manual tilting rotary table factory

The rotating axis of the MTHR rotary table can be intergraded into a CNC machine control as a full 4th axis or it can be operated as an indexer by utilizing TJR’s SAC (Single Axis Controller). The MTHR unit is manufactured with a large radial-axial preloaded bearing system for high rigidity that can perform light or heavy cutting.

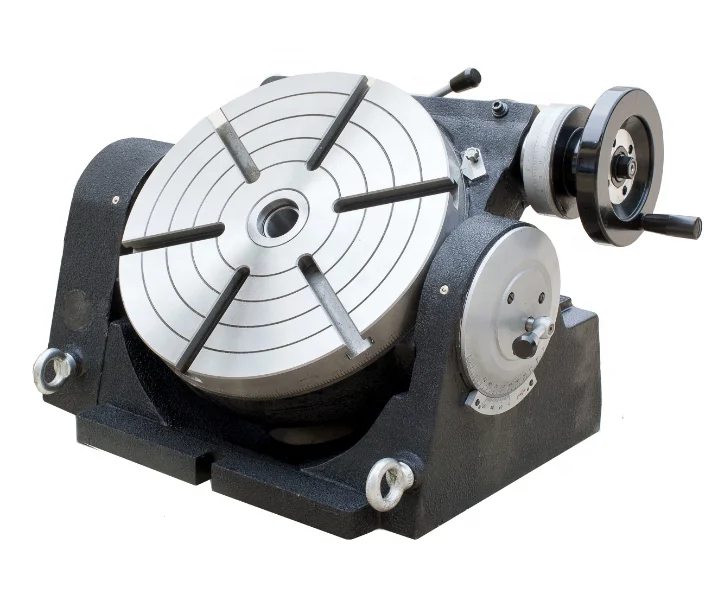

The MTHR is TJR’s 1 degree manual tilt rotary table offering that employs a hydraulic brake system. This manual tilt rotary table is an affordable solution for customers who require an automated rotating axis but also occasionally require the ability of a tilting axis.

The MTHR unit uses a dual lead worm shaft and worm gear to ensure long term indexing accuracy in both directions. In addition the MTHR has a powerful double disk braking system for the tilting axis.

TJR’s standard tilt rotary tables offer several options for turning your traditional 3 axis milling machine into a 5 axis machine for a portion of the cost of a new full 5 axis machine.

The FAR-Series pneumatic brake tilt rotary table line and is offered in multiple sizes and configurations and is available in single arm or dual arm type.

The FHR-Series is a dual arm, hydraulic brake tilt rotary table line offered in multiple sizes and configurations. This series has (3) independent braking systems, and max tilting angle +/- 110 degrees.

The FAR and FHR Series standard tilt rotary tables are capable of being fully integrated into your current machine control so you can utilize as a full rotating and tilting axis for true 5 axis work. It is also capable of being used as a full 4th and 5th axis connecting to TJR’s DAC (Dual Axis Controller) in the event that you need to utilize the unit on multiple machine tools. All are manufactured with large-diameter radial-axial preloaded bearing system for high rigidity that can perform light or heavy cutting.

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Turntables, which can be spun freely by hand are ideal for mounting and rotation of test specimens, cameras, transducers, sensors, and mirrors. They are a convenient, accurate method of quickly positioning or rotating ...

The Siegmund height adjustable rotating table provides an ergonomic and space saving solution. The work top height is infinitely variable and can be fixed in position by a side locking lever.

The Siegmund height adjustable rotating table provides an ergonomic and space saving solution. The work top height is infinitely variable and can be fixed in position by a side locking lever.

This low profile turntable / floor height turntable is less than 1" high and can be loaded by a hand pallet truck. By rotating the load the operator ...

This large non-powered turn table is for those big positioning jobs where heavy loads must be rotated on a regular basis. This turn table has a capacity up to 7,000 lbs. and a platform size of 4 feet ...

The KESSLER Table line includes single-axis rotary tables and dual-axis rotary tilt tables. It incorporates the renowned KESSLER know-how for superior ...

... sprinkling with powdered sugar, cocoa powder, chocolate sprinkles, nuts or almonds, chocolate beans or pine nuts. whether turntables for manual or fully automatic sprinkling powder drums series PTR, the ...

Model LPTG is a heavy duty turntable featuring a 1912 gravity roller top and concave transition sections (2 included) that can be used in a pass thru conveyor line. The transition section can be reconfigured to make 90° ...

S35 Manual Turntables enable workers to easily rotate heavy loads. The heavy-duty design of these manual industrial turntables is specially engineered to withstand the ...

The Heavy-Duty Manual Turntable maximizes workspace and minimizes wasteful motion. Bench top turntables allow workers to stay in one position and rotate items for access ...

Tilting rotary tables are mounted on milling machines to provide the user with two additional axes for machining operations. A tilting rotary table is an economical way to give a three-axis mill five-axis machining capabilities.

Tilting rotary tables resemble rotary indexing tables with an additional rotating axis. They can either be manually actuated or CNC controlled, the latter requiring two additional interface cables to control all five axes.

Alibaba.com offers 55 manual tilting rotary table products. About 29% % of these are other machine tools accessories, 18%% are dividing head, and 14%% are table.

A wide variety of manual tilting rotary table options are available to you, such as manufacturing plant, machinery repair shops and energy & mining.You can also choose from 1 year, 1.5 years and 5 years manual tilting rotary table,As well as from not available, {2}, and {3}. and whether manual tilting rotary table is bearing, gear, or motor.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

The reverse rotary table is perfect for using on the tilting angle table. The reverse mount allows access to the handwheel from the front of the machine (see photo below). If you used a standard rotary table in the previously described set-up, the handwheel would be mounted facing the backside of the X-axis.

NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table.

The rotary tables can hold more weight when they are not under a continual load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

Manual precision rotary table with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications.

Additional direct indexing plate for the indexing plate device for all divisions up to 100 and higher ones, many up to 400, with included adjusting table.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

TJR MTHR(s)-255 is a 255mm diameter CNC rotary table with manual tilting function for customers with specific fixture angles to machine at, or minimal tilt axis requirements and can stop the machine and manually adjust the tilting angle. Comes with a high capacity hydraulic braking system, priced without motor and can be prepared to suit any interface at additional cost. (See our interface listings for details and costs for external interface (motor, switch, cable and connector requirements if you already have a 4th axis interface in the machine) and machine interface costs (if you do not have the additional axis fitted).

Rusach International has continued an on-going program of design and development, benefiting from years of experience in the design of special purpose Rotary Tables, Pallet Automation Systems and Metrology Products,from our Eimeldingen years. An increased product range through acquisitions and product development has enhanced the company"s work on high accuracy rotary tables. A natural progression was the introduction of retrofitting pallet automation systems in 1976. These have subsequently been supplied in "stand alone" and FMS form to suit a wide range of machining applications, also over the last few years supplying rotary and tilt CNC tables fully integrated onto slideways or as full bases for various machines.

Designed and manufactured to the highest level of quality, our rotary tables feature distortion-free active clamping with roller bearings for high-resolution rotation. The rigid design and solid components make loading capacities of up to 100+ tons possible.

8613371530291

8613371530291