indexing head vs rotary table made in china

Depending on what you need to index and how often, a lot of numbers can be done easily on a rotary table (anything that"s a factor of 360 is really easy), which I find convenient for things like drilling holes on a PCD so use for all sorts of jobs. It is worth looking at the gear ratios of dividing heads and of rotary tables - I didn"t and have ended up with a table with an odd ratio and an odd minor increment on the vernier scale (I think it"s 25s seconds so even getting whole minutes is impossible).

A lot of rotary tables can easily be converted to do dividing by modifying or replacing the handle with dividing plates and an indicator arm, so if it"s something you might need occasionally and not to start with, it might be worth starting with a rotary table and converting it later as required. It is also possible to use something with the right number of holes (or indentations like a gear) on the spindle with the item to be machined and index from that by making a detent to fit the holes/teeth. For example, if one needed to make a 127 tooth gear for metric threading on a SB 9" because such a thing were not available where they live, but it was possible to get a 127 tooth gear to fit some completely different application (different DP or pressure angle, possibly a module gear rather than a DP gear) then that could be attached to the same shaft as the gear blank to be machined and used to index the blank for each cut. You don"t even need the worm drive of the rotary table for that, just some thing to lock the shaft in each postion.

Some dividing heads (universal) have advanced functionality beyond indexing using plates, they can be fitted with a compound gear train to acheive numbers beyond the scope of the plates, or to connect to a feed (on a milling machine generally) which enables cutting of spirals (i.e. cams).

I am not sure if 15:1 is a useful ratio for a dividing head, it"s too coarse for a rotary table at 24 degrees per rotation (72:1 is more normal, 5 deg per rotation, I think mine is 90:1) but that"s not necessarily such an issue for a dividing head. I would say if you have the parts it"s a nice project. 6304 bearings are not hard to find - I use them for some of my kite buggy wheels, I think they are about £6 each in stainless, fortunately I don"t need those wheels for the Euros next week because all 6 bearings seem to be seized, I will need 6 off 6004"s for the wheels I will be using though - none are seized but they aren"t feeling very smooth, probably got some sand in!

I"m not sure if I really answered your question, for occasional use you can get away with a rotary table as a dividing device, possibly vice verse although most dividing heads are not as easy to use in both horizontal and vertical orientations as most rotary tables (exceptions on both sides!), but if you are looking for something to do with the worm drive you have I reckon it would probably suit a dividing head better. I"ll try andremember to look in my dividing book later and see what ratios are commonly used - unless you can find the same info on the internet sooner

The way that I was taught is that you have to make up a test bar. Take a piece of 12" by 1" roundbar, drill two centre holes in it"s ends, on your lathe and take a parallel cut between centres. Once you have corrected the error of your lathe and both ends of the test bar measure the same diameter, you can then use the test bar in your milling machine as well, to set the tailstock of the dividing head as well as the alignment of the bar to the table axis.

You can get a set of plates for your rotary table that allow you to index positions, and you put them on the handle.. so its geared down 40:1 or 90:1, And the plates have all kinds of prime numbers all over em, so you can basicly do a billion diffrent divisions. Usally something like 1~100 devisions and lots of non prime numbers after that. "Devider arms" make finding the next hole in the seqence much easyer and efficent.

Buy a horzontal/vertical rotary table, And buy one of the better brands. .some of those cheap ones are pertty crappy. I got a phase II and it looks very impressive and seems well built with nice features.

You don"t need an angle table yet either. First off, usally you can just mount the part on an angle in the vise, or tilt the head, clamp it down on an angled part, whatever.

PS: No rotary table will be doing spirals unless its linked to the X or Y axis of your mill (or has its own X or Y axis). Some have a large geartrain option to facilitate this.. but how often do you really need to make spirals? And linking it up isent exactly easy. since you"ll need to mount a geartrain to your mill and likey some shafts and such.

as gear plate A is supported , the rotation plate rotates smoothly and accurately without vertacal moving error. *when gear plate a completes indexing ,gear plate C goes up to match gear plate A and B ,clamping the index table. *gear plate C has sufficient space to completely match gear plate A and B ,the pressure angle of 30 degree of each gear focuses gear plate A and B accurately ,keeping high accuracy even after long term using.

As for the term "hinge", I made that up. The one I am thinking of is still called a rotary table; there are two parts ... the rotary table, and then the base. The two are connected on one side by the hinges (just two tabs with holes, a rod, and the horizontal hole in the base that the rod goes through). The tab parts fit over the edges of the base and the rod slides through the tab holes and the horizontal hole in the base.

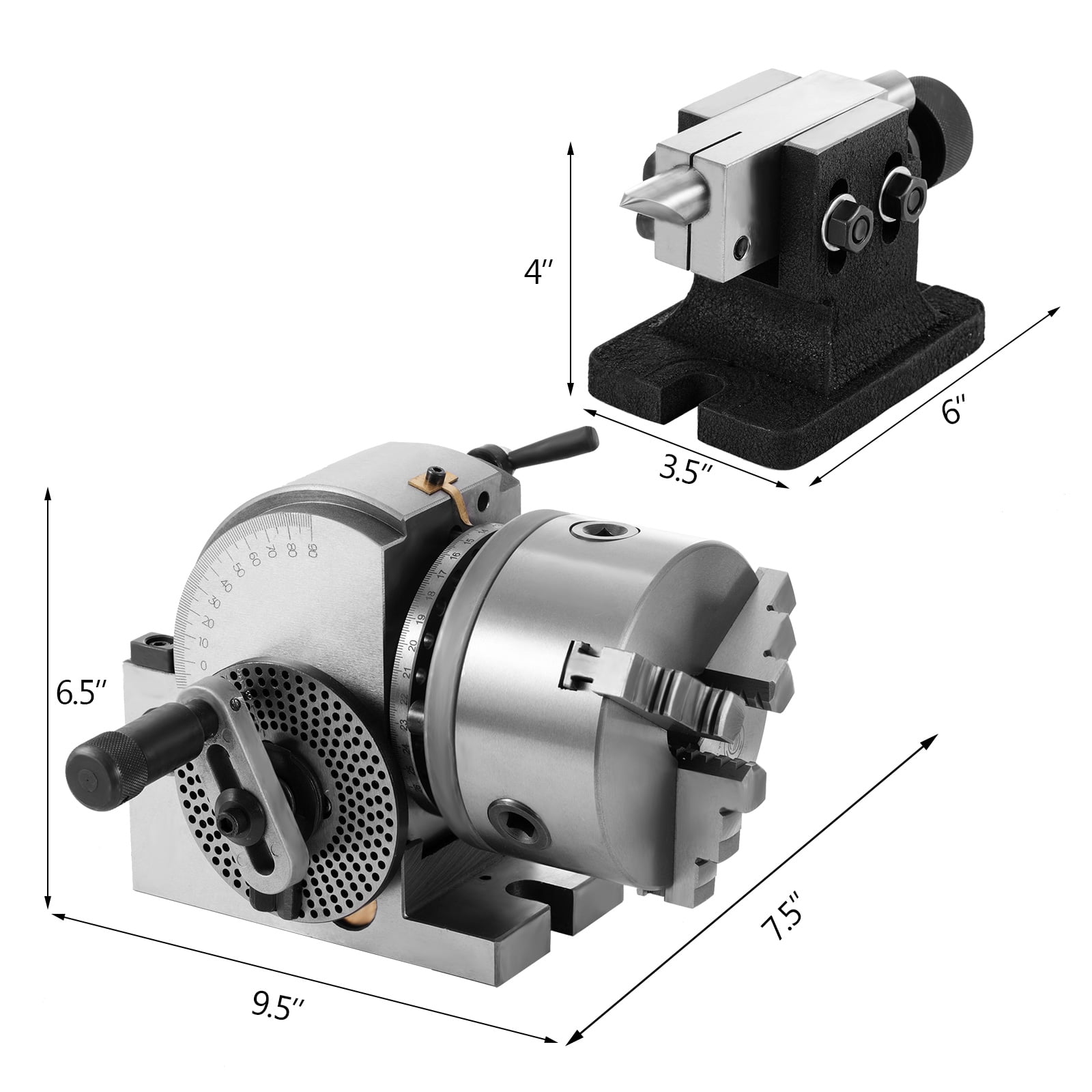

Even with a rotary table that is not hinged, you can mount it vertically and in that position you might call it a dividing head because you can usually buy a tailstock for it, and, for certain ones the dividing plates.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

8613371530291

8613371530291