milling a radius on a rotary table for sale

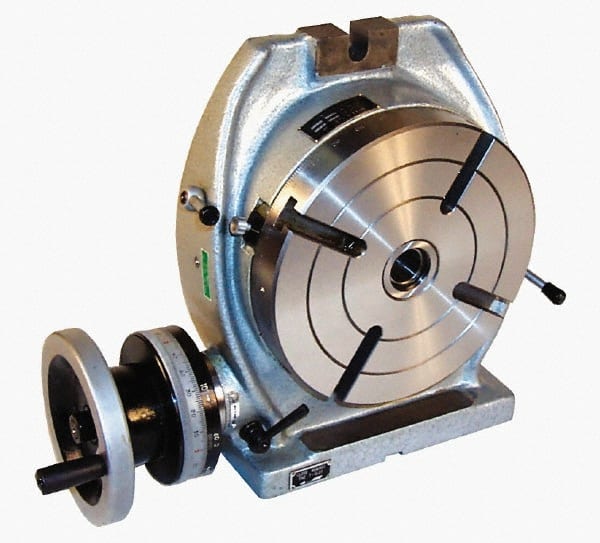

A rotary table is a really nice accessory to have for your mill, but one that you can delay purchasing for a while until you master the basic milling operations. The rotary table is driven by a worm-gear and is accurately calibrated in degrees and fractions of a degree.

It is used to mill or drill accurately positioned holes around a bolt circle, for milling arc-shaped grooves or slots and many other operations. Most, but not all, can be mounted in a vertical as well as a horizontal orientation; a very desirable feature.

Finding a rotary table of the right size for the mini-mill has been a lille problematic. 8-inch tables are really much too big. Even a 6-inch is pushing the limits. I have one from Grizzly. It is well made and works well, but mounting it to the table was a little bit of a challenge.

Sherline offers a very nice 4-inch model, and more recently LittleMachineShop.com has listed a 4-inch model as well. These are very nice, but a little smaller than I would like. In my view, a 5-inch model would be ideal, but I don’t know of one in that size.

The first rotary table I purchased was made in India and was of really poor quality. I returned it to the vendor for a refund. Unfortunately, the return shipping on a heavy object like this is not cheap, so be careful what you buy!

Sherline makes a beautifully finished 4″ rotary table which I got to see first hand at Cabin Fever 2001. I was very impressed by the high quality of this item, but It was a little small for my needs.

The table I currently use is a Grizzly G1049 6-inch model. As of 03/02 it sells for $199 plus shipping. It is well-made, and I have been very satisfied with it, although it is a little large for the mini-lathe as you will see in the photos below.

After cleaning off the packing grease with kerosene, a painbrush and a rag, I mounted it on the mini-mill table using 3/8″ carriage bolts that I also use for my 3 1/2″ Grizzly milling vise. The center hole is a #2 Morse taper.

The RT is really a little oversize for the mini-mill, but still provides enough clearance to be practical. I did not feel that the weight was beyond the capabilities of the mini-mill table.

Here’s a picture showing the table with a 12″ rule and a 1/2″ mill in an end mill adaptor. Mounting the mill in a collet would provide another 2″ or so of working room. The head is at the top of the column. Also shown is the 3″ chuck from the 7×10 mini lathe. As you can see, there is adequate clearance for most operations.

The casting has mounting lugs for both horizontal or vertical mounting. This makes it potentially much more flexlible, but the table of the mini mill is small compared to the RT which makes mounting the rotary table in the vertical orientation a little tricky.

One problem is that the lower edge of the handwheel for the RT is lower than the base of the RT, so it must be positioned off the edge of the table. If the RT is positioned perpendicular to the X-axis, the mounting holes in the RT are outside the limits of the T-slots in the mill table.

These problems can presumably easily be overcome by using custom-made riser blocks and clamps, though. I have not yet attempted to make these items, but would not expect them to be very difficult to make.

For the price, I was pretty impressed by the quality of the table. I would rate it somewhat lower in quality than the Sherline 4″, but much better than the Victor 6″.

The base is painted with wrinkle-finish black paint. Fortuitously, the T-slots in the RT are about the same width as those on the mini-mill, so the same T-nuts can be used on both.

The handwheel is satin-finish steel with cleanly etched divisions. Each full rotation of the handwheel rotates the table by 4 degrees. A brochure included with the RT illustrates an indexing plate accessory which can apparently be attached to the RT, but I’m not sure whether or not Grizzly sells this accessory.

An eccentric cam between the handwheel and the table permits you adjust the meshing of the worm-screw to minimize backlash. A screw with a T-handle locks the cam in place once it is set.

Here’s a nice little 4″ imported rotary table offered by LMS for $134.95. They offer several other models, including the Sherline 4″. I don’t have any first-hand experience with this one, so I can’t really comment on quality or capabilities.

I consent to Excel Machine Tools storing my submitted information so they can respond to my inquiry, for full information on how we manage your data please read our Privacy Policy

·Typical use cases include machining the flutes of a milling cutter, cutting the teeth of a gear, milling curved slots, or drilling a bolt hole circle around the circumference of a part.

As will become more obvious as you read this post, I"m new to the vertical mill - have had mine for a whole three weeks now, and just finished installing a Newall 3-axis DRO (Z-axis on the quill) a couple of days ago. Which brings up a question - one of the guys here posted a photo of a nice saddle block he machined to fit atop the ram of his B"port. It"s sitting right over the hole the machine lift eye threaded into, and is the base he used to mount the arm that holds the DRO control head/console. He did a very nice job of finishing it, even machined a radius or bevel (couldn"t tell which in the photo) around the top edge of the block. My question is how you would set up to machine the radius into the bottom of such a block to match the radius of the top of the ram? I"d like to make a copy of his saddle block out of 6061, and am also looking at machining a one piece scope base (also of 6061) to fit rifle actions that have different radii on the front & rear receiver rings.

I"ve seen a vidio clip of cutting an outside radius by turning the workpiece by hand online, but don"t think that"s going to cut it with either of these projects. I guess I could try to figure out how to keller the radius with multiple passes with a ball end mill, but would sure prefer a quicker, less complicated method, even if it required the construction of a jig or fixture - if it worked well enough, I"d like to make scope bases for sale. I"m starting to wonder if you"d need a CNC machining center to do what I have in mind.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

TSL vertical&horizontalrotary table is one of the main accessories of milling machine, it is used for index boring, milling, circle cutting, spot facing and boring hole etc on the milling machine. The rotary table in vertical with working together can be used on complex work for circle index boring and milling.

8613371530291

8613371530291