horizontal vertical rotary table price

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

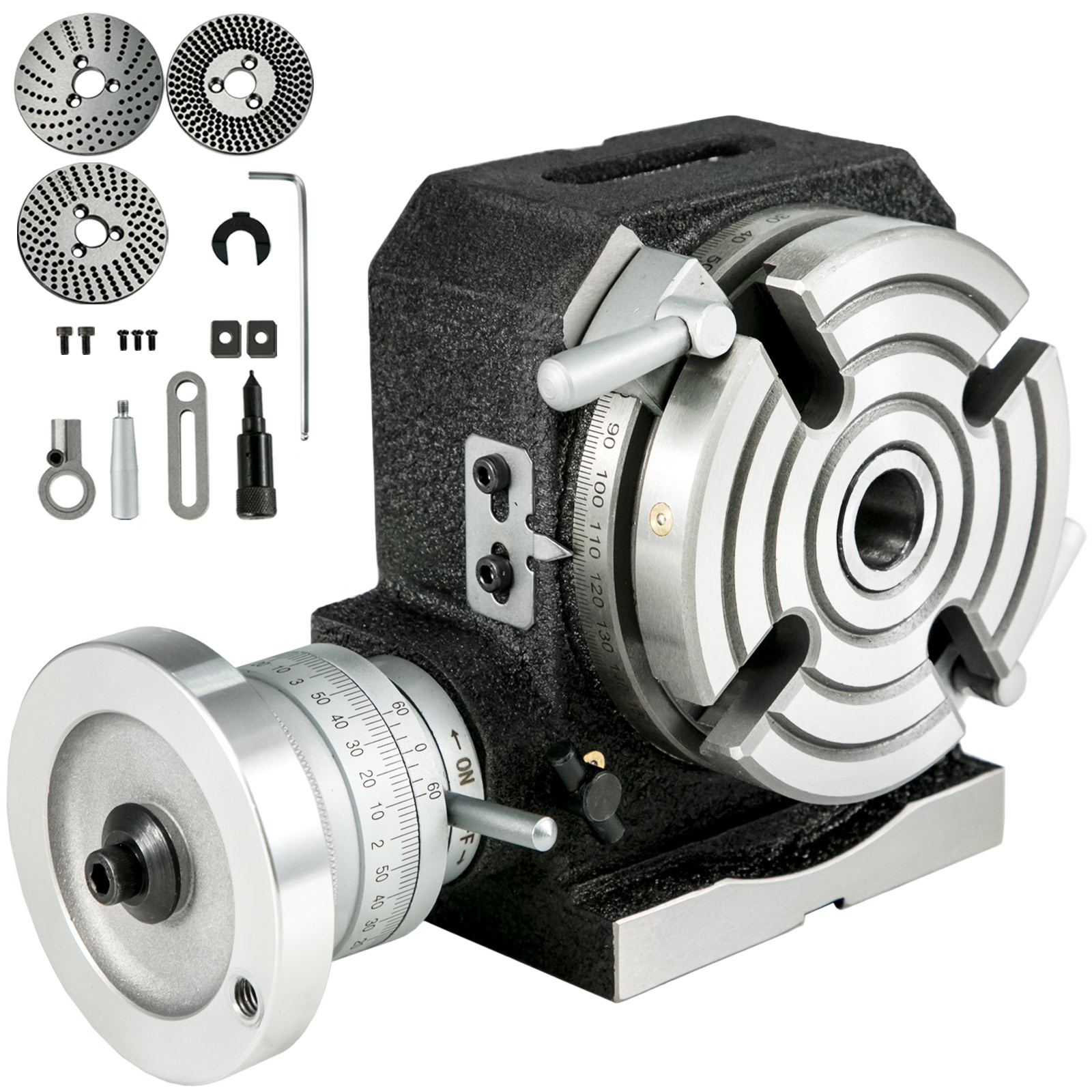

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

The G9293 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your rotary table.

The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts for the rotary table may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.

1.Our Tables are made of high density Meehanite and use "HEIDENHAIN" electronic equipment to inspect angle to assure the excellent quality and durableness.

3.Worm is hardened and ground. The ratio is 90:1. The work table is graduated a full 360° so that one turn of the handle moves the table through 4°. Micro collar is graduated in steps of 1"min. And vernier scale makes settings down to 10 seconds possible.

4.These Rotary Tables are popular for their excellent performance, practical design and reasonable cost. They are widely used for circular cutting work, angle setting, boring, spot-facing and similar work.

• Works as an index center in the vertical position as well as a conventional rotary table for circular cutting, angle setting, boring and spot facing. • 10-Second Vernier reading • Disengageable worm gear permits rapid rotation. Worm gear is hardened and ground. • Optional dividing plates and crank handle can be attached to the rotary table drive mechanism. One rotation of handle equals 4". • The table is made of Meehanite. The base of the body, table surface and rotating parts are ground finished, permitting very smooth rotation.

•Works as an index center in the vertical position as well as a conventional rotary table for circular cutting, angle setting, boring and spot facing. •10-Second Vernier reading •Disengageable worm gear permits rapid rotation. Worm gear is hardened and ground. •Optional dividing plates and crank handle can be attached to the rotary table drive mechanism. One rotation of handle equals 4″. •The table is made of Meehanite. The base of the body, table surface and rotating parts are ground finished, permitting very smooth rotation.

Palmgren"s rotary tables perform a variety of operations. They are very useful for cutting segments of circles, circular slots, cutting irregular-shaped slots as well as other similar operations. These tables permit accurate positioning of work under the machine spindle or for inspection and layout applications.Use in either the vertical or horizontal position

Kaka Industrial HV-8, 8”Horizontal Vertical Rotary Table Rotary table TSL Vertical & Horizontal MT3 Center Sleeve Rotary Table 4 slot Precision Milling Table 360 Degrees Precision Rotary Table

- With double slide table or rotary design, put-in, take-out products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production.

8613371530291

8613371530291