how to make a rotary table quotation

If you send the data entered in the contact form by clicking on the following button, you agree that we may use your details to answer your enquiry or contact you. As a matter of principle, data will not be passed on to third parties unless applicable data protection regulations justify such a transfer or unless we are legally obliged to do so. You can revoke your consent at any time with effect for the future. In the event of revocation, your data will be deleted immediately. Your data will otherwise be deleted once we have processed your request or the purpose of storage has ceased to apply. You can inform yourself at any time about the data stored about your person. Further information on data protection can also be found in the data protection declaration of this website.

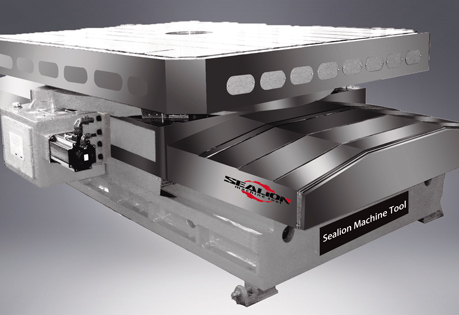

Located at the entrance of a conveyor belt, or directly to the machine that has to feed, performs the function of “station of accumulation and distribution”. The products can be loaded manually or by conveyor belt. The adjustable deflectors allow you to sort and align products to the food evenly and without interruption the machine that receives them. Positioned at the exhaust of a conveyor belt or in the output of a packaging machine, filling machine, labeling etc., Performs the collection and accumulation of products function. The rotary tables are equipped with a speed variator to adapt to the various needs. The rotating disc may be provided in a slippery plastic material or stainless steel.

For medium to large parts, the VH-11 rotary table has an 11" (280mm) diameter platter with a 6.75" center height. A 10" or 12" chuck or fixture can easily be bolted to the table using the six precision T-slots. Its large 4" through-hole can be used for bar feeding and special fixture-locating requirements. The spindle and worm have two bearings for front and back support. As always, the worm wheel is helically cut and throated for greater surface contact between the wheel and worm. There is an optional 10" or 12" manual 3-Jaw chuck and adapter plate available as well as a manual or pneumatic tailstock with matching center height.

The Index Designs VH-11 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

Rotary table set kit for the definition of the rotary table axis (in general) and/or definition of perpendicularity error on the position of the rotary table (only for PRISMO ultra) contains a triple prism, two reference spheres DK30 and two invar cylinders

Dimensions and openings on rotary tables vary greatly from manufacturer to manufacturer. To assist you in measuring, we have provided drawings to guide you. Click on the type of rotary below. A new window will open displaying the rotary as well as the standard measurements for each size of that rotary. If your rotary is not a standard size, print out the drawing and fill in all necessary dimensions. Once completed, email us the drawing and we will work up a price quote for you. If you have any questions, please give us a call at 281-482-8668, and we would be happy to help you.

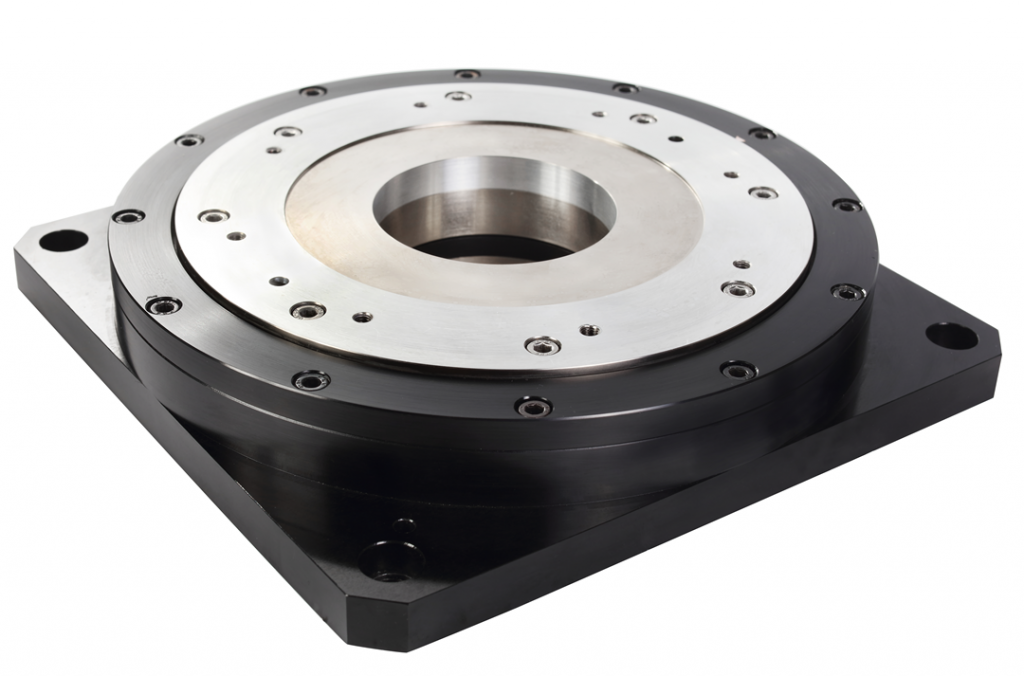

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.See all condition definitionsopens in a new window or tab

Methods & Equipment works with several manufacturers of rotary tables: Tsudakoma, Nikken, Yuasa and more. Give us a call or fill out the RFQ if you would like a quote on any of the high speed rotary tables, direct drive rotary table, or the new ball drive rotary table with zero backlash.

This is an accurate designed table for milling, boring and other machine tools. This table allows indexing, facing and other work to be carried out rapidly with extreme precision. Tiliting range 0-90 degrees fromread more...

Malad West, Mumbai 21, Shripal Services Industrial Estate, Pawan Baug, Chincholi Phatak, Off. S.V.Road, Malad West, Malad West, Mumbai - 400064, Dist. Mumbai, Maharashtra

DELHI,NCR,HARYANA,PUNJAB,UP,RAJASTHAN, Dharuhera, Dist. Rewari 347, Ganpati Plaza, NRP Bass Road, DELHI,NCR,HARYANA,PUNJAB,UP,RAJASTHAN, Dharuhera - 123106, Dist. Rewari, Haryana

Sector 37D, Gurugram, Haryana 122006, Gurgaon, Dist. Gurugram Nath Tools Company , Garauli Khurd, main Pataudi Rd,, Sector 37D, Gurugram, Haryana 122006, Gurgaon - 122006, Dist. Gurugram, Haryana

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Hofmann Rotary Tables has developed a solid reputation for high-quality and affordable indexing devices, rotary tables, and tailstocks. Superior Spindle is proud to be a factory service partner for all, including the HPRS, HTH, R, and WR series.

When you experience issues with your Hofmann products, you can count on our ISO-certified and factory-trained technicians at Superior Spindle. We can repair all types of NC and manual indexing devices, tailstocks, and chuck stands.Our average turnaround time is usually between 10 and 14 business days.

We know that downtime is costly and strive to repair your equipment as quickly as possible. If you’re in an emergency situation, we also provide expedited repair services (based on part availability) with a turnaround time between 1 and 3 business days.

Our Repair ProcessDisassembly & Free Evaluation: When you send your Hofmann rotary table to us, our team will fully disassemble it in our HEPA Class 10,000 cleanroom and evaluate all components for signs of wear and tear or damage.

Repairs: Once you accept your quote, our team will get to work repairing and replacing components, including handles, spears, worm drives, bearings, and more.

Testing & Inspection: After repairs are complete, our team tests the rotary table to ensure optimal performance. Before your table is shipped back to you, our Quality Assurance team will perform a final inspection.

Shipping: All shipping and handling is covered by Superior Spindle. When you receive your newly refurbished table, we will provide you with a list of all components that were repaired/replaced as well as recommended maintenance.

Ourcutting-edge facility allows us to offer a wide array of additional services. Beyond our standard and expedited Hofmann rotary table repairs, we also provide vibration analysis, engineering recommendations, and retrofitting. Superior Spindle understands precision and is able to hold tolerances to 1 micron.

At Superior Spindle, our top priority is your satisfaction. As an ISO-certified business, we ensure quality every step of that way, offer exceptional turnaround times, and back every repair with a peace-of-mind warranty.

Superior Spindle has been a trusted provider of Hofmann rotary table repairs for over a decade and provides services to manufacturers throughout North America. If you’re experiencing issues with your rotary table, or are looking for design upgrade recommendations, call (734) 224-4778 orfill out our online formtoday.

The basic version, M-035.50 rotating table, is equipped with a micrometer drive and a zero-backlash magnetic coupling. The micrometer provides a positioning range of ±9.5 degrees.

The versions M-035.PS and M-035.P0 feature additional piezoelectric fine adjustment over a range of ±520 µrad. They also allow dynamic operation such as scanning or tracking. The .PS version is equipped with a closed loop feedback piezo drive (model P-841.30), while the .P0 version has an open loop piezo drive (model P-840.30). Both drives provide a linear range of 45 microns and sub-nanometer linear resolution (see "PZT Actuators" section for further details and recommended drivers).

8613371530291

8613371530291