manual tilting rotary table quotation

Alibaba.com offers 55 manual tilting rotary table products. About 29% % of these are other machine tools accessories, 18%% are dividing head, and 14%% are table.

A wide variety of manual tilting rotary table options are available to you, such as manufacturing plant, machinery repair shops and energy & mining.You can also choose from 1 year, 1.5 years and 5 years manual tilting rotary table,As well as from not available, {2}, and {3}. and whether manual tilting rotary table is bearing, gear, or motor.

Indexing Heads for 8 inches to 12 inches Phase II Horizontal Rotary Tables. Phase II Indexing heads or Dividing Plates (241-101) allow you to precisely divide a circle into a number of divisions or degrees. The indexing feature helps prevent errors during the repetitive adjustments required in indexing work. The dividing plate set is used to divide one 360° table rotation into divisions of 30". The gear ratio of the compatible horizontal rotary table is 1:90. This means that 90 rotations of the handwheel rotate table one full rotation. This model of dividing plate accessories is compatible with Phase II horizontal rotary tables of size 8 inches, 10 inches and 12 inches. Therefore for one full rotation of the table, the number of handwheel rotations per division "N" times the number of divisions "T" is equal to 90 rotations of the handwheel. So N x T= 90 or N = 90 ÷ T. Say for example, if 17 divisions are required for indexing on a workpiece, then T=21, so N= 90/17 =55/17 = 5 10/34. With 5 full handwheel rotations, 17 divisions are covered and the rest 10/34 by one handwheel rotation. The 10/34 of a handwheel rotation is obtained by using the dividing plates. The annular holes as provided in the dividing plates permit the required number of divisions of one handwheel rotation. The weight of the dividing plate is about 5 lbs.

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Turntables, which can be spun freely by hand are ideal for mounting and rotation of test specimens, cameras, transducers, sensors, and mirrors. They are a convenient, accurate method of quickly positioning or rotating ...

The Siegmund height adjustable rotating table provides an ergonomic and space saving solution. The work top height is infinitely variable and can be fixed in position by a side locking lever.

The Siegmund height adjustable rotating table provides an ergonomic and space saving solution. The work top height is infinitely variable and can be fixed in position by a side locking lever.

This low profile turntable / floor height turntable is less than 1" high and can be loaded by a hand pallet truck. By rotating the load the operator ...

This large non-powered turn table is for those big positioning jobs where heavy loads must be rotated on a regular basis. This turn table has a capacity up to 7,000 lbs. and a platform size of 4 feet ...

The KESSLER Table line includes single-axis rotary tables and dual-axis rotary tilt tables. It incorporates the renowned KESSLER know-how for superior ...

... sprinkling with powdered sugar, cocoa powder, chocolate sprinkles, nuts or almonds, chocolate beans or pine nuts. whether turntables for manual or fully automatic sprinkling powder drums series PTR, the ...

Model LPTG is a heavy duty turntable featuring a 1912 gravity roller top and concave transition sections (2 included) that can be used in a pass thru conveyor line. The transition section can be reconfigured to make 90° ...

S35 Manual Turntables enable workers to easily rotate heavy loads. The heavy-duty design of these manual industrial turntables is specially engineered to withstand the ...

The Heavy-Duty Manual Turntable maximizes workspace and minimizes wasteful motion. Bench top turntables allow workers to stay in one position and rotate items for access ...

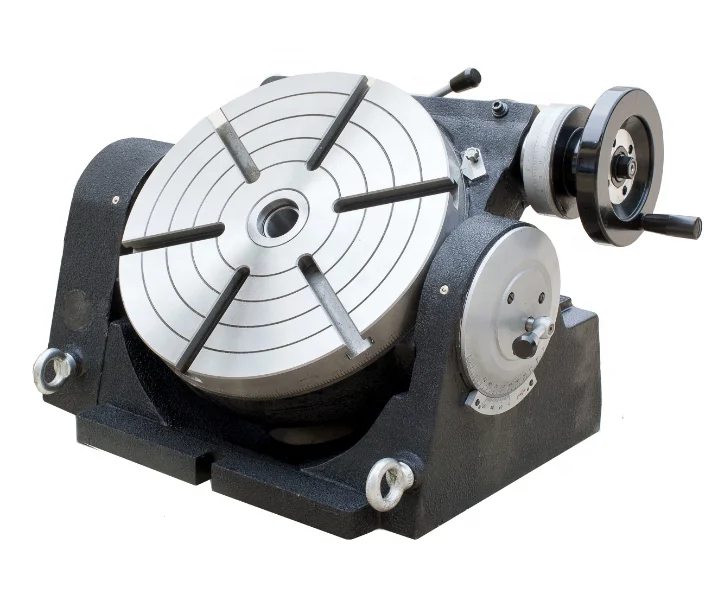

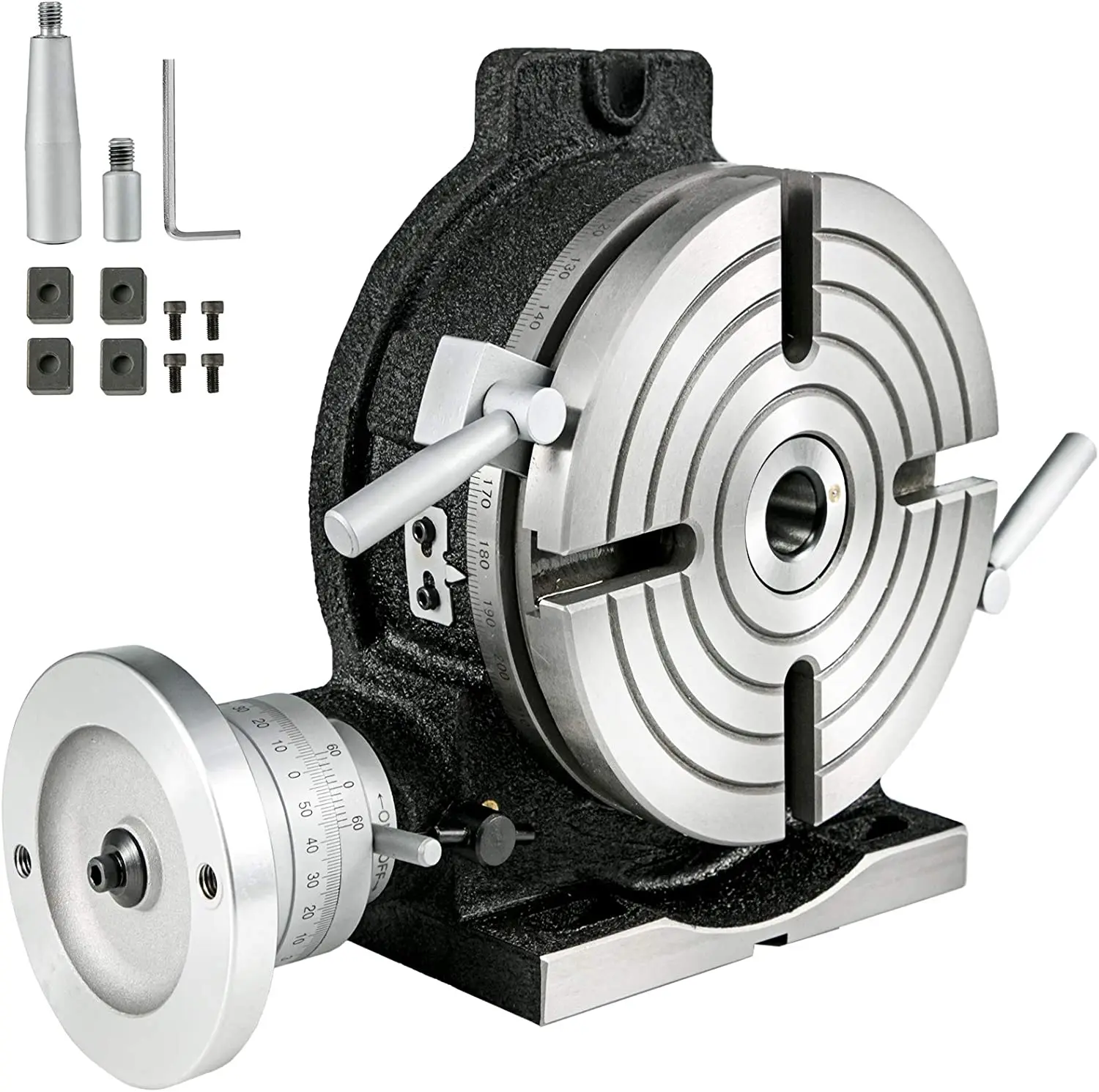

Tilting rotary tables are mounted on milling machines to provide the user with two additional axes for machining operations. A tilting rotary table is an economical way to give a three-axis mill five-axis machining capabilities.

Tilting rotary tables resemble rotary indexing tables with an additional rotating axis. They can either be manually actuated or CNC controlled, the latter requiring two additional interface cables to control all five axes.

The rotating axis of the MTHR rotary table can be intergraded into a CNC machine control as a full 4th axis or it can be operated as an indexer by utilizing TJR’s SAC (Single Axis Controller). The MTHR unit is manufactured with a large radial-axial preloaded bearing system for high rigidity that can perform light or heavy cutting.

The MTHR is TJR’s 1 degree manual tilt rotary table offering that employs a hydraulic brake system. This manual tilt rotary table is an affordable solution for customers who require an automated rotating axis but also occasionally require the ability of a tilting axis.

The MTHR unit uses a dual lead worm shaft and worm gear to ensure long term indexing accuracy in both directions. In addition the MTHR has a powerful double disk braking system for the tilting axis.

CNC Indexing has both pneumatic and hydraulic tables in stock for immediate delivery! Looking for a TJR rotary table price? We have a range of cost-effective options to suit your needs!

For TJR’s pneumatic series of rotary tables, prices start at $5,685. The AR Series is offered in both right hand and left hand motor mount options, with face plate diameter ranges of 125mm – 255mm.

Both the pneumatic and hydraulic brake series TJR rotary table price includes standard features such as an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. For new TJR tables, a standard 3-year parts warranty is included.

Penn Tool Co. has a variety of precision rotary tables for sale. Simplify your production work with a rotary table that can be used for many different machining applications. In production, it is essential that jobs are done quickly, efficiently, and precisely. In the industry of intricate metalworking, precision matters and can make all the difference. All of the parts should look identical in the end, and our tools can help you do just that. To ensure quality and durability, we only carry top-rated, premium brands you can trust including Vertex, Harig and Phase II. With an easy-to-operate precision rotary tablefrom Penn Tool Co., get the accuracy you need and a timely, beautiful end result. Browse our collection, and order today!

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

This is an accurate designed table for milling, boring and other machine tools. This table allows indexing, facing and other work to be carried out rapidly with extreme precision. Tiliting range 0-90 degrees fromread more...

Avail from us a wide range of Rotary Milling Tables, as we are engaged in offering these products in small as well as in huge bulk as per the needs of our clients. These tables are well designed with latest styles and modern technologies. In addition to this, we are offering our range in standard finishing. Lastly, our rangeread more...

Backed with the talented team, we bring forth a qualitative collection of Large Rotary Table. This rotary table is developed according to the industry laid norms by utilizing quality proven material & cutting edge technology. Our given range of rotary table is accessible with different stipulations as per customer’sread more...

Table Rotator provides accurate and steady rotation for medium to large work pieces. Speed is infinitely variable in various ranges and in both forward and reverse directions. A heavy duty foot pedal controls rotation. Table Rotator allows the welder to rotate the work piece through out 360o reposition for welding positioning.read more...

Quality is the hallmark of our company, in order to maintain quality standards we offer wide range of Rotary Tables. Our products are sturdy and durable. We offer Rotary Tables to our clients as per their needs and in recommended specifications. Moreover, customers can avail Rotary Tables from us as per the need of theread more...

We offer a comprehensive range of Rotary Tables that is made using high grade material, sourced from reliable vendors. This range is highly demanded owing to its durability and reliability. Moreover, our range generates low noise and is corrosion resistant. Besides, our range stands on the quality parameters set by the clientsread more...

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

8613371530291

8613371530291