kelly rotary table factory

As one of important parts of drill rig, ZP series of rotary tables are widely used to rotate drill equipment and hold the weight of pipes in well. They are designed and manufactured according to API Spec 7K “Specification For Drilling Equipment”.

Mitchell Rotary Rig #21 is the newest and most advanced rig in the Illinois Basin. It has depth capabilities of up to 12,500 feet (3.81 km) total vertical depth (TVD) and full horizontal and directional capabilities.

Rig #21 has a 17 foot (5.2 m) Kelly Bushing Height (KB) and is outfitted with an 800 Bbl steel pit system that is equipped with dual shaker technology as well as 1,000 GPM mud cleaning capabilities. This rig can be outfitted with up to two 1,005 hp triplex pumps with 5,000# fluid ends. Rig #21 has handling equipment for slim hole and regular hole drill strings. It is outfitted with a full stack blowout preventer (BOP) and can also utilize a rotating head if requested.

Mitchell Rotary Rig #21 has the capability to drill the depths required Carbon Capture Sequestration and Enhanced Oil Recovery (CCS-EOR) technologies.

Rotary Table is an important part of drilling rig. Its function is to slow down a pair of bevel gear pairs during drilling operation, so that the turntable can get a certain range of speed and torque output, and drive drilling tools for drilling operation.

The turntable should be used when lifting transport tools and equipment, and can only be hoisting from the four corners of the lifting hole, not allowed to drag directly on the ground.

Start shopping at Alibaba.com to discover wholesale rotary kelly bushing at incredible prices.Browse through rotary kelly bushing for any type of vehicle.Bearings can be produced from a broad variety of materials, such as different steel, rubber, plastic, brass, and ceramic. These materials, each having their own benefits that render them appropriate to specific operations, including noise level, mass, weight, capacity, and resistance, and a series of options to match your individual needs and requirements.

However, getting a bushing that is properly functioning is critical to a comfortable and smooth ride, as they maintain the car in good conditions. We have variously available bushings including, grounding bushing, polyurethane bushings, energy suspension bushings, brass bushings, and even drill bushings.Buy our selection of rotary kelly bushing now. For those of you who are looking for quality wholesale rotary kelly bushing at a bargain price, well then you should look no further! At Alibaba.com, you may find a great array of quality automotive accessories and everything at an awesome price.

FYPE Rigid Machinery is one of the leading China manufacturers and suppliers in oil and gas industry. Our company now brings you high quality and competitive price rig drilling rotary table manufacturer, rotary table for sale, which is widely used in oilfield. And quick delivery is also offered, please be free to contact our factory.

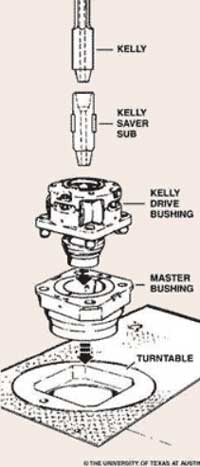

The kelly is a primary link between the drilling rig’s surface equipment and the bit, and is therefore a critical component of the rotary system. Although top drive systems have replaced kelly/rotary table combinations on many rigs, some knowledge of their manufacture and operation is useful.

Their angled surfaces, or drive flats, are designed to fit into a drive roller assembly on the kelly bushing, so that as the rotary table turns to the right, the kelly turns with it. To allow for normal right-hand rotation of the drill string, kellys have right-hand threads on their bottom connections and left-hand threads on their top connections.

The American Petroleum Institute has established manufacturing and design standards for kellys, and has included them in the follwoing publications:API RP 7G, Recommended Practice for Drill Stem Design and Operating Limits.

For a kelly to be efficient in turning the drill string, the clearance between its drive flat surfaces and the rollers in the kelly bushing must be kept to a minimum. Kellys most often wear out due to a rounding-off of the drive corners, as shown in Figure 1 (new kelly with new drive assembly) and Figure 2 (worn kelly with worn drive assembly).

For minimal rounding, there must be a close fit between the kelly and the roller assembly, with the rollers fitting the largest spot on the kelly flats. Manufacturing techniques and rig operating practices play important roles in determining this fit.

Both square and hexagonal kellys are manufactured either from bars with an “as-forged” drive section, or from bars with fully-machined drive sections. Forged kellys are cheaper to manufacture. But machined kellys tend to last longer because:Unlike forged kellys, machined kellys are not subject to the metallurgical process of decarburization, which leaves a relatively soft layer of material on the drive surface that can accelerate the rounding process and increase the potential for fatigue cracks;

To minimize rounding, rig personnel should follow these guidelines (Brinegar, 1977):Always use new drive-bushing roller assemblies to break in a new kelly.

Frequently inspect and periodically replace drive assemblies to ensure that clearance and contact angle between the kelly and the rollers is held to a minimum;

Fatigue failures are seldom a problem with kellys because of the high-quality steels used in their manufacture. Nevertheless, kellys should be regularly inspected for cracks and other signs of wear, particularly within the threaded connections, in the areas where the flats join the upper and lower upsets and in the center of the drive section.

In general, the stress level for a given tensile load is less in the drive section of a hexagonal kelly than in the drive section of a square kelly of comparable size. Hexagonal kellys are thus likely to last longer than square kellys before failing under a given bending load.

Kellys can become crooked or bent due to improper handling. Examples of mishandling include dropping the kelly, misaligning it in the rathole and thereby exerting a side pull, using poor tie-down practices during rig moves, not using the kelly scabbard and improper loading or unloading techniques. Depending on where a bend is located, it may cause fatigue damage not only to the kelly but to the rest of the drill string, and can also result in uneven wear on the kelly bushing.

Unusual side motions or swaying of the swivel are good indicators of a crooked kelly. A good field service shop has equipment for straightening bent kellys, making this an easily-corrected problem.

A kelly saver subshould always be run between the kelly and the top joint of drill pipe. This protects the kelly’s lower connection threads from wear, as joints of drill pipe are continually made up and broken out. A saver sub is much less expensive and much easier to replace than the kelly itself, and it can also be equipped with a rubber protector to help keep the kelly centralized and to protect the top joint of casing against wear.

A kelly cock is a valve installed above or below the kelly, which prevents fluid from escaping through the drill string if the well should begin to flow or “kick.” As an extra well control precaution, an upper kelly cock (having left-hand threads) should be installed directly above the kelly, while a lower kelly cock (having right-hand threads) should be installed below the kelly. Installing two kelly cocks ensures that at least one of them is always accessible, regardless of the kelly’s position.

Automatic check valves, designed to close when the mud pumps are shut off, are also available, and can be installed below the kelly to prevent mud from spilling onto the rig floor during connections.

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

Kelly is the drive part of whole drill string, it transmit the torsional energy from the rotary table to the bit in the bottom of the hole. Threads is phosphated, and each Kelly is furnished with a pressed steel thread protectors. Kelly shall be either square or hexagon and conform to the size and dimensions as per API Standard.

Within those famous China oil and gas rotary kelly manufacturers, GAOTON is a professional such supplier, producer and provider, welcome to wholesale petroleum and oilfield API rotary kelly from our factory.

8613371530291

8613371530291