hv6 rotary table free sample

If the charts for your table are anything like the ones going the rounds for "Other Makes" being sold,you might be as well off without them and try pot luck,or buy a Lotto Ticket.. The errors in these charts have to be seen to be believed.

When you say a chart, what do you want it to tell you, especially as it doesn"t have any plates? Obviously one turn is 4 degrees, and one division a tenth of a degree. As it has a 90 tooth wheel, any tables for a 90 tooth wheel will apply such as those for the Myford DH, of which I have a copy somewhere. That would help you if you had the plates. But actually it"s easy to work out without the tables.

I had no charts with my rotary table (good price, second hand, a long time ago). I have no wish of any charts, especially after reading of the errors here and elsewhere.

It was cutting a 13T gear that highlighted the errors in the Vertex HV6 chart. And, if i was to repair my smash up, I HAD to find a way of correcting things!

Possibly, amending the Ratio formula in the spreadsheet, would enable a chart to be produced for Rotary tables / Dividing Heads with different ratios, such as 40:1 which seems to be a popular one.

Possibly, amending the Ratio formula in the spreadsheet, would enable a chart to be produced for Rotary tables / Dividing Heads with different ratios, such as 40:1 which seems to be a popular one.

Yes indeed,I was refering to the charts,sorry if I caused any misunderstanding. The tables sometimes have their own problems ! How do I know ? Dont even ask !

Have just spent the last couple of hours copying the table of possible divisions with a 90:1 ratio device, onto my PC from Harold Hall"s book on Dividing, Workshop Practice Series No 37. (Might come in handy one day)

If you want to know the number of holes on the plates supplied with the HV6, (which is also 90:1) please PM me, and i will supply the details for each of the three plates, (and the extra two that MAY, one day, be made to supplement) They can be made in an enlarged form to fit your Excel, and you will then be in business.

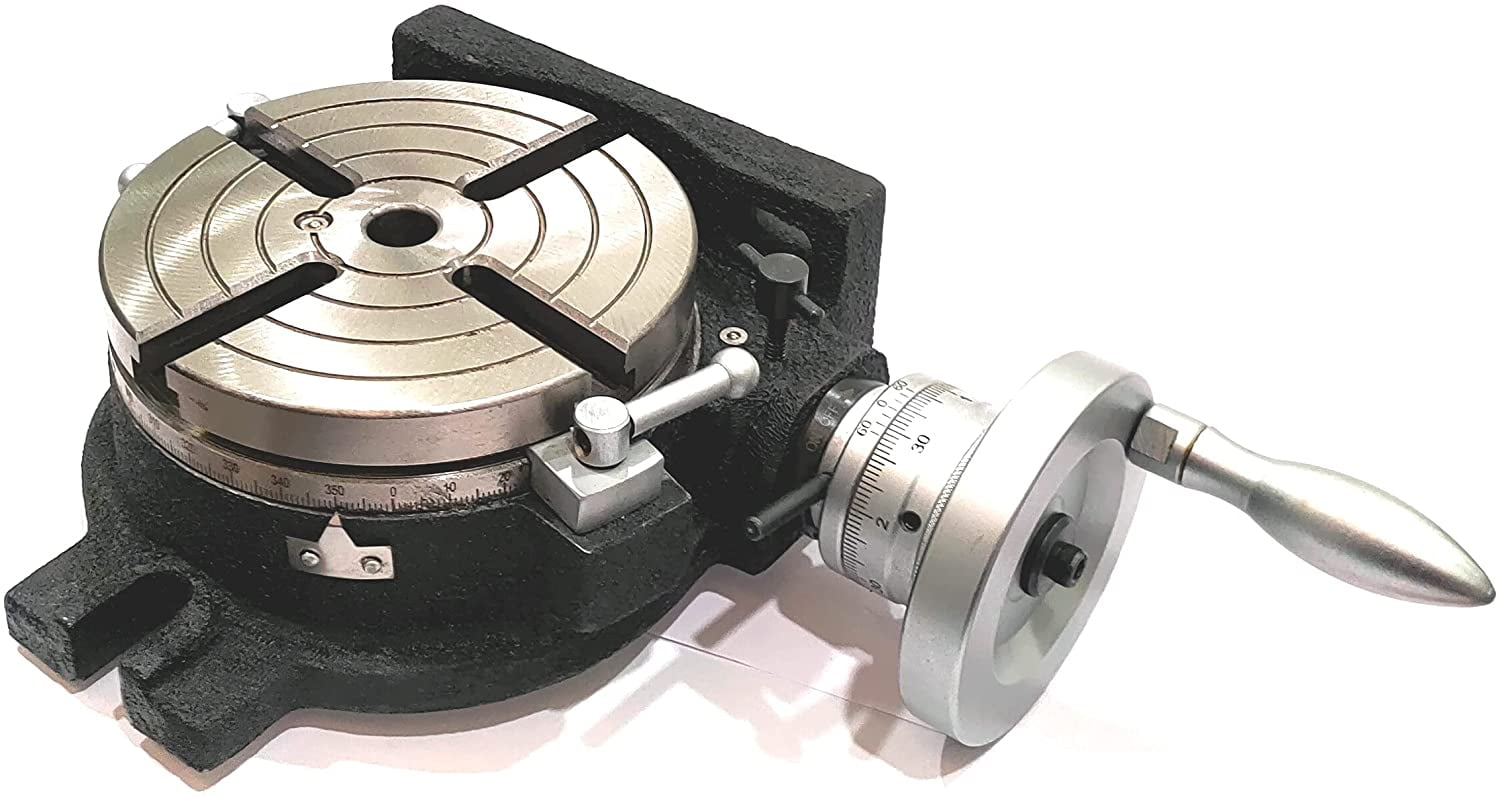

On the HV6-type RT removing the winding handle reveals 3 screw holes that hold the plate mechanism. The mechanics are quite simple - you add a sort of clock pointer to the existing handle that allows you to index a peg into holes drilled in a dividing plate. All it does is help you keep count when keeping count isn"t bleeding obvious. Like cutting a gear with say, 27 teeth, you have to repeatedly do things like "turn the handle completely 4 times and then go past 7 extra index holes" to get the right angle. The tables tell you which plate and set of holes are needed to achieve a given tooth count; the clock pointer follows the position of the extra indexing so you don"t forget where the new start point is.

Easier to do than describe but I make mistakes galore. Instead I built a stepper-motor controlled by an Arduino to do the maths and the winding. It"s just as easy to set up, you don"t need any tables or thinking, and it never gets bored and loses the plot like I do.

Kaka Industrial HV-4, 4”Horizontal Vertical Rotary Table Rotary table TSL Vertical & Horizontal MT3 Center Sleeve Rotary Table 3 slot Precision Milling Table 360 Degrees Precision Rotary Table

8613371530291

8613371530291