kitagawa cnc rotary table factory

TMX160 Heavy Duty Rotary Table with increased rigidity for demanding applications. The internal air hydraulic booster gives extremely high clamping forces.

TUX200 Rotary Table with top mounted motor suitable for horizontal machines. Integrated air booster provides high clamping torque from a standard air supply.

Used in CNC machining and metalwork, rotary tables, also known as indexing tables, provide fine control of a workpiece in order to cut work at specific intervals around a fixed axis. Simply put, it needs to control and rotate the workpiece that is being machined. Since precision and accuracy are so important in the CNC machining process, picking the right machine that fits your needs and requirements is so important.

Kitagawa Rotary Tables feature proven technology with high clamping torque, accuracy, and rigidity. With a wide range of tables to choose from, there is a huge amount of flexibility on offer to meet whatever needs your machine shop may require. Choosing a Kitagawa rotary table is a quick, easy, and inexpensive way of increasing the capabilities of your machining centre, allowing you to increase accuracy, decrease cycle times, and machine more complex parts.

So what are the different types of rotary tables and which is best for you? This greatly depends on what you need to get out of it and your budget. Fortunately, Kitagawa provides some of the best rotary tables on the market and supply a wide range of models for both big and small projects.

Kitagawa’s GT Series are 4-axis rotary tables that offer a higher clamping torque than standard, making them extremely capable of withstanding high cutting loads. Productivity is further enhanced by the tables’ robust yet compact design, which allows maximum metal removal rates to be combined with high indexing accuracy and repeatability. The GT Series also features a rapid clamping action for reduced cycle times and maximum production throughput.

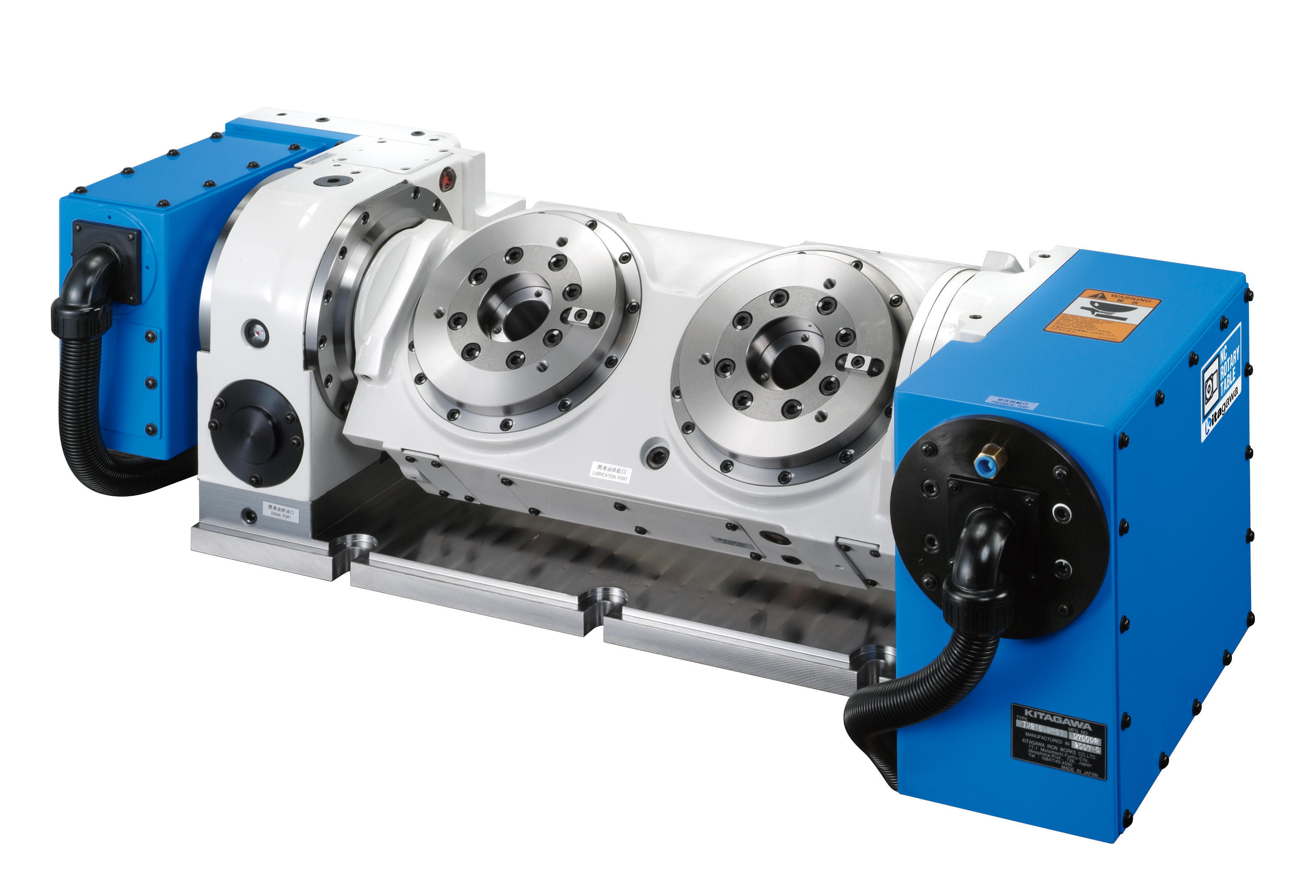

Kitagawa’s TT Series is an example of 5-axis, ball drive rotary tables that feature tilting rotary indexers. These allow for more complex workpiece and machining configurations and make it easy to add 4th and 5th axes capabilities to standard machining centres.

All Kitagawa 5-axis rotary tables are available with a built-in rotary joint if required, simplifying the pipework that would be needed for using a power chuck. When combined with the range of rotary tables, Kitagawa’s extensive range of power chucksallows for a huge amount of flexibility in your machining environment.

Perfect for large scale projects and businesses looking to improve their productivity and efficiency, the multiple components with multiple operations simultaneously, it still possesses all the characteristics of any other 5-axis indexing table.

If you would like more information about Kitagawa Rotary Tables, you can contact us on 01725 512517 or enquiries@1mta.com and arrange a FREE visit with one of our technical representatives. We look forward to hearing from you.

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

Eastec 2019: Kitagawa NorthTech will be displaying its Nobel brand of workholding chucks for vertical turning lathes (VTLs), available up to 3.5 m (11.48 ft.) in size.

Kitagawa NorthTech earlier this year absorbed Itex Workholding operations, which previously held the distribution rights for Kawatatec Nobel Chucks in North America.

PMTS 2017: Kitagawa-NorthTech, a manufacturer of chucks, cylinders, steady rests and workholding accessories, provides custom turnkey workholding services.

Kitagawa NorthTech offers its Digital Grip Force Analyzer software and kit (PC version) designed to enable users to easily, accurately and quickly analyze and measure grip force performance of their CNC lathes and turning centers via a desktop PC, laptop or tablet.

Featuring robust construction and powerful clamping for high accuracy, Kitagawa’s TT-series NC tilting rotary tables are designed to handle a range of applications including shaft work requiring large through holes.

Well-suited for oilfield work, this compact rotary table has a through-hole diameter of 13.6 inches, which has previously been available only with rotary tables having a much larger face plate.

Workholding product manufacturer Kitagawa-Northtech (Schaumburg, Illinois) has established a strategic business solutions team to accelerate and streamline customer support.

At this Chicago-area manufacturer, quick-change chucks from Kitagawa added to the benefits of moving from multiple setups on multiple machines to producing parts in a single setup on Mazak turn-mills.

This shop found a way to modify one of its two-turret CNC lathes so that a tricky aerospace component could be properly supported for critical operations.

While the lack of young people coming into manufacturing industries has been a concern for years, the situation has yet to improve, says Bill Graham, marketing manager for Kitagawa-NorthTech. Mr. Graham believes the industry as a whole needs to better support teachers who are interested in teaching technical skills and dispelling myths about manufacturing.

Kitagawa NorthTech offers the highest level of quality and versatility in custom design, engineering and manufacturing of high performance workholding solutions for turning, milling and grinding applications. They offer a comprehensive range of products including, standard three-jaw chucks, quick change chucks, super large bore chucks, hydraulic cylinders, work grippers, rotary tables, automated workholding systems, custom engineered, rotational and stationary workholding solutions, turning and grinding steady rests, and Nobel Brand large chucks for Oil & Gas.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

China is the world’s processing plant with a large number of CNC. For example, Foxconn has more than 200000 CNC, BYD, Lens, Luxshare and Some companies more than 100000sts, and there are no less than 1000 companies with more than 1000 CNC. All major brands want to occupy their own market in China.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

Thanks to Martin Power and Robert from Kitagawa Europe, I have another guest blog. Robert looks at rotary tables and how the small manual rotary table you might have for your drill press or milling table compairs with it’s bigger brother in the industrial world. For the model engineer, the rotary table would be for cutting curved slots say for an expansion link or rounding the ends of con rods. In industry there is a much wider range of tasks for the rotary table.

Those of you that have converted your shed or garage into a workshop will probably already know what a rotary table is may even have installed one. Even if you haven’t got your own personal workshop; there is a good chance that you have at some time used or at least come into contact with a rotary table. This will most likely have occurred in the school environment when in a Design and Technology class – or similar subject. The rotary table is of course a clamping mechanism that is used in the shaping of metal parts or components, in conjunction with various machines, including lathes, drill presses and milling machines.

In its most basic operation a rotary table is used to hold the object piece firmly in position whilst holes are made in an evenly spaced fashion. The image above shows such a task being carried out on a rotary table which has been mounted on a drill press. There are however much more advanced rotary tables available on the market, which are used in various manufacturing industries.

The photo above shows Kitagawa’s popular GT200 model, which is ideal for heavy machining. The complexity, accuracy and performance levels of such machines make their shed based cousins look like mere toys.

The top end rotary tables are commonly used in the manufacture of components that are used in cars, trains, planes and boats. Every time you travel somewhere in a vehicle you will be making use of metal work that has been created by a rotary table. It is of course important that every component of a vehicle is made precisely to ensure the safety of those using it. In order to deliver this precision, computer numerically controlled (CNC) rotary tables are used in the manufacturing world.

Rather than positioning and turning the rotary table manually; a CNC driven model operates using pre-programmed commands which are entered into a control module such as the one above. The rotary table is also able to communicate with the other end of the metalworking machine that holds the shaping tools. As a result both are able to work in unison; bringing precision and safety.

Whilst rotary tables play a key role in the manufacture of parts in the transport industry, it by no means the extent of their reach. Their usefulness stretches to many other areas of business, from construction to pipe laying. In order to fulfil their role in so many different environments it is important that rotary tables are both adaptable and available in various sizes and configurations.

In the example above we see a rotary table that has a huge through-hole capacity of 345mm. This allows long bar and tube shaped workpieces to be clamped effectively and is ideal for producing pipes to be used to move gas, water and oil. For such tasks, the standard three and four jawed chucks, such as the one below, are not suitable.

Such a clamping solution cannot deliver a suitable torque to hold the piece in place whilst it is being shaped. The result will be that shaping tools will deflect from their target, thus compromising the quality of the final component. Instead a collet chucks as shown below is more suitable for use when manufacturing pipes and bars.

The final main difference between manufacturing rotary tables and those used in schools and hobby workshops centres on the ability to choose tilting options. Standard rotary tables allow for the workpiece to be positioned along 3 axis in relation to the shaping tool. In contrast many models used in manufacturing include a manual or CNC tilting device that enables the workpiece to be positioned on a 4th and 5th axis. The image below shows a rotary table with tilting capabilities being use alongside a drill press.

Last year the Japanese manufacturer Kitagawa introduced the first in a new range of compact, general purpose rotary tables, the MK-series, for adding a rigid fourth CNC axis to a 3-axis vertical machining centre.

Most notable improvement on the MK250 is the 1,000Nm, pneumatically actuated clamping torque, making it more than four-fifths stronger than the first model. As with all Kitagawa tables, this torque is determined by the point at which the force on the worm wheel causes it to displace by 30µm. In contrast, some manufacturers quote the slipping torque as a maximum, which can cause inaccuracy or even failure.

If a Kitagawa TSR181A tail spindle with integral clamp, also available through 1st MTA, is added for securing a component or tooling column horizontally between centres, clamping torque increases to 1,600Nm. The result is even faster, heavier duty, more productive machining. As the table has a small footprint, loss of bed area and working volume in a machining centre is minimised.

Kitagawa has both stronger and more compact rotary tables of similar capacity in its product ranges, for example the GT250 and CK250 respectively, but Kitagawa asserts that the MK250 meets 90% of all customer requirements.

The type of the faceplate is specified by the customer, either with T-slots or pre-drilled holes. The advantage is that a chuck, trunnion or other workholding device can be mounted directly onto the rotary table, reducing the distance from the spindle bearing. Such compact assembly lessens the load on the bearing, increasing rigidity and longevity. Cutting torque is 480Nm and the spindle through-hole diameter is 70mm.

The table design minimises accumulation of chips around the base, reducing cleaning time and ensuring the absence of interference to the workholding arrangement – an important consideration in automated production cells.

Compact, built-in, 7 MPa rotary joints may be selected from 4-, 5- and (6+1)-port types, the latter having a 12.5mm diameter, multi-purpose hole through the centre for additional hydraulic or pneumatic services to actuate workholding. The hole can also be used as a duct for cables feeding signals back from fixture sensors confirming correct workpiece seating, enabling the design of the workholding configuration to be improved and its capabilities enhanced.

1st MTA will alternatively provide a high pressure 25MPa, four-port or six-port rotary joint instead of the standard 7MPa variety, allowing a further reduction in fixtures sizes as well as improved clamping speeds.

Well it"s almost a wrap on 2021....it"s been a tough, though fun year being involved in sales for Kitagawa Europe Ltd. continuing to bring in various different methods of promoting ones products to the world.

#cncmachining #machining #manufacturing #production #cnc #advancedmanufacturing #workholding #technology #kitagawa #innovation #engineering #focus #EMO #EMO2021 #Milano #fieramilano #emomilano2021 Atsushi Ogahara

Performed large-diameter drilling by high-performance NC rotary table MK with large clamping torque. Contributes to high productivity with stable clamping force.

8613371530291

8613371530291