manual indexing rotary table quotation

This indexing unit with collet chuck is specially designed for use on wire-EDM machines provided. Through the mounting holes mounting on hole pattern 40 mm and 50 mm by M8 srews is possible.

The RTBA is a unit manufactured by Kalamazoo company. It is a rotary table with a 6" table index. Furthermore, it has a numerous index combination by changing of index ring on a 36 spaces ...

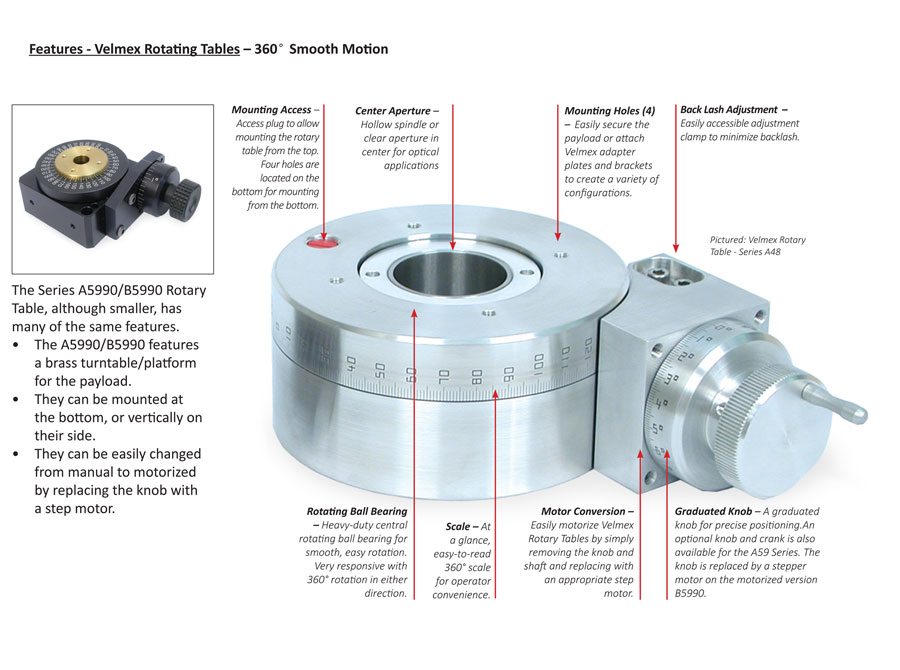

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

CNC Indexing has both pneumatic and hydraulic tables in stock for immediate delivery! Looking for a TJR rotary table price? We have a range of cost-effective options to suit your needs!

For TJR’s pneumatic series of rotary tables, prices start at $5,685. The AR Series is offered in both right hand and left hand motor mount options, with face plate diameter ranges of 125mm – 255mm.

Both the pneumatic and hydraulic brake series TJR rotary table price includes standard features such as an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. For new TJR tables, a standard 3-year parts warranty is included.

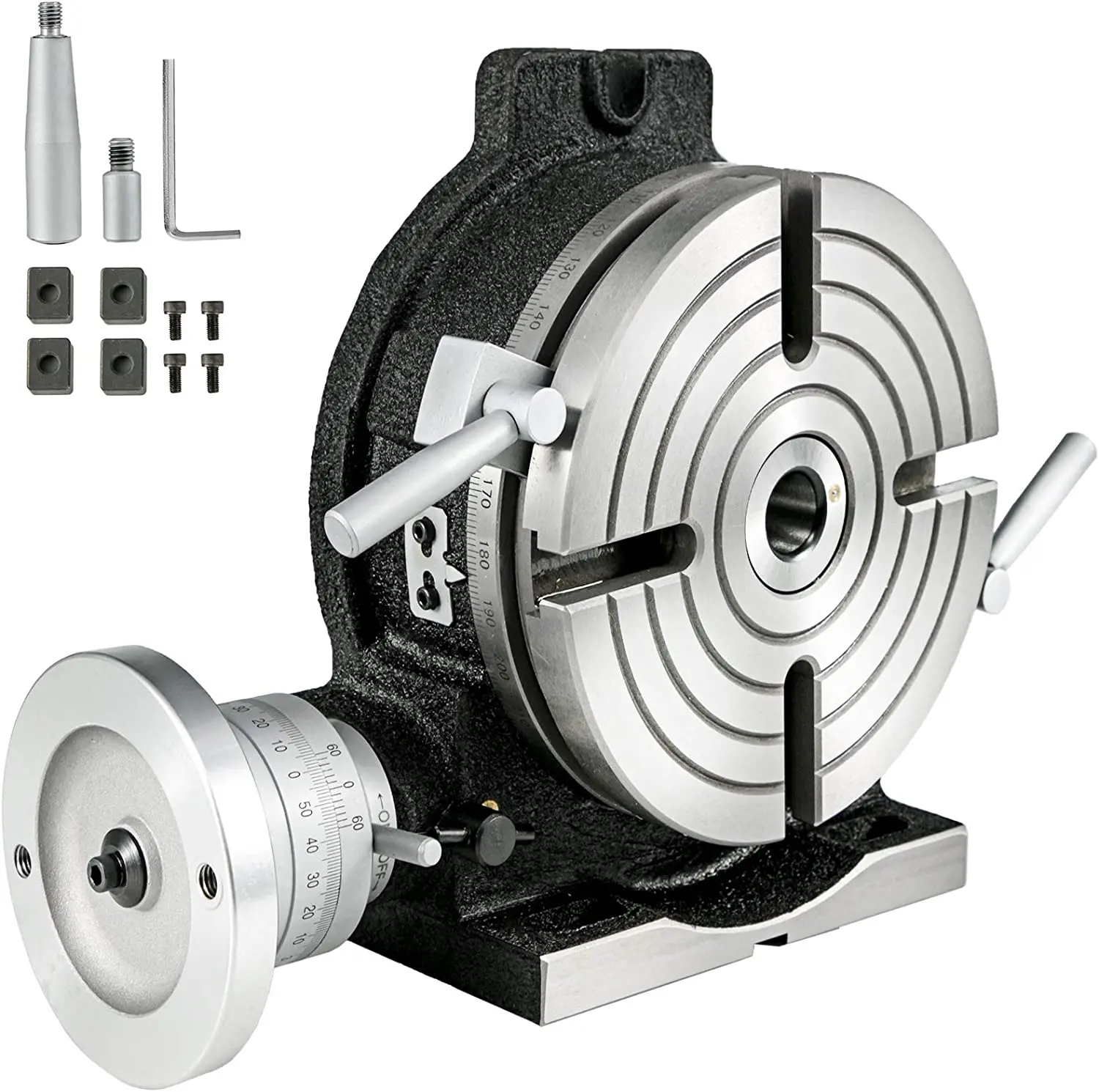

We hold expertise in offering an exclusive range of Manual Rotary Table to our esteemed clients. The offered rotary table is designed by latest technology according to the requirements laid down by our patrons. Apart from this, the offered rotary table is carefully inspected on each section in order to supply fault free range.

Works as an index center in thevertical position as well as convental RotaryTable graduated 360° Indexing Plate is providedto enable the user to convert quickly to use Indexing plates for fast setting

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

The Bison 5901 / 5911 series indexing fixture can be used vertically or horizontally. The compact design allows for two types of indexing; 1. Basic 2,3,4,6,8,12 and 24 divisions, 2. Angular 360° in 1...

Explore rotary table indexing with simple designs on Alibaba.com for efficient metal cutting and strong support for the workpiece while cutting or grinding. The devices are vital components to various grinding equipment, and they are typically easy to mount. Standard machines that apply rotary table indexing as installable or built-in parts include milling machines, boring tools, and drill presses. Some device applications include gear cutting, devising milling cutter flutes, and making bolt hole circles.

The innovative indexing head features a sturdy head and footstock or indexing centers for steady and reliable operation. Alibaba.com delivers different types of rotary table indexing, including plain, optical, spiral, and universal spiral machines to cater to unique project requirements. The device components may operate as a unit or with extra attachments for enhanced accuracy and precision levels. Explore various direct index heads for fluting taps, milling squares, octagons, and many more.

Shoppers can use rotary table indexing to verify precision angles, proportions and measures up to seconds of a degree using optical lenses for sensitive projects. Universal designs are well-suited for all forms of head indexing since they are configurable at any angle. Make indexing work more comfortable and enjoyable by having these machines in the workshop.

Compare mind-blowing rotary table indexing options and exclusive deals on machinery on Alibaba.com. The quality-assured products come with sustainable warranties and are easy to operate and maintain. Customization for orders and aftersales support is also available from trusted dealers and distributors.

Penn Tool Co. has a variety of precision rotary tables for sale. Simplify your production work with a rotary table that can be used for many different machining applications. In production, it is essential that jobs are done quickly, efficiently, and precisely. In the industry of intricate metalworking, precision matters and can make all the difference. All of the parts should look identical in the end, and our tools can help you do just that. To ensure quality and durability, we only carry top-rated, premium brands you can trust including Vertex, Harig and Phase II. With an easy-to-operate precision rotary tablefrom Penn Tool Co., get the accuracy you need and a timely, beautiful end result. Browse our collection, and order today!

Over four decades we have accumulated a vast experience in the design and production of mechanical devices, producing well-received customized cams, automatic tool changers, and intermittent indexing drives for automation applications.

The H7506 Horizontal/Vertical Rotary Indexing Table has an indexing head, a precision adjustable 3-jaw chuck, and can be used in the horizontal or vertical position for a variety of milling applications.

The 24-slot main indexing plate is drilled with eleven holes so the position of the spacer plates can be changed during machining operations for different setups.

The H7506 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your rotary table.

The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts for the rotary table may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.

Indexing Heads for 8 inches to 12 inches Phase II Horizontal Rotary Tables. Phase II Indexing heads or Dividing Plates (241-101) allow you to precisely divide a circle into a number of divisions or degrees. The indexing feature helps prevent errors during the repetitive adjustments required in indexing work. The dividing plate set is used to divide one 360° table rotation into divisions of 30". The gear ratio of the compatible horizontal rotary table is 1:90. This means that 90 rotations of the handwheel rotate table one full rotation. This model of dividing plate accessories is compatible with Phase II horizontal rotary tables of size 8 inches, 10 inches and 12 inches. Therefore for one full rotation of the table, the number of handwheel rotations per division "N" times the number of divisions "T" is equal to 90 rotations of the handwheel. So N x T= 90 or N = 90 ÷ T. Say for example, if 17 divisions are required for indexing on a workpiece, then T=21, so N= 90/17 =55/17 = 5 10/34. With 5 full handwheel rotations, 17 divisions are covered and the rest 10/34 by one handwheel rotation. The 10/34 of a handwheel rotation is obtained by using the dividing plates. The annular holes as provided in the dividing plates permit the required number of divisions of one handwheel rotation. The weight of the dividing plate is about 5 lbs.

8613371530291

8613371530291