troyke 9 rotary table free sample

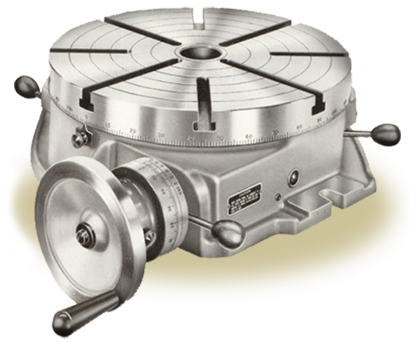

Troyke super precision, heavy-duty manual rotary tables range in size from 10" to 30" in diameter. The Manual Series features a rigid manual rotary table design and can be mounted horizontally or vertically. These precision manual rotary tables are designed to accept dividing attachments, encoders, variable speed drives and a variety of tooling and workholding options.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

I"ve been thinking of getting a rotary table for use on my bridgeport, but haven"t fully formed an idea about what I really want. Based on what I"ve seen, I"m starting to think that I probably want to end up with 2, first a smaller one that would either do horizontal and vertical mounting or adjustable angle, probably in the 6-10" range (small enough that I can easily move), and then a larger one like a big, used bridgeport one for larger work.

Well, I got one as a gift for my birthday a couple of days ago (a PhaseII), and after getting a good look at it close up I realized that I"m probably going to end up returning this one and going with something else. The biggest thing is slot sizes... it has an indexing piece for use up on end that looks like it is intended for one slot size, and the slots on the table face are a smaller size, both smaller than the standard slots/holddowns that I have for the bridgeport. Seems like it would be a hassle mount it down to the table securely and then I"d need another set of hold down hardware just for use with the table.

Micro-Pulse Technology – is specifically designed for low recast and little or no detectable micro cracking in aerospace as well as semiconductor industries during fast hole EDM process.

9. COMPLIANCE WITH TERMS OF SALE – In default of payment of bills in full within the time therein specified, the Auctioneer in addition to all other remedies allowed by law, may retain all monies received as deposit or otherwise, as liquidated damages. Lots not paid for and removed within the time allowed herein may be resold at public or private sale without further notice, and any deficiency, together with all expenses and charges of re-sale, will be charged to the defaulting purchaser.

19. SHIPPING – All coolants, oil and fluids must be drained from all machinery and equipment prior to removal. All of the above must be shipped in compliance with state and federal regulations.

20. INSURANCE – All Buyers, or the Buyer’s riggers, must provide the Auctioneer, Owner and Landlord a certificate of insurance in amounts acceptable to the above parties prior to removal of any machinery and equipment.

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

with the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

Rotary tables have many applications, including being used in the manufacture and inspection process of important elements in aerospace, automation and scientific industries. The use of rotary tables stretches as far as the film and animation industry, being used to obtain accuracy and precision in filming and photography.

Troyke Mg Co Ata Bh-9 Small Rotary Table.Sold as is-where is. REMOVAL TERMS: Buyer is responsible for removal. Removal is by appointment only: No assistance will be available during loadout. Buyer Loadout required. Condition: Fair

Most items offered for sale are used and may contain defects not immediately detectable. Bidders may inspect the property prior to bidding. Inspection is by appointment only. Please use the "Ask a Question" feature to schedule an appointment for Inspection.

8613371530291

8613371530291