kelly rotary table price

Start shopping at Alibaba.com to discover wholesale rotary kelly bushing at incredible prices.Browse through rotary kelly bushing for any type of vehicle.Bearings can be produced from a broad variety of materials, such as different steel, rubber, plastic, brass, and ceramic. These materials, each having their own benefits that render them appropriate to specific operations, including noise level, mass, weight, capacity, and resistance, and a series of options to match your individual needs and requirements.

However, getting a bushing that is properly functioning is critical to a comfortable and smooth ride, as they maintain the car in good conditions. We have variously available bushings including, grounding bushing, polyurethane bushings, energy suspension bushings, brass bushings, and even drill bushings.Buy our selection of rotary kelly bushing now. For those of you who are looking for quality wholesale rotary kelly bushing at a bargain price, well then you should look no further! At Alibaba.com, you may find a great array of quality automotive accessories and everything at an awesome price.

Welcome to Pickett Oilfield’s rotary tables web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used rotary tables and rotary equipment to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including rotary tables to choose from at competitive prices. Browse our inventory of rotary tables and rotary table drilling components for sale at competitive rates.

The Hacker International HTD Rotating System is designed and built as an efficient and economical compliment to drilling rigs utilizing a top drive drilling system. Whether a rig build or a retrofit to an existing rig, the Hacker HTD can be designed to fit any application, any size, and is engineered for the most rugged drilling conditions. Hacker International is world renowned for its custom built rotary tables which are being utilized on every continent in the world. We pride ourselves in our innovative designs and our ability to solve specific needs of our customers in each custom rotating system we build.

With a maximum torque of 25k ft. lbs., a rotating speed of 135 rpm’s and with a static load rating of 1250 tons, our 27.5” table is a brute able to withstand harsh drilling conditions but easily controlled by the movement of a joy stick. These high torque variable speed features make this rotating system the perfect complement to your top drive system.

All of our tables are equipped with precision machined spiral bevel gears and heavy duty main thrust bearings to provide long lasting durability. The dual locking system utilizes ratcheting lock pawls that engage the rim of the table assembly. This enables the table to be locked in a single direction or both directions. The entire pinion shaft assembly uses a sealed cascade lubrication system from a large oil reservoir.

What kind of equipment does the actual drilling on a rotary rig? Before rotary drilling became the industry standard, rig crews would attach a sharp tool to a cable and continuously drop the bit onto the ground, gradually gouging out a hole that would have to be cleaned out by hand. Rotary drilling, with the kelly and swivel or top drive, has revolutionized the industry and made the operation more efficient. This comprehensive training manual acquaints the reader with the function and operation of the rotary table assembly, master bushing, kelly bushing, slips, kelly, swivel, top drive, and spinning and torquing devices. The book also covers maintenance for the components. Readable language, clearly labeled illustrations and photographs, a glossary, helpful appendixes, and self-test review questions help the reader to comprehend the material.

Established in the year 1984, Rasson Energy India Private Limitedis an organization engaged in manufacturing and exporting a supreme quality range of Mud Pumps, Rotary Tables, Traveling Hooks, Circulation Systems andother Oilfield Equipments. We are also engaged in offering Fabrication Job of various oil filed equipments like Mud Tank, Bunk House etc. These products are manufactured using high-grade raw material sourced from some of the reliable vendors of the industry. We also employ latest technology & machinery for carrying out production and other related processes. The entire range of products is widely appreciated by the clients for its rugged construction, durable standards, excellent performance and high efficiency.

The cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. The circulating element permits the passage of drilling fluid and uses the hydraulic force of the fluid stream to improve drilling rates.†

The heavy square or hexagonal steel member suspended from the swivel through the rotary table. It is connected to the topmost joint of drill pipe to turn the drill stem as the rotary table turns.†

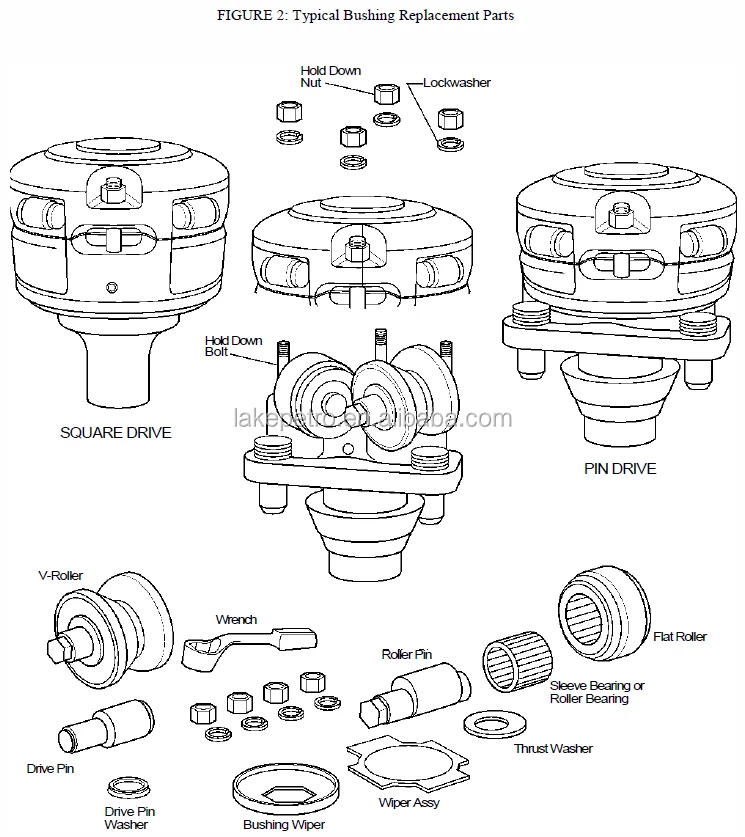

A device fitted to the rotary table through which the kelly passes. It is the means by which the torque of the rotary table is transmitted to the kelly and to the drill stem. Also called the drive bushing.†

A portable derrick capable of being erected as a unit, as distinguished from a standard derrick, which cannot be raised to a working position as a unit.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

The hose on a rotary drilling rig that conducts the drilling fluid from the mud pump and standpipe to the swivel and kelly; also called the mud hose or the kelly hose.†

The principal component of a rotary, or rotary machine, used to turn the drill stem and support the drilling assembly. It has a beveled gear arrangement to create the rotational motion and an opening into which bushings are fitted to drive and support the drilling assembly.

A series of trays with sieves or screens that vibrate to remove cuttings from circulating fluid in rotary drilling operations. The size of the openings in the sieve is selected to match the size of the solids in the drilling fluid and the anticipated size of cuttings. Also called a shaker.†

Wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole or to hold pipe in place. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices that allow the crew to dispense with the manual handling of slips when making a connection. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.†

A relatively short length of chain attached to the tong pull chain on the manual tongs used to make up drill pipe. The spinning chain is attached to the pull chain so that a crew member can wrap the spinning chain several times around the tool joint box of a joint of drill pipe suspended in the rotary table. After crew members stab the pin of another tool joint into the box end, one of them then grasps the end of the spinning chain and with a rapid upward motion of the wrist "throws the spinning chain"-that is, causes it to unwrap from the box and coil upward onto the body of the joint stabbed into the box. The driller then actuates the makeup cathead to pull the chain off of the pipe body, which causes the pipe to spin and thus the pin threads to spin into the box.†

A vertical pipe rising along the side of the derrick or mast. It joins the discharge line leading from the mud pump to the rotary hose and through which mud is pumped going into the hole.†

A rotary tool that is hung from the rotary hook and traveling block to suspend and permit free rotation of the drill stem. It also provides a connection for the rotary hose and a passageway for the flow of drilling fluid into the drill stem.†

The large wrenches used for turning when making up or breaking out drill pipe, casing, tubing, or other pipe; variously called casing tongs, rotary tongs, and so forth according to the specific use. Power tongs are pneumatically or hydraulically operated tools that spin the pipe up and, in some instances, apply the final makeup torque.†

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

A device that turns the drillstring. It consists of one or more motors (electric or hydraulic) connected with appropriate gearing to a short section of pipe called a quill, that in turn may be screwed into a saver sub or the drillstring itself. The topdrive is suspended from the hook, so the rotary mechanism is free to travel up and down the derrick. This is radically different from the more conventional rotary table and kelly method of turning the drillstring because it enables drilling to be done with three joint stands instead of single joints of pipe. It also enables the driller to quickly engage the pumps or the rotary while tripping pipe, which cannot be done easily with the kelly system. While not a panacea, modern topdrives are a major improvement to drilling rig technology and are a large contributor to the ability to drill more difficult extended-reach wellbores. In addition, the topdrive enables drillers to minimize both frequency and cost per incident of stuck pipe.

A rotary table is a mechanical device used in oil fields. It provides clockwise rotational force to the drilling rig and facilitates the process of drilling a borehole. The rotary tables are driven by large chains that resemble huge bicycle chains. They are equipped with a rotary lock that is used to prevent the rotary from turning in a particular direction or even stopping the circular motion. They are used in both onshore and offshore oil wells mainly to transfer the rotary motion to the Kelly drive system.

The outbreak of the COVID-19 pandemic has severely affected the global oilfield rotary table market.Nationwide lockdown imposed by several governments to contain the virus has caused most of the business activities to either slow down or even put to a halt. This has caused a significant decrease in demand for fuel across the globe, thereby affecting the oilfield rotary table market.

Attributed to travel restrictions on national and international transport, the demand for petrol and diesel decreased to a great extent along with the prices of crude oil. This has caused severe impacts on the oilfield rotary table market.

Rapid globalization and industrial development around the world resulted in a steep increase in demand for oil & gas in the market. As a result, the growing number of excavation and production activities of oil & gas companies has acted as a major driver for the growth of the oilfield rotary table market. Moreover, increasing upstream investments by the oil & gas companies and the development of modern drilling equipment add to the growing demand for oilfield rotary table in the market. For instance, Sekal AS, a major international company is offering real-time dynamic monitoring and integrated drilling solutions in the oil & gas industry. Such developments are expected to have positive impacts on the oil field rotate table market. However, the emergence of top drive technology as an alternative along with the fluctuating prices of crude oil might hamper the growth of the global oilfield rotary table market. On the contrary, the growing excavation activities especially in search for shale gas reserves is expected to drive the demand for oilfield rotary tables in the market.

The market in the North America region accounts for a significant share of the global oilfield rotary table market due to increasing investments and the growing number of exploration & production activities of oil & gas companies in the region. The market in the Middle East & Africa region is also expected to witness a lucrative growth due to the presence of high number of oil & gas companies in the region.

Key benefits of the report:This study presents the analytical depiction of the global oilfield rotary table market along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global oilfield rotary table market share.

580 GD Compressor, 5 X 6 Mud Pump, PTO, NO Deck Engine. Rig Was Rebuilt In 2010, New 23" Kelly, New Little Giant Swivel, 2000 Rotary Table, Transfer Case Rebuilt, New 100 Pulldown Chain & New Sprockets, Bowie Inj. Pump, Hyd. Oil Cooler, New Railing On Derrick For Swivel Drives, Mud Pit, 200" Of 2 More Info »

256S2 Leroi Compressor, 5 X 6 GD Mud Pump, PTO, NO Deck Engine. Tophead Drive, Retractable Table, Aux. Lift Line, Sandline, Three Part Main Line, (3) Hyd. Jacks, Weldco Beales Casing Hammer Package Available At Additional Cost. Mounted On 79 4-Axle CCC W/ 290 Cummins. Good Condition.

7 1/2 X 10 G/D Mud Pump, Waukesha Diesel Deck Engine. 32" Mast, 8" Retractable Table, 20" Opening In Table, 23" Kelly, Easy Set-Up Screw Jacks. Mounted On Single Axle Trailer. Good Condition.

5 X 6 Mud Pump, PTO, NO Deck Engine. 3 Speed Stationary Rotary Table, Water End On Pump Needs Gone Through, 23" Kelly, 200" Of Drill Pipe, Drawdown Not In Operation But Can Be Used, 2 Speed Rearend In Truck. Mounted On GMC, w/ V671 Detroit. Good Condition.

471 Detroit Deck Engine. 58" Derrick, 35" X 4" Kelly, Double Drum Drawworks Rebuilt In 2010, Drilling Platform & Side Walk Ways W/ Guard Rails, 7 1/2" Rotary Table Rebuilt In 2011, Air Clutches, Front & Rear Leveling Jacks, Derrick Lifting Cylinders Rebuilt In 2010, Rebuilt Driveline W/ New Clutch Pads In 2010, Deck Engine More Info »

256S2 Leroi Compressor, 5 X 6 GD Mud Pump, 318 Detroit Deck Engine. 10" Retractable Table, Rod Rack, 37" Derrick, (3) Hyd. Jacks, New Kelly Bar, Hydro-Frac Pump, 5 Speed Rotary Transmission, Cable Drawworks, 9 GPM Bean Water Injection Mud Pit, 500" Of 4 1/2" X 2 7/8" IF Drill Pipe, 20K LB. Front Axle, More Info »

Parco 131" X 550,000 Static Hook Load Mast, OIME SL-5 Drawworks W/ (2) 520 HP Cat Engines, Allison 606L Transmission, WPT 4-24 Water Brake, Parco 18.5" Split Level Substructure, 10X30" Doghouse, (2) Weatherford MP9 Triplex Mud Pumps W/ 398 Cat Engine, (2) 5X6 Centrifugal Chase Pumps, 2 Pit 900 Barrel Mud System, 27 1/2" Rotary More Info »

500/125 Compressor, 671 Detroit Deck Engine. 46" Mast, 33 1/2" X 4 1/2" Kelly Bar, 7 1/2" Stationary Table, Rod Box, Leveling Jacks, Work Platform. 5 Speed Transmission To Slow Down Drawworks. Mounted On 1978 Ford 900, w/ 534 Gas.

5 1/2 X 8 Mud Pump, PTO, NO Deck Engine. Range II Derrick, Double Drum, 8" Retractable Table, Centrifugal Charge Pump, Hyd. Rod Spinner, Hyd. Chain Pulldown, Air Clutches, Weight Indicator, Racking Board, 25 Ton Block, Service Winch, Cathead, (4) Hyd. Jacks, (2) New Front Jacks, Mud Pump Rebuilt, Gearboxes Rebuilt, Includes 3 6" Drill More Info »

350 Cummins Deck Engine. 31" Brakes, Jaw Clutches, Hydrostatic Rotary Table, Drawworks Rebuilt, Cathead, Set Of Tongs, No Derrick. Mounted On Trailer.

5 X 6 Mud Pump, PTO, NO Deck Engine. Retractable Rotary Table, Chain Pulldown, (3) Hyd. Jacks, Rod Rack, Manual Clutches, Mounted On 1977 Ford, w/ Diesel.

GD Compressor, 5 X 6 Mud Pump, PTO, NO Deck Engine. Manual Clutches, 7 1/2" Stationary Table, Rod Rack, Pulldown, (2) Hyd. Jacks, 200" Of 2 7/8" Drill Pipe, Mounted On 1991 Mack, w/ Mack Diesel. Good Condition.

5 X 6 Mud Pump, PTO, NO Deck Engine. (4) Hyd. Jacks, Hyd. Pulldown, Rebuilt 5 1/4" Rotary Table, Rebuilt Drawworks, Sandline, Rod Rack, Manual Clutches, 260" Of 20" Drill Pipe, Mud Pump Fluid End Just Rebuilt. Mounted On 1988 Chevrolet, w/ 3208 Cat. Good Condition.

53" Mast, No Mud Or Air On Board, 7 1/2" Retract Table, Hyd. Pulldown, Sandline, 4 1/4" X 23" Kelly, Rod Rack, (3) Hyd. Jacks. Tooling Available, Mounted On 1979 Kenworth, w/ 6V92 Detroit. Good Condition.

4 Cyl. Cummins Turbo Diesel Deck Engine. 46" Derrick, 7 1/2" Rotary Table, 42" X 3" Fluted Kelly, Air Clutches, Swivel Chain Pulldown, Sandline, King Gooseneck & Swivel, (2) 4 Line Failing 2500 Traveling Blocks, 4 Sheave Crown Block, Hyd. Leveling Jacks, 360 Gallon Fuel Tank, 4 Speed Rotary Table Trans., Drillers Skid & Controls. More Info »

500/250 Leroi Compressor, 5 X 6 Mud Pump. (3) Hydraulic Leveling Jacks, 5 1/4" Retractable Rotary Table, Double Drum Drawworks W/ Mechanical Clutches, Rod Rack, 23" x 3 3/8" Kelly, Hydraulic Pulldown, Little Giant Swivel, 200" Of Drill Pipe. Mounted On 1978 Ford, w/ Diesel. Good Condition.

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

BADGER 1250(Ref#4451N) Manufactured 1995, 5 x 6 mud pump, mounted on International truck with diesel engine, hydraulic pulldown, air clutches, 23" kelly Price: $170,000

BADGER 1250(Ref#4418) Similar to Midway - Manufactured 1987 - 2 available - excellent condition, 5 x 6 duplex mud pump, 7.5" fixed rotary table, chain pulldown, rod box, pipe slide, winch, kelly, kelly bushing, handling tools, Mounted on Ford 9000 tandem axle with Detroit 8V92 Price on Request

BADGER 1250(Ref#6983N) Manufactured 1980, Spicer PTO, mounted on 2001 International with N14 Cummins engine, all new hydraulics, Gardner Denver 5x6 mud pump, 667 GD air compressor, 2000 DSM table, mechanical clutches, hydraulic pulldown, 2 rear hydraulic leveling jacks, 200" of new 2 7/8" x 20" drill pipe, all tools Price: $165,000

BADGER 1250(Ref#8508R) Manufactured 1980, Leroi air compressor, Failing 5 x 6 mud pump, foam tank with injection pump, fixed rotary table, fluted kelly, hydrauluic pulldown, mounted on 1979 tandem axle International truck with 290 Cummins engine, 4 leveling jacks, 400" of drill pipe, mud pit, sitting and needs some work Price: $80,000

BADGER 1250(Ref#2019N) Manufactured 1980, 1000 drawworks, Spicer PTO, mounted on 1980 International Paystar 5000 with all wheel drive, with DT466 diesel engine, 13 speed transmission, 35" mast, 5 x 6 Gardner Denver mud pump, LeRoi 50S2 air compressor, 8-1/2" Speedstar stationary rotary table, hydraulic pulldown, mechanical clutches, 2 hydraulic leveling jacks, breakout tongs, tools, 300" of 3-1/2" x 20" flush joint drill pipe, good condition Price: $145,000

JOY2500 DRILLING RIG(Ref#14157R) Double drum drawworks with air clutches, 17-1/2" rotary table, Gardner Denver 5 x 10" duplex mud pump, mounted on 5 axle Mack Cabover chassis, currently being refurbished Price: $325,000

WESTERNGEOPHYSICAL EXPLORATION RIG(Ref#12981) mounted on single axle truck with Ford 350 rebuilt gas engine, PTO, 5 x 6 mud pump, no compressor, 400" 15" drill pipe, 18" bit, Failing tower, 1 collar, 3 hydraulic jacks, 5-1/4" table Price: $30,000

WESTERN GEOPHYSICAL 1000(Ref#7240T) Manufactured 1954, 1200 gear gase, mounted on 2 wheel drive 1964 Ford F600 2-ton truck, 330 V8 gas engine, 5-1/4" stationary table, hydraulic drawworks, 140" of 15" x 2-3/8 Mayhew pipe, 18" kelly, 3-1/4" round kelly drive, pulldown, 3 line machine Price: $29,500

SHOPBUILT GEO RIG(Ref#13488) mounted on Mack Midliner, PTO, 23" fluted kelly, 5 x 6 Gardner Denver mud pump, rebuilt drawworks, clutches and brakes, new pins and bushings, rebuilt table and PTO, 4 stabilizing cylinders w/hydraulic locks, new hydraulic valves, pump lines and tank, 200" of 2-3/8" Mayhew pipe Price on Request

DAVEYM8W DRILL RIG(Ref#2884Na) Manufactured 1976, mounted on Louisville Ford truck with 54 gas Ford engine, 5 and 4 transmission, new clutch, 38,000# rear, 26-1/2" Kelly bar 4" round, King swivel, 35" tower, 7-1/2" sliding table, 671 Detroit diesel deck engine, 500 cfm/125 psi Davey air compressor rebuilt with less than 2000 hours, water injection system hydraulically operated, 100" of 4" x 20" flush wall drill pipe, can drill to 900", can hold 300" steel PRICE: $35,000

DAVEY M8 DRILL RIG(Ref#2884Nd) Manufactured 1975, mounted on tandem axle Ford Louiville truck with 534 gas engine, 5 x 4 transmission, leveling jacks, 38,000# rear, good tires, 671 Detroit diesel engine, 500 cfm/125 psi Davey air compressor, rod box, 7-1/2” fixed table, 32-1/2’ x 4-1/2” Kelly bar, runs 4” drill string, 46’ one piece mast (can be reduced), work platform, holds 300’ drill pipe, 300’ of 4” x 20’ drill pipe, slips, 8-3/4” bit, 5-7/8” sub PRICE: $35,000

DAVEY MA8R(Ref#11076Tb) Manufactured 1965, 871 Detroit diesel engine (rebuitl 7-8 years ago), 350 Cummins truck engine, 500/250 air compressor, 20 gpm Bean water injection, mounted on 1966 Mack V83, retractable table, 500" of 3-1/2" drill pipe Price: $70,000

DAVEY M8(Ref#12376RB) with 600" of drill pipe (400" brand new) and White flatbed water truck, 1500 gallon tank, also 800cfm portable air compressor Price: $55,000

DAVEY M-8(Ref#14212Ra) Detroit 671 diesel engine on deck, 8" table, 4" kelly, mounted on 1981 Mack with 300 Mack engine, 200" of 3-1/2" drill steel Price on request

DAVEY M8(Ref#14212Rb) Detroit 671 diesel engine on deck, 8" table, 4" kelly, monted on 1986 Ford with Cat 3208 engine, 200" of 3-1/2" drill steel Price on Request

DAVEY M8AR(Ref#1696T) Manufactured 1974, 500 cfm/100 psi piston air compressor, Detroit 671 deck engine, water injection, retractable 4- speed 8" table, mounted on 1974 White truck with Cummins 350, off road tires 75%, 500" of 4-1/2 x 20" Davey rods, 6" and 8" tools, 30" x 4-1/2" fluted kelly, currently working Price: $29,500

DAVEY M8(Ref#2884Npartsrig) Parts rig, missing swivel and drawworks, air compressor bad, Manufactured 1970, 6-1/4” table, mounted on Ford Louisville truck with gas engine, 100’ steel, sub and bit Price: $13,500

DAVEY M8A(Ref#6123RB) Manufactured 1958, 300/100 air, 4" kelly, rotary drive, Detroit diesel deck engine, mounted on 1969 Chevy tandem axle truck, 400" pipe Price: $37,500

DAVEY M8(Ref#671Na) Davey 500/120 air compressor, Gardner Denver 3-1/2 x 5 air driven mud pump (can be unmounted from rig and used as stand alone unit), 671 Detroit diesel deck engine, Gardner Denver injection pump, 23" kelly bar, 7-1/2 rotary table, mounted on Ford tandem axle truck with gas engine Price: $75,000

DAVEY M-8(Ref#5217) -1975, 671 diesel engine, 550 cfm compressor, 250 gal water tank, 3-1/2" x 47" kelly, 300" flush 20" rod, on old International truck with gas Price: $35,000 Also has 3-1/2" x 20" kelly for additional cost

DAVEY M8A(Ref#9240R) Manufactured 1969, 8V71 Detroit on deck, 7-1/2" retractable table, rig does not start, mounted on 1969 Chevy C70 tandem axle truck, gas wengine, no mud pump, 490/250 air compressor Price: $37,500

DAVEY M8A(Ref#6569T) mounted on 1964 International 190 truck, 471 Detroit engine, 6 cyl compressor, 28" kelly bar, 34" tower, sliding table, wrenches (hand made), 200" of 4" x 20" drill pipe Price:$14,500

DAVEY DRILLING RIG(Ref#10682T) 500/125 Davey air compressor, 7-1/2” fixed table, 32-1/2 x 4-1/2” kelly bar, 46’ one piece mast (can be reduced), 671 Detroit deck engine with 5 x 4 transmission, mounted on 1978 Ford 900 tandem axle truck with 534 gas engine, leveling jacks, 38,000# rear, rod box (holds 300’ of pipe), slips, work platform, 200’ of 2-7/8” drill pipe, runs 4” drill pipe PRICE: $37,500

EWBANKM-100(Ref#3942Na) Manufactured 1980, 2000" depth capacity, Triple drum, 58" x 70,000# derrick, 18" rotary table, 8V71 Detroit diesel, 4-1/4" x 39" kelly, KG50 King swivel, 4 lines ¾" line, mounted on 3 axle trailer.

EWBANKS 50(Ref#13911Ra) 4 x 5 mud pump, mounted on 1978 International single axle truk, Cat 3208 engine, PTO, 5-1/4" stationary rotary table, no air, square kelly, mud pan, pipe rack, 200" pipe Price: $37,500

SEISMIC MODEL 10 DRILLING RIG(Ref#4188T) Rotary table drive, Gardner Denver 5 x 6 FG-41 mud pump, Ingersoll Rand Type 40 air cooled air compressor, munted on 1979 GMC Brigadier J9500 tandem axle truck, 30’ x 9’ x 11’ (10’ with Kelly and lights removed) Price: $41,000

REVERSE CIRCULATION ROTARY DRILL RIG(Ref#8095T) Manufactured 1982, double drum drawworks, 1” main line, 1” laydown line,-1/2” tail out line, depth sounding line. 75’ x 100,000# derrick (new 2010), 6 cylinder Cat deck engine, (spare rebuilt engine in crate), 24” hydraulically driven removable rotary table, 15’ x 12’ x 8’ custom fabricated substrcuture with guard rails, pipe and accessories Price: $210,000

CUSTOM BUILT 80,000# ROTARY DRILLING RIG(Ref#8354T) Built 2017, 65" x 80,000# mast, 3 drum DSM drawworks, Allison transmission for drawworks, 20" Howard Turner rotary table (hydraulically retractable), hydraulic table drive mounted on Cotta transmission (all new hydraulic pumps), mounted on Peterbilt truck with 350 hp Detroit 6V92T, Road Ranger 9 speed gear box, air twin disc clutches Price: $775,000

CHICAGOPNEUMATIC RT-2000(Ref#11290) Manufactured 1979, mounted on Ford 8000 tandem axle truck with Cat 3208 diesel engine, 40" x 60,000# hydraulically raised mast, 10-1/2" rotary table, 5 x 10 Gardner Denver mud pump, drillers and helpers work platform, chain pulldown, kelly and kelly bushing, hydraulic leveling jacks, rod box, hook/block, trailer and 500" of 4-1/2" drill pipe (10" and 20") Located South Pacific Price: $95,000

CHICAGO PNEUMATIC RT-1800(Ref#2272N) Manufactured 1981, 825/250 GHH air compressor, 50" mast, 35" kelly, 5-1/2 x 8 mud pump, 10" retractable table, air clutches, chain pulldown, breakout tong, 5" x 35" fluted kelly, mounted on Crane Carrier with 400 hp Cummins engine, PTO, 3 leveling jacks PRICE: $155,000

CHICAGO PNEUMATIC RT-1800(Ref#14013R) Manufactured 1979, combination top head/table drive, 750/250 air compressor, 6 x 9 mud pump, hydraulic rotary table, Detroit 60 (550 hp) engine (recently rebuilt), PTO, mounted on Crane Carrier Price: $140,000

CHICAGO PNEUMATIC RT-1800(Ref#15149T) Manufactured 1978, drawworks recently rebuilt, 10" CP table (rebuit), 5-1/4" x 28 fluted kelly, 50" derrick with racking board (will stand 40" in derrick), mounted on Crane Carrier 400 Cummins engine, PTO (rebuilt), ready to work. Gardner Denver 5 x 10 mud pump mounted on trailer. PRICE: 90,000

CHICAGO PNEUMATIC RT-1800(Ref#11586T) Manufactured 1978, 5-1/2 x 8 mud pump, mounted on Crane Carrier with Cummins 400 engine, PTO, 200" of 3-1/2" pipe, 7" drill collars, 22" retracted table drive

HOWARDTURNER M2000(Ref#14336N) triple drum drawworks, Gaso 5 x 10 mud pump, 12" Brewster table, 50" derrick, 6 part line, McKissick block, mounted on Kenworth chassis, 4 hydraulic jacks Currently dismantled

HOWARD TURNER 1500(Ref#5883) Manufactured 1968, 671 Detroit on deck, 24" kelly, 10" retractable table, 2" swivel, mounted on International single axle truck with gas engine Price: $40,000

CAREY(Ref#11065) Wheatly 6 x 6 mud pump, 2" x 21" kelly, non-retractable rotary table w/4-1/2" opening, mounted on 1996 Forl L8000 truck with dieselengine, PTO, 300" of 14" drill pipe Price on Request

FOREMOSTMOBILE B57(Ref#6222R) Manufactured 1983, with top drive, set up for mud rotary, PTO, mounted on 1983 International with Cat engine, new rear tires, new main master cylinder, new exhaust, new kelly hose, new pulleys and pulley sheaves, all new cable, 2" diaphragm mud pump, 145/100 piston air compressor, cathead, mud pit, 300" of new Mayhew Jr. drill pipe, new drill collar, new 8" claw bit, working daily, ready to go PRICE: $44,500

SHOP BUILT MUD ROTARY DRILLING RIG(Ref#7785T) Built approx 2007, 150’ – 200’ depth capacity, rig has heavy duty railroad winch cable for up and down drilling operations or for pulling pumps, 3” centrifugal mud pump, IR 40 cfm developmental air compressor, pump and compressor run off Handona gas engines, boom will handle 10’ or 20’ rods, mounted on 1998 Ford 700 2 wheel drive truck, 7 ltr propane engine, (2) tanks (40 and 80 gal), drilling, hydraulics and truck run on propane, 500 gal water tank, pipe rack, compact rig. Includes approx 120’ of 1-1/4” x 10’ rods, bits for 1-1/4”, 2” and 4” wells, Price: $30,000

SHOP BUILT MUD ROTARY RIG(Ref#8355T) Similar to Failing 1250), 6 x 6 mud pump, mechanical clutches, hydraulic pulldown, 4-1/2" square kelly, 9" stationary table, mounted on Mack truck (Mid 1970"s) with Mack diesel engine, PTO, breakout tongs, pipe rack, 2 rear mechanical jacks, 300" of 3-1/2" x 15" drill pipe Price: $54,500

SHOP BUILT ROTARY RIG(Ref#1900N) mounted on 1988 Ford LN8000 truck with 8.3 Cummins engine, 5 x 6 Gardner Denver mud pump, 5-1/4" retractable table, double drum drawworks, 18" x 3" square kelly, mechanical clutches, hydraulic pulldown, breakout wrench, 400" of 15" x 2-7/8" pipe, stabilizer,

SHOP BUILT COMBINATION RIG(Ref#10457T) Tophead/rotary, PTO, mounted on 1986 International with DT466 engine, double trans, retractable rotary table, 2 rear hydraulic leveling jacks Price on Request

SHOP BUILT COMBINATION CABLE/MUD ROTARY RIG(Ref#2458Na) Isuzu diesel deck engine, mounted on 1998 GMC Topdick with Cat diesel engine, Wheatley 4 x 5 mud pump, LeRoi developmental air compressor, mud mixer, walking beam, stabilizer, hammer, bits, subs, etc., 4 hyd leveling jacks, 200" of 2-3/8" x 10" N rods, some tools PRICE: $70,000

SHOP BUILT RIG(Ref#13816) Built to Speedstar specs, 32" mast, 5 x 6 mud pump, developmental air compressor, mounted on 1971 Ford F600 with new 330 gas engine, 600" of 2-7/8" bottleneck rod, 5-1/4" retract table 3 speeds, 3 speed Ramsey transmission, 12000# winch, has been sitting for several years (but was running when parked) Price: $20,000

SHOP BUILT MUD ROTARY RIG(Ref#4668T) Built 1986, approx 540’ depth, double drum (shop build with triple clutch on each side), Gardner Denver 5 x 8 mud pump, 2” DSM swivel, 8-1/2” retractable table, trailer mounted, 46’ mast mechanically raised, 4” square kelly, 420" of 2-7/8" drill pipe Price: $47,500

SHOP BUILT 6000’ DRILLING RIG(Ref#2918Ta) Trailer mounted, Cat 550 hp engine, 17-1/2” Oilwell rotary table, 7 x 14” mud pump with Cat engine, 4-1/2” kelly

SHOP BUILT ROTARY RIG(Ref#2111T) Drills to 1500 – 2000", trailer mounted, 16" Brewster stationary table, (1) Waukesha gas engine, (1) diesel engine, some tools Price: $45,000

SHOP BUILT MUD ROTARY RIG (Similar to Speedstar 1500)(Ref#5150T) (2) Perkins 1000 Series deck engines freshly reman and not used since, 4 x 3 x 13 centrifugal mud pump, no air, 8-1/2" stationary table, mounted on Volvo with Cat diesel engine, mechanical clutches, 2 mechanical jacks in rear, no kelly, no pulldown, no pipe avaialble Price: $100,000

SHOP BUILT MUD ROTARY RIG (Similar to Speedstar 1500)(Ref#5151T) (2) Perkins 1000 Series deck engines, 5 x 8 Gardner Denver mud pump, no air, mounted on Kenworth truck with Cat diesel engine, mechanical clutches, no table, no kelly, no pulldown, 2 mechanical jacks in rear, no pipe Price: $137,500

SHOP BUILT ROTARY RIG(Ref#9442R) mounted on International with diesel engine, 7" stationary table, 23" Kelly, air clutches, no pulldown, 4x3 centrifugal mud pump with 453 Detroit engine, 2 hydraulic leveling jacks, currently drilling, ready to go

MUD ROTARY RIG(Ref#4964Na) 3 x 4 mud pump, no air, 4 cyl diesel deck engine, 17" kelly, 10" retractable table, pulldown, air clutches, mounted on 1980 Ford Detroit engine, 4 hydraulic jacks, 400" of 3-1/2" x 15" drill pipe, small hydraulic winch, large hydraulic winch Price: $30,000

SHOP BUILT BORING MACHINE(Ref#12952Nb) mounted on 1958 International tandem axle truck with V8 engine, 40" mast, 100" telescoping kelly, 4 winches, ready to go Price: $32,000

SHOP BUILT MUD ROTARY RIG(Ref#10782Ra) Built 1995, 3 x 4 mud pump, 7-1/2" table, (2) 527 Chevy gas deck engines, mounted on 1995 Kodiak single axle with 3115 Cat, 600" depth, rod box, 300" of 20" Mayhew pipe Price: $57,000

8613371530291

8613371530291