lcm rotary table manufacturer

... structure with adjustable feet, on which rotates a circular conical table top, rotating on plastic guides and motorized reducer via coaxial. The table top is equipped ...

The Engrenages HPC catalogue includes an extensive range of rotary tables for use in conveying systems, automated machines or assembly lines. These tables are maintenance-free and have ...

We believe that our wealth of experience and our passion for quality makes Midland Engineering the best choice when it comes to the repair of your rotary table. We understand the need for a quality assured repair service with a focus on keeping downtime to a minimum.

SE S E SOUTHEAST M ANUFACTURING N EWS Serving Since 1997 Alabama, Florida, Georgia, Mississippi, North Carolina, South Carolina, Tennessee & Virginia Feature Editorial Royal Products Introduces New Quick-Grip CNC Collet Chucks Vol. 15 No. 2 February 2011 Complete Online Digital Editions at www.ipnews.com Workholding New AccuteX AX-1165 Wire EDM Haas Hosts HaasTec Open House at SoCal Facility March 10-12 For the first time in over 7 years, Haas Automation, Inc. will host an open house at its headquarters and manufacturing fa-cility in Oxnard, CA. HaasTec, scheduled for March 10 through 12, 2011, from 10 AM to 4 PM daily, will include machine demos, factory tours, a catered lunch and more. Visitors to HaasTec will see the latest Haas CNC technology up close and in great detail, with 20 machines cutting metal, including the new generation ST and DS turning centers, with Y-axis and dual-spindle capabilities. There will be guided factory tours-both above and on the production floor-to see how Haas machines are built; and representatives Continued on Page 4 “Quick-Grip CNC Collet Chucks offer a number of advantages over traditional collet chuck designs,” said a Royal Products spokesperson. See Page 12 for Details Delcam Adds Turning and Mill-Turn to Integrated CAM for SolidWorks Software The AccuteX AX-1165 EDM is a heavy-duty wire machine that weighs in at 18,800 lbs and can handle a workpiece of nearly half its weight or 9,000 lbs. The machine is equipped with an annealing, fully auto-matic wire threading system (AWT) with a tip disposal unit. AccuteX’s intel-ligent servo-control wire-threading tech-Delcam has launched the 2011 version of Delcam for SolidWorks. See Page 26 for Details nology, together with multi-detectors, makes it a fast and reliable (threading at wire break point) automatic wire thread-ing system, the company said. Cincinnati-based Xtech, which Continued on Page 4 Arthur Machinery Hosts Workholding “Lunch & Learn” Robert Arthur Machinery will host a “Workholding/Toolholder” event on Tuesday, March 15, 2011 at the com-pany’s Tampa, FL, facility. Co-host Bob Marinelli, RAM Sales, will have four supplier presenters: Royal Prod-ucts Collet chucks, TE-CO Vises, Mitee-Bite Clamps and Techniks Toolholders. The presenters will be from 9:30 AM Continued on Page 4 Clausing Moves 20” Industrial Drill Manufacturing Back to the USA Clausing Industrial, Inc. has moved its 20” industrial drill manufacturing back to the USA. “All castings, com-ponents and assembly are done by American workers to the highest American Manufacturing Standards, meaning more jobs for America,” said a Clausing spokesperson. “The American Made 20 inch floor drills are de-signed and built to meet virtually any heavy-duty drilling requirement. The drills are available in column, table with legs and up to four head multiple spindle models. All fea-ture a heavy-duty precision head with all bearing surfaces precision bored simultaneously for exact alignment, ball bearing support to absorb both radial and thrust loads, 4 inch turned and ground steel column for rigidity and a precision ground oil through table. “Clausing 20 inch drills are available with low/high infinitely variable speeds from 150 to 2,000 RPM and 200-1,300 RPM or 300-2,000 RPM infinitely variable speed ranges. Clausing Drills have a drilling capacity of 1.25 inches in cast iron, .875 inches in mild steel and 3 MT Continued on Page 4 Center Rock’s Low Profile (LP) Hole Opener drills shortened rescue effort by two and a half months. See Page 34 for Details Chilean Miner Rescue Drills Made with CNCs Programmed by GibbsCAM Applying Technology “Manufacturing for Growth” Meeting to Take Place March 3-6, in Chandler, AZ Four leading associations of small-and medium-sized manufacturing com-panies announced that they are combin-ing resources to host the inaugural Manufacturing for Growth (MFG) meet-ing, a gathering of hundreds of manufac-turing leaders, March 3-6, 2011, in Chandler, AZ. Collectively representing a cross-section of the industry, AMT -The Association For Manufacturing Technol-ogy, the American Machine Tool Distribu-tors’ Association (AMTDA), the National Continued on Page 6 Makino Offers New EDAF Series Ram EDMs EDM Machinery Makino has introduced its latest Ram EDM machinery, the new EDAF Series, featuring a new mechanical design. See Page 40 for Details To make name, address subscription changes contact: • Phone: 800-375-8488 • Fax: 817-488-7813 • E-mail: info@ipnews.com • www.ipnews.com/subscribe.html Subscription Changes: Cosen’s C-320NC is a high production machine which is designed to incorporate a dual column design, 1-1/4” wide blade and a 5 HP drive motor, the company said. See Page 48 for Details Cosen Offers C-320NC Saw Saws Advertiser Index Page 46 Gross Publications, Inc. SOUTHEAST MANUFACTURING NEWS P.O. Box 847 Grapevine, Texas 76099-0847 U.S.A. PRSRT STD U.S. POSTAGE DALLAS, TX PERMIT 4245 PAID

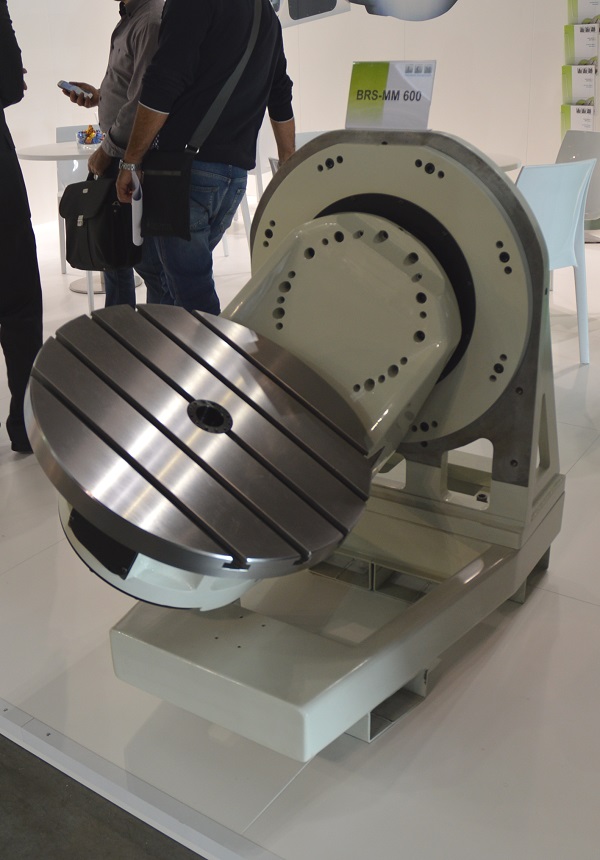

The TDE-V series of LCM rotary tables from Indexing Technologies features a lightweight yet stiff, sealed and pressurized alloy housing with the drive motor safely mounted inside.

Samchully Workholding’s TR-320FF heavy-duty fifth-axis rotary table uses high-torque motors for both the tilt and turn axes, enabling a 330-lb load capacity.

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product"s lifetime, Matsumoto Machine Corporation (MMK) has taken a pragmatic two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

Founded in Japan in 1948, Matsumoto Machine Corporation is a technology-leading provider of innovative, high quality jaw chucks and numerically controlled rotary tables used by industrial machine tool makers throughout the world. A key feature of MMK"s CNC rotary tables is a patented worm and wheel gear assembly developed by OTT GmbH, Germany. Unlike double lead worm gears, the OTT worm and wheel gear is able to minimise backlash, ensuring outstanding accuracy and long life, efficiency and durability.

A further advantageous characteristic of the MMK CNC rotary table is a large diameter through-hole in the table spindle. This greatly increases machine versatility and rigidity, supporting a wider variety of chucks and jigs and the machining of longer workpieces.

By enabling most metal-machining operations to be undertaken on a single machine, the benefits of MMK CNC rotary table are far-reaching. These include the time and cost saving of single machine set-up and single fixturing setup, reduced parts handling and the elimination of tolerance errors as workpieces pass from machine to machine.

Of critical importance in this one-hit machining centre scenario is ensuring the high accuracy of CNC rotary table indexing and control throughout its working lifetime.

As with a machine tool"s linear XYZ axes, the rotary axis is just as susceptible to uncontrollable events that may introduce angular positioning or axis alignment errors. Risking the production of defects in finished parts, these errors can be due to a number of reasons including, mistakes made in the initial machine installation, impact damage caused by collision or general wear-and-tear in use.

With its global reputation for product quality and design innovation, MMK therefore sought to equip its CNC rotary tables with a highly accurate and reliable means of tracking and controlling the indexing of its product throughout its lifetime, irrespective of the type of machine tool, workpiece complexity and duty cycle.

At the same time, in an increasingly competitive global market for CNC rotary tables, MMK also wanted to further enhance its product quality inspection processes. Specifically, the company set itself the task of augmenting index angle measurement as a key component of pre-shipment quality assurance procedures.

To provide machine tool makers and users with the ability to accurately track and control CNC rotary table indexing, MMK elected to integrate Renishaw"s super-compact TONiC™ non-contact optical incremental encoder system. Simple to install and with a compact readhead measuring just 35 mm x 13.5 mm x 10 mm, the TONiC encoder presented MMK with a minimal footprint solution capable of supporting machine speeds up to 10 m/s and resolutions down to 1 nm.

The rotary table readhead was designed to be used in conjunction with Renishaw"s RESM, a one-piece stainless steel ring marked on its periphery with 20 µm pitch graduations and featuring the IN-TRAC™ optical reference mark. With its low profile, large internal diameter and wide choice of diameters from 52 mm to 550 mm, the high stability RESM ring provided MMK with a versatile and easy to integrate scale that is well-suited to the company"s wide range of CNC rotary tables.

MMK selected Renishaw"s compact and lightweight XR20-W rotary axis calibrator to verify the accuracy of its rotary tables during manufacturing and immediately prior to shipment. The XR20-W was used in conjunction with Renishaw"s XL-80 laser interferometer to provide a non-contact reference measurement, independent of the axis under test, with an accuracy of ±1 arc second.

Motorised by a servo-controlled drive and with data capture synchronised to axis movement, the XR20-W requires no operator intervention during measurement. Being lithium battery powered and Bluetooth enabled, it ensures quick and easy setup, and the avoidance of trailing cable hazards. The calibrator"s modular design and flexible mounting systems allow far easier setup than alternative solutions and can be readily configured for a wide variety of rotary tables, chucks and spindles.

By integrating Renishaw"s TONiC non-contact optical encoder system into its CNC rotary tables, MMK has further assured the accuracy and reliability of its products in the field, along with an overall superior motion control performance. For a wide range of different machine tools and end uses, the rotary tables" combination of compact readhead and one-piece stainless steel ring scale has delivered a higher level of tolerance to dust, scratches, grease and oil, and a reduction in indexing errors. The encoder system"s ability to output highly stable position signals of unrivalled purity and ultra-low sub-divisional error have provided smoother velocity control, improved scanning performance and increased positional stability.

MMK"s introduction of Renishaw"s XR20-W rotary axis calibrator and XL-80 laser interferometer has reduced product measurement times by a half compared to conventional autocollimator techniques. Measurement procedures have been simplified and automated. Capable of taking accurate measurements at any indexing angle pitch, the calibrator enables evaluation of the accuracy of the worm and wheel gear-driven table for ultra-fine pitch measurement movements as small as 0.001°. This has allowed any loss of motion control or worm and wheel gear efficiency to be evaluated in detail and addressed. Product performance is now backed by a thorough analysis meeting ISO quality standards.

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product’s lifetime, Matsumoto Machine Company has taken a pragmatic

two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

Job shops may believe that all CNC rotary and index tables are essentially alike. As a result, they often base their selection on price and hope they can use their machining creativity to maximize a rotary or index table.

However, to expand the capabilities of their machine tools when purchasing new ones or retrofitting existing equipment, considering the quality of a table’s sealing, braking and bearing systems and how those systems impact a shop’s current and projected applications can pay big dividends down the road. Shops are also wise to consider the effectiveness of a cable management system—which ensures a rotary table is always connected to the machine without operator intervention and extends connector life—when palletizing tables.

“The initial quality of the rotary table makes a big difference,” said Lee Flick, national sales manager for HPI-Pioneer, “especially at job shops.” The Elk Grove Village, Ill., company supplies CNC rotary and index tables from Yukiwa Seiko Inc., Japan.

Predictably, many end users—especially shops on limited budgets—push the limits of a rotary table’s weight capacity and capability. “Some of our customers will put a car on a little table and try to turn it,” Flick quipped. But by specifying the correct rotary table for the job, shops can extend equipment life while reducing maintenance issues and continuing to machine high-quality parts.

After 2 years of operation, the inside of a Yukiwa rotary table (left) with an automatic air-purge system and a competitor’s table without a purge system.

A table axis’ lack of durability and inadequate clamping power can cause out-of-tolerance features and rough surface finishes. One solution is a dual-bearing system that supports the table on the front and rear with large bearings, according to Flick. Even with an overhanging weight load, this design prevents the table from leaning, he added.

One of the key factors that determine the life span of a rotary table is how well it is sealed against potential contaminants, such as metalworking fluids. Flick noted the most common rotary table service is repairing electronics damage caused by coolant infiltration. “Within 20 years I believe the market will be dry cutting,” he said. “But as long as coolants are involved, sealing is extremely critical.”

Flick indicated that there are three basic sealing arrangements: sealing just the motor cavity, sealing the entire table and sealing the table and incorporating an automatic-purge system similar to check-valve pressure on an airplane. “You pressurize the cabin and if you were to get a leak, it blows outwards,” he said, adding that a rotary table with that type of seal typically lasts twice as long as one that doesn’t, whether it’s an entry-level or higher quality table.

HPI-Pioneer President Nobu Kiriyama explained that the Yukiwa air-purge system uses the 70-psi shop air that also supplies a table’s braking system and enables a table to effectively function when submerged for EDMing. For those applications, an optional nickel-plating is appropriate when the table is submerged in water-based dielectric fluid.

Of course, chips, swarf and other debris produced during cutting can abrade any seal material and provide a passageway for contaminants into a table’s inner mechanisms. Therefore, John Arnestad, tooling product manager for Koma Precision Inc., recommends against aiming a high-pressure coolant line at a seal or an area where a seal is located to reduce that risk. The East Windsor, Conn., company supplies rotary tables from Tsudakoma Corp., Japan, which have seals directly behind the faceplate. The tables also have a metal cover that shields the main seals to decrease the chance of debris abrasion.

For high-pressure coolant applications, Rotec Tools Ltd., Millwood, N.Y., recommends a labyrinth seal on the rotary table. Rotec distributes rotary tables from Peter Lehmann AG, Switzerland. Ivo Straessle, Rotec president, noted the air-supported labyrinth seal attaches to the spindle nose of the table, extending the standard spindle seal, and creates an air cushion underneath the seal to keep coolant out. “We prefer oil-based over water-based coolants because they’re not so aggressive on the rotary tables,” Straessle said. “Many water-based coolants attack seals, cables and electrical components.”

In addition, Lehmann rotary tables have an air-purge seal on the motor housing, and the gear housing has a positive oil pressure at all times. “That makes it very difficult for debris or coolant to penetrate the seal system from the outside,” Straessle said.

To ensure longevity of the rotary table and its sealing system, pressure is reduced to the internal components of the pressurization system during rotation on most of the table models offered by L.C.M. Srl, Italy, said Mike Bickham, president of distributor ITI Tooling Co. Inc., Ramsey, N.J. Then, the pressure increases when the table reaches the preprogrammed working positions.

Cutaway of a Lehmann rotary table: 1) The clamping ring applies 360° equal clamping force on the rotary axis; 2) the rotary axis; 3) the preloaded radial and axial needle bearings; 4) the gear train; and 5) the standard spindle seal, which can be extended with a labyrinth seal for high-pressure coolant application.

Unless it’s an older table, coolant infiltration behind the rotary table seals isn’t an issue in 99 percent of machining applications, according to Jamie Schwarz, national sales manager for CNC Indexing & Feeding Technologies, Mason, Ohio, which offers Taiwanese-made Ganro rotary tables. A combination of oil seals, O-ring seals and silicone caulking keeps contaminants out of the tables’ inner workings, and the company offers an air-purge system as an option.

When coolant penetrates a rotary table, it can short out a servomotor, and fine chips can wreak wear-related havoc on the brake, worm wheel, worm shaft and other parts. “That can get expensive when you start replacing internal components that are important to the table’s accuracy and repeatability,” Schwarz said.

Pressure also comes into play when selecting the appropriate braking system for a rotary table. According to HPI- Pioneer’s Flick, two basic variations exist: a disc brake system and a hydraulic version that provides higher braking pressure than a disc brake. Although hydraulic systems are prevalent, he pointed out that the company offers models with the less-typical air-over-hydraulic booster inside the table’s motor cover, eliminating the need for a hydraulic pump or other external hydraulic supply. Instead, 70-psi shop air does the trick. This is because the table clamp mounted inside the air-hydro structure boosts the hydraulic pressure and achieves higher clamping power simply by providing air pressure. (See image below.)

“The higher the braking pressure, the more aggressive machining you can perform on the rotary table,” Flick said. “Hydraulic boosters are becoming more common because people want to machine harder and harder on the table.”

He added that there’s no angular pressure on any braking system when using a rotary table to cut on-center, but the type of system makes a significant difference when machining off-center because the pressure created on the cutting location increases based on its distance from the center. Hydraulic systems permit more aggressive cuts, even when machining farther out on the table.

The heavy-duty, zero-backlash braking systems on the rotary tables from ITI Tooling can use hydraulic pressure up to 870 psi, according to Bickham, but 580 psi is more typical. In addition, the tables can use an air supply together with an air-over-oil intensifier, which provides benefits because shop air is generally more readily available and is restricted to a safer pressure than a hydraulic system. Bickham added that whether it’s an air- or a hydraulic-actuated brake, the brake operates in the same manner by expanding a 360° pressurized sleeve that wraps around the table’s center axle, holding it rigidly in place.

Cost considerations can play a prominent role when selecting a rotary table’s braking system. The disc brake is the most popular type because repairs are fairly inexpensive, according to CNC Indexing’s Schwarz. The repair is usually performed on tables 10 years and older used for heavy machining, he said. “We can get the repair done within a day for a few hundred dollars.”

With the air-over-hydraulic brake system in Yukiwa’s rotary tables, the increased hydraulic pressure can achieve stronger clamping power by providing air pressure.

Arnestad indicated that Koma offers several braking system options. Called the RNE series table, the pneumatic, dual-disc system is the most economical, while offering good accuracy and a good torque drive, he noted. The mid-range RNA series table has a dual-taper clamping system that uses a pressure intensifier, where a ring of ball bearings are captured between the clamping ring and the piston.

“The piston has an angular feature on it, as well as an angled member inside the braking system so, as the piston moves forward, it displaces that ring of ball bearings and triples the clamping force,” Arnestad said. This enables taking heavier off-center cuts without the fear of the rotary faceplate turning under force.

Arnestad added that the hydraulic, dual-disc clamping system, called the RBA series table, is the company’s most robust. “That’s targeted for high-volume production,” he said, “where they need to hold very close tolerances and want to machine at the fastest rate possible.”

According to Rotec’s Straessle, Leh-mann rotary tables have the same braking system for any application, using a built-in air-over-oil intensifier. This booster coverts 90-psi shop air into more than 4,000 psi of hydraulic pressure, he added, and a clamping ring equally applies 360° clamping force to the rotary axis. “A high clamping force allows high feed rates and high workpiece accuracy.”

End users can also increase machining parameters when a rotary table’s bearing configuration enhances table rigidity. For example, preloaded axial and radial needle bearings in front of the table next to the spindle nose and preloaded axial needle bearings in the rear of the spindle (all inside the gear housing) provide a high level of rigidity, Straessle explained. Preloading eliminates the undesirable “give” for the bearings in the axial and radial directions. “This design allows the customer to work with heavy workpieces and, at the same time, reduces overall vibration,” he said.

According to Arnestad, a cross-roller bearing construction provides the best rotary table support. “It gives better stiffness and less runout than, say, tapered roller bearings, which have a chance of losing their preload over time,” he said.

Yukiwa rotary tables from HPI-Pioneer have a dual-bearing system, where two sets of bearings at both ends of the body provide triple-contact support and the largest angular contact bearing is underneath the table face to enhance bearing support.

In terms of runout, HPI-Pioneer’s Kiriyama noted the bearings in Yukiwa’s rotary tables provide a 0.0001" runout and are the same grade as the ones machine tool builders use for their spindles. According to the company, the tables have a dual-bearing system, where two sets of bearings at both ends of the body provide triple-contact support, and the largest angular contact bearing is underneath the table face to maximize bearing support.

HPI-Pioneer repairs and replaces worn bearings from its rotary tables, as well as from its competitors. “A good table will go 5 to 10 years before it needs work, just like a machine,” Flick said. “With a low-end table, you’re doing it annually. It’s that dramatic of a difference.”

Similar to a braking system, a high-quality bearing configuration effectively supports the workpiece load and machining pressure in the axial and radial directions. This proves beneficial when machining on a rotary table that’s not adequately matched to the application. “Everyone wants to buy the least expensive table they can and push it to its limits rather than going the next size up,” said CNC Indexing’s Schwarz.

When high-volume manufacturers and those performing lights-out machining use rotary tables, they often palletize the tables. In this scenario, the main consideration is the cable management system, which enables a palletized table to shuttle in and out of the machine tool without disconnecting cables while keeping them clear of the machining process, according to Schwarz. It might involve running the cables through the middle of the pallet to some sort of track system or incorporating a spring-loaded arrangement that hangs from the upper sheet metal in a machine and allows cables to extend and retract.

Most end users are quite opposed to having to repeatedly plug in and unplug a rotary table, he said. As a result, the role of a cable management system, which machine tool builders and third-party installation companies provide, is critical.

Koma’s Arnestad added that a cable management system ensures a rotary table is always connected to the machine without operator intervention, which extends connector life. “If you don’t have good cable management, the connections can fail due to abrasion or having the cables flex too much,” he said. “How many times can you plug and unplug a multiple-pin connection before somebody gets a chip underneath the unit, tries to force it on and it leaks and you have problems?”

Going cheap across the board with rotary tables pays initial dividends, but part manufacturers that skimp on quality may miss enhancing the capabilities of their machine tools—even entry-level ones. “If you put the right options on your rotary table,” Frick said, “you can make an inexpensive machine perform as well as a midrange machine.” CTE

Because they don’t have gears and gear-related issues such as backlash, direct-drive rotary tables were expected to eventually replace worm gear-driven ones. For example, CTE’s April 2004 cover story stated, “Whatever the use, more direct-drive NC rotary tables will be purchased in the future, supplanting gear-driven units. These types of tables don’t have a gearbox, thereby eliminating the need to replace worm gears and belts, and are directly driven by the motor.”

That expectation didn’t quite materialize. Although they are quite accurate and rotate considerably faster than gear-driven rotary tables, reaching 250 rpm and higher compared to less than 50 rpm for a standard conventional table, direct-drive rotary tables lack the torque required for machining heavy parts and difficult-to-cut workpiece materials.

Therefore, the primary applications for direct-drive tables are high-volume ones that involve small, lightweight parts and light machining loads, according to Lee Flick at HPI-Pioneer, which offers direct-drive tables. In addition, the motor is essentially the brake. “To get the rpms, you give up torque and braking pressure,” Flick said.

HPI-Pioneer’s Nobu Kiriyama added that rotary table manufacturers have access to the same motors from motor manufacturers, which provide similar motor configurations and specifications. “Then, the various rotary table manufacturers are mostly assembling components and it’s harder to distinguish themselves,” he said. “Direct-drive technology is still evolving.”

Damaged direct-drive tables are also more costly to repair than gear-driven ones, because the components are more expensive than ones for standard servomotors, which can be rewound, said John Arnestad of Koma Precision Inc. “And if you get contamination inside a direct-drive rotary table, the motor is shot and the rotary table needs to be replaced.” Koma offers 5"- to 25"-dia. direct-drive tables.

Ganro also offers a direct-drive table, noted Jamie Schwarz of CNC Indexing & Feeding Technologies, but end users often view them as cost-prohibitive because direct-drive motors are expensive. “We quote it and then the customer says, ‘For that additional cost I think I can live with the standard table I have.’ ”

However, not all suppliers have a less-than-stellar outlook on direct-drive technology. ITI Tooling Co. Inc.’s Mike Bickham emphasized that for L.C.M.’s high-speed, torque-motor-driven tables, the company designs and manufactures many of the direct-drive motors it uses. He added that special direct-drive tables can be ordered that provide enhanced torque and, if needed, a wider range of speed. “There’s tremendous holding power for heavy-duty machining because the motor can be used as the brake,” Bickman said.

In addition to machine tools, the company also offers CNC rotary tables from LCM of Italy, UCAM of India, driven tool holder systems from Algra of Italy, machine guarding, drill/end mill grinders and tool wear/breakage monitoring systems from Brankamp of Germany.

Gregory Volovic, president of Hurco Companies Inc., says, “This strategic acquisition of an innovative business such as LCM further supports our mission to develop advanced machine tool technologies to support our customers, who need increasingly sophisticated and versatile CNC machine tools to stay competitive and to grow profitability. LCM has been an important supplier of components for us as we developed and introduced our SRT line of 5-axis machining centers that employs LCM’s direct drive spindle, swivel head, and rotary torque table to achieve superior simultaneous 5-axis machining. This acquisition will prove vital to our targeted growth plan, which supports the financial strength of our company, ensures product development agility, and will foster an expansion of LCM’s line of high-quality value-added technologies.”

Based in Italy, LCM has been producing and selling mechanical and electro- mechanical components for machine tools since 1986. LCM’s team of technical experts has a wealth of knowledge in the design of direct drive electro-mechanical and torque technologies as well as quality control processes that ensure the reliability of their products while consistently meeting design specifications.

Trading:2 CASE VERTICAL MACHIING CENTER (10KVA, SINGLE SPINDLE) VX380TD WITH FANUC 0IM CONTROLLER, DUAL TABLE AND STD.ACC. 1. 12,000RPM, 14ATC 2. SPINDLE MOTOR 7.5KW(10HP) 3. SERVO MOTOR -X AXIS 3KW(4HP) -Y AXIS 3KW(4HP) -Z AXIS 3KW(4HP) 4. Y-AXIS TRAVE 380MM(15.0") 5. SPINDLE THROUGH COOLANT(20BAR) 6. CHIP CONVEYOR ROTARY TABLE(6PT)

Recommend:The company has a total of 5 transactions related to rotary table in the last two years, the last transaction is on 2022-02-06; the transactions related to rotary table represent 0.22 of the company total transactions of the last two years.

Trading:LOADED INTO 1X 40 -HC-CON. = ARBURG ALLROUNDER INJECTION MOULDING MACHINE TYPE 270 S 350-170 MACHINE NO.: 235564 . ROTARY TABLE 1200 T MACHINE NO.: 235563 . COMPLETE WITH ACCESSORIES . SPARE PARTS FOR INJECTION MOULDING MACHINE . HS-CODES: 84771000

Trading:ROTARY TABLE MOULD SHELF QUENCH LIFTING SUPPO RT ===PANASONIC LOGISTICS SOLUTIONS OF AMERIC A INC 2475A PASEO DE LAS AMERICAS 1063SAN DIEGO CA CONTACT CINTHYA GARCIA PHONE 61 96616995 EXTENSION 111 EMAIL OPERATIONSLB =HJMINTLCOM

Trading:1289 PKG [3 W/CASES + 334 CTNS + 952 CTNS (27 PLTS)] PREMIUM WALKER, POLYMER LOW TOP, PREMIUM WALKER, POLYMER HIGH TOP, PNEUMATIC WALKER, POLYMER LOW TOP PNEUMATIC WALKER, POLYMER HIGH TOP AMS NO UTLC SEA14030014 SCREWS NUTS STICKER, POLYBAG AND CARTON. SCREWS CASTERS - P.O. STK8000-121 PO 332953 SPUN POLY BLANKET AMS NO NMCO PPDEN1403111 CNC ROTARY TABLE SPARE PARTS FOR CONVERTING SH160 GOOSENECK SH200 GOOSENECK SH160 MELTING POT SH200 SHOT TUBE SPRAY NOZZLE SPEED ADJUST METER SH160 GOOSENECK SH200 GOOSENECK SH160 NOZZLE HEATER SH200 NOZZLE HEATER SH160 PLUNGER RINGS SH200 PLUNGER RINGS STUDS,NUTS, SCREWS N/A SO.8761,8768,8770,8772,8775,8733, 8747,8748,8753,8760,8780 IRI/L 27/02/2014

Trading:ROTARY TABLE = 2 SKIDS KM 38051612/6,8 TO BE: 1 PC. RIMSTAR COMPACT 29/16 INCL. ROTARY TABLE FOR "LETS GEL PROJECT" ACCORDING TO OUR QUOTATION NO. 301678/02/04 DD.12/12/2011 1ST PARTIAL SHIPMENT HERE: RIMSTAR COMPACT 29/16 WITH 2 COLOUR DOS;RIM STAR 2 SKIDS KM 38051612/4,5 RIM STAR;RIM STAR = 2 SKIDS KM 38051612/9,10 RIM STAR;RIM STAR = 2 SKIDS KM 38051612/3,7 RIM STAR;RIM STAR = 2 SKIDS KM 38051612/1,2 RIM STAR

Trading:"SHIPPER"S LOAD, COUNT & WEIGHT" 1 CONTAINER CONTAIN 2327 PKGS OF ANTI-FREEZE/COOLANT TESTER,BODY, ORIFICE, HOUSING PLATED & FILTER RETAINER, CABLE TV EQUIPMENT,BELTS,BARREL,ROTARY TABLE, VALVE PARTS,MACHINE PARTS FOR MANUFACTURE OF FOODS,FORGED SHELL NOZZLE,BRAK PARTS OF MOTOR,WORM PINON,SHAFT,NUTS, FITTINGS,COVERING FOLLOWING BUYER"S, TENSION TOOL,ORDER NO.WH293595 VG-270 CENTER PUNCH TOOL,VG-900 STRAP TOOL VG-900A ADAPTER TOOL,SP-104 DIXON HOSE CUTTER SPARE PARTS FOR TOOL,FI204 PUNCH HOLDER +++ +++ FI202 PUNCH,J85785 BLADE CUTTER, BASE, AXIOM RIGHT HAND SCAN MODULE 10390 COLLAR, BAT MK15/MK20 10510 COUPLING 10533 PINION RESTRAINT 11068 HOUSING, CAST,MK400, LOCK TUBE 11343 DOUBLE LIP GASKET, MK400 11397 COVER DIE-CAST 11438 TUBE, MACHINED 11439 HOUSING, MACHINED 11059 TUBE, CAST, MK400, LOCKING 11439 HOUSING, MACHINED 11599 SPRITE HOUSING, MACHINED 11601 SPRITE COVER, MACHINED

Trading:181 PACKAGE TSUDAKOMA NC ROTARY TABLE 1 LOT SPARE PARTS FOR TOYOTA TEXTILE MACHINERY ROLAND ELECTRONIC MUSICAL INSTRUMENTS AUTOMOBILE CABLE 9 PALLETS OF V BELTS EL21 , HANGERS AND SUPPORTS DAP SERGIPE, BRAZIL 41 WOODEN CASES OF KPF RINGS FOR BEARING IQ BA

Trading:3 PCS CONSISTING OF STORING STATION RTVB11 20ST ROTARY TABLE VERTICAL DTV38 20 PART 1 INCL 001120 00362562 210060931INCL 001125 00171841 383060933 INCL 001141 P011807 801096929 STORING STATION RTVB32 20STP STORING STATION RTVN11 20STSTORING STYTION RTVB11 20ST

Recommend:The company has a total of 2 transactions related to horizontal rotary table in the last two years, the last transaction is on 2021-02-16; the transactions related to horizontal rotary table represent 0.09 of the company total transactions of the last two years.

Recommend:The company has a total of 3 transactions related to rotary table in the last two years, the last transaction is on 2021-09-07; the transactions related to rotary table represent 0.48 of the company total transactions of the last two years.

Recommend:The company has a total of 1 transactions related to rotary table in the last two years, the last transaction is on 2021-08-23; the transactions related to rotary table represent 0.02 of the company total transactions of the last two years.

Trading:CNC CONTROLLED, CHUCK TYPE GRINDING MACHINE 1 SET OF KOYO MODEL VG-100, MITSUBISHI MOTION, CNC CONTROLLED, CHUCK TYPE GRINDING MACHINE WITH STANDARD ACCESSORIES AND SPECIAL EQUIPMENT 1 SET OF KOYO MODEL R632 6 AXES CNC CONTROLLED, TWO-SPINDLE, ROTARY TABLE-TYPE, SURFACE GRINDING MACHINE WITH STANDARD ACCESSORIES AND SPECIAL EQUIPMENT "SHIPPERS DESIRE TO STATE THAT" COUNTRY OF ORIGIN: JAPAN

8613371530291

8613371530291