ucam rotary table made in china

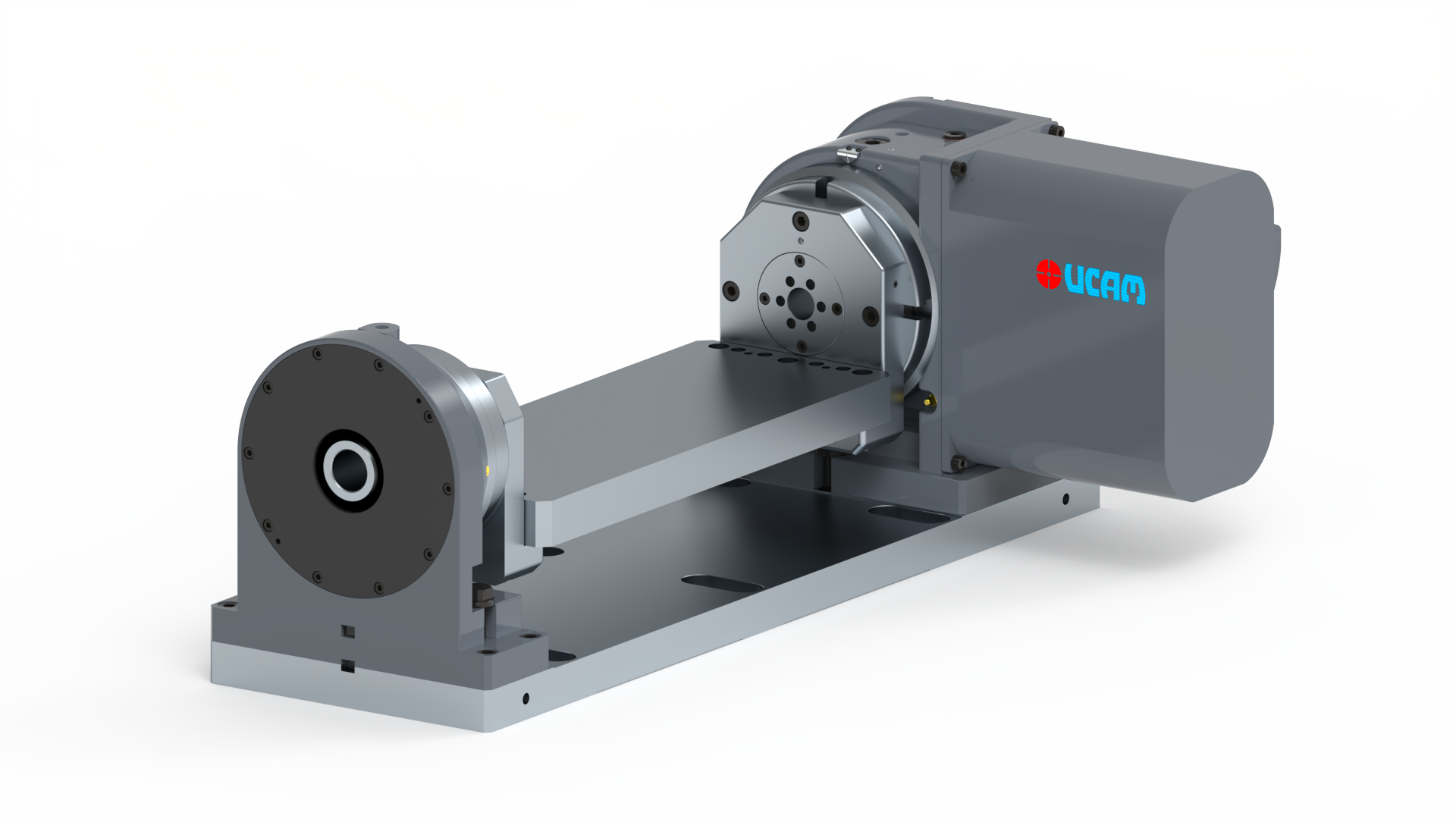

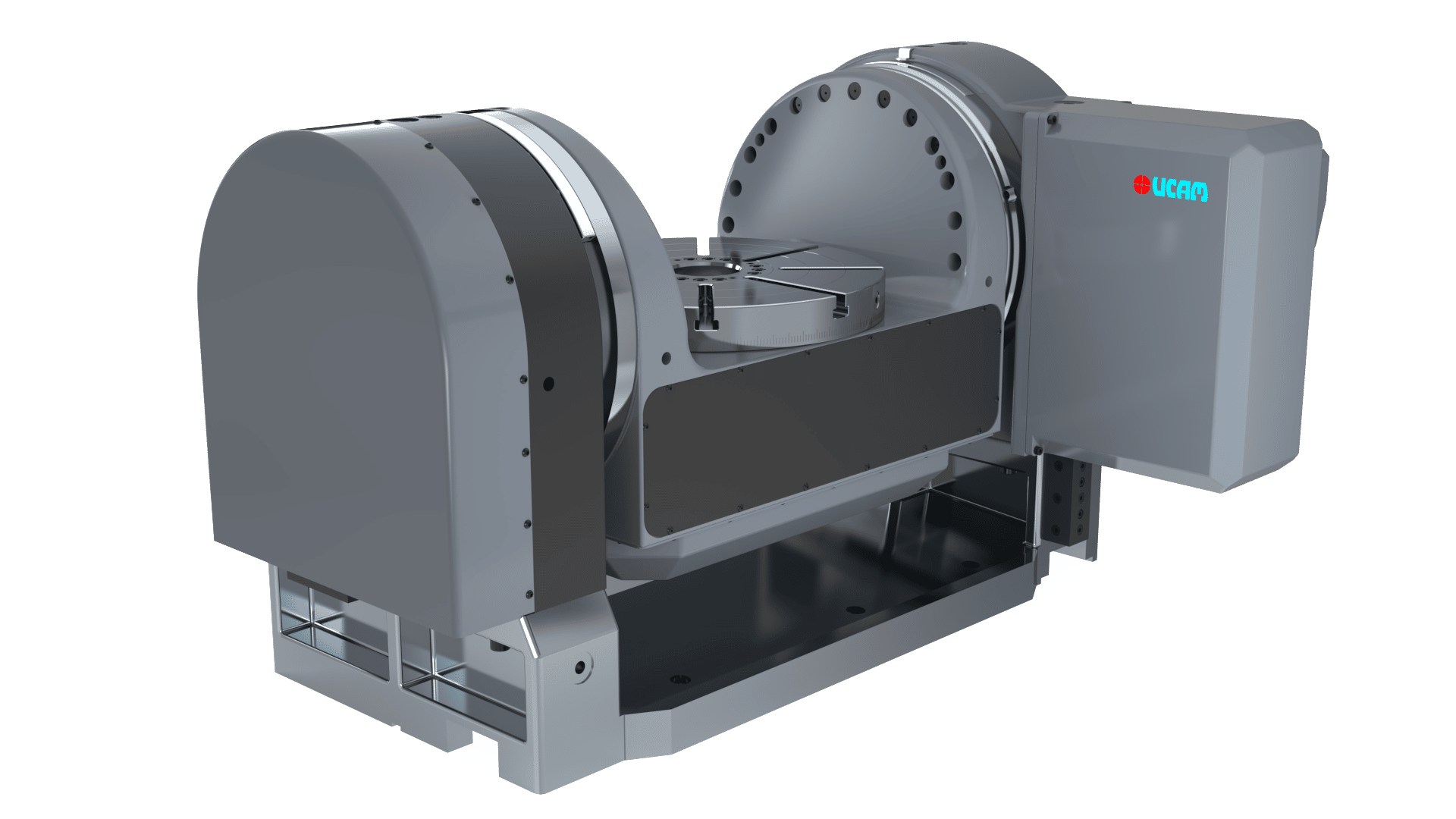

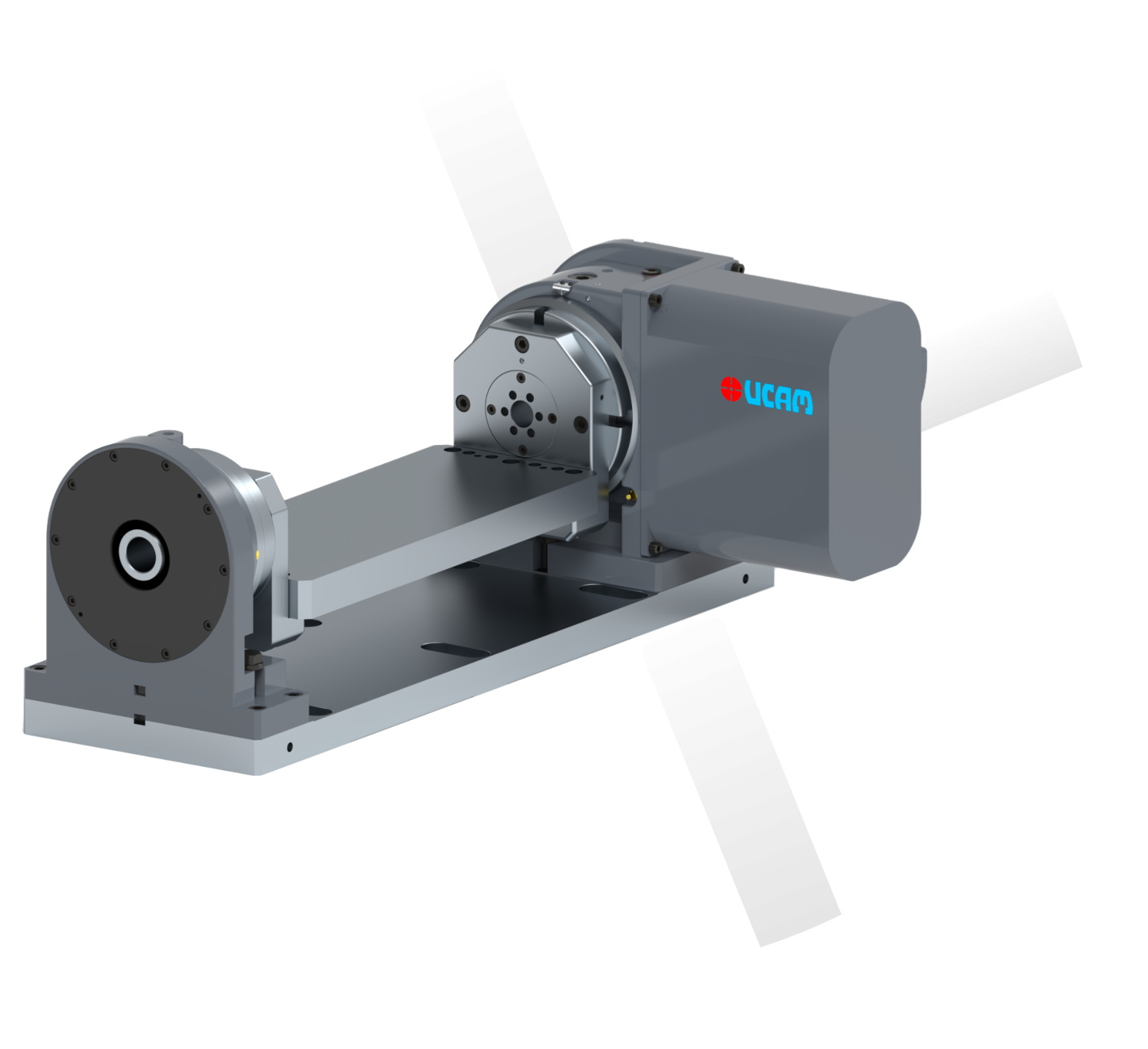

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Kehren RIW9 CNC rotary table surface grinding machine Max workpiece diameter 900mm x 500mm height complete with internal grinding spindle it can be inspected in our warehouse in Gussago BS Italy Mimu Machine Tools

Bengaluru-based UCAM, the manufacturer of high precision CNC Rotary Tables, Index Tables and Pallet Changing Systems for CNC (computer numerical control) machining centres, is planning to set up a new facility at Dobbaspet, with an investment of Rs 30 crore in few months, a top executive said.

Talking to Deccan Herald on the sidelines of IMTEX-2015 here on Thursday, UCAM Managing Director Indradev Babu said, “We have set up a new facility with an investment of Rs 30 crore at Dobbaspet with a built-in area of 60,000 sq ft, which will help enhance production capacity as well as improve production systems and quality.”

Presently UCAM exports 25 per cent of its annual turnover and it is targeting exports to hit the 60 per cent mark in the next four years. The export destinations include Germany, Italy, the UK, Poland, the US and Canada.

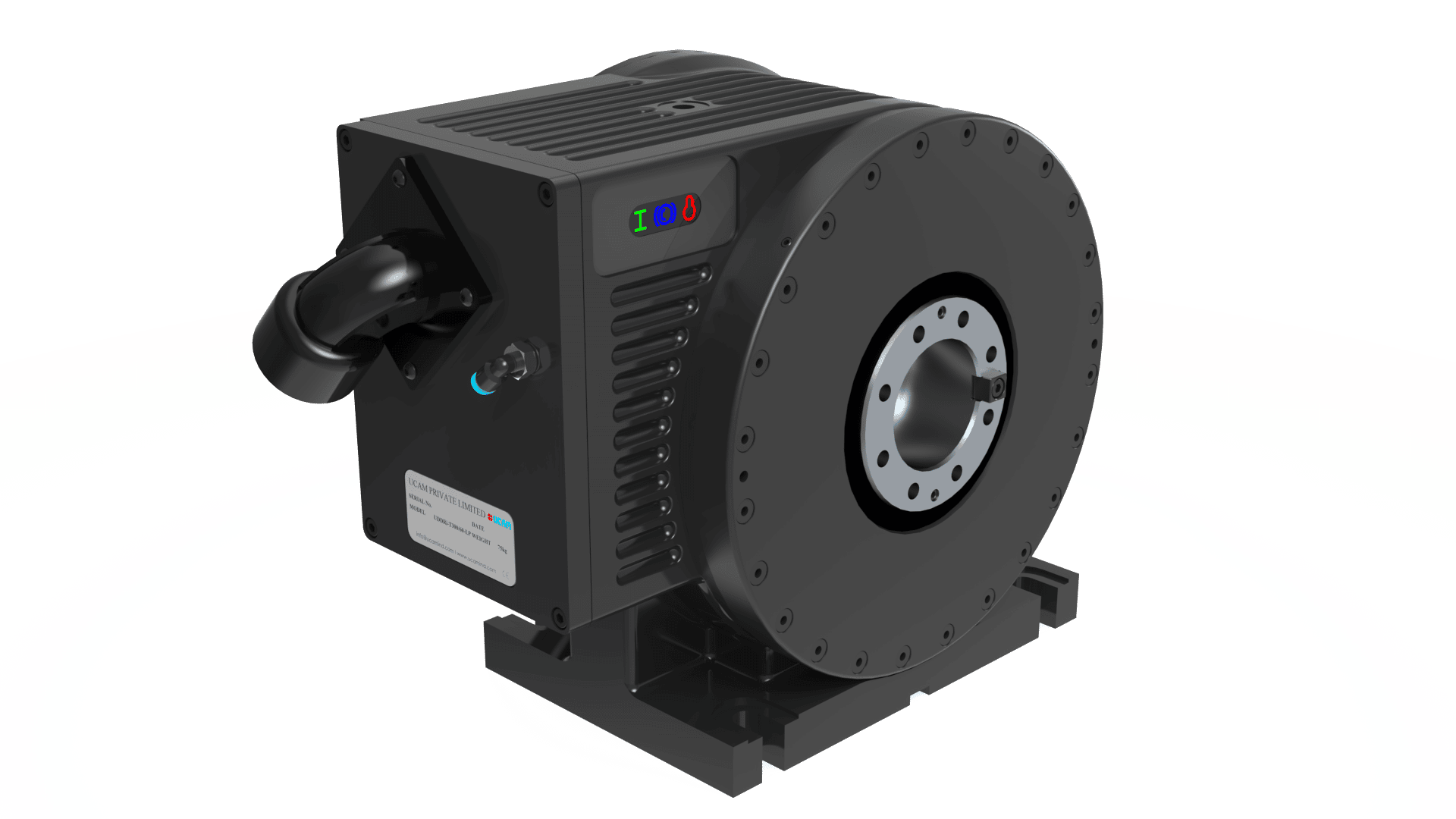

UCAM has launched new business units Nimble Machines and Nimble Electric. Nimble Machines produce high performance CNC Gear Hobber to meet high performance requirements of customers in the domestic market.

UCAM has independent design and R&D departments. UCAM’s in-house R&D facility is recognised by the Department of Science and Industrial Research (DSIR), Government of India.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Ordering code for CNC RotaryTables S-Special None-Standard Braking System H-Hydraulic Clamping P-Pneumatic Clamping Motor Mounting B-Rear Mounting L-Left Mounting R-Right Mounting TableTop None-Round Sq-Square Size of the table CNC RotaryTables * Higher Accuracy ± 5" on request ** Motor RPM 2000 # Check motor models on Page No. 70 ## Option available with pressurisation - Please contact us

Factory: Plot No. 297 & 298, 1st Stage, Sompura KIADB Industrial Area, Dobbaspet, Sompura Hobli, Nelamangala Taluk, Bangalore Rural Dist - 562111. INDIA, Engineering Excellence. Exactly. www.ucamind.com Catalogue No. UCAM-Gen-2017/2/6. UCAM reserves the right to change specifications and dimensions without prior information.

UCAM specializes in manufacturing precision CNC Rotary Tables, Index Tables and Pallet Changing Solutions for Machine Tool applications. UCAM’s tryst with exports started at EMO – Milan in 2003. The positive response received from various visitors at the expo notwithstanding, all products on display being picked up by a single customer with 100% down payment gave a huge fillip for UCAM’s foray in to the export market.

This single defining event, kept UCAM’s export hopes alive, in spite of the global OEMs and end customers being cautious and sceptic about an Indian manufacturer in a high precision field. Slowly but steadily, OEM’s customers started reaching out to UCAM for their customized applications. What began as a single order from a customer, has now grown into a steady relationship with more than half-a-dozen OEM’s across Europe.

During EMO Hannover show in 2005 an Italian Customer “Porta Solutions” evinced interest in the Rotary Tables displayed by UCAM. The requirement was a special Custom built Rotary Tables to Porta’s specification. UCAM sensed an opportunity to build a long lasting relationship with Porta Solutions and started supplying Customized Rotary Tables in batch quantities. These Rotary Tables passed the test and since then, UCAM has been the sole supplier of Rotary Tables to Porta Solutions, shipping around 50-60 nos. every year.

UCAM’s next major breakthrough came from an OEM partner “AVIA” from Poland, who was regularly purchasing UCAM’s standard CNC Rotary Tables for their VMC’s. AVIA wanted to venture into special 5 Axis machines and approached UCAM for Custom built Table in Table and Tilting Head. It was a huge challenge for UCAM, the spindle tilting head and the Rotary Table integrated into the machine bed being the critical axis for the 5 Axis machines, AVIA wanted the engineering to be configured so as to be directly integrated with their machine. The 5 Axis machine was a huge hit in the market for AVIA. The Table in Table & Spindle Tilting Head since then has become a regular product for UCAM. Later AVIA approached UCAM for many more Custom built products, including the Direct Drive integrated Tilting Table. UCAM was able to meet their challenge of both quality and price against stiff competition from European as well as Taiwanese products.

Another success story for UCAM in international market came from their Customer “Pentamac” from Italy. Pentamac used to purchase UCAM standard Rotary Tables for their regular 3 Axis machines. Pentamac wanted to bring out 5 Axis machines and UCAM was their first choice to develop Custom built Cantilever Table. It was a huge challenge as no compromise was acceptable on the Cantilever Table’s specification. UCAM was able to meet Pentamac’s expectations and today, Cantilever Table has become a regular supply to not only Pentamac but also other OEM’s in Europe.

The key drivers for UCAM’s sustained relationship with its export customers are keen to take up challenging customization requirements, ability to provide one-off unique solutions, enthusiasm to embrace new technology, building products of high performance at competitive pricing and above all, partner with our customers to co-create new solutions.

Quick response, always seeking customer feedback to enhance service levels, quality products at competitive prices and a holistic approach to customer needs, has defined UCAM’s global presence since 2003. Today export constitutes 15% of UCAM’s turnover and is expected to double over the next 3 years.

Bengaluru-based Ucam claims to be the largest manufacturer of CNC rotary tables in India. Their wide range of CNC rotary tables and custom built rotary tables which can be used vertically and horizontally based on the application

Ucam Private Limited, established in 1986, has a wide range of products such as 4th axis rotary tables, 5th axis rotary tables, large size rotary tables, value added accessories, etc. The company exhibited its range of R+W bellow couplings, Nimble Electric torque motors, CNC rotary table at the ENGIMACH 2021

Vijay Zaritaklikar, National Sales Manager, Ucam Private Limited, said, “Our company is having a market share of around 70 per cent. We are preferred partner for OEMs and end customers. We mainly manufacture CNC rotary table which is a sub-system for vertical machining centre (VMC). With the help of our CNC rotary tables you can expand the VMC to fourth and fifth axis machining”.

“Through Nimble Electric, a subsidiary of Ucam private limited, we started manufacturing torque motors for our own purpose. But then Nimble Electric motors found applications in many places such as electric vehicles, robotics, defense systems, textile motors, renewable energy, healthcare motors, transportation, etc”.

Ucam Private Limited has its business verticals such as Ucam Mechatronics, Nimble Electric and Nimble Machines. Ucam Mechatronics is involved in the trading of products like spindles, bellow couplings, torque limiters, rotary union and linear motion products. Nimble Electric specializes in the design and manufacturing of high performance torque motors. Nimble Machines designs and manufactures precision gear hobbing machines.

Rotary tables are used for perfection metalworking. They"re generally made with a solid base that can be clamped on to another institution. The table is a slice that rotates freely or by use of a worm( hand coil).

A rotary table is a slice- shaped metalworking device used to gain precise workpiece positioning. It enables a metalworker to cut or drill a workpiece at precise intervals around a vertically or horizontally fixed axis. A rotary table can be both manually or computer numerical controlled. Certain types of rotary tables are designed to be used with indexing plates or dividing plates for technical operations. A rotary table used together with one of these positioning plates is generally appertained to as a dividing or indexing head.

The rotary table device generally has a solid base that can be attached to a separate institution or table using clamps. This device is principally a rotating slice which holds the workpiece in place during slice or drilling operations. The slice portion of a rotary table can be freely rotated for indexing procedures or turned by an attached control arm known as a worm wheel. Tables used in high perfection operations are generally turned by a duplex- type worm wheel to compensate for counterreaction. Rotary tables used in automated essence working processes are turned by computer numerical controlled ministry.

Rotary tables are most frequently used in a flat position with the table’s axis having a perpendicular exposure. They"re occasionally mounted with the axis acquainted in a vertical fashion so that a tailstock can be used to support the free end of the workpiece. When this device is attached to a secondary table, the workpiece can be centered on the rotary table’s axis which is also centered on the slice tool’s axis. In this configuration, the axes of the rotary table, secondary table, and cutting tool are coextensive to grease concentric slice operations. This configuration also permits the secondary table to be neutralize for drilling equidistant holes in a workpiece.

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

Cécile Duflot cambriolée : la police sollicitée En effet, il a dérobé des téléphones portables ainsi que l'ordinateur de travail de la directrice générale de l'ONG Oxfam France

8613371530291

8613371530291