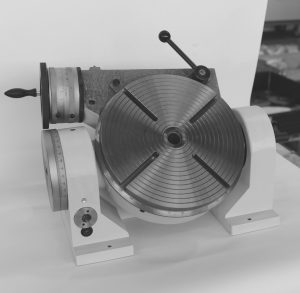

hoffman rotary table made in china

Manual precision rotary table with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications.

Additional direct indexing plate for the indexing plate device for all divisions up to 100 and higher ones, many up to 400, with included adjusting table.

I have the 8” with plates. Don’t use the plates often but easy to fit, otherwise they normally they get in the way but ok when used. I would have liked it to work in vertical mode, but I have a good vertex dividing head so no problem here. it’s certainly is a brilliant bit of kit. The thrust bearing under the table is huge. It’s smooth and accurate. Best bit of kit I have. Same t slots as a myford, but parallel 20 mm bore centre. So no mounting stubby morse tapers but I now have a range of dedicated centres..

I am looking for a Soba 6" rotary table and a chuck adapter plate. Everywhere seem to be out of stock. Does anyone have a secret source or can offer advise on a suitable alternate that is in stock?

I"d look for second hand, sadly there are loads of engineering companies out there selling off top quality equipment at knock down prices. I don"t have a Soba rotary table but their products are, in my opinion at best average. Good luck with your quest though.

If you can afford the Vertex, it is made to a higher standard than Soba. I have a 6" Soba, bought privately, but in new condition, and the first thing I had to do was ditch the central needle roller bearing and turn up an aluminium bush. This was because I noticed a large ammount of radial play when the table was unlocked. I did not think 0.010" movement was reasonable, and who needs a needle roller bearing for the speeds at which a rotary table achieves. Now it works ok. As the table has four tee slots, a four jaw independent with front mounting is easy to fit. I have drilled and tapped holes for a 5" front mount Pratt Burnerd three jaw scroll chuck. This requires some thought, I made the mistake of drilling one of the holes into the drilling for lubrication, and had to re align all three. Now the holes are in the right place, fitting the chuck is easy, and with a test bar in the central Morse taper, and the chuck jaws lightly clamped on it before the screws are tightened, the chuck is centralised to about 0.002" tir which is good enough for my purposes. Having some short grub screws to put in the holes when the chuck is not fitted keeps the muck out of the works.

ps. I note that RDG Tools show a 6" "no brand" 3 tee slot rotary table here Apart from the 3 rather than 4 tee slots, it looks superficially like my Vertex unit.

On the assumption that the graduation lines are of equal width on both machines, an error in rotating the handwheel, of, just for the sake of argument, 1 degree will result in an error of 0.01111111 degrees in the table position.

A sip rotary table used in jig boring will have optical scales, but our scales are good enough for most jobs. The downside of a 90:1 worm ratio is the number of turns required to get anywhere. I prefer not to disengage the worm.

Handwheel markings and Verniers or Division Plates are merely different forms of graduation. What matters in terms of precision is the error, or lack of it, in the position of the Table. So the higher ratio results in less error (greater precision ) in Table position for a given error in the input.

when I was young, strong, healthy, and thought nothing of lifting it, a 10" H & V was my first choice. I still think it was a good choice for the work I mostly do, and this is where you may decide to compromise. If you do small work, an 8" table is much lighter and more convenient to set up. Stood vertical, it interferes less with the spindle to reach center. I don"t think a 6" is a good choice unless you know you will only be working miniature stuff. You use a considerable percentage of a small table just for set ups and hold down clamps on a lot of work, and a small table does not leave much room.

I like 90:1 gear ratio for circular milling, which is presumably your primary interest with a rotary table. My 10" table is 90:1, and that is a pretty good ratio for milling diameters (hand cranking) out to 12" or so. My 20" table is also only 90:1, and out near or past the rim (I do one part at 32" diameter) that always seems _very_ coarse.

If most of your work is small, round to begin with, and will actually be dividing work, where you index the table, lock it, and then drill a hole or mill a slot with the machine axis drive, you might find a dividing head more useful. For instance, I"ve made gears on a vertical rotary table, and in a spin index. On the table, you need an insert collet chuck or other arrangement in the center hole to get the work out far enough to clear the cutter. It"s a lot more convenient on a dividing head. OTOH, I don"t find it fun or convenient to do much circular milling on a dividing head if the work diameter is much over a few inches.

Angled Rotary Table WR is a manual precision angled rotary tables in a compact, space-saving design with high rigidity have been designed for use with horizontal or vertical turning axis on machine tools or for measuring tasks. Its available in the types WR, WRI, WRD und WRDI .Rotary Tables RH are Manual Precision Rotary Tables with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications. Table plate has 200 mm diameter. The table is available in the types RH and RHI.

Choose from over 12,000 standard products and custom solutions backed by over 70 years of HOFFMAN enclosure industry experience. Regardless of your environment or location, you can count on us for local and regional stock, comprehensive product certifications, and global manufacturing.

HOFFMAN products are developed in world-class facilities, based on over 70 years of experience in the enclosure industry and over 30 years of experience in cooling. They are rigorously tested for dust infiltration, thermal cycling, salt spray corrosion, vibration resistance and many other standards to ensure they work.

We are not successful unless our customers are successful. That"s why we work with system engineers to tailor HOFFMAN solutions to their specific projects. We offer over 12,000 standard products or we can customize a product with the innovative HOFFMAN customization tool to meet your needs and timing.

HOFFMAN offers a variety of cooling solutions for automation and electronics to ensure the proper functioning of the equipment. Each unit is functionally tested and is easy to install and maintain. Each unit comes with worldwide after-sales service for complete peace of mind. HOFFMAN works hard to save time and money. Harmful heat can cost thousands of downtime at the factory and reduce component life. This is why we work hard to make it easier to protect the main industrial controls and electronics from overheating. We offer over 1,000 standard cooling products and customized cooling services for specific colors and applications. Each product is rigorously tested in development and functionally tested before shipping. HOFFMAN is the only enclosure refrigeration company with over 1,000 service technicians and spare parts stocks globally to quickly return customers to full uptime. From specification to installation to maintenance, we are committed to simplifying your work.

From in-house manufacturing and outdoor climates to corrosive / wash-down applications and explosive environments, HOFFMAN"s enclosures and cooling products are certified and designed to be compliant in many countries. They are made in ISO 9001 factories in the United States, Mexico, Brazil, Poland, China and India. And they are supported by our offices around the world.

This ergonomic multi-function kid"s desk can be your child"s ideal learning partner! This kids writing table is made of real fir wood, with wood grain surface, height is adjusta...

5. Payments. PIS must receive the balance of the total purchase price no later than the close of business on the day following the auction (the "Final Payment Date"). All payments must be by cashier"s or certified check, federal wire transfer of immediately available funds or a corporate check accompanied with a bank letter of guarantee, and all of the foregoing must be in form, scope and substance acceptable to PIS. Credit cards are only accepted for Electronic bidding registration and for Liquidated Damages in the event of a default. If paying by credit card, the exchange rate for sales conducted in foreign currencies will be posted the day of the sale and will be based upon the current currency conversion rates. Without limiting PIS discretion, no corporate checks without a bank guarantee and no personal checks will be accepted. No title shall pass to Buyer until the total purchase price and all Taxes have been paid to PIS in collected funds.

6. Taxes. Buyer must also pay to PIS on or before the Final Payment Date, all sales, export, use and other taxes due to any federal, state or local taxing authority (the "Taxes") as a result of Buyer"s purchase, including without limitation, any taxes arising from any Buyer"s Premium (as defined below). To receive the benefit of any tax exemption, Buyer must supply PIS with a sales tax exemption certificate acceptable in form, scope and substance to PIS in PIS sole discretion.

8B. Goods weighing more than 100 pounds must be removed by a qualified, insured rigger. Before any removal, Buyer must provide PIS with a certificate of insurance from the rigger, which certificate must be in form, scope and content acceptable to PIS in PIS sole discretion. Without limiting PIS discretion, such certificate must show that the rigger carries comprehensive liability insurance written by an insurance carrier of national standing and in an amount of not less than two million dollars ($2,000,000.00). Without limiting the generality of the foregoing, Buyer shall restore and repair all real and personal property that is altered or damaged as a result of Buyer"s removal of the Goods. PIS shall have no responsibility to disconnect utilities to the sold asset, including electric, gas, waste and water lines. Buyer is solely responsible to properly remove and store in appropriate containers all fluids, oils, hazardous chemicals, etc., from machinery purchased. Buyer does hereby indemnify PIS, the owner of the Goods and the owner of the premises in which the Goods are located, from any and all claims, damages, and losses arising from Buyer"s actions or actions with respect to the Goods and Buyer"s presence on the premises in which the Goods are located, including without limitation, injuries to persons or property and environmental violations or contamination. Risk of loss on any Goods shall pass to the Buyer upon payment in full to PIS of all sums due from Buyer in respect to the Goods.

8613371530291

8613371530291