how to build a rotary table supplier

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

Looks to me like you are using a 240V single phase welder. In Oz I would use a Satin craft 13 electrode as these have a slower flux than a Satin craft 12. This helps stop the flux from running into the weld pool and stopping the arc. My welder has only 2 settings 2.5 and 3.2 mm so I try and use the shortest possible cable between the power point and the welder. If I have to go longer a heavier duty cable helps keep up the volts and amps.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

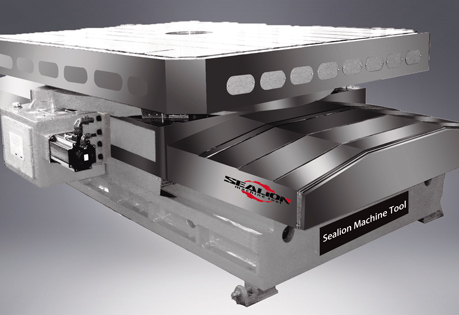

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

Cameron rotary tables range from 27 1/2 in to 60 1/2 in and feature a large oil capacity that adds to the unit"s durability. The rotary table includes a forged-steel fabricated housing and a heat-treated forged-steel turntable. Each rotary table is supplied with spiral-bevel, induction-hardened gears and two independent ratchet-type locks, with lever access from the top to lock the table in position.

The SV type are designed specially for servo motor gearbox for motion control applications. It takes full advantage of the flexibility of the servo motor, giving designers greater freedom of mechanism design.

It is a brand-new kind of rotating load device. Incorporating high transmission efficiency, high precision, high rigidity, and high cost performance, it combines the advantages of the servo motor and DD motor, obtaining a balance between these three products.

The adoption of the top spiral bevel gear and the optimized design of contact tooth surface makes the even load and allow high torque output. When it combined with planetary reducer or right angle reducer, the gear ratio shall become bigger up to 1:180.

Equipped with the servo motor, it can make segments at any angle, which can meet the digit control that the cam indexer cannot achieve. The positioning accuracy is comparable with the direct drive motor which can realize the positioning of the inertia load in a short time.

The equipment table and robot arm can be directly mounted on the output table of Rotary Table. It can save the time and cost for mechanical design, parts allocation, belt debugging, etc., which compared with the use of mechanical parts such as pulleys and belt.

Wiring and piping are more convenient and simple, and the advantages of this feature are particularly prominent in complicated wiring and piping environments.

Applied for many application like CNC Indexing Device, Military Radar, Gravity Sensor Test, Electronic Compass Test of mobile phone and other precise electronic product. It also can used for robot arm joints, testing device, laser cutting, etc.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

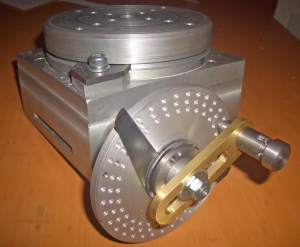

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

... conventional machines. Axis movement is performed by high quality servomotors, increasing accuracy and efficiency. Simple handling and reliability make this model very popular.

... approximation of the motorized table, automatic advance of the rod, square guides on Y / Z axes, tilt front / rear of 45 ° and centralized lubrication as standard.

... stainless steel structure, these machines feature multi-station rotary tables for optimized processing time, and automatically manage the unwinding and winding of the cloths; the moving ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Index Designs is an all-American company. Our founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. We entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Our products are completely manufactured in our Chatsworth, California facility. We use state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines. You are always welcome to visit our plant and see for yourself.

Index Designs provides engineering and manufacturing professionals with top quality products and services for the manufacturing industry. From the small job shop to the large OEM’s our customer base serves any and all types of industries including automotive, aerospace, defense, medical and energy just to name a few.

Our rotary tables are constructed of heavy-duty materials and are designed to provide long lasting, dependable service. Compare the components and design of our rotary tables with others in the industry. We take special care at our Chatsworth, California facility to manufacture and assemble products to the highest level of performance, yet offer a very cost competitive price for our customers.

For machining components from small, 5C collet sized parts, up to 15 inch diameter or larger work pieces, Index Designs offers a rotary product to fit your needs – including 5 axis rotary tables.

Want to increase your efficiency? Try one of our multi-head configurations that allows you to make more parts in less time by significantly reducing the number of tool changes and allowing operators time to tend to other machines and duties.

Whether your CNC control has AC or DC drives, or uses Fanuc (Alpha or Beta), Mitsubishi, Yaskawa, Glentek, Siemens, Baldor, etc. we can build a rotary table with a compatible motor for just about any 4th axis-ready machine on the market! If you need help getting a machine 4th axis ready, we can also supply the parts you need; such as amplifiers, drives, cables and connectors.

If your application does not require true, continuous 4th axis simultaneous cutting, we offer an easy-to-program, single-axis control box that can be interfaced using a spare M-function from your CNC machine. The control box can either be programmed directly or fed data via RS-232 for fast, accurate indexing to any angle.

The rotary core making table provides a slow moving, continuous work surface that is designed for varied core production. The standard table design has the mixer and the operator position outside the table. However, the tables can be designed for interior operator or machine use as an option.

Adjustable rotational speed provides for timed production rate that is required based on the curing rate of the sand. When the core box arrives 180° from the fill point, it is stripped. The empty box is placed back on the rotary table while the core is set on staging racks, out-feed conveyors, or the like.

The table is powered with a DC, variable-speed chain and sprocket drive. A standard heavy duty foot pedal for the mixer operator or core box stripper that can be configured to either stop or start the table on initiation depending on need.

A rotary table is a tool that allows you to rotate an object around a fixed axis. They are perfect for precision work and can be used for everything from metalworking to woodworking. You can also use these machines for other types of handiwork, such as drilling holes in different angles, sanding curved surfaces, or even welding on both metal and wooden surfaces.

A rotary table can be used for cutting, drilling, and milling metal. It"s perfect for precision work and can help you achieve a high level of accuracy. You can use it to create gears, brackets, and other metal parts.

It essentially consists of a circular plate that can be rotated on a horizontal axis. This rotation allows the user to easily and quickly position the workpiece in the exact location required. In addition, most rotary tables also have a graduated scale, which further increases accuracy by allowing the user to work with specific measurements.

For example, if you want to create gears, you can use a rotary table to drill the gear"s teeth. But you first need to create a template for the gear. The rotary table can help you do this with ease with a graduated scale.

A rotary table can also be used for welding. To create welded brackets, you can use a rotary table to drill the holes in the brackets. You can then use a welding torch to weld the brackets together. Overall, the rotary table is an essential tool for anyone looking to do high-quality metalwork.

A rotary table is a versatile tool that can be used for various woodworking tasks. One of the most common uses for a rotary table is routing. A rotary table can be a lifesaver when you need to create a perfect circle or an intricate design. Simply attach your router to the table and let the rotary motion do the work for you.

Rotary tables can also be used for drilling holes. By attaching your drill bit to the table, you can ensure that your holes are perfectly spaced and evenly distributed. And when you need to make curved cuts, a rotary table can be attached to your saw blade, giving you the ability to make clean, precise cuts every time.

Sanding curved surfaces can be a pain, but it"s a lot easier when you have a rotary table. With this tool, you can easily sand the curves and contours of your piece. It"s an excellent tool for creating custom furniture and other woodworking projects.

As you can see, a rotary table is a versatile tool that can be used for various tasks. Whether you"re working with metal or wood, a rotary table can help you get the job done quickly and easily. So if you"re looking for a tool that can help you achieve precision results, a rotary table is a perfect choice.

If you need a wholesale rotary table, Alibaba.com is the platform to visit. This online shop has collaborated with many Alibaba.com dealers to offer customers a wide range of products that lie within their budget. Moreover, the platform offers customization services. So, if you need a custom-made machine, you can place a customization order. This shop also operates on a 24/7 hour clock allowing you to place your order at any time.

Looking for wholesale rotary table? Depending on the type of plastic, sheets and other related materials have many uses for consumers and businesses. Some offer greater strength and stiffness than others. Plastic material has common use for different types of processes and products such as plastic materials are displays, screens, furniture, window replacement, etc. There are also plastic applications used for roofing, fencing, weather protection, and bullet-resistant applications. Manufacturers can also help with related materials for your plastic needs. Request a quote for rotary tables from wholesale businesses today.

The rotary table has cooling holes on the sides. Its intelligent design yields excellent cleaning performance. Save your costs and time with from Alibaba.com. Once set up and running, you are free to perform other tasks. The equipment will look after itself. You’ll love the portable and ultra-light construction. It’s easy to move and store. And thanks to the heating and ultrasound settings, you can customize your cleaning to meet your specific needs. If you’re not using the rotary table to clean home objects, you can make the machine an ultrasonic cleaning solution for your automotive workshops. Clean all your hard plastic instruments or engine and mechanical components parts.

8613371530291

8613371530291