember any encrypted codes. As computer technology advances, Haas makes their controls even faster and smarter. Their goal is to keep the spindle turning which keeps the cash flowing into your pocket. Haas is known for their easy-to-learn controls.

The primary operating system for Mazak CNC’s is the Mazatrol, which was first introduced in 1981 and has since been developed into an advanced connected digital platform. In 2014 Mazak introduced the CNC Mazatrol Smooth controller and now offers five versions of their controllers for various applications. They are known for their technology which optimizes machining speed and accuracy with numerous advanced features. From position-controlled hobbing, to fast rotary axis speeds and variable acceleration controls as well other features to shorten cycle times, Mazaks are excellent for high-production shops and/or product lines with complex features in competitive markets. Mazak offers multiple software solutions and boasts the ability to connect and secure there CNC’s of all ages. This makes it possible for you to buy a used Mazak CNC machine and still take advantage of newer software solutions. For example, the Mazak SmartBox, developed in 2015 together with Cisco, provides security, analytics and machine monitoring which is backward compatible with older Mazak machines. Mazak also provides many automation accessories to CNC machining such as bar feeders, gantry loaders and articulating robots. Newer CNC’s are available with digital solutions including MTConnect, which is a key component ofMazak’s iSMART Factory conceptsince 2015.

Haas provides extensive online resources for training and support. They have troubleshooting guides, how-to procedures, mill operator manuals and lathe operator mills readily available on their website. You can watch videos for troubleshooting as well as service and maintenance and get regular tips on how to best operate and care for your Haas machines. In addition, operators can search from alarm codes for all kinds of resources. They also have an extensive network of service technicians at their Haas Factory Outlets and recommend that certain machine repairs be done only by authorized personnel.

Be informed. When you buy a used Haas or Mazak machine, you’re going to need to do more research than when buying a used CNC. Start by making a list of your requirements. You should consider the:Types of materials you want to machine – Are the easy or hard to machine?

You may want to buy a similar CNC to a Haas or Mazak that you already have, or you may want to look for one that is newer, so you can begin to connect everything via ethernet or Wi-Fi to take advantage of software innovations.Ask for good photos. Zoom up in the photos and look for signs of damage and worn components.

Ask for the maintenance records of the specific Haas or Mazak that you are considering. Repair work isn’t a bad thing, in many cases, it will help you know what been replaced, what hasn’t and if it was done right. Ask for as much documentation as the seller can provide. This will help you in case you have problems at later date and provide you with details for buying parts. One advantage of buying a used Haas or Mazak is that since these machining centers are relatively common, finding parts shouldn’t be too difficult.

HTEC (Haas Technical Education Centers) are proud to be a part of Smartforce as an extension of their ongoing efforts to help shape the next generation of manufacturers. Educators attending IMTS can register for a drawing to win one of 5 Haas CNC Simulators to use in their machining education programs. All who register will also receive free online training software from Immerse2Learn that explains how to learn and operate the Haas Control.

IMTS 2014 is sure to be an exciting show for the expected 100,000 visitors from 112 countries coming to Chicago September 8 -13, 2014 to see more than 1900 exhibitors, including Haas Automation.

Haas plans to showcase 18 machines with live demos and special IMTS promotions. On display will be the new ST Series turning centers that incorporate an advanced tailstock design, new turret and turret drive, and a completely reimagined base and tailstock frame for greater rigidity and stability. Among the featured CNC machines are the UMC-750SS high-speed universal machining center, and the large-capacity ST-55 lathe with 12.5″ through-bore.

Stop by and check out the Haas booth (S–8119) at this year’s IMTS, September 8-13, 2014 in Chicago. While you’re in our booth, ask for a collector’s pack of limited-edition Haas trading cards, featuring all the Stewart-Haas Racing NASCAR drivers, and special Haas machine cards. Some packets will contain a special winner card that you can trade for collectible items, like a Kurt Busch race suit, or one of Kurt’s helmets from the 2014 Cup Series. One lucky winner will get an on-track ride-along with Kurt – buckle up! Plus, if you’re one of the first 300 people to visit our booth each day, you can get your hands on a special No. 41 Haas T-shirt.

As CNC machine tool technology has evolved it’s possible to do more operations better, faster and at lower cost than ever before. These advances also mean that there are more machine components and accessories to monitor and maintain. Often overlooked are rotary or trunnion tables that reduce setup and cycle times and, in many applications, enable the machining of complex parts.

Properly functioning rotaries and trunnions are essential to making accurate parts, and like other critical machine components should be checked regularly for signs of wear or damage. The most obvious tipoff that something is wrong with the rotary device is that you experience difficulty setting up a part, or begin producing out-of-tolerance parts. However there are 3 simple checks that, if done regularly, can help keep your rotary tables and trunnions in peak working order:

Check the oil sight glass for discolored or cloudy conditions. This may indicate that a seal has failed and coolant, dirt or other debris is in the lubrication system. Contaminated oil cannot properly protect the inner workings of the rotary device and can cause thousands of dollars in damage.

If you find that your Haas made rotary devices need maintenance or repair, contact your Torrance, CA Haas Factory Outlet for quick and reliable service. Since 1986 Haas has built and sold over 55,000 rotaries and trunnions for Haas and other machine tools, and provides comprehensive service on all 35 models.

Most jobs are turned around in 7 to 10 business days and include a thorough inspection to determine what components need attention to bring the rotary device back to factory specifications. This process includes:

Your Torrance, CA HFO technical service professionals will be happy to discuss your specific rotary device needs and can provide rentals or loaners to help minimize the impact on your production schedules. Learn more by calling Gabriel Monroy, 310-381-0750 Ext. 17526. Or email: gmonroy@haasfactoryoutlet.com. Visit www.haasfactoryoutlet.com for all the local Haas news.

For more ways to improve your CNC shop’s profits talk your Torrance, CA Haas Factory Outlet consultants. Call (310) 381-0750, email: jphillips@haasfactoryoutlet.com, or visit www.haasfactoryoutlet.com.

How reliable is your turning machine?Downtime is costly, and if your machine isn’t performing consistently over time, requires excessive servicing or doesn’t deliver repeatable results, it’s costing you time and money. You need a high-performing CNC lathe that is extremely rigid, highly accurate and thermally stable.

If the answers to these questions have you wondering if a new CNC lathe could improve your productivity and profits, it’s time to talk your Pittsburgh Haas Factory Outlet consultants. They’ll introduce you to the new ST generation of Haas CNC lathes and turning centers that meet the demands of today’s machining challenges and those of the future.

How reliable is your turning machine? Downtime is costly, and if your machine isn’t performing consistently over time, requires excessive servicing or doesn’t deliver repeatable results, it’s costing you time and money. You need a high-performing CNC lathe that is extremely rigid, highly accurate and thermally stable.

If the answers to these questions have you wondering if a new CNC lathe could improve your productivity and profits, it’s time to talk your Torrance, CA Haas Factory Outlet consultants. They’ll introduce you to the new ST generation of Haas CNC lathes and turning centers that meet the demands of today’s machining challenges and those of the future.

8613371530291

8613371530291