hurco rotary table quotation

The SRT series of 5-axis CNC mills offers multiple advantages, starting with the machine"s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.Request PriceScroll to Machine Specifications

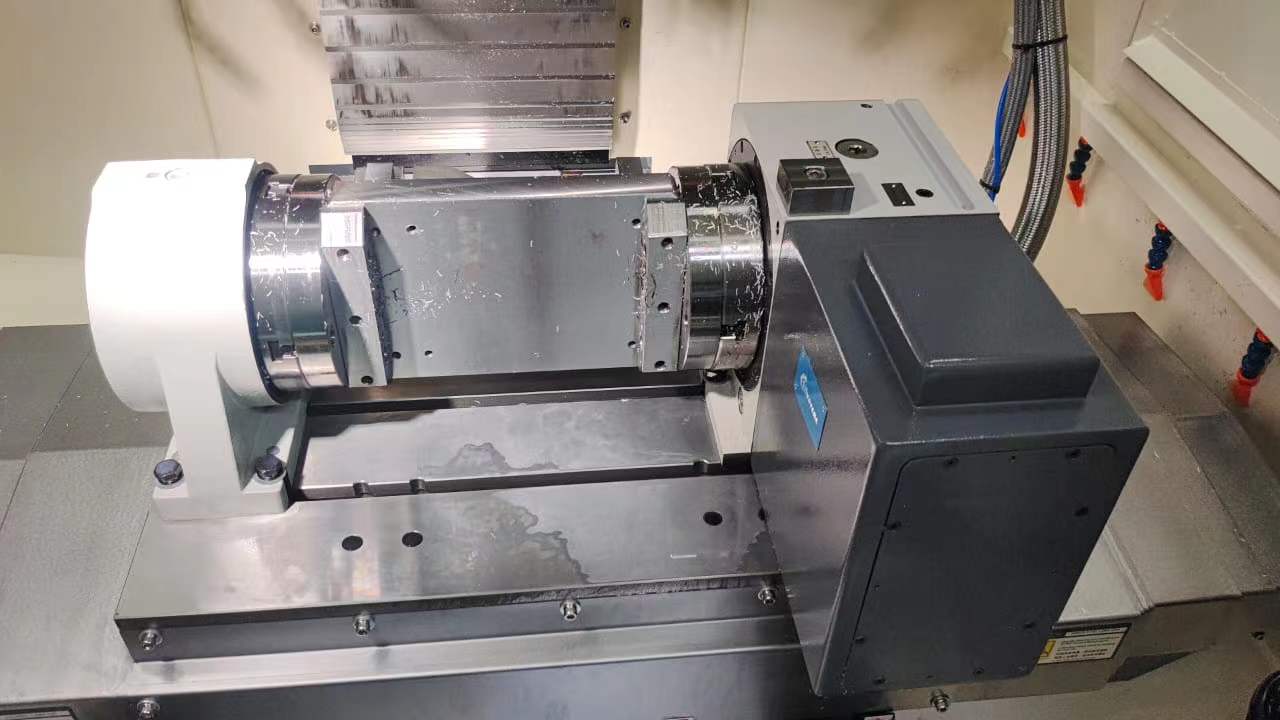

The Hurco VMX42SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a torque B axis swivel head and C axis style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

Select the axis configuration for all of the axes on your machine, even if you don’t think they will be used in the program. Rotary- and/or tilt-axis data blocks can be added to an existing program as long as the rotary-axis and/or tilt-axis configuration was selected when the program was first created.

Once an axis configuration is set for a program, it cannot be changed. However, you can use an existing Conversational program to create a new program that contains rotary-axis and/or tilt-axis programming data blocks. Follow these steps to create the new program:

4.Save the new program under a new name. You now have a rotary-axis and/or tilt-axis version and a standard version of the same Conversational part program.

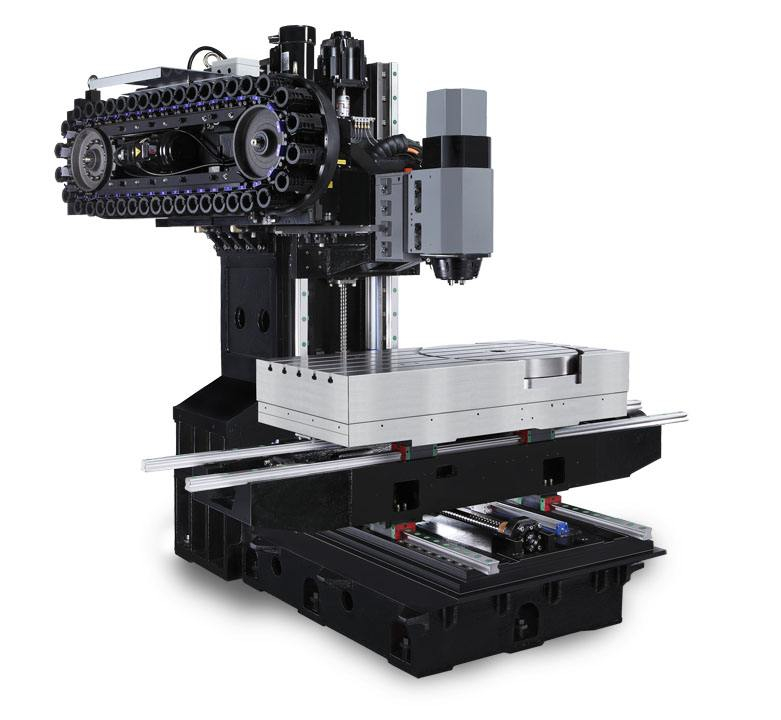

The VMX30UHSi combines the features of our VMX mills with a high-speed integral motor spindle featuring ABEC-7 ceramic hybrid bearings and 18,000 rpm base speed. The VMX30UHSi features an integrated trunnion-style 5-axis rotary table. Premium components provide the speed and power associated with high-speed machining.Request PriceScroll to Machine Specifications

The Hurco VMX42HSRTi high-speed 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head and C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

The efficient design of the Hurco 5-axis trunnion table machining centers is a key benefit to consider—we use an integrated trunnion table at Hurco instead of simply sticking a trunnion table on a 3-axis machining center and passing it off as a 5-axis machine. The integrated trunnion table design provides more clearance in Z compared to other brands.Request PriceScroll to Machine Specifications

The Hurco VMX60SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head and C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

Tool Center Point Managementeliminates the need to account for the machining center’s centerlines of rotation. Instead, you simply use the solid model zero location. Post the program independent of where the stock is fixtured on the table.

Transform Plane calculates the other locations for each of the rotary moves after you locate part zero. The control software only needs you to define part zero one time, and it figures out all of the other part zero locations automatically.

At Hurco, we are immersed in 5-axis technology. We have carved out a niche in this arena because we made a commitment fifteen years ago to focus on 5-axis. We determined this type of machining center, combined with the capabilities of our control, would make our customers more profitable. Similar to the transition from manual mills to CNC mills, we believe the time is right for shops across the country to increase profit margin by investing in 5-axis.

Because we listened to our customers’ reservations about switching from a 3-axis process to 5-axis, we assembled a 5-axis applications team with a dedicated phone number and email to help. If you do NOT OWN a 5-axis machining center, the most important message you need to know: 5-sided machining on a 5-axis machining center will increase the profit margin of the parts you are producing on your 3-axis machining centers. The Hurco control makes programming easy for 5-sided—NO CAM needed!

According to benchmark data from Modern Machine Shop magazine, 24% of the highest performing shops in the U.S. are using 5-axis positioning. Hurco has carved out a niche in the 5-axis arena due to years of research and development. When we decide where to invest our resources at Hurco, our primary criteria are customer productivity and profitability. We evaluate the past, the present, and the possibilities of the future to determine what technology will benefit our customers the most. Nearly a decade ago, we determined that 5-axis machining warranted our attention and set a path to become the experts. We continue to lead the industry in developing control technology that optimizes the process for full 5-axis and 5-sided (3+2).

When you invest in a Hurco 5-axis CNC machining center, you get two machines in one. A machine that will immediately increase the profit margin of the parts you’re producing on a 3-axis machining center via powerful 5-sided programming (no CAM needed) and a rigid machine that is fully compatible with CAD/CAM packages for simultaneous 5-axis.

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

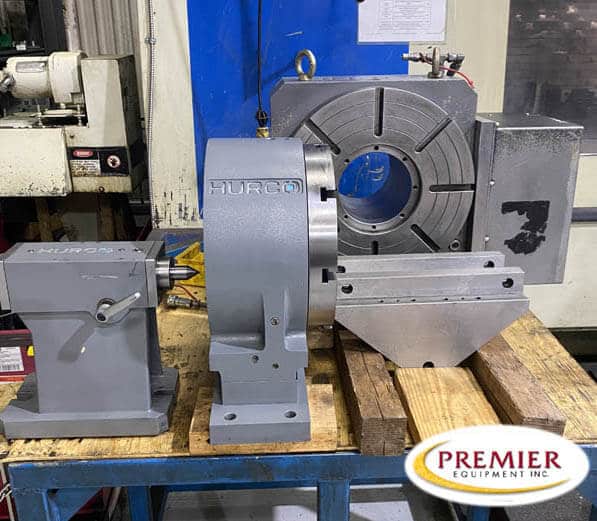

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

Increase efficiency and production of your CNC machine with our Dual VH-8. Perfect for making 2 parts at a time thus reducing the number of tool changes and allowing the operator more time to complete other tasks. The standard configuration places the motor at the side or we also offer the option to wrap the motor around the back to save space, reduce overall length and eliminate possible machine interferences. The Dual VH-8 has twin 8.25" spindles (210mm) with dual tapered roller bearings supporting the front and back of each spindle. The VH-8 worm wheel is helically cut and throated for increased surface contact between the wheel and worm. This provides longevity and helps maintain the accuracy of the rotary table over time. There are optional 8" 3-Jaw chucks and adapter plates available as well as a 5C nose pieces with either manual or air collet closers for your workholding needs.

The Index Designs Dual VH-8 is a true 4th-axis rotary table with two platters,complete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

The latest addition to the firm’s 5-axis capacity is a Hurco VMX42SRTi, which has powerful conversational programming capability built into its WinMax control system.

“We already had eight 3-axis Hurco machining centres on-site, including one with an add-on rotary axis, so were familiar with the manufacturer’s twin-screen, menu-driven control system and graphical user interface,” states TGM director, Sarah Stephens. “Our operators have always found it to be user-friendly for shopfloor programming and on the latest machine only the fifth B-axis that swivels the spindle head is different, so adaptation was easy. The skill sets were already in place to create 5-axis cycles involving the positioning of both rotary axes.

“We purchased extra WinMax software to run on a laptop and use it to program around 90% of jobs run on the Hurcos, including the 5-axis machine, with data for the remaining work entered at the controls on the shopfloor.

“Essentially, the Hurco software is an inexpensive way of preparing components for 3+2-axis machining. It is like an extra CAM seat, but costs vastly less than the £50,000 purchase price and £5,000 annual maintenance of one of our top-end CADCAM packages alone.”

Cycles currently being run on the Hurco 5-axis machine contain no ISO content generated in the CADCAM systems at TGM, although it could be included via the NC Merge capability in WinMax. There are no plans to put fully interpolative 5-axis jobs on the machine either, but that would also be possible with a suitable post processor.

The Hurco VMX42SRTi, with its more than one-metre X-axis travel and 610mm movement in Y and Z, is of ideal size for producing smaller parts for Airbus A350 wings, such as ribs, intercostals and brackets. All components are aluminium except for one, which is machined from titanium billet.

Over two-thirds of TGM’s throughput is destined for Airbus, with the remainder going mainly into the Boeing supply chain, notably for the 787 Dreamliner. This Prime’s build rates are also rising, so all of the machining centres at Preston, including the Hurcos are very busy.

“One advantage of the Hurco 5-axis SRTi design is that the fifth axis is provided by a ±90° swivelling spindle head, so you do not lose Z-axis travel as on a machine with a trunnion-mounted rotary table,” explains company operations director, Steve Holmes. “The configuration fitted well with our need to produce 40 Airbus T-pieces per month that are over 30cm tall.

“The other thing we like about the machine is that we can ignore the flush rotary table and lay a large component across the full 1.27m fixed table for 3-or 4-axis machining. Alternatively, there are Op 1/Op 2 opportunities. The machine provides a lot of versatility.”

Kitamura HX300iG CNC HMC, 12" x 12" Pallets, Full 4th Axis Table, 18.1" x 20.1" x 22.0" Travels, CAT40 BIGPLUS Taper, 15000rpm Spindle Speed, 50 Station ATC, Work Probe, Laser Tool Probe, Through S...

21" x 16" x 19" X/Y/Z Travels, 10000rpm Spindle Speed, CAT-40, 20 Station ATC, Full 5-Axis Rotary/Trunnion Style Table, Hurco WinMax CNC Control, Loaded with Hurco Software Options!

For Sale: 2017 Haas VF-2YT CNC VMC, 8100rpm, CAT40, 30" X-Axis Travel, 20" Y-Axis Travel, 36" x 18" Table Size, 8100rpm, CAT-40, Chip Auger, Through Spindle Coolant System, 24 Station Side Mount Tool Changer, Programmable Coolant Nozzle, Remote Jog Handle. Machine is in plant and under power in Detroit Michigan Area. We are helping the original owner sell the machine. Priced at $59,900. Call Don at 616-916-5990 or email me don@hindleymts.com for a full quotation.

Hurco VM-1 CNC Vertical Machining Center "Plastic Cutting Machine" New 2007 ***New CPU Control and video board installed by Hurco 7/22*** New LCD Monitor, Machine is in Excellent Condition! Extra ...

8613371530291

8613371530291