hypoid gear rotary table brands

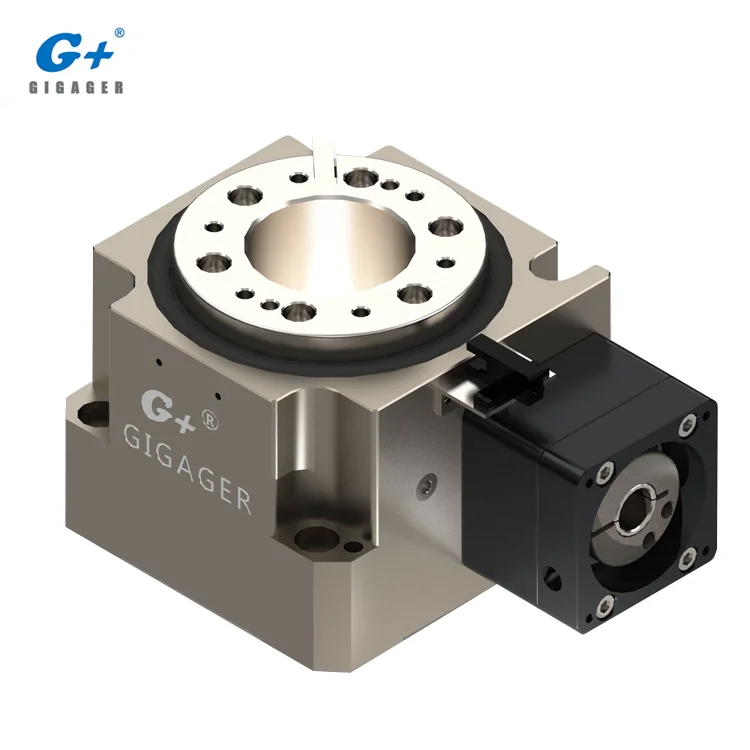

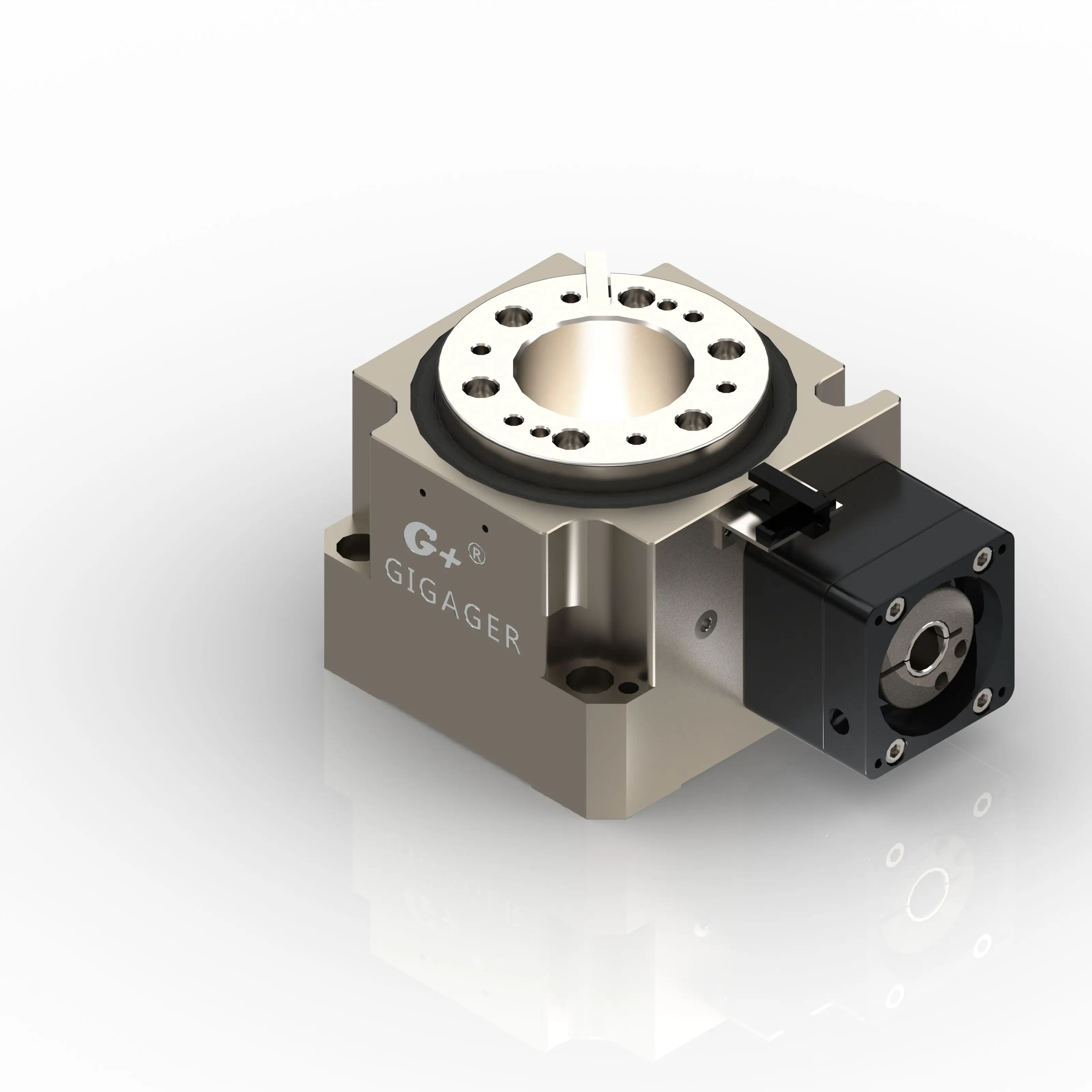

Hypoid Hollow Table is a kind of gearbox integrated right angle gearbox and Hypoid gears, featured with high torque, high gear ratio, high IP grade, high precision, low wear.

Hosea provides a diversity of Hypoid gear rotary tables for customers to choose from, our Hypoid gear rotary tables with stable index accuracy and high transmission efficiency. Moreover, they are easy to adjust. Please feel free to contact us as you are interested in our products detail!

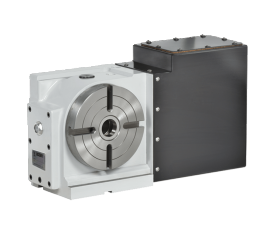

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

Guangdong Saini Intelligent Equipment Technology Co,Ltd. is a professional manufacturer integrated with production, R & D and sales for more than 10 years in China. We supply high precision hollow rotary actuator, harmonic drive gearboxes, high precision planetary gearboxes, 90 degree gearboxes ( for servo motors and stepper motors), right angle hollow reducer, high precision alignment platform, etc.

Hypoid Gear Rotary Table is a kind of gearbox integrated right angle gearbox and Hypoid gears, featured with high torque, high gear ratio, high IP grade, high precision, low wear. It adopts sliding mode to rotate, the transmission precision can reach 30 arc seconds, the transmission efficiency is up to 96%; the gear geometric tolerance ≤ 0.002mm, up to JIS0 level standard. Hypoid Rotary Table also called High Torque Rotary Stage, Hypoid Hollow Rotary Stage, Right Angle Hypoid Gearbox, etc.

The turntable is a rotating plate at the bottom of the rig that turns the drill string clockwise. The rotary table has four or six-sided bushings and a drill string attached around a keel drive that transmits power from the platform drive system to the drill string and drill bit. Since the power supply connects the rig to the rotary table and the drill string, it can be described as a coupling. Most drilling rigs have a rotary table as the primary drive of the drill string, but overhead drive systems that provide continuous rotation of the drill string replace rotary tables, keel bushings and general drives through a trenchless conversion. Construction requirements. The drive bogie is used on top-drive platforms, meaning the drive motor is on top of the platform. Drill string segments are first attached to the bottom of the well. As the drill string segments enter the well, additional drill string segments appear

Rotary tables are used for precision metal work. They are usually made of a solid base that can be attached to another bracket. The table is a disk that rotates freely or with the help of a spiral (hand crank).

The rotary table is a disk-shaped metalworking device that enables precise positioning of the workpiece. It allows the metalworker to cut or drill the workpiece at precise intervals vertically or horizontally around a fixed axis. The turntable can be controlled both manually and digitally by computer. Some types of rotary tables are designed to be used with indexers or separators for special operations. A rotary table used with one of these positioning plates is often called a dividing or indexing head.

The Rotary tables is usually a sturdy base that can be attached to a separate stand or table. This device is basically a rotating disc that holds the workpiece in place while cutting or drilling. The disk portion of the rotary table can be freely rotated or rotated for indexing operations by means of an attached control lever known as a worm wheel. Tables used in precision operations are usually turned with a duplex type helical wheel to compensate for clearance. Rotary tables used in automated metalworking processes are connected to a digitally controlled computer.

Rotary tables are mostly used in a flat position with the table axis vertical. Sometimes they are installed with the shaft pointing horizontally so that the suppository can be used to support the free end of the workpiece. When this device is attached to the secondary table, the workpiece can be centered on the axis of the rotary table, which is then centered on the axis of the cutter. In this configuration, the axes of the rotary table, secondary table and cutter are coaxial to facilitate concentric cutting operations. This configuration also allows the secondary table to be moved to drill evenly spaced holes in the workpiece.

Rotary Table offers an unparalleled combination of good accuracy and high load capacity. These rotary stages utilize a precision worm gear with the worm “flexed” against the gear to ensure a proper mesh. This feature provides high repeatability with very smooth operation. Additionally, the rotary stages incorporate an oversized pre loaded cross roller bearing, offering exceptional stiffness and load capacity.

Manufacturer of spur Gear, spur gears, automobile Hypoid gears, diesel engine gears, automobile gears, motocycle gears, car transmissions, springs, spring raise suspend frames, metal products, forgings. It has passed ISO9002:9004 certification.

Hangzhou Ocean Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, bearings, Gear, gear rack, belt, sulzer loom spare parts, rapier loom spare parts and other loom spare parts.

Hangzhou Xingda Machinery Co., Ltd. specializes in the development, manufacture and sale of metal machining. Our main product, MNRV worm Gear speed reducer has reached the advanced techique index of the congeneric European and Janpanese products. We also accept orders of non-standard products, such as gears, shafts, punching parts and so on according to customers" drawings or samples.

Ningbo Kingbell Powder Metallurgy Co., Ltd. specializes in manufacturing various of powder metallurgy components, which have more than 1500 items, including structure parts which have complex shapes, high mechanical & physical performance and accuracy demands, gears, oil pump rotors and so on.

Founded in 1995 and renamed in 2006, Shenzhen Chaojun Plastics and Mould Co., Ltd has been working as a well-known plastic gears, Gear boxes ( speed reducer), plastic parts & products manufacturer for more than 11 years in China. Now we own precise Gear machining, tooling and testing instruments like Japan Sodick EDM machine , Japan OKK CNC machines, Mitsubishi EDM machines,laths,milling machines grinding machine for making the mould and and 3-D vision measuring system and Gear rolling test for checking the moulded products, advanced brand injection machines like battenfeld do injection etc. If you are a design engineer searching for a development partner or a corporate purchaser researching price competitive plastic/ mould supplier, we provide total solutions which are cost-effective, manufactured...

Zhejiang Dafa Gear Co., Ltd. specialized in producing the engine gears of automobile and motorcycle who found in 1988. During these more than 10 years, we are always persist in taking the market as the guidance and set up company"s system for independence, innovation, science and technology. It makes DAFA developped continuously and quickly so that have today"s splendid success.

Zomax Group has gone through the attestation of ISO 9001:2000 and ISO/TS- 16949:2002 quality system. It has the authorization to import and export products independently. The business covers car transmission car Gear, motorcycle Gear, car spare parts, garden machinery, real estate, foreign trade and so on.

Hypoid Rotary Table is a kind of gearbox integrated right angle gearbox and Hypoid gears, featured with high torque, high gear ratio, high IP grade, high precision, low wear. It adopts sliding mode to rotate, the transmission precision can reach 30 arc seconds, the transmission efficiency is up to 96%; the gear geometric tolerance ≤ 0.002mm, up to JIS0 level standard. Hypoid Rotary Table also called High Torque Rotary Stage, Hypoid Hollow Rotary Stage, Right Angle Hypoid Gearbox, etc....

Saini Intelligent provides wide ranges of Hollow Raotay Table and their Combination Axis. We provide the following Hollow Rotary Table and its combination.

For some application, the bigger gear ratio are needed, it can be achieved by combination of Hollow Rotary Table with Planetary Reducer or Right Angle Gearbox. Below is a combination list for different gear ratio.

The Hollow Rotary Table could be applied for many application like Rotating Platform, Laser Marking machine, Gyro Test, Gravity Sensor Test, Electronic Compass Test of mobile phone and other precise electronic product. It also can used for robot arm joint, automation production line, testing device, laser cutting, etc.

Key products on the stand include the highly-regarded Hypoid Rotary Table which adopts hypoid gear making the high torque transmission possible. Hypoid Rotary Table is a kind of gearbox integrated right angle gearbox and Hypoid gears, featured with high torque, high gear ratio, high IP grade, high precision, low wear. The precision of repeatability are less than 10 arc seconds, the transmission efficiency is up to 96%; the gear geometric tolerance ≤ 0.002mm, up to JIS0 level standard. Hypoid Rotary Table also called High Torque Rotary Stage, Hypoid Hollow Rotary Stage, Right Angle Hypoid Gearbox, etc.

Saini Intelligent also presented a series of rotary solutions, such as hollow rotary table, right angle rotary reducers, etc. Besides, a series of Precision Positioning Table also presented in the booth which draw great attention from the visitors.

Swing head is suitable for any spindle from any brand, the clockwise and counterclockwise for swing angle and multi-axis elliptic arc machining application.

Cameron rotary tables range from 27 1/2 in to 60 1/2 in and feature a large oil capacity that adds to the unit"s durability. The rotary table includes a forged-steel fabricated housing and a heat-treated forged-steel turntable. Each rotary table is supplied with spiral-bevel, induction-hardened gears and two independent ratchet-type locks, with lever access from the top to lock the table in position.

8613371530291

8613371530291