mounting chuck to rotary table pricelist

6" base adapter plate is ideal to use on 6" rotary tables of either 3 or 4 slots to mount either 4" , 5" 3-jaw ,6-jaw or 4-jaw self-centering lathe chucks.

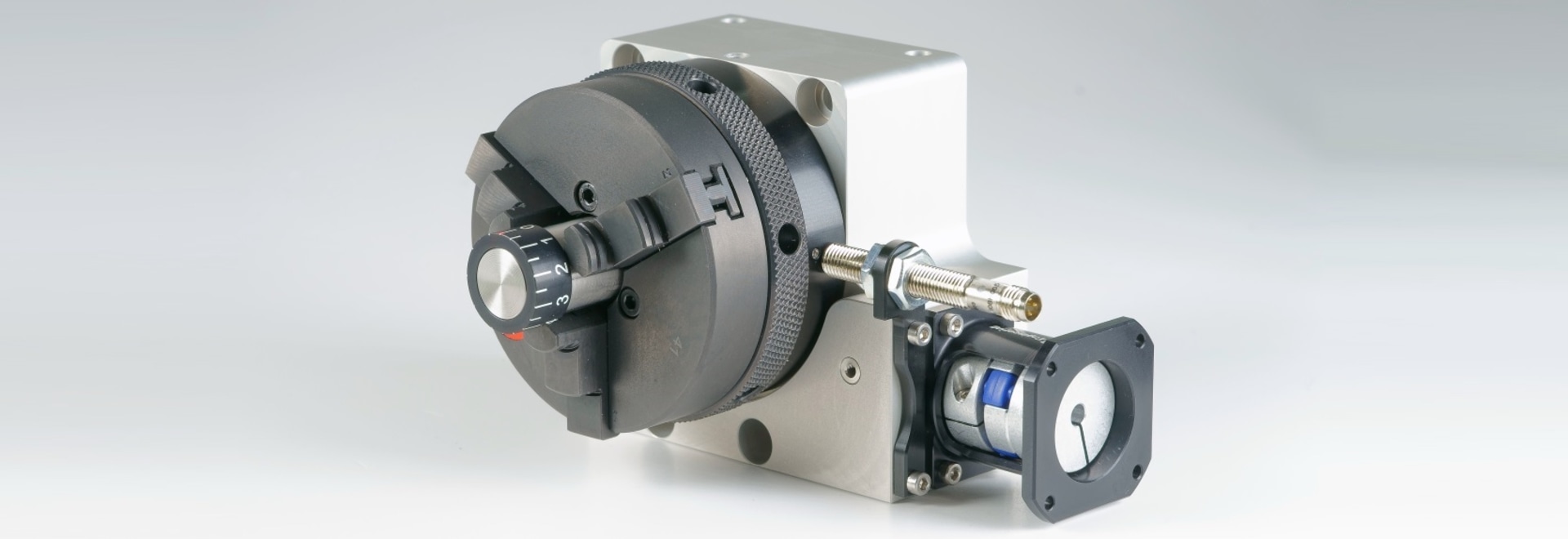

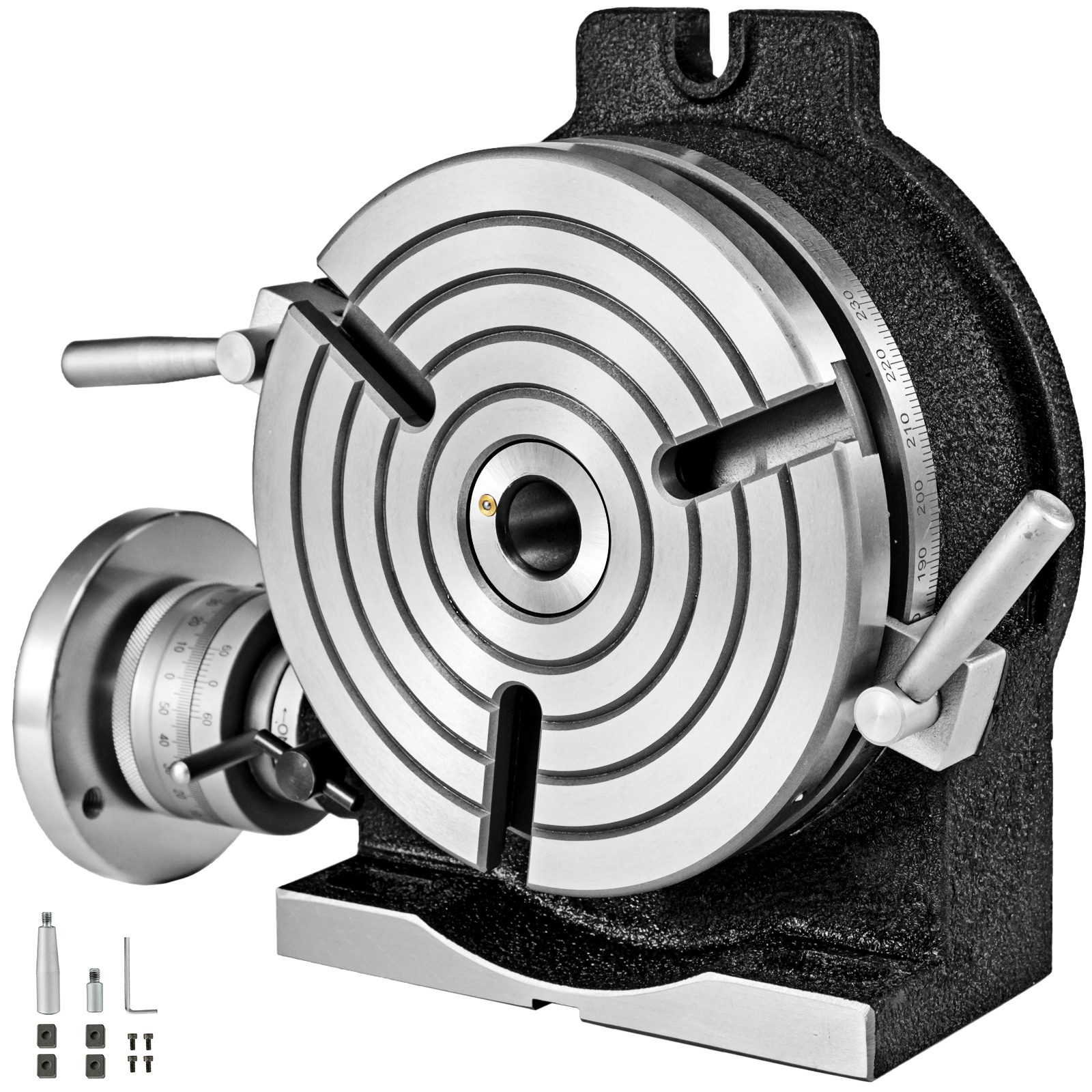

6" PRECISION 3 slot ROTARY TABLE /HORIZONTAL&VERTICALwith 6" 3-jaw self-centering chuck top&bottom reversible jaws, front mounting. All bolts and T-nuts to mount the chuck included.

I"m a wanna-be machinist newbie. I have a small mill (no lathe). I obtained this small 6" rotary table (a Griz product). I would like to get a small 3-jaw chuck mounted to it, but have NO CLUE as to how to choose a chuck that will be compatible with this RoTab. Am I looking for a 6" chuck? Or 4"? I can"t go too "tall" or I waste all my Z axis. I don"t even know how the chuck would mount to the RoTab. The hole in the center is a MT#2, would a chuck use the MT? Or attached how?

Can someone guide me to some options regarding how to get a chuck on here, where to find the components needed? I am not looking for gold-plated accuracy. (It"s just an inexpensive $900 ChiCom mill with an inexpensive $250 ChiCom RoTab. Not proud of it, but I"m lucky to have it, and it works good enough.) In fact I"d love to buy a chuck used if possible and save some coin. Ideas?

More info on my intended useage of chuck-on-rotab, if you are interested: This RoTab will mount horizontal or vertical. With the RoTab in the vertical position, with its associated tailstock, I believe you can "fake" some lathe operations on a mill. I need to do some small lathe operations with it, which will entail bringing down an endmill to the work and then slowly turning the RoTab. So sort of reverse of a lathe, in this setup the bit is powered and the work is being turned slowly by hand. Yeah, I wish had a lathe but in this obanomy, you make do with what you got.

Alternately, I think I can do some vertical lathing without the RoTab. If the stock is small enough to go into the mill"s chuck (5/8 max) and stout enough to hang free, some lathing can be done by clamping a lathe bit in the vise and running it up and down the work using the Z axis. For small work only.

I suppose you could also chuck a larger round piece in the rotab/chuck (with the rotab/chuck in the horizontal position, and the work sticking up vertically), and use an endmill to make bushings, and other short, squat round work, etc. by spinning the work in the rotab/chuck against the endmill.

What would be really helpful is to find a tutorial that discusses how to fake a lathe on a mill...anybody have a source? As I say a lathe is not in my immediate future. Even if I had the $ I do not have the space right now!

I have been thinking out my options on installing a chuck on my rotary table. It"s an antique Excel 12" table with 1/;2" T-slots and a 1" center pilot. Looking around it seems the standard way is to make a backing plate that bolts to the table, then you bolt a chuck to the plate. This requires a chuck that mounts from the face side with through-bolts. I have spied on some suppliers and it seems that most offer only tiny chucks to fit their tiny rotary tables. A 3" vise on a 12" table seems a bit silly. To get into anything of decent size will take a fair chunk of bitcoin.. I"m a certified cheapskate. So....

I do have a pile of chucks. One has a 1-3/4-6 mount. It"s from the dividing head. The rest are 2-3/8-6 from the lathe. There are four of those from 5" to 12", basicly small and large in 3 and 4 jaw. I also have a 3" long chunk of 5" round in 1045. S I"m thinking of making an adapter with a 1" dowel for center, slots for four T-nut mounts, and a 2-3/8-6 spigot to mimic the South Bend spindle nose. The down side is that is several joints, each with a potential accuracy loss. Table to adapter, adapter to back plate, back plate to chuck, chuck to ...... The upside is I could move work in the chuck from the mill to the lathe and back.

The questions: Is the 1045 a good choice for the adapter? I don"t want to heat treat it and risk warpage, so it would be annealed 1045. And the more important question. Am I missing an easier way to do this that doesn"t require cubic dollars?

Now you can attach a 1/4″ or 3/8″ drill chuck, an older Unimat chuck with 12 x 1 mm or 14 x 1 mm threads or a 1/2-20 Sears chuck to your Sherline rotary table. The adapter screws into the 3/8-16 threaded center hole of the table.

The chuck adapter has a 15/32 through hole with 3/4-16 thread for the chuck and a 5/8-24 thread for the rotary table. The through hole allows stock to pass through the chuck and P/N 3710 4″ Rotary Table.

• dadurch, dass die Möglichkeit einer Bewertungsabgabe von einer vorherigen Anmeldung in einem registrierten Kundenkonto abhängig gemacht wird, von dem aus ein Kauf getätigt wurde

• dadurch, dass die Möglichkeit einer Bewertungsabgabe von einer vorherigen Anmeldung in einem registrierten Kundenkonto abhängig gemacht wird, von dem aus ein Kauf getätigt wurde

Home / Rotary Tables, Rapid Indexers and Dividing Heads / SCT Rotary Tables / New 100mm 3 Jaw Chuck and Mounting Plate to Suit Soba 6 and 8 inch HV6/8 Rotary Tables

Price includes delivery to the UK mainland (excl Scottish Highlands). You can add this product to the shopping basket and pay with a credit/debit card, or with PayPal.

Under the guidance of Sh. Suresh Chandra Gupta, the company was started in 1975 with a small set up to start manufacturing the American type Turning and Parting Tool Holders to supply to the people exporting it in their name from India. Today after around four decades years of manufacturing experience & with his 2nd generation in business, WE are one of the leading manufacturers- Exporter from India of large variety of Machine Tools Accessories for Hobby Machinists, Model Makers, Wood Workers, Carpenters & Industrial applications supplying to the various renowned retailers of Europe, USA, Asia & Other parts of the Globe.

With the Help of our well developed production & tool room facilities, and by the ardent efforts of our experienced team who possess sound knowledge & experience of the industry, have enabled us in becoming one of the most reliable name in the market today. The company"s capabilities of manufacturing CUSTOM DESIGNED Items as per the customer"s specification has made ASSORTS Machine Tools Company, a trusted source for a wide & comprehensive range of Precision Tools of International Quality Standards at Competitive prices.

Our main Product line range includes Lathe"s Quick Change Tool Posts, Lathe Parting & Turning Tool Holders, Rotary Tables & Its accessories Like Clamp Kits, Dividing plates, Tailstocks, ER Collets Adaptors & Small Chucks with Back Plates, Knurling Tools, Lathe Alignment Test Bars, Vee Blocks, Revolving Centers, Vertical Milling Slides, Boring Heads, Fly Cutters, Arbors, Sleeves, Precision Vises For Milling, Drilling & Grinding, Bench Vises, HSS Lathe Form Tools & Carbide Brazed Tools Set, Lathe Chucks, Angle Plates, Surface Inspection Plates, Various DIY Hand tools, Punches, Jwelry Tools, Indexale Tools & many more.....

Why do we have to do that? Quite simply, you have forbidden us to watch Your steps on our site with Google Analytics. That sounds dramatically to You, we know. But look at it: we do not even know who YOU are, we just see that SOMEONE looks at our pages, how he/she does that, how long this SOMEONE lingers on the respective pages, etc. We do not know who You are, whether You are male or female, how old You are, how Your weight is - no idea. Nor do we pass this data on to Google, we don not have them not at all! Nevertheless, this data of SOMEONE will provide us with valuable information about our site, we want You to like everything here, that You feel good and - of course - buy our products ...

So we can see where there are problems. If many visitors leave our site during the purchase process while choosing the payment method, we know that something is wrong and can improve it. Sounds good, right? Thats good for You and good for us. So it´s a win-win situation. So let us accompany You on Your way through our store. Deal?

The chuck is a specialized clamp-type used to hold objects with radial symmetry like drills or perforators. By fixing rotary table chuck on the front part of your rotary tools, you will be able to fix various tools and parts such as screws, nuts, drills, and cutters. Having a chuck in your toolkit will allow you to finish your jobs quickly thanks to its versatility and practicality.

rotary table chuck can also be used to fix a workpiece. This small tool facilitates the transition between different activities, like going from drilling to screwing. Furthermore, you can also use it as a rotating element in drawn glass manufacturing. Some chucks are composed of retractable keys, which give you more freedom in your work and improved performance.

You will find various types of wholesale rotary table chuck in our online collection. The jawed chucks are one of the popular types, and they often have three jaws. They are ideal for gripping circular or hexagonal cross-sections. The four-jawed chucks are also available, and they are generally suitable for gripping square or octagonal material.

We also have other modern types of rotary table chuck. For example, the collet chuck is perfect for small-sized bar stocks, and you can operate it by hand or by power. Another modern type is the magnetic chuck, which is perfect for holding ferromagnetic workpieces. Without forgetting to mention the vacuum chucks that you can use to hold non-ferrous materials such as plastic, aluminum, and stone.

The settings you specify here are stored in the "local storage" of your device. The settings will be remembered for the next time you visit our online shop. You can change these settings at any time (fingerprint icon in the bottom left corner).

The Soba 4 jaw comes with an adapter plate to allow mounting on a tee slotted rotary table or face plate/mounting. This is pretty basic but functional - the adapter location recess in the chuck is 55mm diameter, and the male register on the aluminium plate measures 54.9mm using my vernier in last few minutes. This site does to accept photos show cannot show you.

I have ditched the adapter plate to save wiring height on the milling machine, and drill through the chuck and counterbored front face so I can mount direct to the rotary table. There is lots of meat in this chuck.

8613371530291

8613371530291