hauser rotary table supplier

MACHINE OPTIONS Rotary and rotary tilting axes A and A-B axes in customized version are available as additional units. Option with Fanuc 30i ATC automatic tool changer ATC automatic tool changer with 22 magazine positions, permitting automatic machining with grinding wheels from Ø 3 mm to Ø 50 mm. Option with Fanuc 30i Measuring probe Grinding motor Grinding motor 70HS ATC with its extremely wide range of application, from 9000 min-1 to 70000 min-1. This grinding motor, and its state of the arts design is an absolute must for getting optimal use out of the grinding tool changer. Measuring...

MEASURING SYSTEM New Hauser jig grinding head High-grade rigidity and stiffness leads in duplicating the stock removal capability and cuts in half the spark out time. Allows the combination of grinding and hard milling. High-grade rigidity and stiffness leads in duplicating the stock removal capability and cuts in half the spark out time. Drive section Significant boost in stroke speed and stroke frequency leads into reduced grinding cycle time. Significant boost in stroke speed and stroke frequency leads into reduced grinding cycle time. Hydrostatic guided spindle bearing system allows...

CONTROL SYSTEM If you appreciate user friendly menu programming and insist on the advantages of ISO/DIN programming, then the HAUSER product will be the right choice. Axis X, Y, C, U, Z and W are CNC controlled, as a standard with Fanuc 30i. With Fanuc 31i the C-axis is an option. Based on these controllers we have created HAUSER-Software cycles, ensuringthat the control will perfectly cover all the special requirements of jig grinding FANUC SERIES 31i • Max. number of path: 6 path • Max. total number of control axes: 34 axes (26 feed axes, 8 spindles) • Max. number of simultaneous control...

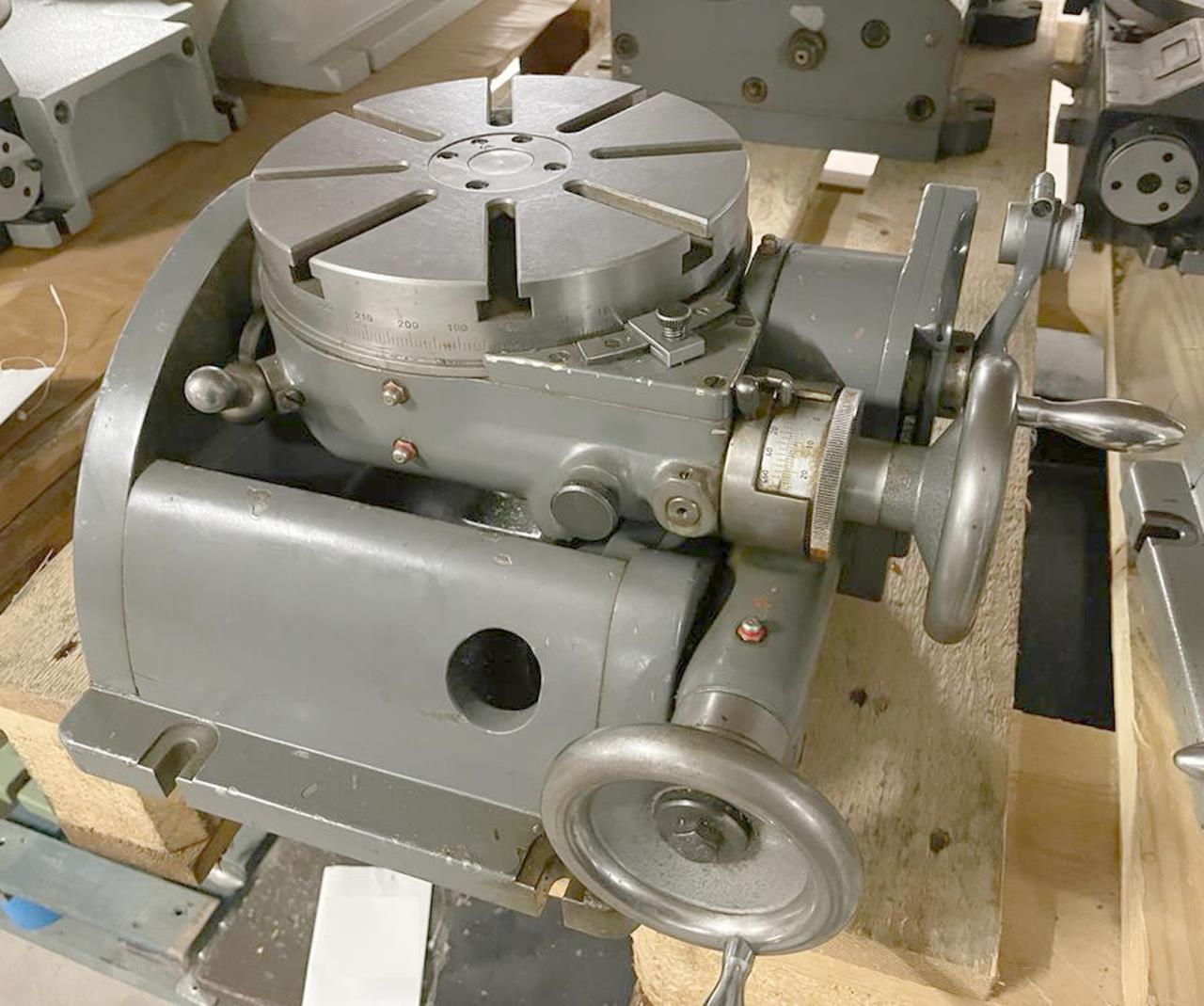

HAUSER 12" Low Profile Precision Rotary Table. Swiss Made Jig Boring Grinding. Hauser 12" 300mm Precision Low-Profile Rotary Table Description: In good condition! Swiss Made. Table turns smooth. Missing graduation pointer. 12" Table Diameter Dimensions: 19"L x 13"W x 3.5"H Micrometer Drum Reading 140 lbs Comes as shown. Check out our feedback & bid with confidence! The above information is to the best of our knowledge from sources deemed reliable, but should be verified at the time of inspection to confirm accuracy. Quoted prices do not include applicable sale taxes or freight costs. 30-day return policy if item is deemed unsatisfactory. Buyer to pay return freight. Email us with any technical questions you may have or email with zip for a freight quote. CA residents subject to sales tax. Freight and removal are the responsibility of the buyer. Local Pick-up ok. We will help load small items at no charge Feel free to contact us TOLL FREE @ [phone removed by eBay] or Email Us ([email removed by eBay] ) We are conveniently located @ 2430 Cypress Wy. Fullerton, CA 92831 Hours: M-F 7:30AM - 4:30PM Saturday by appointment only GENERAL TERMS : By Purchasing equipment from Rohner Machinery Sales, Inc. the buyer agrees to all the terms and conditions listed and any other terms expressly added to this invoice. PRICES : All Prices are in U.S. Currency (Dollars). Prices are exclusive of state, county or federal taxes. Any taxes shall be paid by the buyer in addition to the quoted purchase price. DELIVERY DATES : While every effort will be made to meet quoted or verbal delivery dates, those dates are estimated target dates only. Date of delivery is not guaranteed as those delivery dates are necessarily subject to fire, strikes, or labor trouble, storms, acts of governmental authority, acts of public enemies, freight embargo, acts of God, and the like. ACCEPTANCE : All proposals and acceptances of orders are made with the mutual understanding that orders are not subject to cancellation, and that a deposit is REQUIRED within 7 calendar days or this invoice is invalid. CLAIMS : Any and all claims for errors in merchandise must be made in writing immediately upon receipt of goods; no credit will be allowed on returned goods without Rohner Machinery"s permission. It is expressly agreed that the Buyers sole and exclusive remedy for any claims arising under this agreement against Seller shall be limited to return of goods and repayment of purchase price or to repair or replacement of goods at RMS" option. In no event shall RMS be responsible or liable for special or consequential damages. MACHINE USE & SAFETY : Buyer acknowledges that the goods on the invoice are pre-owned goods which were neither designed or manufactured by Rohner Machinery Sales, nor does RMS have any knowledge, or control over the prior use or misuse of said goods. Nor does RMS have any control or knowledge of the future use of the goods by the buyer. By purchasing the machinery on the invoice, the buyer, his employees, assigns or agents; agrees not to exceed the manufacturers design specifications, whether known or unknown. It is the buyer"s responsibility to provide the proper safety equipment, devices and instructions for any particular use, and to take the necessary steps to conform to all to all Federal, State and Local safety standards including OSHA. INDEMNIFICATION : Buyer agrees to hold harmless, indemnify and defend seller, its subsidiaries, affiliates or agents from any and all claims or liabilities involving or alleged to involve these goods which are caused by acts or omissions of the buyer, his employees, assigns or agents. ENTIRE AGREEMENT: These terms & conditions, together with the provisions on the invoice, are intended by the Seller and the Buyer to be a complete and exclusive statement of the terms of the agreement, and such agreement may not be modified, amended or waived except by a writing with reference to this subject and superseded by this agreement. Seller shall not be bound to any terms of sale set forth herein unless the same shall be specifically agreed to in writing by an authorized officer of Rohner Machinery Sales, Inc. Seller objects to provisions contained in Buyer’s forms which are different or in addition to the terms herein. Buyer’s purchase order is accepted expressly conditional on the buyers assent to the terms and conditions, as the complete and exclusive statement of the terms of this agreement, which assent shall be manifested by buyer’s accepting or retaining possession of the goods described on this invoice. Powered by eBay Turbo Lister The free listing tool. List your items fast and easy and manage your active items. We don"t broker machinery at RMS. Every machine listed for sale by Rohner Machinery is on our warehouse floor and has been gone through & tested by our service techs.

Hauser 16" Rotary Table, Inv 17736 . Hauser 16" Rotary Table. (Inv.17736). Not What You Were Looking For?. MikeKandu Portland, CT Hauser 16" Rotary Table Made in Switzerland Norden N-26 331 Bakelite handles Broken (Loc.304) (Inv.17736) Not What You Were Looking For? Check out our eBay Store ! where we keep a wide selection of Machine Tools , Tooling Components , Parts , Accessories , and More in stock for your convenience. Please Note!!! When bidding on this item the following will be added to the amount you bid: a handling/loading charge of $50; and the actual shipping cost (to be determined based on your location). Also: Skidding/Crating of items are extra costs. This is in addition to the actual shipping charges paid by the buyer. We have the right to resell the item if it is not paid in full within 10 days of the auction. All items are subject to prior sale. For the purpose of obtaining shipping quotes our Zip Code here is 06480. To Our International Bidders: The only method of payment we accept for international sales is an international money order. All international sales are subject to a $15 surcharge in addition to normal shipping and handling costs. All items are sold "AS - IS, Where - IS" and with all faults. Items are described to the best of our knowledge, however, We (Mikekandu and/or the Seller) make no guarantees regarding accuracy, errors or omissions in item descriptions and make no warranty, express or implied as to the nature, quality, value or condition of any item. We expressly disclaim any warranty of merchantability or fitness for a particular purpose of any item. Questions? For more information, click the "Contact seller" link in the top right corner of this page. Terms All sales are final. Buyer is responsible for actual shipping. Payment must be made within 10 days. For full terms and conditions of sale, Click Here . Shipping If you need help getting shipping quotes, click the "Contact seller" link in the top right corner of this page. View My Other Auctions

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, NO ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, NO ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, NO ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.25 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, ALUMINUM HELIX COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, NO ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, NO TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, NO HOME SWITCH, BELLOWS COUPLING WITH 0.375 INCH BORE, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, MAGNETIC HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, NO ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, MAGNETIC HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, NO ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, MAGNETIC HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, MAGNETIC HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 4.115 ARC-SEC RESOLUTION ENCODER, OVERSIZED TOP

PARKER DAEDAL:200RT SERIES ROTARY TABLE, 5 INCH TABLE DIAMETER, 180:1 GEAR RATIO, IMPERIAL MOUNTING, STANDARD GRADE, MAGNETIC HOME SWITCH, NO COUPLING, NEMA 23 MOTOR MOUNT, 0.412 ARC-SEC RESOLUTION ENCODER, STANDARD TOP

HAUSER 2BA Jig Borer -- circa late 1950s/1960sWhilst the No. 4 and No. 5 Hausers may not have enjoyed the popularity of similar SIP models, the smaller models were in great demand, with waiting times, in the 1950s and 1960s, stretching to over a year on some occasions. Of the pair, the No. 2BA was first to market with over 1000 sold before the introduction of No. 3. The No. 2 was eventually to be built in at least six versions - the direct-reading, screw-feed 2BA, 2A2 and 2A3, the optical-reading OP2 and two unusual combined jig boring and jig grinding machines: the mechanical dial-reading 2SB and optical 2SBO.

All models of the No. 2 can be found in M.1 and Mk.2 form - the earlier having "round" styling typical of the kind used on machine tools until the late 1950s, and the later more modern, angular lines with the Hauser name picked out in large letters arranged vertically down each side of the stand"s front face.

Most popular of all, the 2-BA was versatile and adaptable, its larger table and longer head and spindle travels - together with a slightly better speed range than the other more specialised versions - giving it a clear advantage for run-of-the-mill toolroom work. With a working surface of 450 x 310 mm (17.75" x 12.25") the table had six T-slots and a longitudinal travel of 350 mm (14") and a cross-feed of 200 mm (8"). Carried on the back of the main body, the complete head assembly, together with the 0.75 h.p. spindle-drive motor and gearbox, could be elevated under power through a distance of 390 mm. Raised to its maximum height, a clearance of 570 mm (22.5") was created between spindle nose and table surface, a figure that allowed unusually large jobs to be accommodated that would otherwise have tied up larger and more expensive machines. To ensure complete safety, electrical switches were fitted that cut power if the limit of up or down travel was reached. To preserve their accuracy and maintain lubrication, the vertical ways were completely enclosed by bellows.

Manufactured from special hardened, aged and ground steel, the table feed-screws were turned by large, smooth-faced handwheels - both positioned on the right-hand side of the machine and facing to the right. The final setting was achieved by knurled-edge knobs of a size comfortable to grip with the whole hand - and by which means the job could be perfectly positioned. In order to ensure an even greater degree of accuracy, this Hauser was fitted with the automatic screw-pitch correction mechanism described in the opening to the Hauser section above.

The Sauter rotary table is ideal for machines designed for complete machining. Our tables can be used for milling or grinding machines as a base for the main spindle or the workpiece carrier an allowing easy access from any position.

Our design for the B-axis rotary table focused on flexibility, precision, and robustness. This was achieved by means of:Backlash-free pre-loaded gear train

A Cartesian three-axis system, a turntable, a stack magazine and a machining centre – these are the most important components of a new production cell from König Automatisierungstechnik GmbH. With only minimal conversion effort, the cell can be used for the series production of different parts and still achieve high throughput: The automation technology is designed so that the cell can operate with a minimum cycle time of 15 seconds. At this cycle speed, the processing machine does not slow down and high spindle running times can be achieved. In practice, the machining times per part are usually much higher, meaning that in these cases, the automation solution can even supply several machine tools with blanks at the same time or transport the finished parts away.

The workpieces are fed and removed by a Cartesian three-axis system, which is made entirely of HIWIN components. This gantry retrieves the semi-finished products to be machined from an externally accessible stacking magazine secured by light grids and places them on a rotary table. In the following cycle, the rotary table transfers them to the loading system of the turning machine(s), which loads the turning machine and removes and returns the finished parts to the rotary table. Once there, the finished workpieces pass through several stations. First a cleaning station, followed by a measuring site in the next cycle.

The data recorded there is not only used for gapless documentation, but also by the turning machine control system to correct trends. Statistical evaluation takes place separately for each interlinked turning machine. After measurement, the part can pass through another station, for example to apply a QR code. Finished parts identified as good are then taken from the rotary table by the gantry and placed in a washing basket or goods carrier in the palletiser. The goods carriers stacked on floor rollers are easily accessible for machine operators so they can remove full baskets and set up new empties in the shortest possible time. Bad parts are ejected via an ejection chute. They are then checked manually and the error patterns are analysed.

Six production cells based on this new concept are already installed in the production halls of König Automotive, a manufacturing service provider that produces serial parts for many well-known automotive suppliers on a subcontract basis and from which König Automatisierungstechnik emerged as an independently operating company in 2018. Components for a CVT gearbox of a well-known automotive supplier are currently being produced on the lines in four shifts. Thanks to the high degree of automation, one employee can operate three lines, each with two turning machines. "But we are still at the very beginning of the project. There is still potential for optimisation", says Tobias Hauser, Design Manager at König Automatisierungstechnik GmbH. "In other systems, we have used robots to make it possible for every machine operator to operate ten turning machines. This is our long-term goal here as well".

For handling of workpieces in the production cell, however, König Automatisierungstechnik decided against using a robot from the outset. For good reason, as Hauser explains: "A robot is heavy, takes up a lot of space, requires one robot expert per shift in case of problems and, last but not least, is expensive”.

At the beginning of the project, Hauser still had a classic Cartesian system in mind for handling the workpieces within the production cell. In such a system, linear guideways are mounted on a stable machine bed and the linear movement in the X and Y direction is generated with ballscrews. As part of the process of selecting suitable products, Hauser discussed the proposed design with the responsible HIWIN account manager. However, he ultimately advised against it for several reasons: With the required stroke of 800 mm, the critical bending speed would have been exceeded at the targeted cycle time. In addition, the solution would have required a relatively large number of components with correspondingly high assembly and alignment expenses, which is why the HIWIN expert suggested using the three-axis system. Its core consists of an HD (X) double axis and two HT-B (Y and Z) linear tables from HIWIN. "Since HIWIN offers components as well as ready-to-install axes and multi-axis systems, I knew from the very beginning that they would recommend the best solution for me", says Hauser.

"I took the recommendation and decided on the two-axis system from HIWIN. The technically sophisticated and rugged construction as well as the high-quality design simply won me over", says Hauser. "An important aspect is that the HIWIN system has a particularly maintenance-friendly design. For example, this means we can easily replace the toothed belt on our own when it wears out. Another plus is the cover strip, which is available as a standard option on HIWIN axes. The rugged stainless steel cover strip reliably protects the inside of the axis from chips and cooling lubricant, which significantly increases the service life. In addition, unlike with a robot, which usually requires special know-how, shift supervisors are also able to perform axis referencing on their own if required, which in turn increases the availability of the system.

HIWIN has also considered the constructor: With an online configurator, the gantry can be set up in minutes. At the end of the process, CAD data can be retrieved. HIWIN also stands for fast delivery after the order is placed: It only takes about two weeks. "Even in the boom year of 2018, the promised deadlines were kept, even while we had to wait for up to 40 weeks for delivery from other suppliers", emphasises Hauser.

In the case of König Automatisierungstechnik, the three-axis system consists of a size 3 HD double axis with two axes driven in parallel (profile cross section: 80 mm, stroke: 400 mm) as a base and is combined with one HT-B linear table each with belt drive (profile width: 150 mm, stroke: 800 mm) in the Y and Z direction. "I also like the fact that we can get complete packages from HIWIN, such as the gantry, but also individual parts that we assemble ourselves", says Hauser. Among other things, König Automatisierungstechnik ordered the drive components for the palletiser from HIWIN and set up the drive system itself.

The result has impressed Hauser and the customers of König Automatisierungstechnik: "Also thanks to the Cartesian three-axis system, with this machine we have succeeded in combining minimum cycle times with a high degree of flexibility and availability, enabling us to map production processes very efficiently. Due to the high adaptability of the basic machine, we were able to create a highly automated solution for competitive series production in Germany for our customers in the shortest possible time. Our customers’ interest in the new automation solution is very high".

8613371530291

8613371530291