hofmann rotary table quotation

Hofmann Rotary Tables has developed a solid reputation for high-quality and affordable indexing devices, rotary tables, and tailstocks. Superior Spindle is proud to be a factory service partner for all, including the HPRS, HTH, R, and WR series.

When you experience issues with your Hofmann products, you can count on our ISO-certified and factory-trained technicians at Superior Spindle. We can repair all types of NC and manual indexing devices, tailstocks, and chuck stands.Our average turnaround time is usually between 10 and 14 business days.

Our Repair ProcessDisassembly & Free Evaluation: When you send your Hofmann rotary table to us, our team will fully disassemble it in our HEPA Class 10,000 cleanroom and evaluate all components for signs of wear and tear or damage.

Testing & Inspection: After repairs are complete, our team tests the rotary table to ensure optimal performance. Before your table is shipped back to you, our Quality Assurance team will perform a final inspection.

Shipping: All shipping and handling is covered by Superior Spindle. When you receive your newly refurbished table, we will provide you with a list of all components that were repaired/replaced as well as recommended maintenance.

Ourcutting-edge facility allows us to offer a wide array of additional services. Beyond our standard and expedited Hofmann rotary table repairs, we also provide vibration analysis, engineering recommendations, and retrofitting. Superior Spindle understands precision and is able to hold tolerances to 1 micron.

Superior Spindle has been a trusted provider of Hofmann rotary table repairs for over a decade and provides services to manufacturers throughout North America. If you’re experiencing issues with your rotary table, or are looking for design upgrade recommendations, call (734) 224-4778 orfill out our online formtoday.

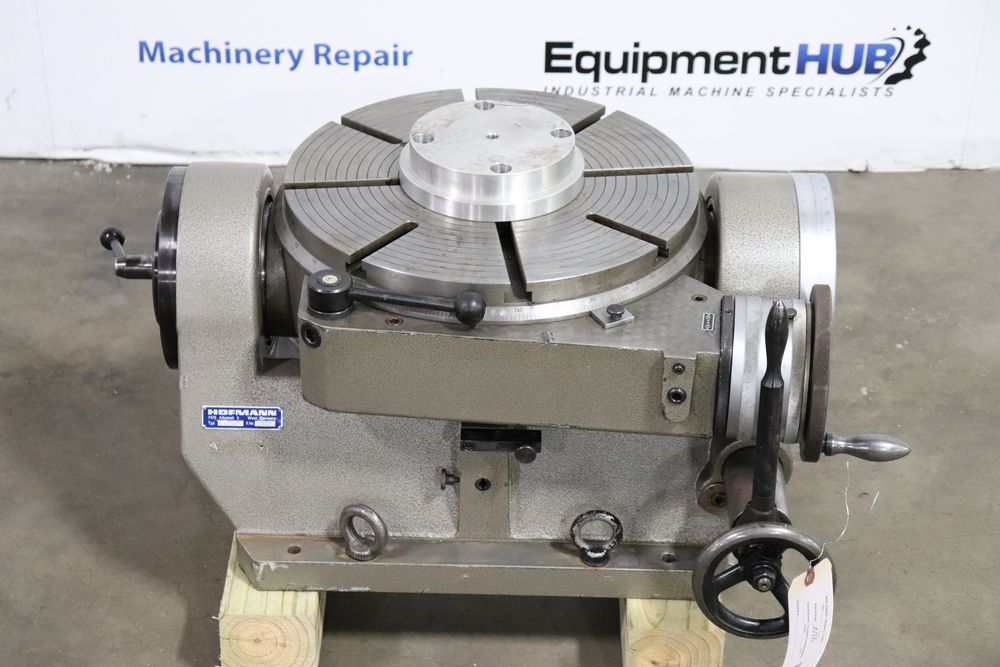

Manual precision rotary table with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications.

Additional direct indexing plate for the indexing plate device for all divisions up to 100 and higher ones, many up to 400, with included adjusting table.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

Angled Rotary Table WR is a manual precision angled rotary tables in a compact, space-saving design with high rigidity have been designed for use with horizontal or vertical turning axis on machine tools or for measuring tasks. Its available in the types WR, WRI, WRD und WRDI .Rotary Tables RH are Manual Precision Rotary Tables with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications. Table plate has 200 mm diameter. The table is available in the types RH and RHI.

Please contact us with questions or to receive a quote for any of our rotary products. Because we build our rotary tables with the motors and cables to match your CNC machine, we"ll need to review the details with you to offer a realistic quotation. Please let us know what time would be best to contact you. We make every effort to reply to your submission immediately.

Stephan W Kirsch John P Hofmann CEO / Director Owner / DirectorLeighton White Erich J Hofmann Erich F Hofmann Technical Director Managing Director Owner / Director Company Overview

Hofmann Engineering Pty Ltd was established in 1969 as a family business by the two brothers John P and Erich F Hofmann. It has grown, developed and diversified to become one of Australia’s foremost manufacturers of specialist engineered equipment.

The Hofmann group has extensive capabilities incorporating leading technology. A clear example is welding of alloy steels in heavy formed sections and machining of large-diameter high precision gearing. Another example is the improve engineering of key mineral processing and mining equipment.

HOFMANN ENGINEERING HOFMANN EngineeringNORTH AMERICA LTD ► Peru (Lima / Arequipa)CAMBRIDGE, ONTARIO HOFMANN Engineering China (Ningbo)

HOFMANN Engineering INDIA (BANGALORE) Sales and engineering sourcing offices with detailed metallurgical, mechanical and inspection capability Key Industries

Hofmann Engineering Group Design and Engineering Services Mechanical Component and Gear Design

Naval / Rope Shovel HPGRs & Valves & Defence Gearbox Portable Line & Drill Crushers Pumps Components Fitting Boring Components & Services

Double Helical Gears Worms & Worm WheelsHofmann Cone Crusher Improvement Parts HPGR DesignHofmann Cone Crusher Improvement Parts HPGR Design

I – Main frame FJ B – Pinion shaft Assembly IJ – Main shaftHofmann Cone Crusher Improvement Parts HPGR Design

MAX SHELL SIZE: Ø13.4m (44ft).LIFT CAPACITY: 210t (231 ton)x 17m (55.7ft).VERTICAL PRESSES: 6000t(6600 ton) & 3000t (3300 ton).SUB ARC WELDING: usingtandem head inverter technology.MACHINING: to Ø16m (52ft) x 6m(19.7ft) x 300t (330ton) capacityrotary table.FLOOR BORERS: 15.3m (50ft) x5.0m (16ft) & 12m (39ft) x 3.9m(12.8ft).HEAT TREATMENT: StressRelieving Ø14m (46ft) x 4m(13.1ft) high.SURFACE FINISH: AbrasiveBlast / Paint Booths, RubberLining.Mills Heads Sugar Mills

Gearbox Casings Onsite and On-Machine Metrology 6-axis Portable Co-ordinate Measuring Arms Gear Plot

Mill Head Gearbox Casing Slew Bearing Product Support and Field Service DRAGLINE & SHOVEL SITE WORK Hofmann Engineering completely: • Inspect, audit and condition monitor critical dragline and shovel components. • Do complete site installation including machining and welding.

OIL & GAS RIG EQUIPMENT REPAIRS ONSHORE & OFFSHORE • Onsite machining, fitting & laser alignment.WORLD WIDE MILL AND KILN SITE INSTALLATION & SERVICE • Gearbox & gears manufacturedInstallation by the Hofmann Site crew of Hofmann Engineering manufactured girth and repaired.gear, and twin pinion self-align gearbox, inching drive & electric motor at a Gold minein Ghana. • Pump and valves installed and serviced.Product Support and Field Service

Machining to Ø16m (52ft) x 6m () x 300 tonne (330 ton) capacity rotary table Floor Borers: (50ft) x (16ft) 12m (39ft) x () Heat Treatment: Stress Relieving Ø14m x 4m high Surface Finish: Abrasive Blast / Paint Booths / Epoxy Coating, Rubber Lining

Grinding machine; Grinding machine; Hand operated press; Jig boring machine; Lapgrinding machine; Lathe; ... Tools balancing machine HOFMANN PTB Used; SOPREM SOP10/12 Used; Luthy Machines SA General sales conditions : Download our GSC; Boulevard des Eplatures 37 CH2301 La ChauxdeFonds

Grinding machine MA68/1 for blade type 08HQ (article ref 810510) Grinding Machine for table mounting, including special blade holder type 95/08 HQ with .

8613371530291

8613371530291