manual tilting rotary table in stock

Alibaba.com offers 55 manual tilting rotary table products. About 29% % of these are other machine tools accessories, 18%% are dividing head, and 14%% are table.

A wide variety of manual tilting rotary table options are available to you, such as manufacturing plant, machinery repair shops and energy & mining.You can also choose from 1 year, 1.5 years and 5 years manual tilting rotary table,As well as from not available, {2}, and {3}. and whether manual tilting rotary table is bearing, gear, or motor.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Penn Tool Co. has a variety of precision rotary tables for sale. Simplify your production work with a rotary table that can be used for many different machining applications. In production, it is essential that jobs are done quickly, efficiently, and precisely. In the industry of intricate metalworking, precision matters and can make all the difference. All of the parts should look identical in the end, and our tools can help you do just that. To ensure quality and durability, we only carry top-rated, premium brands you can trust including Vertex, Harig and Phase II. With an easy-to-operate precision rotary tablefrom Penn Tool Co., get the accuracy you need and a timely, beautiful end result. Browse our collection, and order today!

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

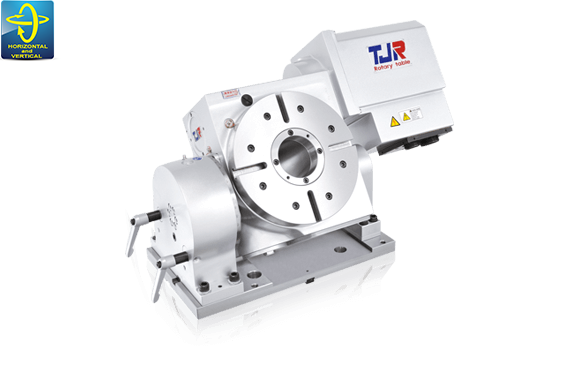

The rotating axis of the MTHR rotary table can be intergraded into a CNC machine control as a full 4th axis or it can be operated as an indexer by utilizing TJR’s SAC (Single Axis Controller). The MTHR unit is manufactured with a large radial-axial preloaded bearing system for high rigidity that can perform light or heavy cutting.

The MTHR is TJR’s 1 degree manual tilt rotary table offering that employs a hydraulic brake system. This manual tilt rotary table is an affordable solution for customers who require an automated rotating axis but also occasionally require the ability of a tilting axis.

The MTHR unit uses a dual lead worm shaft and worm gear to ensure long term indexing accuracy in both directions. In addition the MTHR has a powerful double disk braking system for the tilting axis.

Indexing Heads for 8 inches to 12 inches Phase II Horizontal Rotary Tables. Phase II Indexing heads or Dividing Plates (241-101) allow you to precisely divide a circle into a number of divisions or degrees. The indexing feature helps prevent errors during the repetitive adjustments required in indexing work. The dividing plate set is used to divide one 360° table rotation into divisions of 30". The gear ratio of the compatible horizontal rotary table is 1:90. This means that 90 rotations of the handwheel rotate table one full rotation. This model of dividing plate accessories is compatible with Phase II horizontal rotary tables of size 8 inches, 10 inches and 12 inches. Therefore for one full rotation of the table, the number of handwheel rotations per division "N" times the number of divisions "T" is equal to 90 rotations of the handwheel. So N x T= 90 or N = 90 ÷ T. Say for example, if 17 divisions are required for indexing on a workpiece, then T=21, so N= 90/17 =55/17 = 5 10/34. With 5 full handwheel rotations, 17 divisions are covered and the rest 10/34 by one handwheel rotation. The 10/34 of a handwheel rotation is obtained by using the dividing plates. The annular holes as provided in the dividing plates permit the required number of divisions of one handwheel rotation. The weight of the dividing plate is about 5 lbs.

8613371530291

8613371530291