horizontal cnc rotary table factory

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

The HHI-Series is TJR’s horizontal CNC index rotary table design. The HHI-series is available with table tops ranging from 320mm (12.59”) to 800mm (31.49”) square. TJR’s HHI-series can be used in various areas of manufacturing but are ideal for horizontal boring mill applications.

The HHI series is available in 1 degree or 5 degree indexing increments and employ a hydraulic braking system. HHI-series does not lift the working table during indexing to ensure positioning accuracy and they are designed for horizontal mounting only which offers high weight capacities for large workpieces. They are capable of being used as a full 4th axis that is integrated into the CNC machine control or as an indexer with the use of TJR’s SAC (Single Axis Controller).

The HHI Series horizontal CNC index table from TJR Precision Technology employs a hydraulic braking system and is designed to be incorporated into a machine’s CNC control or operated with TJR’s SAC (Single Axis Controller).

CNC machining, or computer numerical control, refers to machines that are used for milling work. This industrial process, created to operate without the need for human supervision, allowing companies to create parts with accuracy and little down time.

The machine receives coded instructions, sent by a computer for precision fabrication. Whereas old CNC machines received code through wired controllers, newer models operate computer software. Communication between the devices works via CD, USB drive or even over a shared network.

There are actually several kinds of CNC machines that work with the almost limitless number of different parts that might be needed. These milling machines, machining centers and lathes work most effectively with accessories that maximize their capabilities and efficiency. One of the most effective of these is the Ganro Industrial Corp.’s index rotary tables, available through CNC Indexing & Feeding Technologies.

Let’s start with the parts of an index rotary table. Among these parts is an indexing head. This spiral head is a specially made tool that allows a workpiece to be indexed in a circular fashion. Indexing means that the piece can be easily rotated to a specific angle. Indexing heads can be placed on milling machine tables, as well as other CNC machining devices.

What’s the difference between a rotary head and a rotary table? The rotary table is made to tilt, and to rotate. This ability lets the piece positive-lock at finer gradations of rotation. It is held the same way as the indexing head, even though the function is slightly different. Tables use an indexing head to better cut and shape to perfection, using pre-set angles, circles or dividers.

The rotary table’s contribution to metalworking is in the fact that it lets the operate drill or cut a piece around a fixed axis. In addition, it can be fitted with plates that provide divisions that cannot work with regular indexing plates.

First, understand that CNC rotary tables are a type of automated rotary tables. The difference comes in the manually controlled rotary tables that operate via lever or a hand wheel.

What makes these CNC rotary tables automatic is the fact that commands are being programmed into the machine via Computer Numerical Control. Some machines are controlled by computer-aided design programs, and this also increases efficiency. The indexing heads are also available in manual or automatic function.

The primary use of an index rotary table is to make arcs and circles in part fabrication. Many workpieces must be rotated at a precise angle or division and in between operations.

Important parts to remember include a dividing head and an index plate, since these can help to make the tables rotate in precise and controlled measurements. The tables can also be mounted in a few ways, whether horizontally or flat, or even used with tail stock to help work in between narrow centers.

Another advantage is that index tables can hold round parts for better milling accuracy. However, for this capacity, you must also use a three jaw chuck. They can also be mounted on a tilt table. This lets you mill even if you need compound angles or other complex pieces.

The premise for adding an indexing rotary table to your existing machining tool is to practically and affordably increase the menu of what your equipment can do. This can increase your business’s efficiency in production, reduce your down time and increase your profit margin.

There is a wide variety of companies that use index tables and others that can benefit from these machines, if only they would consider all the options.

Companies that produce new products obviously are the biggest industry that utilizes index rotary tables. However, contract shops and other workpiece producers stand to profit as well.

Engineering and planning is a major business that is thriving and which requires careful attention to details. This is why product makers use machine accessories like index tables to make precise specifications and to document the process for their own records.

Most companies that create workpieces specialize in a particular type of part, as opposed to custom making any and all orders. Therefore, they may only see fit to have one CNC machine or tool. They may only have one small area for production. This is why efficiency is important for specialization purposes. If the process is not efficient then the work is not profitable.

Planning is key; especially when it comes to saving on resources. CNC machines and index tables are used according to a documented cycle and process, that can match the production volume.

Operating index rotary tables in conjunction with a milling machine or other equipment requires a certain degree of education and work experience. Most CNC machinists have excellent conceptual skills, process improvement knowledge, supply management experience and the ability to manage inventory control. They must also possess careful attention to detail in their everyday behavior, with the ability to make good judgment.

The work load will involve programming or adjusting the software as needed, operated the index table with a CNC machine, maintaining safety and quality standards, managing complex and potentially dangerous equipment, and keeping accurate records for transparency. The ability to study work orders is also important, whether through blueprints, engineering plans, drawings or graphics, mathematical parameters and even the educated interpretation of geometric information.

Lubrication is very important. The rotary indexing tables’ gear box and worm shaft require high quality oil (such as ISO 100-150). The oil levels should be monitored on a regular basis. The oil should be completely changed every 6 months if the rotary indexing tables are used in normal operation conditions. This is important to insure high quality function as well as to increase longevity of the index rotary table.

Use the machine only as directed. This heavy device cannot be dropped or used recklessly, as this will easily affect or impede performance. Do not hammer the table face. Indexing is about precise shaping, not experimenting with your own tools.

Do not attempt to run the table without lubrication, as indicated, and do not use the machine if any debris is still lodged in between moving parts. The worm assembly part, for instance, must be completely clean. Dry and generally cool temperatures work best; dampness can lead to rusting.

Rotary indexing tables can help to improve your industrial business, and it can not just save money but also increase your income by increasing your market size and production capabilities.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

For situations that require horizontal rotary tables, CNC rotary tables, positioning rotary tables, indexing rotary tables, turning rotary tables, direct drive rotary tables with high accuracy and heavy loading capacities, and are suitable for heavy machining and metrology applications. Large rotary tables is one of our specialties!

Preloaded axial-radial roller bearings are incorporated, to provide high rigidity in both planes. Sensitivity and fine positioning are ensured. We are experts in the design of horizontal rotary tables, positioning rotary tables, indexing rotary tables, turning rotary tables and large rotary tables.

The modular design permits freedom to match application requirements. The worm gear drive is specially configured for maximum torque and minimum (adjustable) backlash. Our horizontal rotary tables are designed for production jobs, heavy duty machining, large part machining, heavy load capacity machining.

Rusach International & Innovative Rotary Table Solutions are a leading worldwide supplier of small to medium sized compact CNC rotary tables, standard and application oriented designs, high accuracy, compact rotary tables. Thru bore rotary tables, horizontal rotary tables, vertical rotary tables, combination/convertible H-V rotary tables, multi spindle rotary tables, 2-axis tilting rotary tables, direct drive rigid and flexible rotary tables. Production style rotary tables to fit any machine.

Innovative Rotary Table Solutions has a full line of accessories like tail stocks, magnetic plates, rotary supports, steady rests, rotating tail stock supports and controllers, all designed to fit your application. Contact Rusach International today with your application.

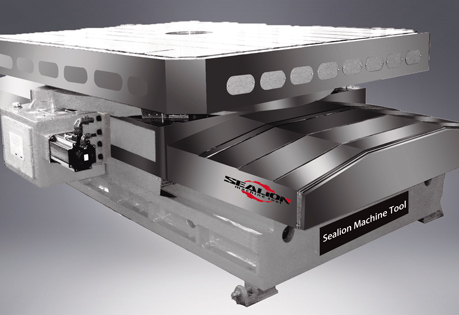

Ganro Industrial Corp. has made significant specification improvements to its horizontal rotary table series including the new HR-3030, which offers a new larger size table top and is available from CNC Indexing & Feeding Technologies.

The new HR-3030 CNC horizontal rotary table has a table top dimension of 3000mm (118.11"), 3905mm (153.75") table swing diameter, minimum indexing increments of 0.001 degrees, and a maximum work load capacity of 50,000 kg. or 110,230 lbs.

Changes to each of the current horizontal CNC rotary tables include upgrades to more powerful servo motors and stronger clamping torque with a newly designed hydraulic braking system. Also improved are work load capacities and additional built-in net weight for rigidity.

The HR Series is available with table tops ranging from 400mm (15.74") to 3000mm (118.11") square. Ganro"s horizontal CNC rotary tables can be used in various areas of manufacturing but are ideal for horizontal boring mill applications. The HR Series design can be used as a full rotating axis incorporated into a machine"s control or as an indexer with Ganro"s M-Mate AC servo controller. They are designed for horizontal mounting only and offer high weight capacities for large workpieces. The HR Series rotary tables use a hydraulic brake system to insure rigid clamping during machining.

All Ganro horizontal CNC rotary tables and indexers use Ganro"s core technology of a double lead worm shaft and worm wheel system for high precision and reduced backlash. Ganro rotary tables are assembled using cross cylindrical roller bearings with high rotation accuracy capable of bearing heavy loads in every direction.

To select the right rotary table for you is our aim, not just by the cost-effectiveness but by the most appropriate, so let us work together to find you the optimum solution from a wide variety of manufacturers from all around the world.

Now a day’s machining of component within single setup is more important concept for manufacturing any product. The objective of this paper is to give a design of CNC rotary table, this paper discuss design and analysis which include the finite element analysis of pallet with the structural static and modal behavior, The work focuses on design of rotary table used to support and hold components weighing up to 815 kg for machining, The rotary table should be designed with positional accuracy of…Expand

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

8613371530291

8613371530291