motor driven rotary table brands

... RIGIDIAL" rotary tables by COLOMBO FILIPPETTI spa have a globoidal cam which transforms the uniform rotary input motion into an intermittent rotary output motion.

The indexing rotary tables of the "IR" Minindex series by COLOMBO FILIPPETTI spa are cylindrical cam mechanical units that transform the uniform rotary motion of the ...

... a heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HT Ring Table Series are designed to propose new solutions for fixed or flexible positioning of heavy loads, thanks to the high performance of the cross-roller bearing.

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ...

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide range of product ...

Direct drive: Electronically commutated 3-phase-synchronous motor with permanent magnetically excited rotor. The motor develops a high torque up to revolutions zero. ...

... with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives with integrated absolute ...

The rotary indexer RT is often used in the assembly technology, the testing technology, the welding technology, the printing, the pressing, the automotive industry, the microelectronics, the food industry, ...

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

Numerous advantages are offered by indexing tables. No matter whatever is the transfer velocity or the load is, the motion is very smooth and progressive. Robust and accurate MCPI cam shaft movement design ...

This turnkey, four-station rotary indexing assembly station from ISUMATIC is meant for driving multiple fasteners simultaneously. They have horizontal and vertical heads, X-Y robots, rotary ...

The TS Series is manufactured by SOPAP Automation. It is a rotary indexing table, that is constructed mainly for plates of a large diameter. Features of the TS includes continuous or ...

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or water; SAT rotary ...

... distributed on the turntable (or total weight)(*) – the maximum total load refers to the forces on the turntable. This does not mean that the indexing table will be able to rotate this ...

Motion’s Multi-dex Indexer solution provides one large base rotary index table with smaller satellite indexers. This allows the tooling or part to be rotated on one end of the work cell ...

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

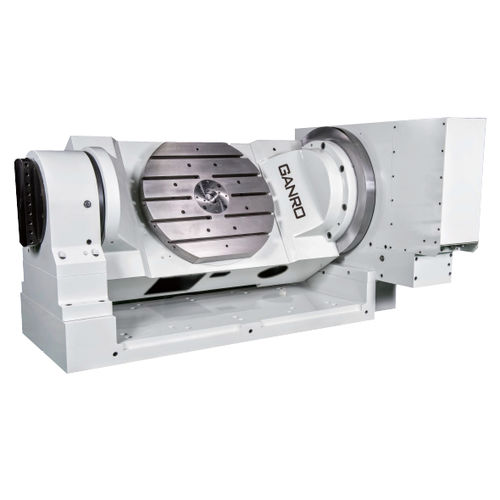

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

... models is available to make the whole range of HMCs complete. The rotary tables dedicated to the Spark line match the 5000 kg max load with excellent dynamics whereas the hydrostatic tables ...

The tilting tables are designed and produced for 5-axis operations on complex work-pieces requiring accessibility to the most unreachable surfaces thus ensuring fast swarf removal at the same time.

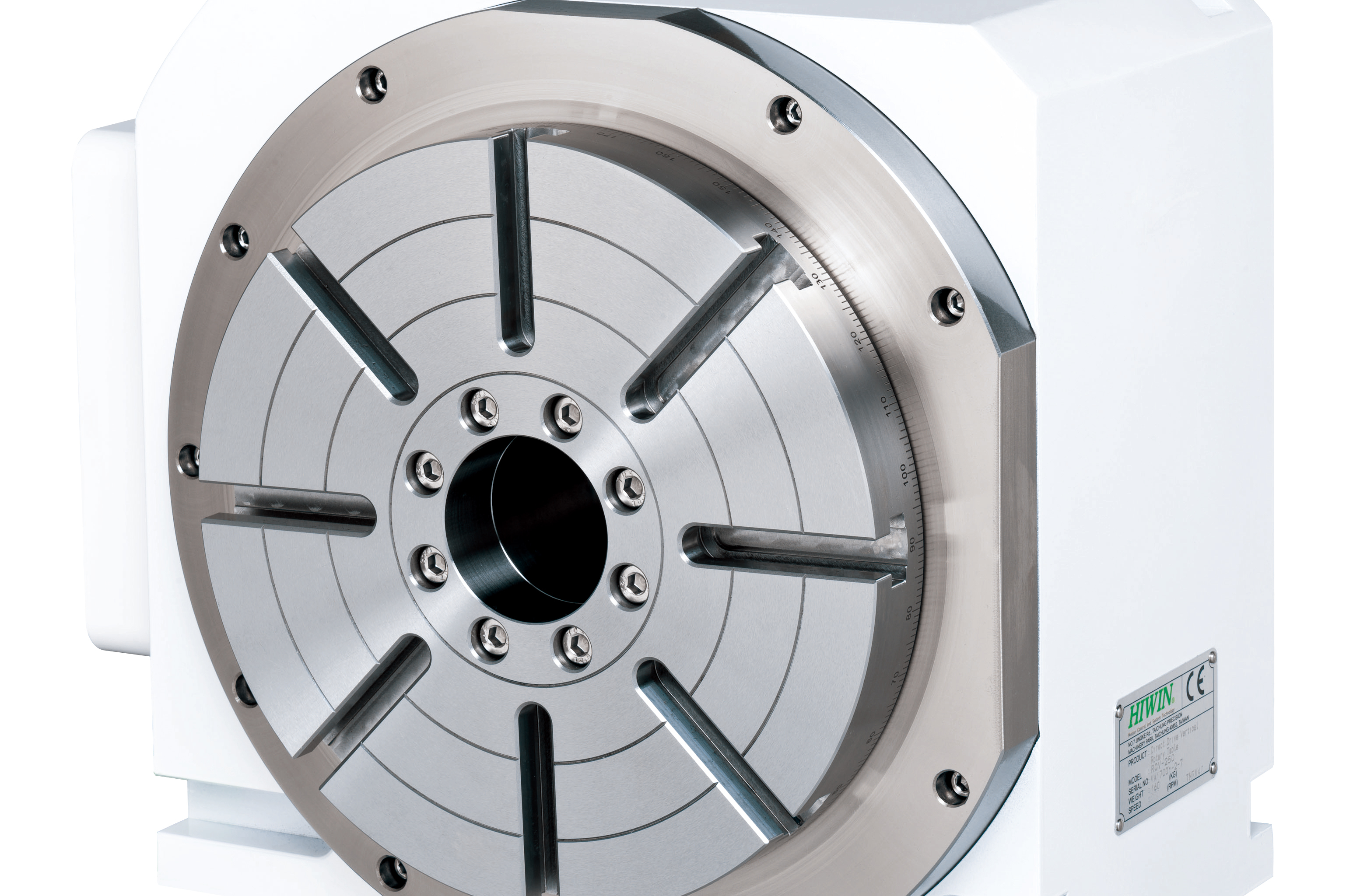

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

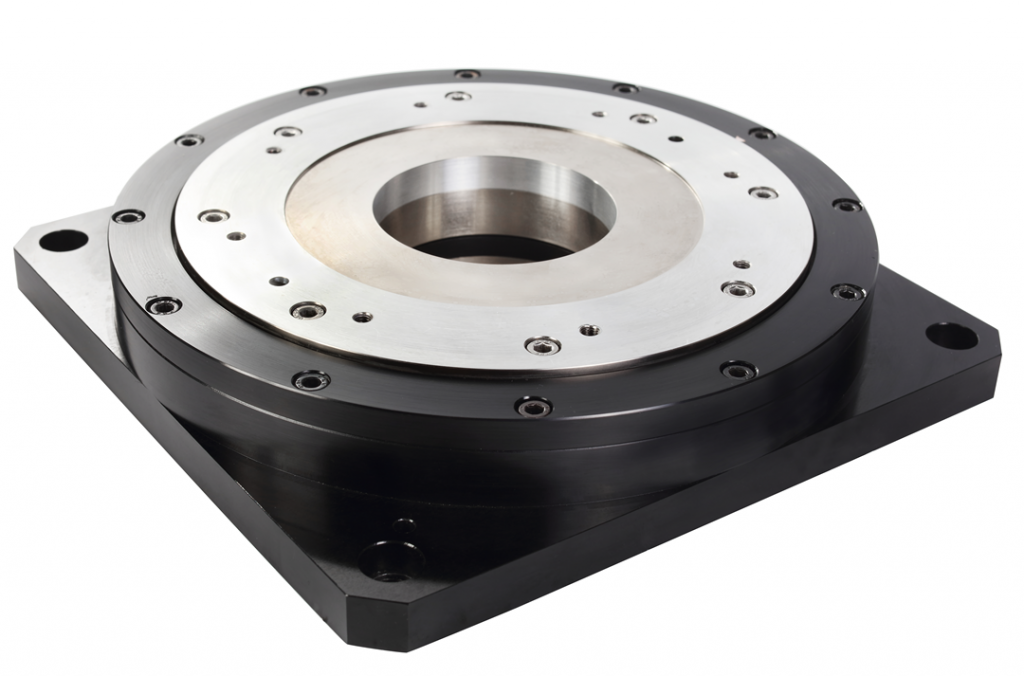

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

CNC Indexing & Feeding Technologies is proud to represent the TJR line of rotary tables, indexers and accessories. TJR originated as a rotary table sales and service agent and established itself as an OEM in 2009.

TJR tables feature an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. All new TJR tables come standard with a 3-year parts warranty.

Standard Rotary Tables. The AR Series is TJR’s standard 4th axis pneumatic brake rotary table. It is offered in both a Right hand motor mounting and Left hand motor mounting option. The HR Series is TJR’s standard hydraulic brake 4th axis rotary table.

CNC Indexing & Feeding Technologies offers a wide range of TJR rotary tables. However, many are unclear about what rotary tables can do for their business, as well as how they work in CNC machining. First, let’s consider the basics about a rotary table and how it works in the machining and manufacturing processes.

A rotary table can tilt and rotate. The table makes use of the indexing head in order to cut according to a specific technique. This makes it possible for the machine to create a workpiece with complete flexibility in rotation and angling.

A rotary table can help to create arcs and circles, an important process in part or tool fabrication. Tools can be specially made, such as car parts, machine parts, and many other objects.

The CNC process lets companies make straight cuts even with multiple angles and to cut small objects into even smaller parts. CNC rotary tables can also help in the processes of cutting gears, drilling or cutting holes.

The table can also be used along with a dividing head and index plate, to further concentrate the shaping. Tables are also used to hold certain parts for superior milling techniques.

Adding rotary tables will improve your capacity to produce the parts you want and increase profits. This brings us to the primary advantage of CNC rotary tables: less time and greater accuracy in cutting.

The benefits of using cnc rotary tables include consistency, faster production and increased capacity. Products and work pieces assembled through CNC systems are more reliable than products created manually or through other methods. The process is identical each and every time, so consistency can be guaranteed. This is critical for a company trying to ensure safety protocol.

The capacity of complexity of product is another benefit. Complex motions are made simpler by CNC rotary tables, making them more affordable to produce.

Naturally, such an intricate process cannot be unsupervised, since efficiency depends on optimal performance. A supervisor must oversee a rotary table operating with CNC controls to ensure the machine and software are configured correctly.

We offer a wide variety of rotary tables to meet all of your needs. This includes standard rotary tables with full rotating axis capabilities, and vertical and horizontal mounting positions.

We also offer large rotary tables with hydraulic brake systems, which allow higher clamping torques. You can also find assistance with smaller rear mount rotary tables or tilt rotary tables.

Horizontal rotary tables are specially made for horizontal mounting and carrying a much heavier weight. Horizontal index tables are available, whether in manual or CNC index tables style. Finally, there are face gear rotary tables and rotary table accessories, ideal for projects that need higher degrees of accuracy.

CNC Indexing & Feeding Technologies can help you find the machine tool accessories you need to meet your production demands. This includes simple rotating feature, larger work pieces, vertical and horizontal applications, or even 4 or 5 axis work. With TJR rotary tables, you can improve your cycle and process time, reduce your down time and increase your profits.

There is no mechanical reduction mechanism such as a worm system in a rotary table with a DD motor. DD (Direct Drive) motor is built in the rotary table to drive directly. The compact two-axis direct drive rotary table enables rapid acceleration/deceleration and high-speed rotation. Its biggest advantage is the super high speed up to 2000 rpm. Thus, it can work as a mill/turn component. As a result of the lack of a mechanical reduction mechanism, the driving torque of the rotary table is not strong. It is necessary to choose an application for the rotary table with a DD motor.

A high torque motor drives the direct drive rotary table directly. There is no backlash or abrasion generated during rotation because it is not driven by worms and gears. Typically, these rotary tables are used in applications requiring high accelerations and decelerations, such as blade machining. For high-speed drilling centers with very important indexing times, a two-axis direct drive rotary table is an excellent choice.

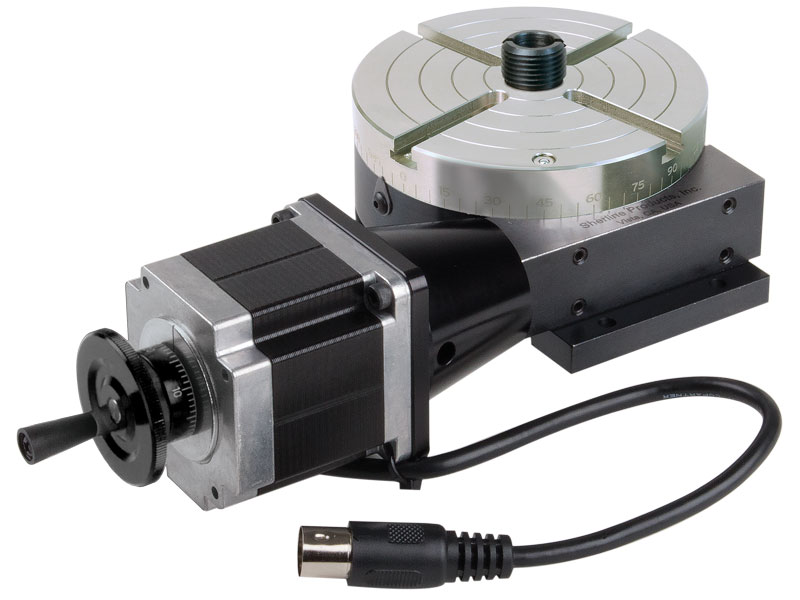

The 200RT Series Rotary Tables are designed for precise motor-driven rotary positioning and indexing. These tables are designed to function independently or in conjunction with linear tables used for precision automation applications. Their low profile design minimizes stack height in multi-axis configurations and enables them to fit in many places where other motorized rotary devices cannot. Models are available in 5, 6, 8, 10, or 12 inch diameters and are offered with four gear ratios making it convenient to match size, speed, and load requirements. They can be selected in either English or metric mounting. They are found in virtually all industries where intermittent part indexing, part scanning, skew adjustment, or precise angular alignment is required. At the heart of these tables is a rugged main support bearing which is comprised of two preloaded angular contact bearing races. It is designed for high load capacity and smooth, flat rotary motion. The drive is a precision worm gear assembly which is preloaded to remove backlash. The top and base are constructed of high quality aluminum with an attractive black anodized finish. The top and bottom mounting surfaces are precision ground to assure flatness.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

TANSHING products can be selected depending on different machining conditions. A wide range of models, such as the type of high load, high rigidity, high speed, high precision, long life span, zero backlashes, ultra-high load 10-60 tons large precision rotary table, and hydrostatic table can be customized. In addition, there is a variety of new 5 axis rotary tables, swing head rotary, etc. The complete series is available in our product line.

TANSHING’s R&D team is capable of dealing with a variety of machining requirements, such as speed and load capacity improvement. Any customized accessories can be planned and designed quickly. The same type of rotary table with a direct drive motor has been widely installed at domestic and foreign machine tool manufacturers. Our techniques for the function application of product, assembly, and testing are well-developed. We welcome machine tool manufacturers and machining shops to contact us for any kind of inquiry.

There are manual and motorized stages, open-loop and feedback stages, and stages of various sizes, so it is important to select the right one for each application.

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

Hiwin Corp., a manufacturer in motion control and system technology, highlights its families of precision motion control components with a focus on its Torque Motor Rotary Tables (TMRT).

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy, Hiwin says. Directly coupled encoders and zero backlash intend to enable tighter part tolerance. Direct drives are designed provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, promoting thermal stability even during high-duty cycle, high-load conditions, which yields consistent part quality, Hiwin says.

Hiwin Torque Motor Rotary Tables utilize Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hexram CNC machines feature FANUC controls, moving gantry, moving portal, moving table, as well as moving and fixed rotary table options. According to the company, a selection of durable cutting heads enable manufacturers to take on applications from nearly any industry.

Roller cam: Compared with worm gears type it is with higher wear resistance, high transmission efficiency , affordable prices and basically maintenance-free of table.

Table directly driven by a motor, high rotary speed , no backlash, no weariness and low inertia. But relatively technical requirement is high and difficulty, the price is the most expensive. Generally used for five-axis machine tools.

Our rotary table can be used in the aerospace industry, 3C high-tech industry semiconductor parts, auto parts and components automation manufacturing, or bathroom equipment and daily necessities manufacturing etc.

The backlash control of our rotary table is stable and reliable, it can be adjusted at the same time and is easy to operate to meet high-precision processing and production requirements, so that it can help customers reduce costs and create more profits.

Motion Index Drives has developed the new standard for fixed or flexible Indexing Rotary Table. The TMF series of servo driven programmable rotary tables was engineered to meet our customer’s vision of the ideal programmable rotary table and to exceed expectations.

The TMF Series is an innovative line of programmable rotary index tables with zero backlash operation. These rotary indexing tables are built to maximize the potential of Motion’s flex technology with streamlined housing and dial plate to match. The power to rotate the index drive is provided either by means of servo motor coupled to a gear reducer or AC motor with encoder, coupled to a gear reducer. Our servo programmable rotary tables are manufactured to be identifiable by all robot brands and controls. The index drive is completely sealed to eliminate intrusion from foreign particulate matter and fluids.

The rotary index table transforms a constant input drive motion into an intermittent output drive motion. The intermittent drive motion occurs by means of a flame or inductively hardened and high accuracy-milled barrel cam. The use of mathematical laws of motion guarantees a soft, shock-proof and jerk free movement that has been optimally designed for its intended purpose. The designed assembly allows for accurate and secure mounting to the output dial which is also backlash free.

The power is provided either by means of a three-phase brake motor via a gear reducer or by means of a chain-wheel or belt-wheel on the drive shaft of the rotary index table. This is firmly connected to the barrel cam, without any further internal gear sets, and it turns the cam followers and subsequently the output flange. The output flange is mounted within a wire bearing assembly, backlash free of play (within steel ring – not in casting). The index drive is completely sealed to eliminate intrusion from foreign particulate matter and fluids.

8613371530291

8613371530291