how to use a rotary table on a mill pricelist

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

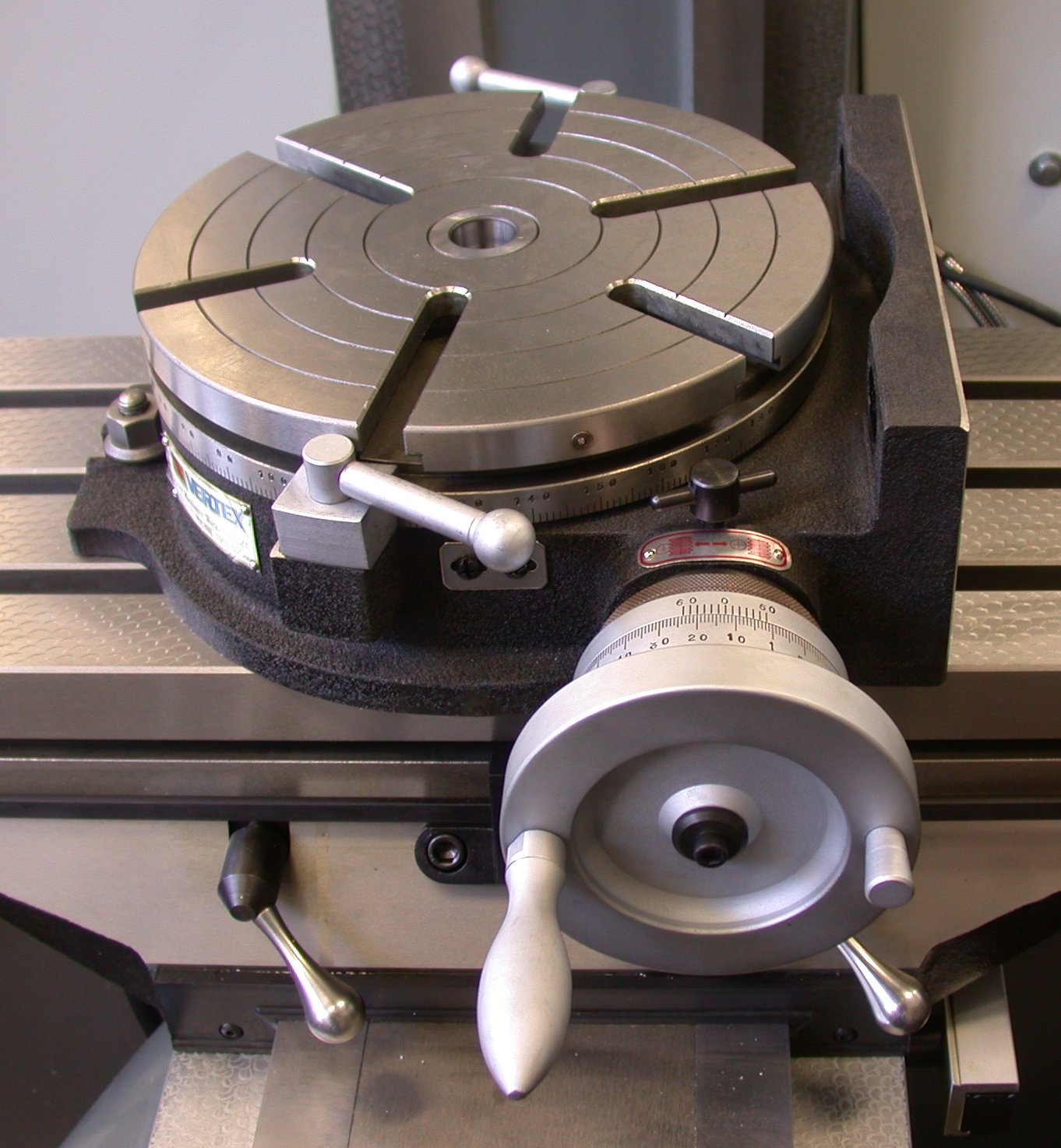

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

"Save Half", "Half Price" or any other similar expressions used by us only represents an estimate of savings you might benefit from buying certain tools with us compared to the major top brands and doses not necessarily mean to cover all categories of tools offered by us. You are kindly reminded to verify carefully when you are placing an order with us if you are actually saving half in comparison with the top major brands.

For cancellations, you can reach us out at +91 9319511441 / support@chandcompany.in or request for Order cancellation from the My Orders section in your My Account option.

You have up to 48 hours from the time of placing your order to cancel your order. Once the order is cancelled, the amount will be reimbursed for all ‘PREPAID ORDERS’

Order can be cancelled before the shipment of the order has been processed i.e 48 hours after placing the order. CHAND COMPANY can cancel the order for various reasons such as:-

Unavailability of products – in exceptional cases, is a product runs “out of stock” with us at our warehouse, the product will be cancelled and all the necessary information will be given beforehand to the customer about the unavailability of the order and order cancellation

Chand Company and its logistic partners take due care in delivering the product(s) in the best condition, however, in the rare occasions of damaged goods being received or any discrepancies with the products received, you can reach us out with the images of the damaged product along with the packaging pictures at support@chandcompany.in and +919319511441 within 48 hours of receiving the material, to resolve your issue.

All products have a Warranty against Manufacturing defects IF STATED OTHERWISE IN THE ITEM DESCRIPTION, which can be easily identified when the product is put to use. In case of any manufacturing defect in the product, the customer needs to inform us within 5 days of receiving the order. The return intimation will then be taken into consideration and will be followed up with the customer, ensuring a proper solution to the customer and change the material with the same product, if need be. Please note that the products can not be interchanged with any other item even if the return has been accepted.

In case of any manufacturing defect in the product, the customer needs to inform us at support@chandcompany.in or +919319511441 within 5 days of receiving the material. Our executive team will then get in touch with the customer and work their best to solve the issue as soon as they can with utmost diligence and precision. If the product, in a perfect working condition, is deemed faulty and irreparable, then the customer will be provided with a new piece once the old material has been received by us

In case the product is delivered damaged, the customer needs to inform us at support@chandcompany.in or +919319511441 within 48 hours of receiving the material along with the pictures of the damaged item and the packaging of the product. The customer is then entitled to send us the material back and a proper inspection will be made by our engineers to infer the reason for the damage. If the item is then informed by our engineers to be damaged in transit. the customer will be provided with a fresh new piece within 2-3 working days.

All items must be returned in their original condition, with packaging and boxes intact, user manual, Calibration / Inspection certificates and original accessories in it

In order to return the product, the customer has to send the product to us through the India Post only. Once the product is received by us, then the courier charges will be reversed to the customer if a manufacturing defect has been found by our team after a thorough inspection

The customer needs to pack the product with brand packaging. keep the invoice inside the box and courier it to us at CHAND COMPANY, 4772, HAUZ QAZI DELHI-06.

After a thorough inspection of the product, the customer will be informed about the situation of his product and also if the return is possible on the product or not. Our Quality inspection team will do their best to reach maximum customer satisfaction and help them in all ways possible.

In case, after receiving the material if we find any discrepancy by our Quality check team, a new product will be shipped to the customer free of cost and will reach the customer in 3-4 working days.

Products marked as “non-refundable” on the item description page cannot be returned under any circumstance. If any problem against manufacturing is observed in the product, then our executive team will look into the matter and get it resolved for the customer"s satisfaction.

After receiving the required information for a refund, a refund will be processed in 2 business days and the same will reflect in the customer account in another 2-4 business days

Tariff Information Surveys on the Articles in Paragraph 1- of the Tariff Act of 1913 and Related Articles in Other Paragraphs, United States Tariff Commission

8" base adapter plate is ideal to use on 8" rotary tables of either 3 or 4 slots to mount either 6" 3-jaw ,6-jaw or 4-jaw self-centering lathe chucks.

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Technical data: - center distance 1500 mm- center height 400 mm- max. machining diameter FI 400 mm- motor power 4,0 kW- voltage 400 V / 50 Hz- spindle speed 3000 rpm- number of controlled axes 3- guide linear guides and ball screw- control MACH3 + software- pneumatic workpiece clamping- V-shape steel- milling spindle for flat engraving- compressed air supply 6 bar- dimensions L=2700, W=1400, H=1750 mm- net weight 1800 kg

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Kehren RIW9 CNC rotary table surface grinding machine Max workpiece diameter 900mm x 500mm height complete with internal grinding spindle it can be inspected in our warehouse in Gussago BS Italy Mimu Machine Tools

Are there any books on the rotary table ? I know there are several on the dividing head but information on the rotary table seems to be scarce. When i was serving my time we done a fair amount of work on the dividing head, what it could do, the maths involved etc, when i asked about the rotary table i was told that in production situations and general commercial engineering that cnc had made them nearly obsolete. A friend gave me an old table a year or two back and i have amused myself cutting arcs etc on bits of scrap, but i feel there is a gap in my knowledge of the thing.

You can use a rotary table to cut gears or drill a number of equaly spaced holes without dividing plates. Just divide 360 (The number of degrees in a circle.) by the number of teeth (Or holes) you want. For example if you wanted a 33 tooth gear 360/33 = 10.90909 Deg Most rotary tables are marked in degrees, minutes and seconds so you neet to convert the decimal value to this format.

So 0.90909 degreed is 60 * 0.90909 minutes = 54.5454 Then 0.5454 minutes is 0.5454 * 60 seconds = 32.724 seconds. You could use a spreadsheet to do the calculation and list all the table positions.

In the example you would cit the first tooth with the table set to 0 deg 0 min, 0 sec. for the second tooth move the table to 10 deg, 54 min, 33 sec (32.742 rounded to nearest second) For the third tooth set the table to 21 deg, 49 min, 5 sec. And so on. You are more likely to make errors using this method than dividing plates. Here is some information on rotary tables that you may find useful.

You can also use tham for non regular spacings such as a series of radial holes and tangental surfaces. The part below was done with the R?T vertical then rotated for the two angled faces and the four different angles for the holes then laid on its back for the curves all of which radiate from the same centre point

I do loads of jobs on my (home made) rotary table as its much more rigid than my (home made) dividing head. The handle is graduated to 1/10 of a degree and I find that accurate enough. Any technique that works with a dividing head can be applied to a rotary table, if you add dividing plates to the handle.

Thanks for the replies and links everyone, the rotary table is just something i have never seemed to use somehow. I have one now and just wondered how to do some of the trickier work, cam milling for instance ?

That rather depends on the cam cutting method, you can do it without the calculations if its a short cam. With the R/T laid flat and the work held in a 3 jaw just wind the handle in approx increments, no fine setting of the cutter for every increment

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the

We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

I got the Grizzly H7527 6" rotary table a couple of years ago for around 1/2 price on Ebay. Actually bought it before the mill. I got the dividing plates and tailstock with it. The table is horizontal/vertical. Most are, but not all. 6" is great on the PM-30MV. The table has 4 slots not 3. It just seems easier to me when setting up the work. I"m used to X-Y on the mill or with 4 jaw chucks. Setting up the work is the problem, not centering the table. A quick table setup is only a couple of minutes good to 1 or 1 1/2 thousand. Plenty good for most radius work. If you need more then that, then you have to dial it in.

The center hole is 2MT not straight. I personally thick it is more accurate, but that"s me. The MT2 allows you to get small 3 jaw chucks and plug directly into the center. After using the table I"m going to go a different route. The MT2 dead center sticks out a couple of inches, so I guess that a commercial chuck would also stick out a good deal. One of the first taper projects on my new lathe is to cut a shortened MT2 version and attach to a flat plate and buy a cheaper 3 jaw chuck. The table surface clears the mounting base by around .030. I am on the look out for a flat bottom 8" 4 jaw chuck to speed up work holding.

Take the MT2 center and drop it in. Mark on either side where it touches the table. Grind two small notches in it to allow you to pry the center out. Doesn"t hurt the center. I use it in horizontal to center the table by touching the point with a dowel. I use 3/8" & 1/2" drill rod with a center hole in it. I use it in vertical with home made on the spot lathe dogs to clamp and rotate the piece. If you have to give up something, make it the tailstock. You can do work arounds without it.

The dividing plates are another story. Don"t leave home with out them. The increased accuracy and speed are what it is all about. You can layout holes without them, and your accuracy is only as good as your eyes.

The ideal for me was a 6" 4 slot horiz/vert MT2 with dividing plates and tailstock. 2nd choice was the same only 3 slot. Vertex HV-6 or the clones were the ones I looked at.

I am currently collecting fixture plate pictures. I plan on making drop in plates that self center and attach with 2 bolts. As stated above, it"s centering the work and attaching to the table that takes all the time.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer. Below are links to the pages on the various versions of the Sherline 4″ rotary table. The table is driven by a worm gear with a 72:1 ratio making each turn of the handwheel equal to 5°. Fifty laser engraved handwheel marks indicate positions 1/10 of a degree apart. A 90° fixture is available to position the table in a vertical position. Our P/N 3750 Tilting Angle Table is also available for positioning at any angle from 0° to 90°.

Sherline’s rotary table is one of the most popular accessories in the tool line. Its popularity extends from the home shop to the professional machine shop due to its compact size, solid construction, and long-lasting accuracy. The handwheel is calibrated in 1/10° increments with marks every 5° around the table’s periphery. Included is a set of hold-down clamps, T-nuts, and a threaded center fixture for attaching Sherline chucks with a 3/4-16 center thread. Read more about the Sherline manual rotary table.

P/N 3700-CNC 4″ CNC-Ready rotary table with stepper motor mount: In place of the manual handwheel, a NEMA 23 stepper motor mount is attached, allowing use of the rotary table as a 4th axis on Sherline CNC mills or for whatever CNC application a customer may have where a small but accurate rotary table is needed. Read more about the Sherline CNC-Ready rotary table.

P/N 8730 4″ CNC rotary table with stepper motor mount and NEMA 23 stepper motor: This takes the above rotary table one step further with the inclusion of Sherline’s own NEMA 23 stepper motor already attached to the rotary table and including a 5-pin plug that connects directly to the Sherline 8760 4-axis driver box. Read more about the Sherline CNC rotary table with stepper motor.

Sherline offers the answer to your small rotary indexer needs by providing a programmable control box with its own power supply and driver for running the rotary table. Inputs can be entered by either degrees (to 3 decimal points) or by divisions of a circle (up to 999 divisions). Also programmable are the direction of rotation, the speed of rotation and backlash compensation. In the PROGRAM mode, two different programs of up to 40 blocks each can be entered that control rotation speed, direction and degrees or divisions plus the option to continue or pause at the end of each block. Read more about the Sherline programmable rotary indexer.

For the laser marking industry, Sherline now offers several accessories including three sizes of tooling plates designed for holding parts during scanning. Read more about the Sherline laser scanning plates.

8613371530291

8613371530291