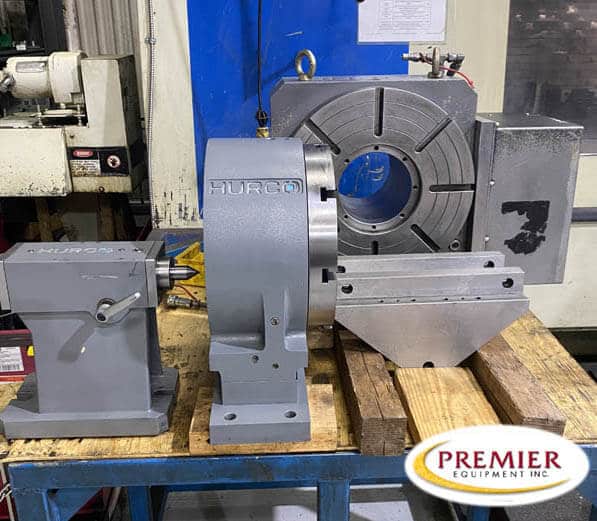

hurco rotary table factory

Select the axis configuration for all of the axes on your machine, even if you don’t think they will be used in the program. Rotary- and/or tilt-axis data blocks can be added to an existing program as long as the rotary-axis and/or tilt-axis configuration was selected when the program was first created.

Once an axis configuration is set for a program, it cannot be changed. However, you can use an existing Conversational program to create a new program that contains rotary-axis and/or tilt-axis programming data blocks. Follow these steps to create the new program:

4.Save the new program under a new name. You now have a rotary-axis and/or tilt-axis version and a standard version of the same Conversational part program.

The SRT series of 5-axis CNC mills offers multiple advantages, starting with the machine"s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.Request PriceScroll to Machine Specifications

The Hurco VMX42SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a torque B axis swivel head and C axis style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

Viewing the video on a machine may cause the system to slow during viewing and for a short period of time after the video is closed. For best results, the video should be played when there is no other activity (for example, programming or cutting a part) on the machine, and the video window should be closed after viewing. The video may also be viewed from a PC at www.hurco.com.

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

My question is, Is there anyone that has a working post for the VM10i (I have a H200 rotary table attached) and would be willing to be so kind as to let me have it... and if not, can anyone point me in the right direction as to what I need to change in the fanuc post to get it working myself.

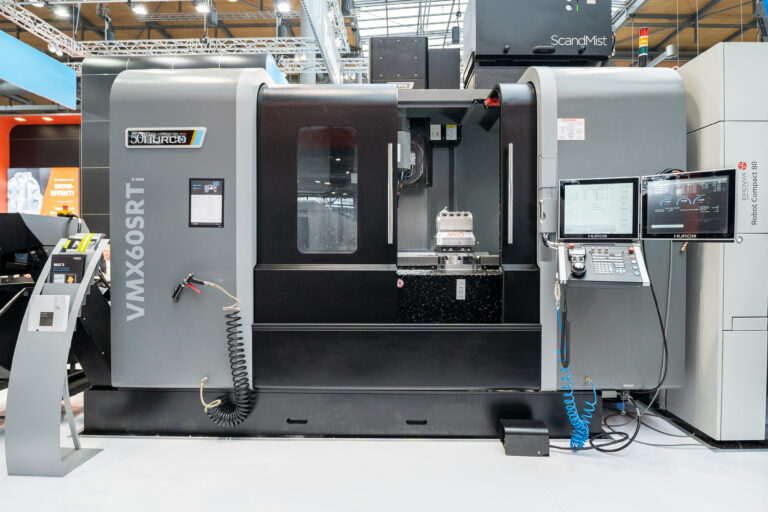

The Hurco VMX60SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head and C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

Tool Center Point Managementeliminates the need to account for the machining center’s centerlines of rotation. Instead, you simply use the solid model zero location. Post the program independent of where the stock is fixtured on the table.

Transform Plane calculates the other locations for each of the rotary moves after you locate part zero. The control software only needs you to define part zero one time, and it figures out all of the other part zero locations automatically.

At Hurco, we are immersed in 5-axis technology. We have carved out a niche in this arena because we made a commitment fifteen years ago to focus on 5-axis. We determined this type of machining center, combined with the capabilities of our control, would make our customers more profitable. Similar to the transition from manual mills to CNC mills, we believe the time is right for shops across the country to increase profit margin by investing in 5-axis.

Because we listened to our customers’ reservations about switching from a 3-axis process to 5-axis, we assembled a 5-axis applications team with a dedicated phone number and email to help. If you do NOT OWN a 5-axis machining center, the most important message you need to know: 5-sided machining on a 5-axis machining center will increase the profit margin of the parts you are producing on your 3-axis machining centers. The Hurco control makes programming easy for 5-sided—NO CAM needed!

According to benchmark data from Modern Machine Shop magazine, 24% of the highest performing shops in the U.S. are using 5-axis positioning. Hurco has carved out a niche in the 5-axis arena due to years of research and development. When we decide where to invest our resources at Hurco, our primary criteria are customer productivity and profitability. We evaluate the past, the present, and the possibilities of the future to determine what technology will benefit our customers the most. Nearly a decade ago, we determined that 5-axis machining warranted our attention and set a path to become the experts. We continue to lead the industry in developing control technology that optimizes the process for full 5-axis and 5-sided (3+2).

When you invest in a Hurco 5-axis CNC machining center, you get two machines in one. A machine that will immediately increase the profit margin of the parts you’re producing on a 3-axis machining center via powerful 5-sided programming (no CAM needed) and a rigid machine that is fully compatible with CAD/CAM packages for simultaneous 5-axis.

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

In addition to plenty of machine demos and technology previews, Hurco will toast the company’s 50th anniversary with a happy hour each day at 4:00pm (CDT) and host a 50th Anniversary After-Hours Party on Wed., Sept. 12 from 4:00pm to 9:00pm (CDT) at the Hurco

“We’re excited to use our 50th Anniversary IMTS events to showcase our customers who make some really cool products. Beverages will be dispensed from a th Anniversary IMTS gift was made by Bottle Breacher, an Arizona customer, Eli Crane, who used his winnings from the television show Shark Tank to buy his Hurco VM20i. Eli is a Navy SEAL veteran who turned his hobby into a thriving business. We hope the owners of both Bottoms Up Beer and Bottle Breacher will be able to break away from their shops for a few days and celebrate with us at IMTS. Both companies are a testament to the entrepreneurial spirit that is indicative of Hurco customers everywhere,” says Maggie Smith, Hurco marketing manager.

The Hurco booth will be divided into four quadrants: Automation, 5-axis, 3-axis, and Turning. In the Automation quadrant, attendees will see Industry 4.0 and the Internet of Things (IoT) in action with Hurco CNC machine demonstrations in partnership with Erowa

In the Turningquadrant, attendees will see the latest control software release that streamlines turning and milling. Hurco will also premiere its 3D Import feature with 3D DXF.

In addition to the 50th Anniversary parties and displays, Hurco will showcase the next generation 3D print head adapter that was first introduced at IMTS 2016. The following Hurco CNC machines will be under power at the Hurco booth:

Hurco CNC machines will also be featured at the AMT Emerging Technologies Center and at customer GWS Tool Group VM5i - AMT Emerging Technologies Center

8613371530291

8613371530291