how to use a rotary table on a mill factory

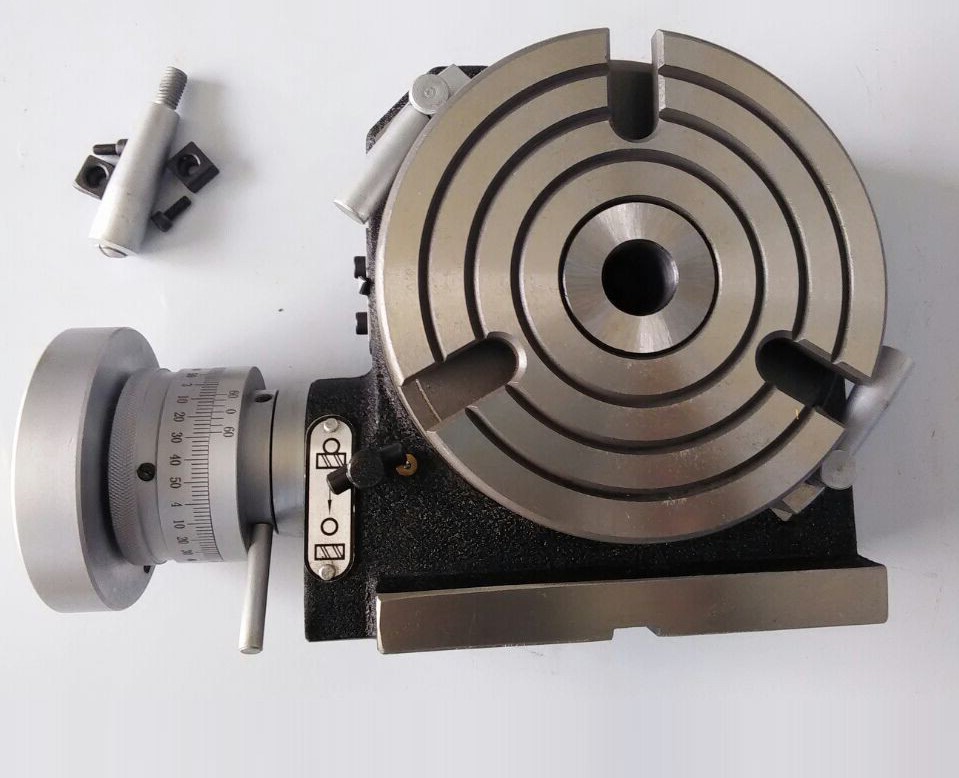

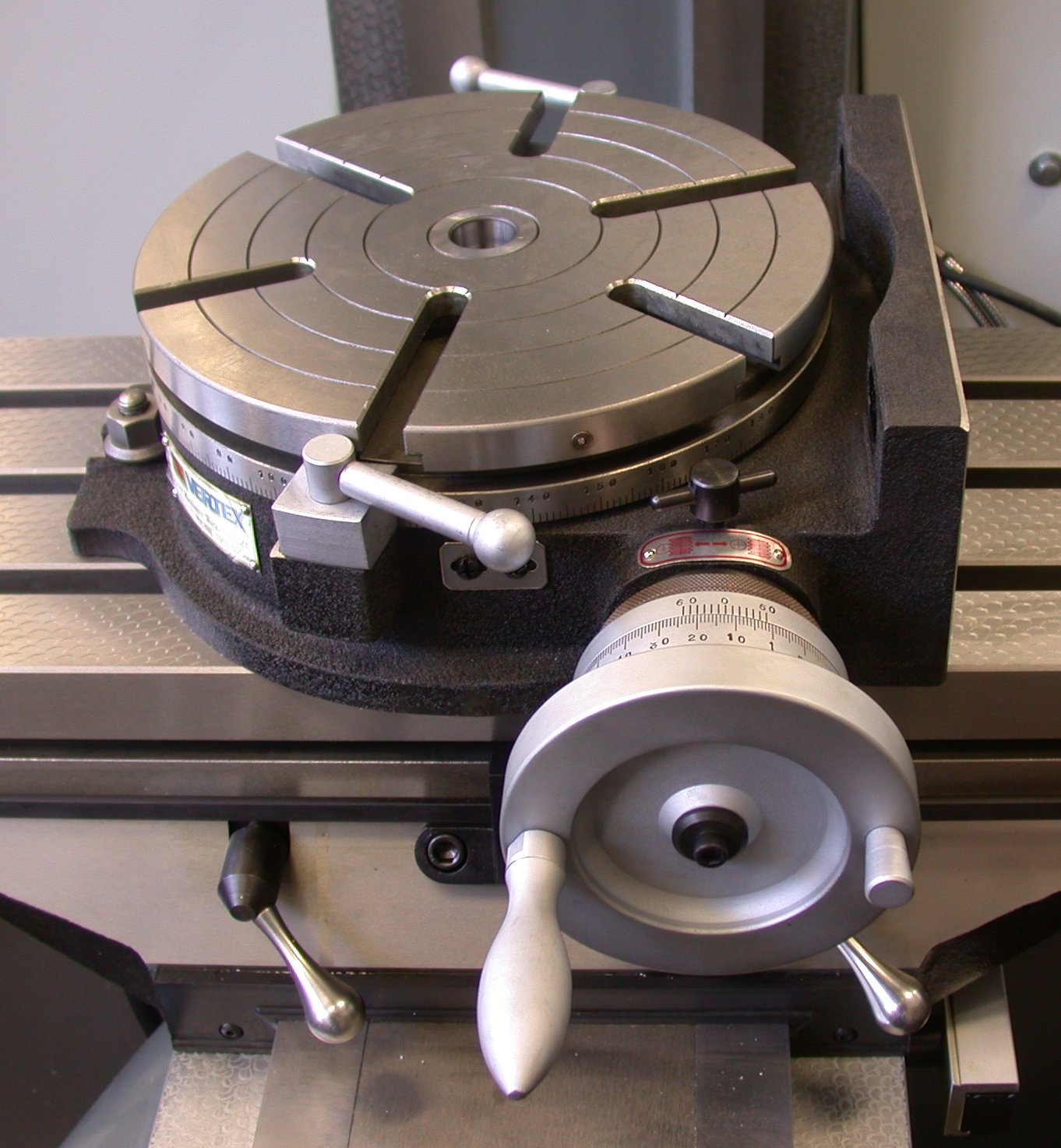

Years ago, before I learned CNC, I owned a Phase II 8″ horizontal/vertical rotary table that I purchased from Kap Pullen’s Getmachinetools.com store. He has them at a good price, BTW, and he’s a darned nice fellow to deal with as well as being a frequent HSM contributor. Anyway, its a nice little table, but I hadn’t done a whole lot with it for quite a while after purchasing it. As is so often the case, one day, a project landed on my doorstep and I was glad to have it.

Before I could get started, however, I had to make some accessories for it. Basically, I needed some T-Nuts to fit the table, as well as a little fixture that makes it easy to hold a plate up off the table through a hole in the center so you can machine it. The latter, what I call a “plate machining fixture”, was inspired by something similar I saw the Widgitmaster of CNCZone fame using to make Dremel clamps for his mini-router:

The Plate Maching Fixture and 3 Homemade T-Nuts. T-Nuts are easy to make: square a block to the proper dimensions, mill the side reliefs, drill, and tap. These are much smaller than the mill’s Bridgeport standard T-slots, so I made them myself and I’m using 1/4-20 bolts with them. They’re made of mild steel.

I turned the round spigot using the 4-jaw on the lathe. I’m making the fixture out of MIC-6 aluminum plate, which is pre-ground very flat on the sides. This is a 5 inch by 3 inch piece. I’ve clamped it to the rotab using my T-nuts and the regular mill clamps and step blocks. It is sitting on parallels to make sure I don’t cut into the table. You can also see how I’ve clamped the rotary table to the mill table using a big cast iron V-block I have. You can never have to many blocks with precision faces hanging around!

Having a 4-jaw chuck on your rotary table is mighty handy! Because it’s a 4-jaw, you can dial in the workpiece by adjusting the jaws until it is perfectly concentric with the table’s axis of rotation. The best way is to make an adapter plate that attaches to the back of the chuck in the same way that your lathe does so you can exchange lathe tooling with the rotab. Here is an example:

For the example, the chuck is threaded onto the adaptor plate, and then the holes in the adapter plate’s flange are used to bolt down to T-nuts on the table.

In my case, I bought a 4-jaw from Shars brand new, and simply drilled some through-holes in the chuck to mount to the table directly without an adapter plate:

First, you want to make sure your part is properly centered on the table. To do that, I clamp the table down on the mill table (no special place is needed), put my Indicol indicator holder on the mill spindle, and find some round feature on the part to indicate on. For example, on the plate milling fixture above, indicate on the round boss, or on the center hole. Spin the table and bump the part in until spinning the table doesn’t move the indicator.

Second, locate the center of rotation directly under the mill spindle. You can simply use the X and Y table handwheels to do this. Use that Indicol to indicate off of a circular feature you want centered under the spindle. Turn the indicol around on the spindle and adjust the handwheels until the indicator stays put relative to the spindle position. A Blake Coaxial indicator will make this last even simpler.

When you’re rounding partially by cranking a part around on the rotary table, it’s really easy to go a little too far and screw things up. The answer is to drill the end points to make the exact stopping point on the rotab a lot less sensitive:

Centering with a Blake indicator is really fast, but what if you don’t have a Blake, or worse, what if your mill is too small to accomodate one? Here is a nice solution I found on a German site. This fellow has made an ER collect fixture for his rotary table, and has taken care that when installed on the table, the axis of the collet is aligned with the table’s axis. He can then place a dowel or other straight pin in the collet and line up until it will go into a similarly sized collet on the spindle. Nice trick! It’s similar to how Widgitmaster showed me to align a drill chuck on a QCTP to the lathe centerline with a dowel pin held in the lathe chuck.

Run the quill down and touch the sharpie to the rotary table table and by moving the mill table (cross feed) draw a line that will be parallel to the work.....

Now, use an indicator to final align the edge of the plate to be true to the machine ........Do this by rotating the table....Be sure to make all corrections by turning hand wheel in the direction that you will

If you have a moveable degree pointer for the table also set it to zero (most have some adjustment here)....If that is not available on your table make a simple sheet steel pointer plate that is just plain(no pointer.

Move to and cut features as needed...be sure to account for backlash in the table worm...(The starting point for the rotary cuts need to be positioned by moving in the direction you moved to set the plate to zero.)...

The crosslide table all depends on where the slides are...above the point of rotation or below. Below is pretty much the cheap line and really is redundant putting on a mill as you already have 2 axis there. Now, slides above the pivot point allows you to position your part any where on table, center it above the pivot using the slides (U & V axis?) all with out tapping it about like a rotary table w/o slides. Also, you can then offset a part to center a desired radius elsewhere...example: you need to mill a 4" square hole with r.535 in corners. On a plain rotary table you would need to relocate the part for each corner...with topslides you use the U & V axis to position the center of R.535 over the pivot and turn the corner. This works for all kinds of stuff...milling angles off the X&Y that come tang to a rad, or even milling multiple circles or countours on a single pc w/o remounting and locating the pc. Think of 3 O-ring grooves on a hydraulic cover, or the snowman shape in a gearpump hsg. These can get confusing as now you have a manual machine with C,U,V,W,X,Y,&Z axis....wow.

The best has to be Advance 15X15. I know this unit cost $4500 15 years ago.Troyke made them also but I don"t know of others. Palmgren I thought made the bottom slide type. Alas, the 2axis CNC retros can outrun it and these are rapidly becoming dinosaurs.

I usually get a good many arguments started about rotary table setups. I worked in a large forge die shop, and I still do the setups the way we were shown in that shop. Probably 95% of the time you used a rotary table on a rotary head milling machine, so getting stuff on center was step #1.

The first thing to be pointed out is that the center hole and OD of the table aren"t necessarily on the axis of rotation. Easy to check, take the worm out of engagement and pull the table around by hand with an indicator zeroed on the center hole. Just like indicating a part in a four jaw.

If it is on center, that"s great. If not, you can eyeball your part on center and lightly clamp while you indicate it in by pulling the table around by hand and tapping it. If you don"t have a concentric hole or OD to use an indicator on, a center punch mark and a pump center can be used.

Once the part is on the center of the rotary tables axis, it"s a simple matter to center it under the machine spindle by locking the table and rotating the machine spindle and indicating like you would normally.

rotary filing—that is, running a circular cutter withfile-like teeth in the headstock of alathe.Rotary filling and later,true milling were developed to reduce time and effort

Here is what I like to use as a test indicator holder. It can allow you to indicate in something without removing the tool. They have several options for in spindle or spindle nose clamp styles. eBay does have some cheaper import version that work ok, but once you have use the Indicol quality, there is a big difference. You will need to buy the test indicator as a seperate item. There are a lot on the market. I have had my B&S(brown and Sharp) "Best Test" indicator for almost 30 years and one repair. Reasonably rugged and very reliable. Sticky indicators like some imports do you no good. If the needle pointer does not move, it is inviting a false sense of security.

The whole premise is to use the spindle bearings to sweep an indicator around the surface you wish to align it to. It is much easier in concert with a DRO, but dials will get you there too.

As long as you do not move the table, you could indicate the part in by knocking it around until it sets in the same location. You could also spin the table itself and knock the part around to find its true center on the rotation of the table bearings. Some of the cheaper import rotary tables may not have the spindle bore as reliably on center as what they will rotate on their shaft.

The same indicator setup can check for spindle tram also. This will need to be checked periodically anyways to verify the spindle is perpendicular to the table surface. If the head is tilted and you indicate in a feature. If the point that it is indicated in at changes in height, so to will the location of the features you intend to machine in relation to that reference. The longer the tool bit is away from the indicated origin, the further off location the new feature will be. Where this is seen is when the part is indicated in at one level, but the distance between the spindle and work needs more room for the tool. So when the table drops away, the point of origin in relation the spindle center (being at an angle) is out lost in space now. The new feature(s) can be found way off location even though the table was moved correctly during the setup. Best advice is to keep this in mind if the knee or head will be moved in a Z axis, always check the tram first. Especially after a crash, broken cutter or large unexpected force at the cutter.

The same holds true for vises parallel to an axis. For critical work, always check the solid jaw for axis alignment. If it is at an angle and a feature is indicated in on one end of the jaws, it might not be at the other end. More or less exponentially to the angle it is off over XX distance from the origin.

Main objective here is to use as much of the machines built in geometry to maintain pure geometry on the part as the machines is capable of. A test indicator is the best way to obtain this level of precision.

PO Box, APO/FPO, Africa, Alaska/Hawaii, Albania, American Samoa, Andorra, Armenia, Azerbaijan Republic, Bangladesh, Bhutan, Bosnia and Herzegovina, Brazil, Brunei Darussalam, Cambodia, Central America and Caribbean, China, Cook Islands, Ecuador, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Greenland, Guam, Jordan, Kazakhstan, Kiribati, Kyrgyzstan, Liechtenstein, Macedonia, Marshall Islands, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Nauru, Nepal, New Caledonia, Niue, Norway, Pakistan, Palau, Papua New Guinea, Russian Federation, San Marino, Solomon Islands, Svalbard and Jan Mayen, Taiwan, Tajikistan, Tonga, Turkmenistan, Tuvalu, Ukraine, Uzbekistan, Vanuatu, Vatican City State, Venezuela, Vietnam, Wallis and Futuna, Western Samoa, Yemen

Drill holes and bolt-hole patterns, mill intersecting slots and curved slots precisely. Includes worm drive hand wheel with Vernier ring for 4-degree table movement per turn, three T-slot ways for easily mounting a chuck, and two table clamp handles for stability. Main body mounts horizontally and vertically. You will need the table, tailstock, and chuck to complete your rotary table. The 6” table is a complete pack including the dividing plates and the tailstock. The 8” table takes 1/2” T-slot nuts (35-110) and has an MT3 bore. The 6" table uses 10 mm t-slot nuts and has an MT2 bore.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

New electronic items fulfilled by Amazon AU can be returned for change of mind, for a replacement or a full refund of the purchase cost of the item within 30 days of receipt of delivery.For information about returning faulty electronics please see Returning Faulty Items.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy If fulfilled by Amazon AU, this item is non-returnable due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items. To return faulty items see our Returning Faulty Items policy.

Amazon AU does not accept returns for items sold and fulfilled by third-party sellers. To determine whether items sold and fulfilled by a third-party seller can be returned, check the returns policy set by that seller.

Returns Policy You may return most new, unopened baby items fulfilled by Amazon AU within 90 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds. Change of mind returns of baby items fulfilled by Amazon AU will qualify for Free Returns shipping if the item detail page includes "Free Returns" messaging. Otherwise original shipping fees for change of mind returns are not refunded.

This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You may return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds. Amazon AU offers free returns shipping for change of mind returns on eligible items. Look for the "Free Returns" messaging on the detail page of an item to confirm if it is eligible for free returns. Please also see About Free Returns. Otherwise, original shipping fees for change of mind returns are not refunded.

This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You may return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds. Amazon AU offers free returns shipping for change of mind returns on eligible items. Look for the "Free Returns" messaging on the detail page of an item to confirm if it is eligible for free returns. Please also see About Free Returns. Otherwise, original shipping fees for change of mind returns are not refunded.

This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You may return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds. Amazon AU offers free returns shipping for change of mind returns on eligible items. Look for the "Free Returns" messaging on the detail page of an item to confirm if it is eligible for free returns. Please also see About Free Returns. Otherwise, original shipping fees for change of mind returns are not refunded.

This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

Returns Policy You can return most new, unopened items fulfilled by Amazon AU within 30 days of receipt of delivery for a replacement or full refund of the price you paid for the item if you change your mind - see About Replacements and About Refunds.

In some cases, the nature of the item means that it is non-returnable, for example, due to hygiene/health and personal care/wellness/consumable nature of the product. In some circumstances, these items may be eligible for a refund or a replacement (for example, if you receive the wrong item due to an Amazon AU error or if the item is faulty). Please Contact Us and see About Items That Can’t Be Returned.

Unless otherwise stated, original shipping fees for change of mind returns are not refunded. This change of mind return policy is in addition to, and does not affect your rights under the Australian Consumer Law including any rights you may have in respect of faulty items.

For items ordered on Amazon.com.au from a seller that fulfils and ships its own inventory (also called a third party seller), any returns will be in accordance with the returns policy set by that seller (not the Amazon AU returns policies). Please see About Marketplace Returns & Refunds for details on Seller returns policies.

A CNC rotary table is the precision positioning accessory that can provide a reliable 4th axis or even 5th axis for modern machining centers. Utilizing a computer-controlled rotary table can turn the original 3-axis machine tools into 5-axis CNC machines, expanding the accuracy as well as decreasing the costs while performing complex machining operations at one time.

A CNC rotary table is the precision positioning accessory that can provide reliable 4 or even 5 axis cutting operation capabilities for modern machining centers. Utilizing it can turn the original 3-axis machine tools into 5-axis CNC machines, expanding the accuracy as well as decreasing the costs while performing complex machining operations.

Rotary tables typically have rigid frames and coatings, and also excellent torque capacity, which makes the small device flexible and effective for a wide variety of turning, milling, drilling, and more metalworking operations. The easy setup and seamless interface allow the operators to easily add the rotary table to fit their 4-axis or 5-axis applications. .

The working principle is similar to the basic rotary tables, which is to support the workpiece by accurately rotating the workpieces on the axis in order to locate the parts for high precision tooling. Under rapid rotation, which is driven by CNC instructions, the cutting tools of larger machine tools or machining centers can remove the material and add the feature to the products at exact intervals. On rotary tables, there are vertical and horizontal axes for various tools to perform these high-performance metalworks. To enhance the accuracy and flexibility, there are models that employ additional dividing plates and come with additonal material handling mechanisms and features.

Since 4-axis and 5-axis machining is increasingly popular today, adding the CNC rotary table as the 4th axis is an ideal solution to easily open up more complex machining options at a lower cost. Due to the arrangement, they are widely also called the 4th or 5th axis or tilt rotary. The 4th axis, which is the rotational operational direction, is added to the original three linear axes which are known as X-axis, Y-axis, Z-axis. In some cases, there are two rotational axes add to the original 3-axis machining center, achieving utmost accuracy as well as effective multiple face cutting to reach the difficult area on the surface. Rotary tables are usually mounted parallel to the ground or the bed, with the platter rotating around the vertical axis, for example with the most common vertical milling machine combination. Sometimes the machining application requires an alternative setup with the table mountet on its end so that it rotates around the horizontlal axis. Often, a tailstock is used in this configuration. Virtually all models today come with a clamping kit to mount it onto the bed of your machine tool.

The function of the high precision rotary table is also to rotate the workpiece so the cutting tool can create the contour we desired out of the workpiece. However, a rotary table with higher precision has the ability to achieve great accuracy just as its name implies. There is also a major misconception between the resolution and the accuracy.

A common example is that if a digital readout displays to four decimal places, then the high precision rotary table must also be capable of achieving the accuracy to that same value. Even though for higher accuracy to be achieved, the resolution has to also be high, but there is no guarantee that the accuracy is going to be high. The accuracy is the concept which is the difference between the actual position and the position measured by a reference measurement device. The feedback mechanism such as the rotary encoder, and the drive mechanism can influence the accuracy of the advanced rotary table.

A CNC rotary table can provide great rigidity for stable machining operations. It consists of the worktable where the metal parts are held, the rigid bearing that withstands the forces and loads during the rotation, the solid base which is used for attaching the rotary table to the machining center or other equipment, the motor, and the CNC system.

The worktable is the tooling surface where the workpieces are machined after accurate positioning. The worm gearing is the core mechanism of the table, which mesh with the steel worm which is submerged in the lubricants. Both the rigid bearings and the worm gears have large diameters. Excellent concentricity is the key to smooth operation, durability, and most importantly, accuracy. Driven by a computer and electric motor, the worktable can position the materials at exact intervals. For more flexible or critical operations, dividing plates can be added to this component.

A CNC system regulates the simultaneous 4-axis motion of the rotary table. The instructions are programmed and transmitted via CAD software, reducing the time for adjustment and monitoring by human workers.

The type and size of the electric motors utilized in can define the router accuracy as well as the efficiency of the device. Servo motor and stepper motor are two typical types that can be divided into more subtypes. The servo motor uses a closed looping variable circuit, the circuit will constantly run to keep the function. The brushes must be replaced every 2000 hours of operation in the servo motor. Compared to stepper motors, servo motors are more efficient in power consumption. On the other hand, the stepper motor has a simpler setup which are the wires that are attached to the driver. The bearing of the stepper motor is the only wearing component. However, the stepper motor consumes a great amount of energy.

There are currently several different types and models available in the industries. Each of them possess its own traits and abilities. Let us take a look at the most common ones other than standard three axis tables

The 4 axis CNC rotary table will process the workpieces by holding them in the same position while the cutting tool performs along the XYZ plane to trim away the unwanted material. In general, a 4 axis model is very versatile equipment that can be used for several different industrial processes such as engraving curved surfaces, continuous cutting, and intermittent cutting. Besides, people can also add other devices such as cam machining, blade machining, and helical grooves to the 4 axes rotary table. Such a feature is simply impossible to achieve with the machining center which has only 3 axes.

Besides the 4 axis ones, there are also 5 axis models. They have the ability to allow the workpiece to be processed automatically from five sides at one time. people usually utilized the 5 axes rotary table in the industries such as the automobile, the aerospace, and the boating industries. The reason that the 5 axes rotary table is commonly used in heavy industries is that the 5 axis machining is an important technique to be used when the components need better intricacy and quick precision. All of these have more than three axes are called the multi-axis rotary table.

The installation method of the precision rotary table can be horizontal, vertical or inverted. When installed horizontally, the workbench surface is in a flat, vertical and horizontal position. When installed vertically, a rotary table is installed so that the surface of it can run up and down. In the reverse layout, itcan be rotated upside down in a horizontal position. The location of the drive of the rotary table can depend on the mount. The drive can be placed on the back, below, on the top or on the side.

When mounted horizontally, the spinning table top drive is positioned above the table floor. When the rotary table is horizontally placed, the side-mounted drive is located on the edge of the table board. The driving mechanism of the rotary table may be manual, electrical, pneumatic, hydraulic or non-driven. For manual revolving workbenches, release the workbenches and manually spin the workbenches with the crank.

Workpieces are gathered and machined through PC and fully programmed instructions. The 5-axis simultaneous operations will be measurably more reliable than products machined via different technologies. Also, the setup is simple and provides an indistinguishable process in every production cycle, the consistency of the quality of the metal products can be ensured under critical control and precision cutting.

Since the metalwork is driven by software, the preferred frameworks can be programmed and adapted by the rotary table. Saving both the cost and the room makes themis the ideal solution for potential users who don’t want to install larger equipment and new machines which may take up a great room for a wide variety of machining applications.

Another benefit is the utmost movements can be completed precisiely and faster. There are more favorable positions, operation angles as well as accessible machining that can be achieved through the technology. The complex operations are suitable for blade, helical grooves production, and other applications required to add complex features or require critical inspection in machining processes like the manufacturing of aerospace, automotive parts, and scientific equipment.

Addding a rotational table saves time because the extra finishing jobs or other sub-operations can also be performed at one time in the machining center.

A rotary table can be used in many applications including manufacturing, inspection, and assembly. Indicators are used, for example, for assembly, manufacturing, and bottling equipment. They typically use a single item in workspaces or move relatively small layouts of items around stations for sequential work or assembly.

In automated assembly machines, the rotary tables implementation is widespread, and choosing the right mechanism is important for both improving efficiency and reducing the cost of this vital component. This guide discusses two common devices for rotating indexing and offers guidance on the right range. There are several ways to get mass mobilization when it comes to the development of rotary indexing tables. Regardless of whether the load or load in centuries of thousands of kgm2 is incredibly light. When choosing a robust rotary index solution that will match or meet your standards, there are several factors to take into account when spinning, elevating, or pushing.

When determining the influencing factors on the postitioning accuracy, the first thing to look at is the mechanical properties of the table itself. A rotary table contains six degrees of freedom. Each of these movements increases the total risk of positioning errors. Usually, a rotary table is driven by a worm gear, which is connected to the motor through a rotary encoder on the back. The position of the table can be determined by the number of pulses transmitted from the encoder to the control device.

The four main sources of error due to the semi-closed position loop are geometric errors, thermal deformation, elasticity, and wear. The sum of these errors is called angular positioning error. To greatly reduce the angular positioning error, the ideal position for installing the angle encoder is on the rotating shaft under test. The angle encoder is installed under the rotary table, and the rotary encoder is installed under the rear motor, the position loop is now considered a closed-loop system.

Precision is a relative term. About a quarter of an inch is great and will meet the accuracy of its application. Others, for example, require micron-level accuracy in measuring and indexing devices. Then, some applications fall within these extreme ranges.

The misunderstanding is that you may have used an inaccurate indexing device and made it accurate by introducing a pin or wedge locking device. These devices increase the complexity and cycle time of use, and when they are used together with a high-precision positioning device, they may cause damage and reduce accuracy.

In the actual test, by selecting specific components, motion index drive, servo rotary indexer, the measurement accuracy is as high as 5-6 microns. These are not the results approved by Motion Index Drives, but the results of customer certification. When starting and stopping large amounts of data, it is important to know how fast it takes to stop the application with large amounts of data.

In a less rigid environment or the presence of higher recoil, a faster start and stop will bring many control problems. When moving masses (whether rotating mass or linear mass), starting and stopping in a system with a backlash of several arc minutes will cause a lot of back and forth movement in the gear system. The result is a force that is difficult or even impossible to calculate. In addition, when the gear head is used in rotating applications, the farther the mass is from the center of rotation, the greater the backlash. In applications with very slow deceleration times, recoil may not be a problem.

Backlash in the positioning process is a big issue – when it comes to the beginning and stopping volumes, it"s crucial to know how quickly you need to avoid the mass of your rotary indexing table applications. In a less rigid system or where there is an increased backlash, quicker start-ups and stops can cause a lot of control issues. When shifting a mass, whether rotary or linear, starting and stopping in a system with several minutes of backlash arc will create a lot of back-and-forth motion within the gearing system. The effect is a power that can be difficult and probably hard to quantify. In comparison, as the gear head is used for rotational applications, the more the mass is from the axis of rotation, the further the backlash is magnified.

The backlash may not be a concern in systems where deceleration times are incredibly long. In the case of cam indexers, there is " Zero Backlash." The cam indexer and rotary table dynamics give an incredibly rigid, highly regulated framework. A modern cam indexer system is capable of withstanding short cycle times with stop times in milliseconds.

So you want to get the smart manufacturing going but are not sure of what to look for in rotary tables. The information provided in this section may be able to help. The primary factor is to determine the mass snapshot of inactivity. This is often overlooked when measuring a rotary table for the machine.

Another significant factor is the size of the workpiece being rotated, including how big it is and how substantial it is. You want your rotary tables to be large enough to handle enormous pieces. This is where tilling rotary tables may become handy so that the pieces can be handled without causing interior harm. They allow the quickening and decelerating of machining at appropriate rates.

The last factor is accuracy, the applications for which, for instance, pivoting a gigantic part to allow welding highlights on it where the individual stop positions can be genuinely free. On an additional note, when choosing direct drive rotary tables, factors that you should consider when selecting a rotary table for your CNC machinery include accuracy, backlash, mass moment of inertia, acceleration and deceleration, speed, and environment.

Indexing system use is commonly possible in automatic assembly machines and the right process is important for both performance maximization and cost reduction.

Cam indexers are an omnipresent tool used for several decades for rotary indexing tables. They are suitable for applications that often index the same angle and need a high degree of accuracy at a relatively low cost. To place the load, a cam indexer uses a mechanical cam. A math curve is pushed onto the cam and provides incredibly smooth and repeatable movement.

Another popular alternative is a fully programmable rotary index table. A rotary table is advantageous in two different situations. Firstly, a versatile movement pattern is important. An example is if two components are running on one computer, each of which requires different index patterns. For incredibly fast placement accompanied by a long period, another condition that matches the servo pointer is. The need to accelerate the camshaft while the cam indexing mechanism was operating before starting the output movement reduced the on-demand cam indexer. Acceleration of the camshaft is possible, but there is a delay before the movement begins. There are realistic restrictions.

With an indexing table, the output rotates as soon as the servo starts moving. This is not difficult for a continuous cam indexer or a zero-backlash servo indexer, but it can also be difficult for an on-demand cam indexer. For applications with high-speed servo indexing, smooth movements are crucial. A zero-backlash preloaded reducer can achieve this. The ideal alternative for correct positioning with high dynamic response would be the zero-backlash reel drive system.

Application parameters, like a moment of inertia, indexing angle, indexing period, and residence time, are required for each indexer style. The rotary indexing table for the application should also be sized correctly by a reputable manufacturer.

8613371530291

8613371530291