motor driven rotary table free sample

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

M-035 series high precision rotary tables rotation stages feature high resolution, excellent repeatability and minimum wobble. These high performance rotational positioning stages are equipped with double ball bearings for minimum backlash and high load capacity. Both the rotation stage platform and the scale ring (graduated in 2-degree increments) can be independently coarse positioned over 360 degrees and then be locked by screws.

The basic rotary table version, M-035.D0, is equipped with a DC servo motor drive providing a positioning range of ± 6.3 degrees. A set of limit switches eliminates the possibility of overtravel. For the highest precision and highest performance, high speed air bearing rotary tables are recommended.

A turbo among rotary tables – the new FIBRODYN DA direct driven rotary tables with torque motor are optimally suited for all handling and assembly applications that require the shortest indexing times and flexible positioning. Thanks to its measuring system directly in the rotary table axis, any position can be moved to with the highest precision. The slim design with its very space-saving, compact construction and its fitted boreholes makes it very easy to integrate the rotary tale into your system. FIBRODYN DA is also available as decentralized stand-alone solution with integrated control. In this version, it offers the ideal opportunity to save a separate external NC control to minimize the implementation and start-up costs and to realize small machines without complex peripherals. The rotary tables are lifetime lubricated and maintenance free.

The KP1-V single-axis turntable with vertical rotational axis is used for direct workpiece positioning or as a modular base. It is available with a payload capacity of 500 ...

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or larger machines. It is ideal for smaller ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility than its predecessor. ...

The rotary table TP 004 is a simply designed turning unit of high-quality gear and drive motor as a main component. It is equipped with an inductive reference ...

The base and circular positioning tables are made out of anodized aluminium alloy. The self-locking spindle is made from steel and its slide bearing is maintenance-free. The table has ...

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

... turning table is equipped with motorized roller conveyors. It is used in conveying systems for changing the direction of the package units, without difference in the forward front. In addition, it is ...

Microplan"s TR rotating tables are designed and manufactured out of 2 granite disks each, moving on pressure/vacuum air bearings in ways to obtain highest possible stability. These apparatuses ...

Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

The Compact Clean room rotary table PSX Series is manufactured by ITALPLANT. The product is made of plastic, making it very light. It is suitable for corrosive and explosive environmental conditions. ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating ...

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating ...

... positioning accuracy, bi-directional repeatability, motion stability and low friction. Rotary stages 8MRL80 have clear aperture of 5mm while 8MRLP80 have dedicated pneumatic collet holder ...

The turntable roller conveyor is used for rotating a pallet to any desired angle. The transport direction of the pallet remains the same. Its modular structure consisting ...

This compact closed-loop direct drive rotary table uses a 3-phase motor for maintenance free, frictionless power transmission. It comes in two variations, standard and with holding brake.

Application video of the silent ultrasonic piezo motor rotary stage in a Leica Theodolite and Principle Design of the PILine drive used in the M-660 PILine� rotary stage

This miniaturized closed-loop rotary positioner is driven by an ultrasonic direct-drive motor and provides high rotational velocity up to 3 revolutions / second. An optical encoder is integrated for direct position measurement and feedback with 35 �rad resolution.

A fast ultrasonic ceramic ring-shaped resonator motor provides high speed to 120 RPM. An optical direct metrology encoder is integrated for position feedback.

Q-motion series miniature rotation stages are driven by inertia-type piezo motors. These miniaturized positoining tables are direct-driven, backlash free and provide micro-radian resolution. The self-locking design requires no holding current and provides excellent long-term stability. Three different diameters are available: 14 mm, 22 mm and 32 mm.

The PI miCos line of goniometers and rotation stages is specialized on miniature stages with different motor drives (belt-drives, worm-gear drives) and also on ultra-high precision stages with torque motors, direct metrology and air bearings.

P-5x8 series, Z/tip/tilt nanopositioners are open-frame, high-resolution, piezo-driven stages providing Z motion to 240 �m and rotation around X and Y to 2.4 mrad with resolutions of up to 0.5 nm and 50 nrad. The 66 x 66 mm clear aperture is ideal for transmitted-light applications.

Goniometric cradles are used to rotate samples and objects to a precise angular position. The units here are equipped with precision servo and stepper motors and high-resolution encoders for angular position feedback.

Ultra-slow motion animation of the PILine� ultrasonic piezo motor. The ceramic tip (pusher) is moving on an pseudo-elliptical trajectory. In reality the tip only moves a few nanometers at frequencies to 100"s of kHz.

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an AlphaStep closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

AlphaStep products are stepper motor based hybrid motors with a unique hybrid control system combining the benefits of "open loop control" and "closed loop control".

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.

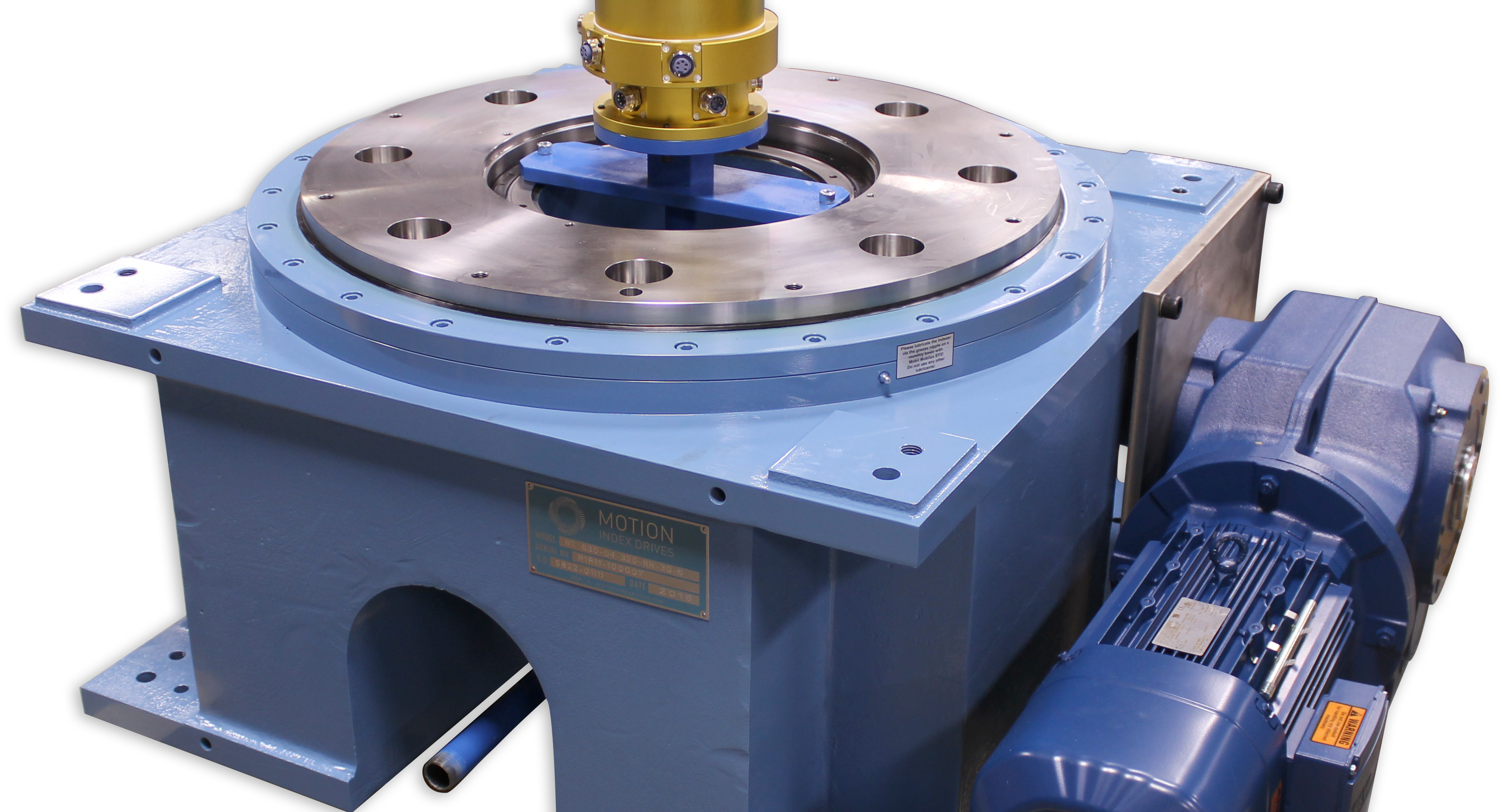

To achieve rotary motion, Cross Company pairs a rotary table with a servo motor, drive and control to create a complete rotary actuation system. This allows greater flexibility for your rotary positioner because you’re not tied to just one or two positions. Some examples of rotary actuation that Cross Company has worked on recently include:Robotic cells which require precise rotary indexing for manufacturing stations

Cross Company’s Automation Group works with several different manufacturers of motors, drives and rotary tables. We work with you to understand your application and then we size and specify the best combination for your particular need. We have literally decades of experience working with rotary actuators, so we can specify a robust solution optimized for the application.

Cross is proud to represent the following manufacturers of rotary positioners:Parker:Worm gear-driven precision rotaries, manual stages and direct drive rotary servo motors which are suitable for light to medium industrial precision positioning

In virtually every industry, a right-sized rotary solution increases the throughput and efficiency of your process. By working with Cross Company, we can help reduce the risk of incorrectly sized and specified equipment, delivering a complete solution perfectly tailored to your application. Contact the experts at Cross to discuss your rotary positioning needs.

There is no theoretical limit to the speed of a linear engine because there is no contact. However, speed is typically limited by the mechanical bearings. For example, the maximum speed for linear control systems with rails and guide cars is usually limited to 5m/s. Therefore, the speed for linear motors in most applications is limited to 5m/s. The use of ceramic ball bearings allows speeds of up to 10m/s. By using air bearings, higher speeds can also be possible.

There is no length limit for linear motors. This is because the engine tracks can be connected to each other in sections. The linear rails can also be connected to each other. The linear scale for donor repatriation can be delivered in large lengths as well. Therefore, linear engine applications can be built up to 20m or even longer.

If the current is suddenly interrupted, a linear motor can move on under its own inertia, until it encounters the final attack or comes to a halt due to friction force. This is not usually a problem, but it can be a problem for some applications. It is possible to install a brake with the linear motor, which will be activated, when power interrupts. In this way, the engine can stop immediately. Such a brake is typically installed on the rails of the linear guidance.

Linear Motors can be used in cleanroom environments. In fact, many front-end semiconductor applications have linear motors in use. In wafer manufacturing plants, high-precision lithography machines, for example, use linear motors in XY positioning tables with very high accuracy (nanometer resolution) and submicron accuracy in cleanroom classes according to ISO 2.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Sherline has taken its manual 4″ rotary table with reverse mount and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

The reverse rotary table is perfect for using on the tilting angle table. The reverse mount allows access to the handwheel from the front of the machine (see photo below). If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis.

NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

X-ray table means a patient support device with its patient support structure (tabletop) interposed between the patient and the image receptor during radiography or fluoroscopy. This includes, but is not limited to, any stretcher equipped with a radiolucent panel and any table equipped with a cassette tray (or bucky), cassette tunnel, image intensifier, or spot-film device beneath the tabletop.

2001 CSO Mortality Table means that mortality table, consisting of separate rates of mortality for male and female lives, developed by the American Academy of Actuaries CSO Task Force from the Valuation Basic Mortality Table developed by the Society of Actuaries Individual Life Insurance Valuation Mortality Task Force, and adopted by the NAIC in December 2002. The 2001 CSO Mortality Table is included in the Proceedings of the NAIC (2nd Quarter 2002). Unless the context indicates otherwise, the “2001 CSO Mortality Table” includes both the ultimate form of that table and the select and ultimate form of that table and includes both the smoker and nonsmoker mortality tables and the composite mortality tables. It also includes both the age-nearest-birthday and age-last-birthday bases of the mortality tables.

Applicable Mortality Table means the mortality table based on the then prevailing standard table (described in Section 807(d)(5)(A) of the Code) used to determine reserves for group annuity contracts issued as of the date as of which the value of the benefit involved is determined (without regard to any other subparagraph of Section 807(d)(5) of the Code) that is prescribed by the Commissioner of Internal Revenue for purposes of determining the value of benefits.

Emission Summary Table means the table prepared in accordance with O. Reg. 419/05 and the Procedure Document listing the appropriate Point of Impingement concentrations of each Compound of Concern from the Facility and providing comparison to the corresponding Ministry Point of Impingement Limit or Maximum Concentration Level Assessment.

Rate table listing means a schedule of rate payments for each provider. The rate table listing is defined as the output that shows the final payment rate by hospital before being multiplied by the appropriate DRG weight.

Seasonal high water table means the highest zone of soil or rock that is seasonally or permanently saturated by a perched or shallow water table. A planar surface, below which all pores in rock or soil (whether primary or secondary) that is seasonally or permanently saturated.

motor cycle means any two-wheeled vehicle, with or without side-car, which is equipped with a propelling engine. Contracting Parties may also treat as motor cycles in their domestic legislation three-wheeled vehicles whose unladen mass does not exceed 400 kg. The term "motor cycle" does not include mopeds, although Contracting Parties may treat mopeds as motor cycles for the purpose of the Convention.

Yearly (1/Year) sampling frequency means the sampling shall be done in the month of September, unless specifically identified otherwise in the effluent limitations and monitoring requirements table.

8613371530291

8613371530291