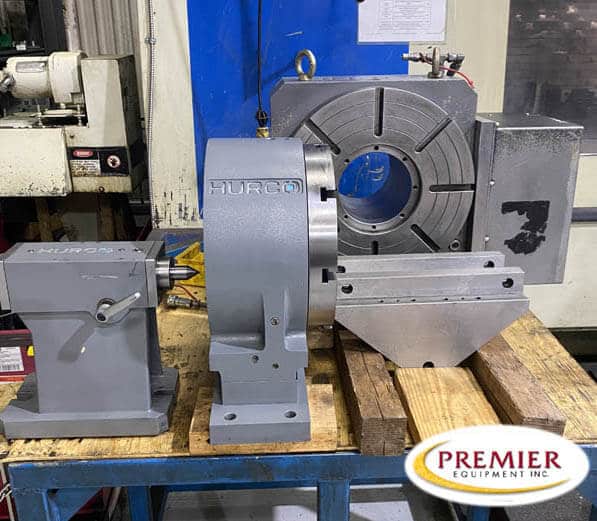

hurco rotary table supplier

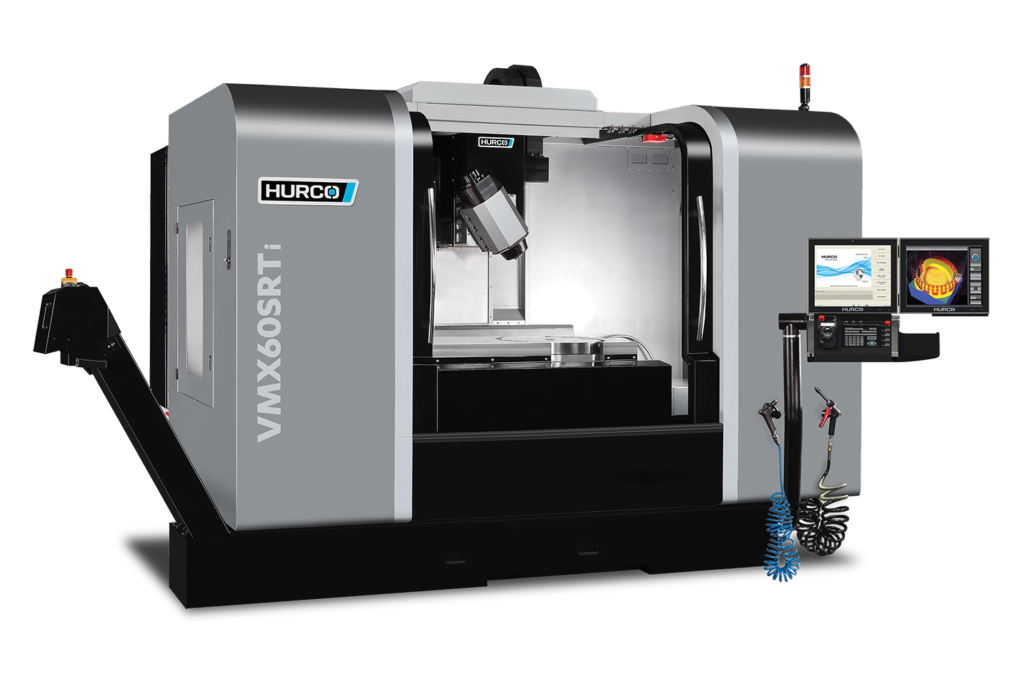

The SRT series of 5-axis CNC mills offers multiple advantages, starting with the machine"s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.Request PriceScroll to Machine Specifications

The Hurco VMX42SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a torque B axis swivel head and C axis style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

The SRT series of 5-axis CNC mills offers multiple advantages, starting with the machine"s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

The Hurco VMX50i w/4th Axis is an exclusive part of our Vertical Machining Centers inventory which we own and service. We"re the international CNC specialists with the best guarantee in the industry.

Regular attendees of Hurco Europe’s traditional Christmas open house will be pleased to learn that this year’s event will take place at its High Wycombe facility on Tuesday 6th and Wednesday 7th December 2022.

It’s a very popular show because in addition to a showroom full of new Hurco CNC machine tools under power and cutting metal, there is the added attraction that all of Hurco’s primary suppliers will be in attendance.

This year, as many as 20 specialist suppliers covering tooling, workholding, CAD/CAM, metrology, automation, mist extraction, rotary tables, angled heads, coolant and lubrication, probing and machine tool finance will be taking part, each with their own small stand. This allows existing Hurco users and potential clients the opportunity to discuss ancillary equipment in a relaxed and informed environment.

On show will be four different 5-axis machines with an emphasis on larger toolchanger capacity, represented by the new VMX30UDi-60ATC. There will be two automation solutions in operation: Hurco’s ProCobot range for component transfer and the Erowa Robot Compact 80 showing pallet transfer and the automation of one-offs.

In addition, there will be three Hurco CNC turning centres, including the new TMX10MYSi driven tool lathe with Y-axis and sub-spindle. As ever, the majority of the show will be represented by six models from Hurco’s bestselling 3-axis CNC vertical milling ranges. Sizes ranging from the compact, entry-level VM One to the powerful VMX60i with 1,680mm (X) and 660mm (Y) travels and a 12,000rpm 40 taper spindle.

The Government’s super-deduction scheme ends on 31st March 2022 where significant savings can be made on this year’s tax bill for profitable limited companies. But, time is running out because the machine must be delivered before the deadline. Check out Hurco’s website under News/Finance for detailed examples.

%20resized.jpg)

The efficient design of the Hurco 5-axis trunnion table machining centers (U Series) is a key benefit to consider—we use an integrated trunnion table at instead of simply sticking a trunnion table on a 3-axis machining center and passing it off as a 5-axis machine. The integrated trunnion table design provides more clearance in Z compared to other brands.

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine"s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

As a Hurco Distributor in Indiana we are certified to repair, install, troubleshoot and perform preventative maintenance for all Hurco CNC Machines throughout the ENTIRE state of Indiana.

8613371530291

8613371530291