tsudakoma rotary table oil made in china

The Japanese textile industry was hit hard by the trend of the times represented by the switch to a floating exchange rate, the strong yen, and the 1973 oil crisis. Many loom manufacturers in Ishikawa went out of business or were forced to change their business fields. Amidst these circumstances, TSUDAKOMA set its management policy as "diversification within our specialty" and poured its effort into developing jet looms. The company’s jet looms business expanded globally and TSUDAKOMA grew into a globally recognized company.

With over 37 years of experience we are the exclusive importer, national distributor and service center for Tsudakoma rotary tables, Alberti angle heads & live tools, Romai angle heads, tool presetters and swiss tools.

Fourth- and fifth-axis rotary tables bring added flexibility to conventional three-axis VMCs. At IMTS, Koma Precisionintroduced the Tsudakoma RG series of rotary tables that uses a ball-drive system for table rotation.

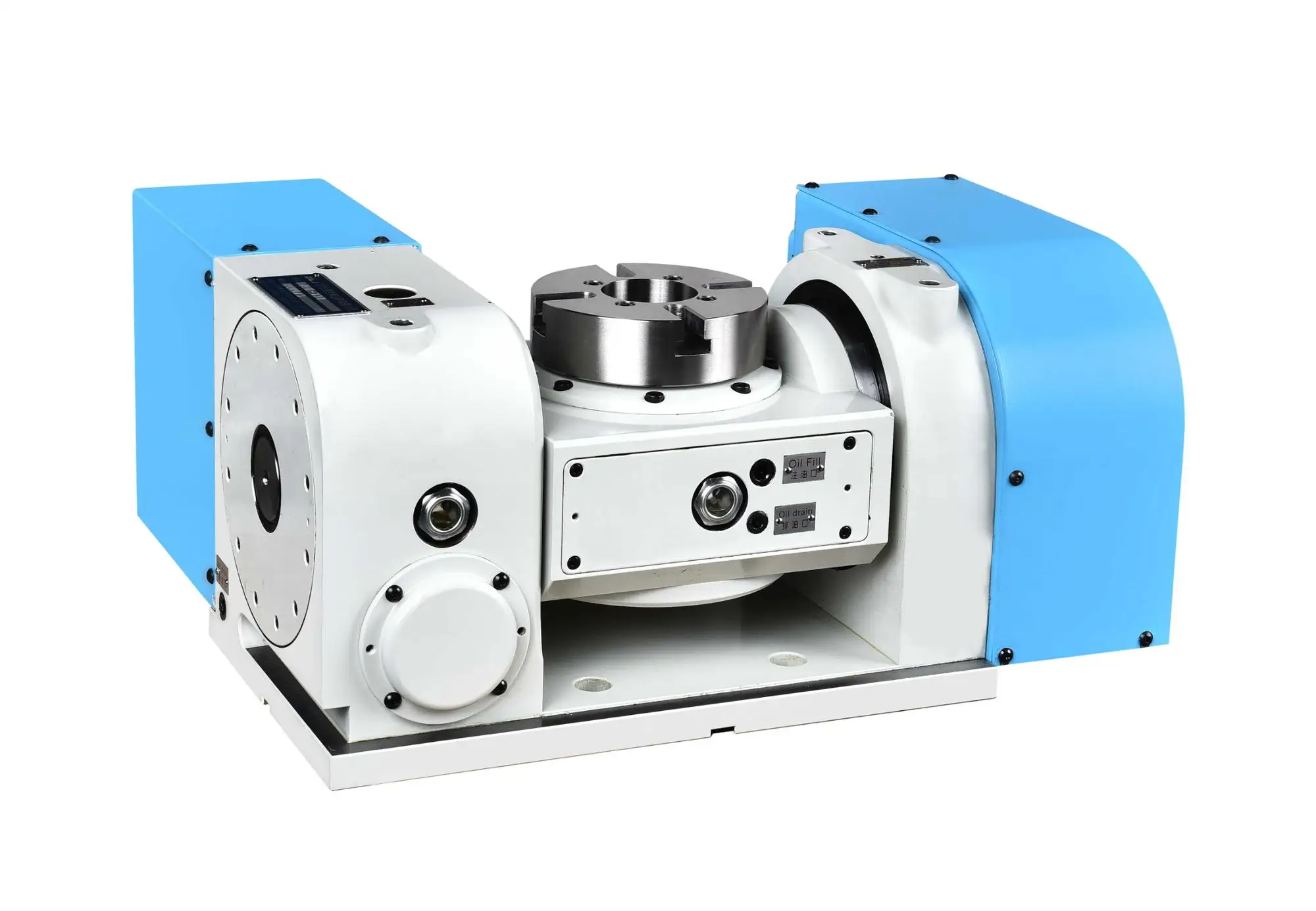

Koma Precision showcases the dual platter Tsudakoma TWM-250 five-axis rotary table. This high precision unit has two 10" platters that can be equipped with rotary unions for hydraulic or pneumatic work holding actuation. The unit can be setup for 12-16" between platters, which Koma says enables for a variety of work holding and workpiece shapes and sizes.

The TWM series is said to be ideal for high-production single or dual spindle VMC’s that require five-axis machining. The TWM series unit can be setup for simultaneous five-axis movement or 4+1, enabling the machine to get around five sides of the workpiece. The hydraulic brake on the tilt axis reportedly provides 3100 Nm of brake torque, which enables the machine to take heavier cuts at more aggressive speeds and feeds while maintaining the accuracy of the part. According to Koma, the machine tool is only as accurate as the work holding and rotary table; therefore, the rigidity is critical to the entire throughput rate and quality of the cutting process.

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

The Third-Party Rotary provision provides access to the rotary parameters in the Haas control, allowing you to use a third-party single- or two-axis rotary table on your Haas machine. The option supports full simultaneous machining up to 5 axes, and is compatible with Dynamic Work Offsets and Tool Center Point Control. It is the responsibility of the customer and the third-party manufacturer to troubleshoot and fine tune the different parameters. Requires the purchase of the 4th-Axis Drive option to operate a single-axis rotary, or the purchase of both 4th- and 5th-Axis Drive options to operate a two-axis rotary.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

8613371530291

8613371530291