how to build a rotary table quotation

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

Looks to me like you are using a 240V single phase welder. In Oz I would use a Satin craft 13 electrode as these have a slower flux than a Satin craft 12. This helps stop the flux from running into the weld pool and stopping the arc. My welder has only 2 settings 2.5 and 3.2 mm so I try and use the shortest possible cable between the power point and the welder. If I have to go longer a heavier duty cable helps keep up the volts and amps.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This is a re-post of how I built a home-brew rotary table for my mill just over two years ago. Having used it quite extensively, it still works perfectly well for my needs. During the posting, I"ll add some additional comments coloured red in the form of a review; it"s not often one gets to review or re-think a tool or operations after a period of time! I"ll also add a timeline to show how the build progressed.

Some research turned up bits and pieces of information on RTs, and then I hit gold on DeanW"s build of his rotary table - excellently detailed as always by Dean - and the plans available there. Thank you both Dean and Steve

My build was based on Dean"s, but I adapted some dimensions and methods to the materials and tools I had available, as well as changed some bits to suit my own needs.

2. An adapter to take any of my Myford chucks and to do machining securely on it. (This adapter gets used very frequently - in fact it is mounted on the RT 90% of the time)

3. Adjustment of backlash on the worm drive - and full disengagement of the drive for "quick indexing" (The backlash adjustment works a treat, though I rarely use full disengagement)

One thing that I added later in the build was to make the handwheel zero-able - This really should have been included in the above list; it"s one of the features I use the most on the RT!

I sourced and scrounged whatever materials I would need for the build; some I had lying around, and a lot I had to buy. I ended up with: Some bits of 10x60mm flat bar and a bit of 12mm plate for the base, a lump of cast iron for the table, phosphor bronze to make the gear out of, an old bit of bolt for some material to make diverse bits, aluminium for the handwheel, a brand new angular contact bearing, a bit of shaft from a printer with 2 small bearings to salvage for mounting the hand wheel shaft, and some 8mm and 16mm silver steel to make the shaft, worm and gear cutter from:

I started on the base; the bit of 12mm plate I had was too big, so I sawed it down in the bandsaw. It was a bit too big for the bandsaw as well; so I started with as much as possible of the plate clamped in the saw vise:

Then I clamped the plate to the mill table with some bits from the clamping kit and supported on two identical bearing outer rings as spacers, and milled three of the four sides square, with the two opposing sides I could get to, to the exact width for the plate (140mm):

The last side of the plate was done by adding an additional small clamp on the opposite completed side to keep the plate in position, and then moving the main clamps over to the finished side as well to clamp down properly to mill the last side both square and to dimension.

Fortunately, I could chuck the plate in the 4-jaw on my lathe; this made it easy to face and bore the hole for the bearing. The corners barely cleared the bed while swinging in the head-gap. :

To prevent the corners of the plate from hitting the apron while feeding, I just used the top slide to offset the toolbit enough. The cross slide was pretty close to maximum extension as well!

With the old Myford in medium back gear speed, I started the biggest facing cut I have tried to date. (Back then it was, and still is!) It took a while; very slow infeed at the start with interrupted cuts, and looking at the chips coming off to increase feed rate towards the center. Not a pretty picture, but the "ringy bands" looks worse than they were actually:

Next I center drilled, the plate, and drilled an 8mm hole through it with the lathe running at its second highest speed, followed by a 19mm drill (the biggest I have) in high back gear speed:

Then I bored the hole bigger; (from 19mm to 61.97 mm) I started with a cheapy tungsten carbide tipped boring bar and 20 thou (~0.5mm) depths of cut and things went OK until I tried some bigger cuts. At 40 thou cuts things were going well, but then the carbide tip splintered and everything ground to a halt. Not feeling in the mood to try and re-sharpen the tool, and with the hole big enough for my favourite HSS left-hand(that should be right-hand!) turning tool bit to have adequate clearance, I just plonked that in and finished the cut. I intentionally left a 0.5mm thick ridge about 2mm wide at the back.That was to allow the bearing I have to be pre-loaded without the center of it actually rising up and touching the bottom of the table later on :

A test with the bearing showed that the hole was just about the right size for a press fit for the bearing, but with the plate a bit warm from machining, and the bearing cold, I decided to let everything cool down to the same temperature overnight to make sure of the final fit for the bearing.

First thing that morning, I picked up with the bearing fit, and as I thought, it needed some final sizing. With all the bits at the same temperature, the fit for the bearing would have been too tight, and I ended up taking another 0.02mm (a 0.01mm cut) out of the plate. Then the bearing was a nice hand press fit part-way into it"s hole; the rest will need a bit of tapping with a hammer:

Then I flipped the plate in the chuck - just loosened two adjacent jaws of the chuck, flipped, and tightened down the same jaws, making sure the plate was flush on the chuck teeth with no swarf trapped. There was no need to perfectly re-center it - the last facing was just to get rid of the scale and to make sure the top face was completely parallel with the bottom. As the table will be riding on this surface, I tried to get a better finish - and succeeded:

After getting rid of the scale off the plate, I stopped and honed the cutting bit to get it really nice and sharp, thus the better result. The scale on HRS plate really blunts a HSS cutting bit quickly.

I just clamped the whole lot together in the mill vise and fly-cut the sides flat. A milling cutter might have been quicker, but once again, the scale on the plates would have made it blunt in short order. I could (and did - twice) re-sharpen the HSS bit I had in the fly-cutter. I also pushed things a bit hard; you can see the blue chips that came off; had me doing a dance while feeding getting hit by those

Then with both the longer pieces one-at-a-time, I squared the bandsawed ends down; one end just square, and then moved to the other end and squared , and then down to the 140mm length needed. After initially squaring the second end, I just measured how far it must be machined down (both plates were about 4mm too long at that point) and went down in 1mm steps on the mill hand wheels with the last step the required fraction of a mm on the hand wheel:

I"d not made a final decision on whether to bolt everything together, or to weld it together. I was thinking of welding the side-plates together, and bolting the top plate to them to prevent distortion on the top plate...

I milled both the "short" sides of the base square and to length. As I"d decided on welding the lower part of the base, I thought it prudent to mil the clamp-down slots in these as well, before welding things together. For milling the 10mm slots, I marked and drilled 8mm holes at the ends:

While locating the holes, I set the mill"s x-axis stops, which I have not used thus far, to stop on the holes - so I could do incremental cuts and just stop at the ends without looking at the hand wheels. Disappointment; I have not looked closely at the stops supplied with the mill, and thought they were steel, but it turned out it was plastic looking (and feeling!) like steel. Found that out when tightening the first one down; It went kgrrk and cracked on me. Another mill mod chalked up! (I have not used the stops much after this build, and now, 2 years later with a DRO scale installed on the mill in the general area of where the stops were, I don"t even miss them. I just use the DRO to get to dimensions.)

On the first slot, things didn"t go entirely to plan though... The milling bit easily chewed out the slot with 2.5mm down feeds on each pass. Then I got greedy; and tried a 3.5mm down feed... No problem for the cutter; it worked happily, but left a much rougher finish on the sides of the slot - that seemed to get worse as I went...

By the other end of the slot, I could visibly see the slot was a LOT (~1mm) wider than at the start. I did lock the y-axis on the mill, but it shifted. Note to self! - lock down harder and don"t get greedy. I ended up with an 11mm slot and rough edges. I smoothed both sides of the slot out with some fine milling cuts to look OK - with a very fine climb-milling pass (0.1mm) on each side - fortunately the clamp-down slots are not crucial in size.

The slot on the other piece went much better; I wasn"t greedy. I"ll have an RT with one wider mounting slot. I could have milled the second slot to match the first one, but I"ll leave it as is - as a permanent reminder not to be greedy in future

And another thing, from now on, if I want a slot of "x mm" size, I"ll make it with a cutter of "x-1 mm" size and have some clean-up room left! (This has worked very well since

First I clamped the bits of the frame together on the bottom of the base top where it would mount. I did this to make sure that the clamping didn"t push things out of kilter, and it also allowed me to make final adjustments with a small hammer to get everything lined up as close as possible:

Then very carefully shifted the clamped assembly over onto a spare piece of plate to make sure nothing shifted, and put the whole lot down in an open space on the workshop floor for welding together :

Four good tack-welds with the stick welder mid-way on the inside of each corner to prevent distortion as much as possible, and then a lot of welding followed. All welded up on the inside corners:

I first faced off the one side of the welded base frame in the mill. I made a couple of quick clamping plates from more of the flat bar I used for the base - just saw off and drill an 11mm hole to allow some pivot clearance for a 10mm bolt , and sawed the heads off a couple of 10mm bolts to make shorter clamping studs than are in my clamping kit. The "new" clamping plates was needed as the clamping plates in my clamping kit is too thick for the slots I milled in the base. (Two years later, and these same ad-hoc clamping plates still hold down the RT in use!) T-nuts and the clamping nuts came straight from the clamping kit. I cleaned the mill table VERY thoroughly before clamping down the piece on a bit of paper to prevent it slipping:

Then I flipped it upside down to do the other side. Same process as above - clean and a new piece of paper. With the slots now higher above the table, I needed thicker spacers for the off-set ends for clamping... I settled on using some of the triangular step blocks from the clamping kit; a small one and larger one combined to provide the height. I couldn"t use the flat bar clamp plates as-is on just one triangle block, as it is both a bit soft and too rounded on the ends to ensure a good grip on the step block. I don"t recall ever seeing step blocks used in combination like this to , but it worked a treat

It was a public holiday here in Namibia... I forgot about it... Completely... Imagine my surprise when I pitched up at the bolt & nut store to buy some M5 cap screws for mounting the base plate to the frame

The lump of cast iron centered near-enough on the 4-jaw. Neither of it"s faces was particularly square, so I chose the "best" one to go into the chuck:

As I would be doing some "interrupted" cuts because the workpiece is not entirely round, and having a skew face, I center drilled it first, and added a revolving center. This was purely a precaution to make sure the workpiece stayed in the chuck if something came loose or jammed up. Some thoughts, a prayer and a thumb-suck made me select high back-gear speed on the lathe for cleaning it up on the circumference. This worked quite well, but my first cut was a bit on the shallow side (0.2mm), and quickly revealed a hard spot in the C.I. skin:

So I re-sharpened the toolbit (that hard spot just flattened it), and took a 0.5mm (0.040") cut to try and get under the hard spot. Instead of using the apron wheel for feeding, I locked the carriage nut, and used the lead screw handwheel for feeding; that gives a finer feed than the apron wheel. This cut came out much better:

Next I faced the front down as far as I could - this face was far out of square, and with a 0.01" ( 0.25mm) infeed per cut on the topslide, with the apron locked on the bed it took a couple of passes (8 in total) to get here:

First up, I finished facing the piece - with tailstock removed. then I drilled a pilot hole through with a 7mm drill bit - pecking all the way to try and keep the hole as true as possible. The 7mm drill was just long enough for the job:

Then I drilled the pilot hole out to 13mm, and re-sharpened the tip of the carbide tipped boring bar that I broke earlier in the build, and bored the hole to 16mm dead. A test with some 16mm silver steel and I got a light push fit; precisely what I wanted. Then I bored the recess for the mounting flange with light face cuts from the inside to the outside with a HSS toolbit that I ground to a good shape for this type of job on a previous occasion. This is part-way done:

Next I made the needed undercuts on the face. They came out a bit rough on the surface, as I used a threading tool to make them. Fortunately the running faces are nice and smooth - that"s where it matters most for this project. Next up, it was the clamping groove. I did that with a parting tool and the lathe at its absolute lowest speed (back gear low speed). This was still slightly too fast, and I ran into problems with chatter. So I added the tailstock back for some additional support; fortunately my revolving center has a couple of different tips, and I could fit a bigger one to use with the 16mm center hole. This didn"t help a lot though, so at the risk of chipping off the parting tool bit tip, I increased rate of infeed. Fortunately this worked and I soon got into the "groove" with nice chips coming off the parting tool and no chatter. A couple more passes with the parting tool, and I had the groove done:

I removed the 4-jaw from the lathe with the table-in-making still mounted on it, and set it aside. The 3-jaw went on, and I started on the main shaft. First off, cut a bit off the big bolt from the first photo in this thread:

Then gripped in the outside jaws of the 3-jaw on the non-threaded part of the bit of bolt, I lightly faced off the end and center drilled it for tailstock support. Then I rough-turned it down to get rid of the threads and then down to 26.5mm - this section will later be turned down to 25mm with some other steps and sizes included:

I flipped the main shaft-in-making in the 3-jaw, and turned the flange section that mounts into the back of the table. The outside of the flange actually becomes a register to keep the shaft concentric with the table, and was turned as accurate as I could for a light push fit into the hole in the table. For some reason I got a poor surface finish; but could not do anything about it. This photo shows the part with the right hand section turned down to "register" size and the end already faced:

Action photo of drilling a 13mm hole part-way through the shaft - I love it when the swarf comes out in nice consistent curls like the ones lying below on the apron:

And done with the boring; the 16mm silver steel rod is a smooth fit in there - it acts like a piston and with the air trapped in the blind hole it pushes itself nearly right out again

I centered the chuck using the table feeds and a bit of that 16mm silver steel in the drill chuck to go into the hole, zeroed the X handwheel and dialled in the 17.5mm offset I needed. Drilled the first hole, loosened the clamp, rotated the chuck against the fixed blocks to maintain position, and indexed with the little square on the same "side" of the next jaw. Clamp down the chuck again, drill & repeat for next hole... QED

Next the holes needed countersinking from the back side... My countersink bit was too big, and waaay to short to reach in there. A broken 8mm drill bit volunteered, and I carefully ground its end to a 90 degree angle with suitable cutting faces. That made countersinking easy, and the holes turned out quite well with no chatter:

The last step, was to punch a witness mark into the flange and the back of the table; these I then "connected" with a scribed line - this will be used to make sure everything can be put back exactly the same at a later stage:

Then I used the punch to mark the table for the screw locations; simple; keep the alignment mark I made aligned; the punch is a close fit in the holes and stands upright by itself in each hole; and a good whack with a hammer on it and each center is marked:

I carefully centered and drilled each hole 4.2mm and 7mm deep on the mill with the chuck clamped to the table. After each hole, I used the drill chuck as a guide to run in the first tap from my M5 tap set. It only left a couple of threads on each hole before bottoming out, but enough to start the 2nd tap outside of the mill on the workbench. Each hole was run down with the second tap till it bottomed. Then the holes were run through with my modified version of an M5 plug tap - it had a pointed tip that I ground down while building "Fred" to really thread some holes to the bottom:

I mounted the 4 jaw with the table/shaft assembly back on the lathe. I know my 3-jaw grips eccentric by about 2 thou - but dead parallel from the chuck to about 100mm away from it - on a 26mm workpiece, and when I tested the shaft on the whole lot as mounted now with a dial indicator, that"s what I got. About 0.05mm eccentricity along the shaft"s entire length, but it was parallel. The outside of the table part as mounted was still spot-on center. So I carefully turned down the shaft part to the needed 25mm for the bearing inner race; it was at 26.5mm so for a first cut I just took off an infeed of 20 thou (that takes _just) over 1mm - off the total diameter). Then I measured the piece to be sure - it was down 25.48mm. I honed the cutting bit in-place on the lathe; just a couple of light touch with the oilstone - then went down to just over size at 25.1mm. A last cut part-way for the last 0.1mm, and I stopped for a test with the bearing and it lightly pressed over - so I finished the cut:

Next I turned the shaft down to 24mm up to a point 15mm away from the base of the table; the bearing is 17mm thick, and with the slight indentation in the table and the offset lip in the bearing mount hole in the base, that leaves me room for threading and run-out to the bottom of the bearing inner race. The 24mm section will be single-point threaded at 1mm pitch for the bearing pre-tensioner nut. I stopped short of the threading; that will take a while, and had better wait for the weekend.

Looking for something more to do, I decided on doing the holes to bolt the base top to the frame. I forgot to mark out the circle the table would run on on the base top plate, and being hit by a sudden sense of aesthetics, I needed to "see" a ring on the base top plate where the table would run. I pressed the bearing in the plate, and fit the whole lot over the shaft and used a permanent marker to mark the outline of the table on the plate:

I stopped there, as while punching the holes, I found my concentration wandering to what I"d have for dinner, and also distracted by the swarfmagnets (dogs) bashing around their stainless food bowls (must have had the same thoughts

First thing, I decided to make the pre-load nut. I removed the 4-jaw chuck (with table in making et al) from the lathe and put back the 3-jaw with outside jaws. Some 50mm aluminium rod was then turned down to just under 40mm for just long enough to make an 8mm wide nut and allow parting off. Then I drilled it out to 19mm for the same depth (19 mm, as it is my biggest drill):

The white liquid is synthetic water soluble oil mixed with water. Normally I would have used methylated spirits on the aluminium, but I ran out. Sometime in the past, I did try this soluble oil on aluminium, but had less-than-satisfactory results on a 20:1 water / oil mixture as recommended for this oil. This is a "new" batch I made up just the other day, and through a fumble, this mix is more like 10:1 - and it worked a treat on the aluminium!

Then I changed back to inside jaws on the chuck, and chucked up the parted off bit of aluminium. It needed to be bored to inside diameter thread size next. I originally intended to thread the nut and shaft M24x1. The change wheels for turning a 40 tpi thread was still mounted from making the Dremel chuck adapter for the mill.

My thoughts went as follows: "I"m lazy to change the gear train. Would this much finer thread work ?... It would actually work well for the pre-tentioner nut - finer adjustment control and more than adequate grip. PLUS - I can use the thread dial indicator instead of reversing the lathe after each cut." Choice made

For running a 40 tpi thread with a 60 degree angle, the thread depth would be 12.5 thou - roughly 0.32mm So the Inner diameter of the nut needed to be bored to 24 - (2 * 0.32) = 23.36mm. I bored it to that, and started setting up for threading.

I have a little multi-purpose boring bar I made out of an old carbide tipped tool shank that takes 4mm HSS inserts. I had a 60 degree threading "insert" already, so I put that in. Here I"m setting it to center height using a gauge I made as one of my first lathe tooling projects:

Note that the tip is upside-down. When I do internal threading, I do it with the tip upside down and cutting against the back of the workpiece. This allows me to do normal infeeding, and I can see what"s happening in the cut. It"s just easier for me

Next I set the toolbit square using a fishtail gauge; the piece of paper is not to hide the swarf below for the camera shot, but to make it easier to see the tool tip relative to the "V" in the gauge. To set the angle like this would be tricky on the workpiece itself, so I used a length of silver steel chucked in the tailstock drill chuck to do it:

This looks like I"m running at high speed, but actually I was running at the lathes second lowest back-gear speed. I didn"t try to take a photo while in the cut; had to mind the leadscrew disengagement lever then.

The finished threads after taking 2 thou cuts per pass, and about 2 passes on the same cross slide setting for the last two to work out the "spring" in the boring bar:

I then put the 4-jaw with contents back on the lathe, and turned the threads on the shaft. I was lazy, and just turned the insert bit in the boring bar upright again - that eliminated the need to set up a new toolbit - and turned the external thread on the shaft with it. The only thing I did before turning the thread, was to use the edge of a half-round file to make a thread run-out groove. When approaching final dimensions, I just tested with the nut for final fit. Here the thread is finished and the nut screwed on:

Next I did some more work on the nut in the mill. I want to be able to lock that nut in position when fitting the table together, so it needed some method of achieving this. I slit and counterbored it on one side with a 6mm center cutting slot mill to clear the head of an M3 cap screw, then center drilled the bottom of the counter bore, and ran a 2.5mm drill (that"s for M3 tapping) right through, and then just drilled 3mm down to the slit for thread clearance. Then the 2.5mm section remaining below the slit was tapped M3 for as deep as my taps would go. I also milled two opposing flats on it for use when tightening it up. I didn"t take photos of every step mentioned here; but here are two I did take:

First thing, I wanted to get the top plate of the base bolted to the frame; I"d marked it out already for the bolt holes, so I just needed a way to make the whole lot stay together for drilling and so on. I sawed two longish strips of 20x5mm flat bar off a length I keep handy for incidental needs such as this. Both strips were drilled for clearance holes for some 6mm cap screws, and then the top plate and frame were bolted together like this:

Then I started drilling all the holes. Even though I had laid out the hole locations, I decided to go for X and Y coordinates using the handwheel calibrations - as each hole had to be center drilled, then tap size, for clearance trough the top plate and finally counterbored for recessing the M5 cap screws I would be using. So I located the edges of the right front corner the primitive way; with a bit of 6mm silver steel chucked and a piece of paper. Then I started counting turns and reading handwheels while center drilling each hole, and jotting down the figures on a bit of paper. Here all the holes are drilled to tap size (4.2mm):

That lot was followed by a 5mm drill just deep enough to provide clearance through the top plate. The heads of the cap screws measured out at 8.4mm in diameter and just below 5mm high, so I used a 9mm mill to counterbore the clearance holes 5mm deep. My advanced lubrication delivery system is the orangey bottle in the right of the photo

With all the holes I needed to tap full of swarf from the counter boring, I used a drill chuck with a 4mm drill to manually clean out the holes. Just plonked the lot on its side, and by hand turned the drill in each hole to get the swarf out. Photo without the hand that should be turning:

Then I sat down on the bar stool I keep handy (my "working table" is a bit high), and tapped each hole. The 5 mm clearance holes in the top plate are excellent tap guides to keep things square when starting with the first tap, so nothing fancy required as guide. Just manual work

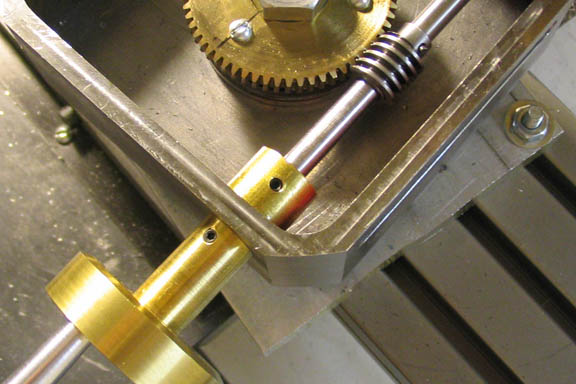

I needed the hob before I could cut the gear, and while making the hob I could just as well make the worm.Attached (Can"t Attach Excel files to MadModder posts)is an Excel spreadsheet I set up quickly to do some calculations from information I drew off the Internet. An interesting thing I found was "crowning" of worm wheels to make sure that the worm/wheel combination can stay properly lubricated. The crowning entails cutting the gear teeth with a slightly bigger hob than the worm would be. Just for the heck of it (nothing like learning from testing) I"ll be doing this.

There is a good amount of information on gear calculations here on the web, so I won"t go into detail except for that my original planning was for a 72 tooth MOD 1 wheel with a 20 degree pressure angle. Screwcutting for MOD 1 is pretty close to 8 TPI - and bliss; my lathe has an 8 TPI leadscrew. 8 TPI calculates back to about MOD 1.01 - so that"s fine with me - I"m lazy to set up weird & wonderful combinations on the change wheels, and this is one of the easiest to set up.

First up, I needed a toolbit with the correct shape; a point with a 40 degree included angle; clearance for helix angle, and so on. I marked out an 8mm bit of HSS for the angled tip using a protractor:

In the first of the above photos, you can clearly see the the bottom of the bit is at an angle to the top; not straight down. This is for adequate clearance of the helix angle; I did not calculate that or anything; just ground it on by gut feel. Also, you will notice I didn"t touch the top of the toolbit with the grinder or oilstone; the original ink I marked out with is still on there.

A trial run to measure sizes on the worm-in-making from some 16mm silver steel. I added a lot of run-out space at the headstock side, as this is a fairly coarse thread and the space is needed to stop. I also have the topslide set parallel to the work and locked, as I might have to add some additional side-feed with it to make cutting easier if it becomes too difficult. (That"s frowned on by screw-cutting purists, but have stood me in good stead on large threads like these in the past):

I stopped with the threads half-done for that night. Just jotted down the necessary readings from the dials so I could continue from there when next I had shop time:

And yes, it was slow going; I didn"t have space to add tailstock support, so I went in 2.5 thou infeed steps with a repeat pass at the same depth after every 10 thou.

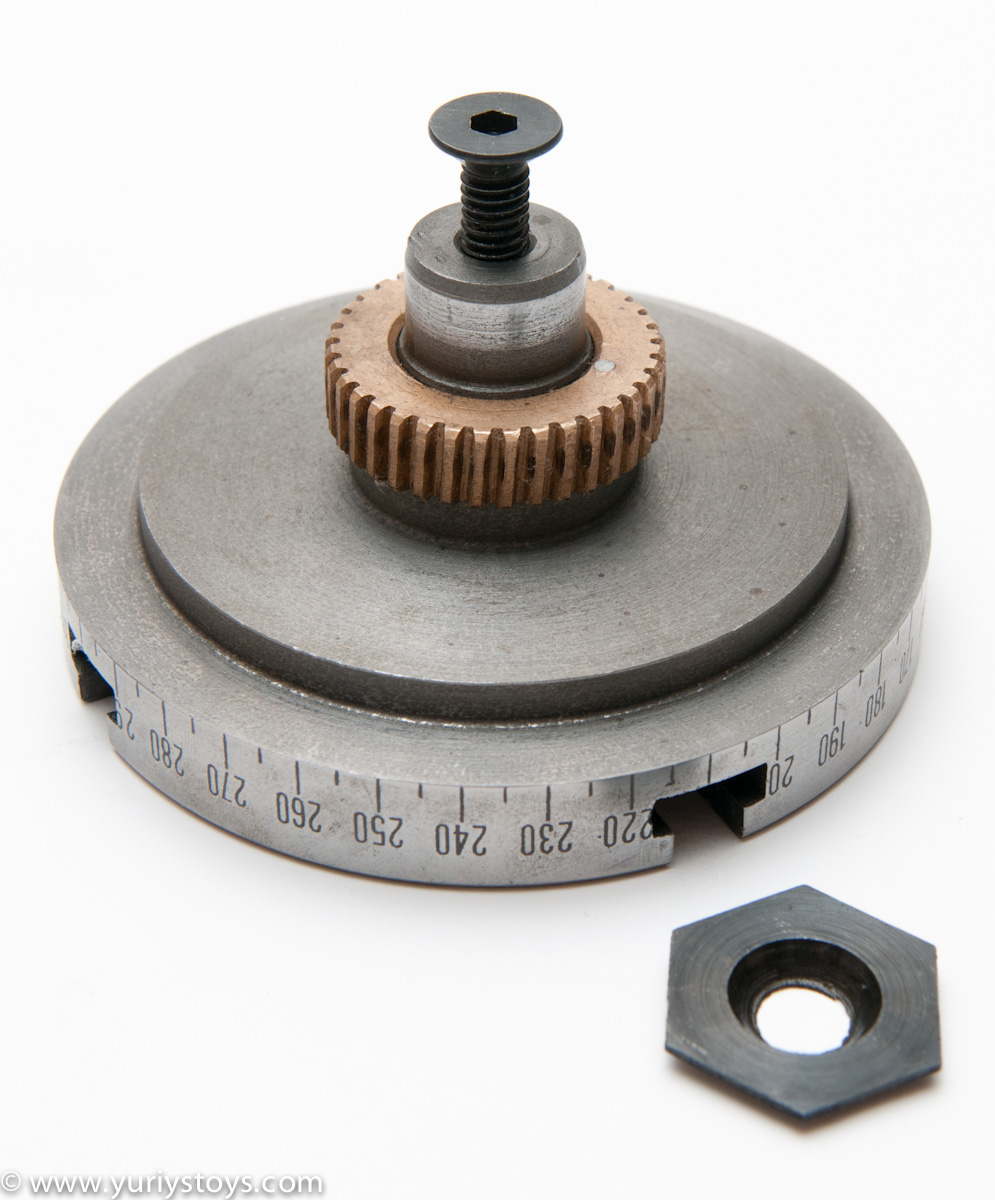

I finished off the worm; it was a simple process of finishing of the threading, drilling it through and reaming for an 8mm shaft. I then parted it off at length leaving a shoulder, in which I cross drilled and tapped for an M4 grub screw (set screw). All done:

Next I started on the hob - after honing the edges of the toolbit again. The threading process was exactly the same process as for the worm, but the hob is 1mm larger in diameter as I explained in a previous post. I didn"t take photos of the threading done on it; except for a close-up of a bit of swarf that came off while I was turning it. Why? - the swarf shows that the toolbit was cutting properly on all sides and the front:

I milled the cutting teeth into the hob; no fancy setups for indexing; I just judged by eye for indexing, but I took pains to make sure I got the cutting edges dead on center, and triple-checked that I was cutting the teeth for right-hand rotation of the hob when in use.

Instead of milling clearance behind the "teeth", I just took a file to it; 5 minutes in all, and I had some clearance behind the teeth all round. I didn"t want to take away too much for clearance, as the hob will be used to auto-rotate the gear blank when I eventually get to cut it. I didn"t bother de-burring anything either; the heat treatment will get rid of some burrs, and once hardened, I"ll give the cutting edges a once-over with the Dremel with a grinding stone to really sharpen them up - and should remove any left over bits of burr. In this photo you can see how I filed clearance to just behind the tips of the teeth - there"s a little facet left just on top of the tooth cutting edge that I did not touch with the file:

The day"s bit involved more thinking than working. Like mentioned, I cleaned the milling burrs off the hob, and then hardened it. This is a fairly big bit of metal, so I went outside and heated it with my butane torch (took quite a while to get it to temperature). When I thought it was about right, I heated it some more, to allow me enough time to turn the torch off first and then plunge in the oil bucket. This is for safety - I don"t allow any flames (not even a lit cigarette) when I do an oil dunk, as the smoke coming off is potentially very explosive - and yes - I am positioned between a fire extinguisher and the dunk site to allow me to pick up the extinguisher while departing a possible fire. If you have the luxury of choice, rather use water hardening than oil hardening silver steel.

Once cooled, I carefully hand-ground the cutting faces with the Dremel and a small green grinding wheel. Everything feels nice and sharp, and the burrs are gone completely:

Next I turned down and bored out the gear blank to size - well on the OD at least. I miscalculated the last feed while boring, and ended up with the hole 0.1mm over size

The last challenge was mounting the vertical slide to the mill table. I nearly started cutting metal to make new T-nuts and so on, when I noticed the cross-slide extension I made for the lathe about 4 years ago. Some checking followed; and YES! - I can clamp it to the mill table to mount the vertical slide on. The completed assembly looks like the cobbled together solution that it is, but it should work:

I"m a lazybones; normally I sleep till 9 or 10 am on a Sunday. That morning I awoke at 6 am with the same feeling of anticipation as a 6 year old on his birthday, and just could not get back to sleep... Once in a rare while I get days like this, and I cherish them; things were going to be good.

I forgot to turn a groove with a radius of just over 5mm to a depth of 1mm on the rim of the gear blank the previous day. That was done first - I used a 10mm slot mill to make it, hoping that the tendancy for slot mills to cut slightly bigger than their stated size would do the job. I just cranked the dividing head through 3 full 60 turn revolutions - first infeed cut 0.5mm deep, second as well, and for the third one left as-is to do a final cleanup. Light feeds, as the setup most definitely was not as rigid as one would want:

Next I set the whole lot to the needed 4.5 degree angle from horizontal. This meant my center reference to the blank was gone. Measuring things were difficult - well pretty much impossible - but fortunately I did zero the mill on all axes before changing the angle. I was able to calculate the new "center cutting spot" from those with a bit of trigonometry, and dialed in the differences as appropriate. I then spent more time checking that I did indeed change the angle in the correct direction - upwards vs downwards, and that I didn"t make a mistake in my calculations. My dividing head is based on a 60 tooth worm, so some calculations and it turned out I needed to stop on every 35th hole on the 42 hole plate to make a 72 tooth gear.

I have 2 slitting saws (And I still do only own these 2 saws!); the 1mm thick one I used above, and a 0.5mm thick one of the same dimensions (brand new; never been used before). When I checked visually with the hob against the slits, I wasn"t sure that it would have enough depth to start auto-rotating the blank once I got to hobbing. So I added the second slitting saw to the mandrel - without removing the mandrel from the collet chuck - and then lifted the Z feed by 0.25mm to account for the "new" total thickness of 1.5mm. Then I ran a full revolution again slitting only 1.2mm deep with the thicker combined saw. If you look carefully, you can see the additional cut in the grooves:

With the blank now slit, I needed a way to hob it. I have a bunch of old bearings I get from a local auto-electrician for free - and I selected 2 of the same size with a slightly larger ID than the gear blank - but that were still "sort of OK". Then I dug around for more bits and bobs, and once found, I turned a mandrel to suit the bits "n bobs, gear blank and bearings from some HRS rod.

The Bits "n Bobs mentioned is a block of brown stuff... My metals are too precious to waste on a once-off use like this, so wood it will be. With the 4-jaw still occupied by the table-in-making, the wood "jumped" onto the face plate after some persuasion. I then started boring out a pocket to fit a bearing in - after center drilling and drilling a 6mm hole right through the block:

1: A note: I made the mandrel so that it would pre-load the bearings while tightening down the gear blank on its end. I don"t have a picture, but if anybody wants one, I"ll be happy to make up a quick C-o-C of what I mean.

2: A Gotcha: When I drilled clearance for the center hole in the wood block, I forgot to make it big enough to clear the bearings" inner races. When I fit everything together and tightened up to pre-load, everything froze up. I ended up fashioning clearance for the inner races with the Dremel and a smallish routing bit. (Too much work to re-setup everything on the face plate!)

3: Another Note - the method I used is to make this "jig" is VERY crude; it worked for me - I think primarily because I did take the time to make sure both faces of the wood block were parallel, and one side (that was then marked as a reference side) was square to the faces.

I then clamped the wood block with bearings et al on the mill, standing on the mentioned "reference" side. then with the hob in a collet, I advanced on the Y axis, turning the mill chuck by hand until I could see that everything would mesh, and the blank would auto-rotate. Then I set the mill to it"s slowest speed, held my breath and started up. I nearly fainted from holding that breath; things were going really slowly, but the wheel started revolving, and bits of swarf started appearing. I made a mark on the blank with a permanent marker so I could judge progress around, and I slowly started feeding in 0.1mm for every revolution of the blank. after about 5 passes, I stopped, selected the next higher speed on the mill, and started off again; a bit quicker:

Sorry; the photo is a bit out of focus; its pretty hard to try and take a photo of this!. As you can see, the profile is slightly offset to the right -but it will do for me for now.

Another note: From the above I obviously gashed the teeth too deeply with the slitting saw, but that was the only way I could ensure proper meshing for auto-rotation. I think this can be eliminated by using a much smaller slitting saw - or even better, a little cutter made up to the same OD as the hob with some taper on it"s edges.

Having said that though; I"m over the moon - I"ve never ever made a gear (That was back in May 2010 Remember!), and for a first foray into gear cutting, this came out MUCH better than I expected - especially for a worm & wheel setup

Back to the here and now of August 2012 - I edited the above smileys slightly to fit with MadModder"s ones. This day 2+ years ago still ranks as one of my all-time favourite and most enjoyable days in the shop; in fact, I can remember it like it was yesterday!!

Today"s little bit is pretty boring. I milled three small flats on the gear flange and drilled and tapped in those for 4mm grub screws. Then I turned down the end of the shaft for a nice slide fit for the bore in the gear wheel, and milled flats on the turned down section for the grub screws to tighten up on:

With the dividing head still mounted on the mill this was a breeze. I"ll make a dedicated mounting for it at some stage though; as the setup is far from rigid enough for serious work on steel - and I have quite a couple of future projects lined up that will require some gear-making.

A bit of a revelation to me as well; the ideas I had for making the worm shaft adjustable just went down the drain; not enough clearance, so it"s back to a bit of head scratching. And people wonder why I"m going bald...

When I got home after work, I had a good look at what I have already, and an eccentric will work a treat. The gear height is adjustable - so that"s not a problem; if it needs to move closer to the table top I can counter bore its face to clear the bearing pretension nut. Just some fine detail to finish off in my noggin - mostly related to the vernier scale I want on the assembly. As I"ll need to turn an eccentric soon, it"s time to get the table off the 4-jaw chuck. But this is no time to rush. I thought things through, and decided to graduate the table first; everything was set up ideally already; easy 72 divisions on the dividing head to mark 10 and 5 degree divisions on the table.

I haven"t made a spindle lock for my mill yet, so I opted to cut the division markings rather than broach them like Dean did. Darn; all my suitable toolbits have square shanks... So first, a tool was needed. Some 10mm silver steel, a 4mm cross-drilled hole through at a slight angle (not needed here, but possibly in future) and drill & tap the end for a 4mm grub screw. A short length off the 4mm round HSS sticks I keep around; a bit of grinding, and the result:

On to the mill - with the cutter set dead on center. I fed Y till the cutter tip just touched against the side of the table, and then moved the workpiece away on X. Another 0.2mm feed on Y and then I started cutting the first 10 degree graduation. Just deep enough in on X till it looked good to me, then I set the mill table stop to stop there. Then it was turn the DH, feed X to the stop & back out; repeat till all the 10 degree marks were done:

Bandsaws being the fairly rough machines that they are - and I"ve taken some pains to get mine as accurate as possible - the cut will inevitably shift slightly and not be perfectly square - especially in the vertical plane while cutting. I kept a careful look on the work, and when I detected too much of a deflection in cutting lines, I would stop the machine and turn the workpiece. I did this three times, as can be seen from the photo showing the table and the offcut:

The cut took about 15 minutes to complete - but the blade I have on the machine is not exactly new any more and is begging for replacement. The offcut will make a nice cast iron flywheel for a future project

Next it was back to the 4-jaw with the table. I put bits of soda can on the radius of the chuck jaws to prevent marring of the graduation marks. Then I dialed in the table dead on center on the outside body with just a vibration coming off the needle of my best indicator when revolving the chuck. This step is crucial in the long term:

I then added a close fitting 16mm "test bar" in the hole I bored initially through the table center. For me this is a length of silver steel that I know is straight; no fancy test equipment in my shop (YET!). I tested run-out on this a good distance away from the table body. This was to make sure that the back of the table is at a precise 90 degree angle to the axis so that I could turn the face completely parallel with the back side:

Fortunately my old 4-jaw is pretty darn accurate on the faces of its jaws, so I did not have to resort to tricky measures to get things sorted; It was less than 0.005 mm out at the distance I measured, and that"s fine with me in the environment I have.

I then faced the table repeatedly with very light cuts - just 2.5 thou infeed at a time; I didn"t want a sudden heavy cut on the irregular bandsawed surface to knock things out of kilter! Then I bored the center hole out to 20mm diameter to a depth of 5mm - this will become the register for my lathe chuck mounting plate - and chamfered the register hole and internal 16mm step left at a 30 degree angle. This is for easy location of mounting the chuck plate in future, as well as for easy centering of the RT on the mill table with a bit of 16mm rod clamped in the collet chuck. As a final step, I used a sharp-pointed threading bit to turn light alignment rings on the face 10mm apart from each other.

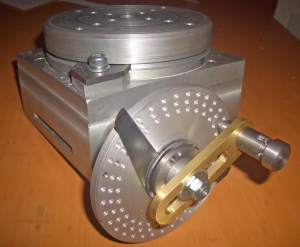

The assembled lot is starting to look like an RT - with the exception of the glaring blunder on the bottom right hand cap screw counterbore that caused so much heat in the shop a while ago

An eccentric/bearing carrier/vernier plate carrier combination thingumyjig that would give me the features I want. You can download a dxf CAD version here

Then I bandsawed the excess off, and mounted the workpiece 5mm off-center in the 4-jaw. Then I turned down the body (not really needed, but makes things easier in future) and drilled a hole through and bored a pocket for mounting a bearing:

With the body turned down, it was easy to mount the three-jaw chuck and bore the opposite bearing"s pocket. If the body wasn"t turned down, this would have meant using the 4-jaw to bore the pocket. It might have been quicker to do this... I thought I took a photo of the finished eccentric, but while downloading the photos from the camera to my PC I saw that I thought wrong

I took measurements from the thus far assembled RT to determine the "center" hole position for the worm shaft "as if I was not going to use an eccentric". Then I added in the eccentric factor and the rotational position I wanted it to occupy for "worm engaged" - which should be the same as not using an eccentric. Some trigonometry calculations and I had the center coordinates for drilling and boring the hole in the RT base for the eccentric.

I marked that, and set up the base on the mill for drilling and boring. After center drilling, and drilling a 7mm hole, I switched to my biggest drill; a 19mm one:

I"ve used this drill bit in the lathe quite a bit, and the old Myford copes with it at medium back gear speed with some complaining. My 16mm drill press does not; it"s lowest speed is too high. The mill utterly surprised me. On it"s highest low range speed, it just turned that "little" drill bit - no complaints whatsoever - and at a good feed rate as well!

I still need to make or buy a boring head for the mill. The 19mm hole I had needed to be bored out to 30mm for the eccentric. I used the boring bar I made for the degree markings and another bit of HSS ground to what I thought would be appropriate angles to bore the hole out. Another surprise! I could go at a good depth of cut - in this photo I"m taking 2mm out of the diameter of the hole (1mm DOC) at a slow but steady down-feed:

To test everything - the moment of truth - I installed one bearing on the eccentric, and with an 8mm drill as "shaft" tested everything. Next two photos show both the locked and unlocked positions:

One end was turned down to 6mm for a length, and a space for thread-runout made with the rear parting tool, then I threaded the section left between the 6mm section and the run-out M8 - today I "cheated" and used a die instead of single-point turning the thread. Then I milled flats on the shaft; one on the 6mm section, another short one that will be the mounting spot for a collar, and the last flat for mounting the worm on:

Next I made the collar I mentioned above from a scrap of HRS rod. The small ridge on it"s side is so that it will only engage on the inner race of the ball bearing it will be pressing up against:

Then I cut a 12mm thick disc off some 40mm aluminium rod, faced it both sides and drilled a 16mm hole through it; this will become the Zero/Vernier plate. I then located it on the eccentric"s bearing bore with a bit of 16mm rod and marked hole positions for drilling it"s mounting holes by twirling the 2.5mm drill through the holes drilled in the eccentric. Then I drilled 3mm holes trough the plate on the marks, and counterbored the holes to 5.5mm to clear M3 cap screw heads. I also turned the end of a standard 8mm nut down to engage a bearing center like the collar I made earlier. Here is the collection of parts to make up the RT drive unit:

Then I marked and drilled a 3.2mm hole from the top of the RT base through into the eccentric hole, and then opened it up part way down to 4.2mm and tapped M5. A short bit of 3.2mm bronze brazing rod to locate in the groove and a cap screw (for now) to tighten it down:

A bottom view with everything assembled - I had to move the worm wheel over about 1mm towards the end of the main shaft to get perfect engagement with the worm:

Planar ServoRingrotary tables provide superior angular positioning and are designed to eliminate backlash, friction and wear problems associated with worm, gear and belt drives.Low maintenance and high throughput characteristics of the Planar ServoRing stage yields the lowest total cost of ownership.

Compact package and Superior designof the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system working height. Angular contact bearings are used to maximize performance with respect to wobble, moment stiffness and friction. ULTRATHIN ServoRing stage has large clear center aperture that can be used for air or wire line feed-through or beam delivery.

Planar ServoRing utilizes direct drive three phase planar brushless motor technology. There are no brushes to replace and no gear trains or belts to maintain. “Lo-Cog” magnetic design assures smooth rotation and dynamic performance.

Accurate Positioningis assured with contactless encoder.The motor and rotary encoders are directly coupled to eliminate coupling backlash. The low inertia and zero backlash make Planar ServoRing the ideal solution for applications requiring frequent directional changes.

ABTech’s standard line of high precision, air-bearing rotary tables (AT Series) and heavy-duty rotary tables (HDRT Series) are ideal for low-speed TIR measurements, optical inspection, precision assembly, or light machining and grinding where radial and axial accuracies down to 2.0 µ” are required. These are available with tilt and center worktables, precision fixtures, 3-jaw chucks, vacuum feed through the center, and motor drives. They are manufactured with 440CSS and hardened to 58 – 60 RC, making these rotary tables the most robust available.

Located at the entrance of a conveyor belt, or directly to the machine that has to feed, performs the function of “station of accumulation and distribution”. The products can be loaded manually or by conveyor belt. The adjustable deflectors allow you to sort and align products to the food evenly and without interruption the machine that receives them. Positioned at the exhaust of a conveyor belt or in the output of a packaging machine, filling machine, labeling etc., Performs the collection and accumulation of products function. The rotary tables are equipped with a speed variator to adapt to the various needs. The rotating disc may be provided in a slippery plastic material or stainless steel.

The Concave rotating table for heavy products is situated at the end of the packaging line they are used as an “Accumulation station” to ease the product unloading stage at packaging machine output and to help the operator in pickup and boxing operations.

The end-of-line rotary tables are made completely in stainless steel, with concave or flat trays and mechanical or electronic (inverter) speed variator.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

600 mm (23.6") Servo Rotary Table. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation. Requires a Haas mill with software version 18.00 or later.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product"s lifetime, Matsumoto Machine Corporation (MMK) has taken a pragmatic two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

Founded in Japan in 1948, Matsumoto Machine Corporation is a technology-leading provider of innovative, high quality jaw chucks and numerically controlled rotary tables used by industrial machine tool makers throughout the world. A key feature of MMK"s CNC rotary tables is a patented worm and wheel gear assembly developed by OTT GmbH, Germany. Unlike double lead worm gears, the OTT worm and wheel gear is able to minimise backlash, ensuring outstanding accuracy and long life, efficiency and durability.

Shaped in order to maximise gear surface contact area, thereby reducing adverse surface pressure effects, the OTT worm gear teeth are split into separate right and left parts (shank worm and hollow worm) connected by a span ring. This unique structure enables backlash adjustment simply by reducing the distance between the two parts. This design also ensures that only one side of a worm gear tooth is in contact with the wheel gear, leaving a clearance on the other side. As a result, the 2-piece split gear design will not seize up, even with zero backlash.

A further advantageous characteristic of the MMK CNC rotary table is a large diameter through-hole in the table spindle. This greatly increases machine versatility and rigidity, supporting a wider variety of chucks and jigs and the machining of longer workpieces.

By enabling most metal-machining operations to be undertaken on a single machine, the benefits of MMK CNC rotary table are far-reaching. These include the time and cost saving of single machine set-up and single fixturing setup, reduced parts handling and the elimination of tolerance errors as workpieces pass from machine to machine.

Of critical importance in this one-hit machining centre scenario is ensuring the high accuracy of CNC rotary table indexing and control throughout its working lifetime.

As with any form of precision equipment that is integrated into a machining centre by a third party machine tool maker, and which in turn is used by an end user in any number of industrial sectors, assuring consistent accuracy and performance over time presents a challenge.

As with a machine tool"s linear XYZ axes, the rotary axis is just as susceptible to uncontrollable events that may introduce angular positioning or axis alignment errors. Risking the production of defects in finished parts, these errors can be due to a number of reasons including, mistakes made in the initial machine installation, impact damage caused by collision or general wear-and-tear in use.

With its global reputation for product quality and design innovation, MMK therefore sought to equip its CNC rotary tables with a highly accurate and reliable means of tracking and controlling the indexing of its product throughout its lifetime, irrespective of the type of machine tool, workpiece complexity and duty cycle.

At the same time, in an increasingly competitive global market for CNC rotary tables, MMK also wanted to further enhance its product quality inspection processes. Specifically, the company set itself the task of augmenting index angle measurement as a key component of pre-shipment quality assurance procedures.

To provide machine tool makers and users with the ability to accurately track and control CNC rotary table indexing, MMK elected to integrate Renishaw"s super-compact TONiC™ non-contact optical incremental encoder system. Simple to install and with a compact readhead measuring just 35 mm x 13.5 mm x 10 mm, the TONiC encoder presented MMK with a minimal footprint solution capable of supporting machine speeds up to 10 m/s and resolutions down to 1 nm.

The rotary table readhead was designed to be used in conjunction with Renishaw"s RESM, a one-piece stainless steel ring marked on its periphery with 20 µm pitch graduations and featuring the IN-TRAC™ optical reference mark. With its low profile, large internal diameter and wide choice of diameters from 52 mm to 550 mm, the high stability RESM ring provided MMK with a versatile and easy to integrate scale that is well-suited to the company"s wide range of CNC rotary tables.

For improved reliability and higher immunity to any scale degradation over time, the TONiC readhead incorporates third generation filtering optics, tuned for low noise (jitter) and further enhanced by dynamic signal processing. The outcome is an ultra-low sub-divisional error of typically ±30 nm. The TONiC encoder is compatible with industry standard controllers and features a detachable analogue or digital interface inside a robust D-type connector, which can be located up to 10 m from the readhead.

MMK selected Renishaw"s compact and lightweight XR20-W rotary axis calibrator to verify the accuracy of its rotary tables during manufacturing and immediately prior to shipment. The XR20-W was used in conjunction with Renishaw"s XL-80 laser interferometer to provide a non-contact reference measurement, independent of the axis under test, with an accuracy of ±1 arc second.

Motorised by a servo-controlled drive and with data capture synchronised to axis movement, the XR20-W requires no operator intervention during measurement. Being lithium battery powered and Bluetooth enabled, it ensures quick and easy setup, and the avoidance of trailing cable hazards. The calibrator"s modular design and flexible mounting systems allow far easier setup than alternative solutions and can be readily configured for a wide variety of rotary tables, chucks and spindles.

By integrating Renishaw"s TONiC non-contact optical encoder system into its CNC rotary tables, MMK has further assured the accuracy and reliability of its products in the field, along with an overall superior motion control performance. For a wide range of different machine tools and end uses, the rotary tables" combination of compact readhead and one-piece stainless steel ring scale has delivered a higher level of tolerance to dust, scratches, grease and oil, and a reduction in indexing errors. The encoder system"s ability to output highly stable position signals of unrivalled purity and ultra-low sub-divisional error have provided smoother velocity control, improved scanning performance and increased positional stability.

MMK"s introduction of Renishaw"s XR20-W rotary axis calibrator and XL-80 laser interferometer has reduced product measurement times by a half compared to conventional autocollimator techniques. Measurement procedures have been simplified and automated. Capable of taking accurate measurements at any indexing angle pitch, the calibrator enables evaluation of the accuracy of the worm and wheel gear-driven table for ultra-fine pitch measurement movements as small as 0.001°. This has allowed any loss of motion control or worm and wheel gear efficiency to be evaluated in detail and addressed. Product performance is now backed by a thorough analysis meeting ISO quality standards.

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product’s lifetime, Matsumoto Machine Company has taken a pragmatic

two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

8613371530291

8613371530291