testing gas safety valve manufacturer

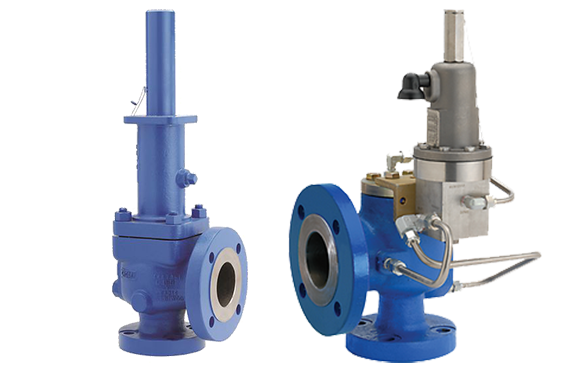

Safety valves are used in a variety of industrial applications to include air/gas, vapor, steam, and liquid service, among many more. These pressure relief valves are critical to the safe operation of our customer’s equipment and provide—as their name implies—a safety measure that can reduce the number of risks that can threaten both your personnel and facilities.

Millennium Power Services’ safety valve technicians will get your valves tested, repaired, and quickly set to the exact specifications. We serve as your knowledge partner and will also evaluate the repair condition of every valve and make recommendations as needed to help you make the best decisions.

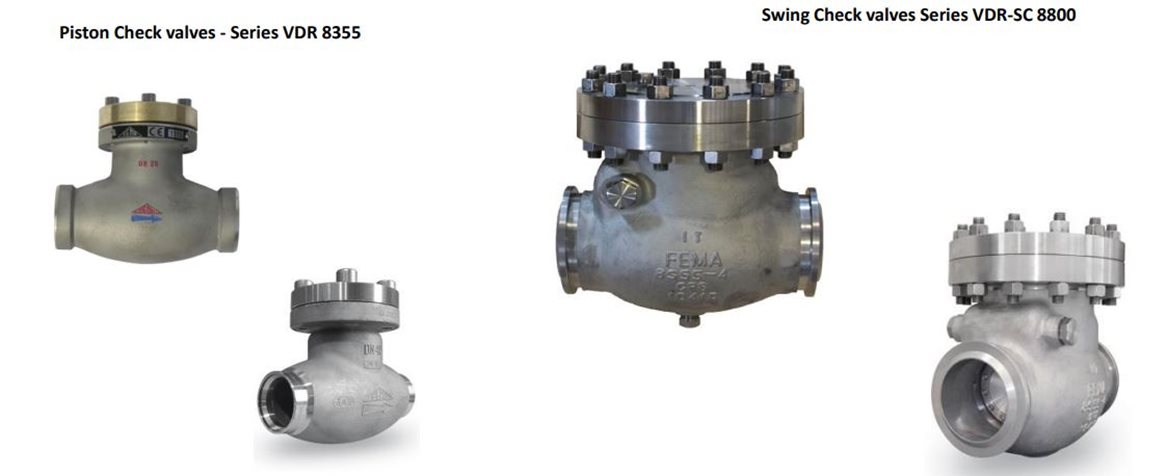

Distributor of pipe, valves, piping accessories, industrial pumps & valve automation. Fluid handling products such as steam traps, control & high performance valves, corrosion resistant piping & grooved piping systems are also available. Valves include sanitary butterfly, plug, ball, check, gate, globe, sampling & rising stem valves. Instrumentation include actuators, limit switches, instrumentation fittings, transmitter manifolds, low pressure brass fittings, quick connectors, thermometers, gauges, RTDs, thermocouples, temperature & pressure sensors, pressure & temperature regulators, fluid & gas meters & sensors, positive displacement & turbine meters, positioners, switch boxes & pneumatic cylinders. Pumps & process equipment include rotary, positive displacement, air operated double diaphragm, progressive cavity, centrifugal, vertical & horizontal, end suction & submersible pumps.

IVI is a VR certified safety valve repair facility, approved by the National Board of Boiler and Pressure Vessel Inspectors as a VR certificate holder (stamp 179). We certify pressure relief valves in the shop and in the field for sections V and UV. We also perform on-site testing (while the plant operates) providing documented reports for all valves tested. We are also certified to administer special process conversions regarding machining, welding, heat treating, and N.D.T. (non-destructive testing) with our VR certificate.

With our VR stamp, we repair all types of pressure relief valves such as Consolidated, Crosby, Kunkle, Farris, Spence, Anderson Greenwood, and numerous other O.E.M. safety and pressure relief valves.

Ensure compliance, prevent overpressure and protect downstream equipment with industry regulated repairs for Section I & Section VIII Pressure and Safety Relief Valves. We offer rapid response and delivery times to minimize plant downtime while maximizing valve performance. We service all major makes and manufacturers for emergency, maintenance and scheduled outage needs. We also repair and replace conservation, tank and vacuum vents. Contact our sales team today to receive a quotation to repair, test or replace your safety relief valves.

Valsource is certified by The National Board of Boiler and Pressure Vessel Inspectors to repair and test Section I and Section VIII Pressure relief and Safety Relief Valves. Every valve is repaired to standards set by The National Board’s VR program. We provide 24/7 repair, testing and engineering services. We also maintain an extensive inventory and can provide replacement valves and parts with same day delivery options.

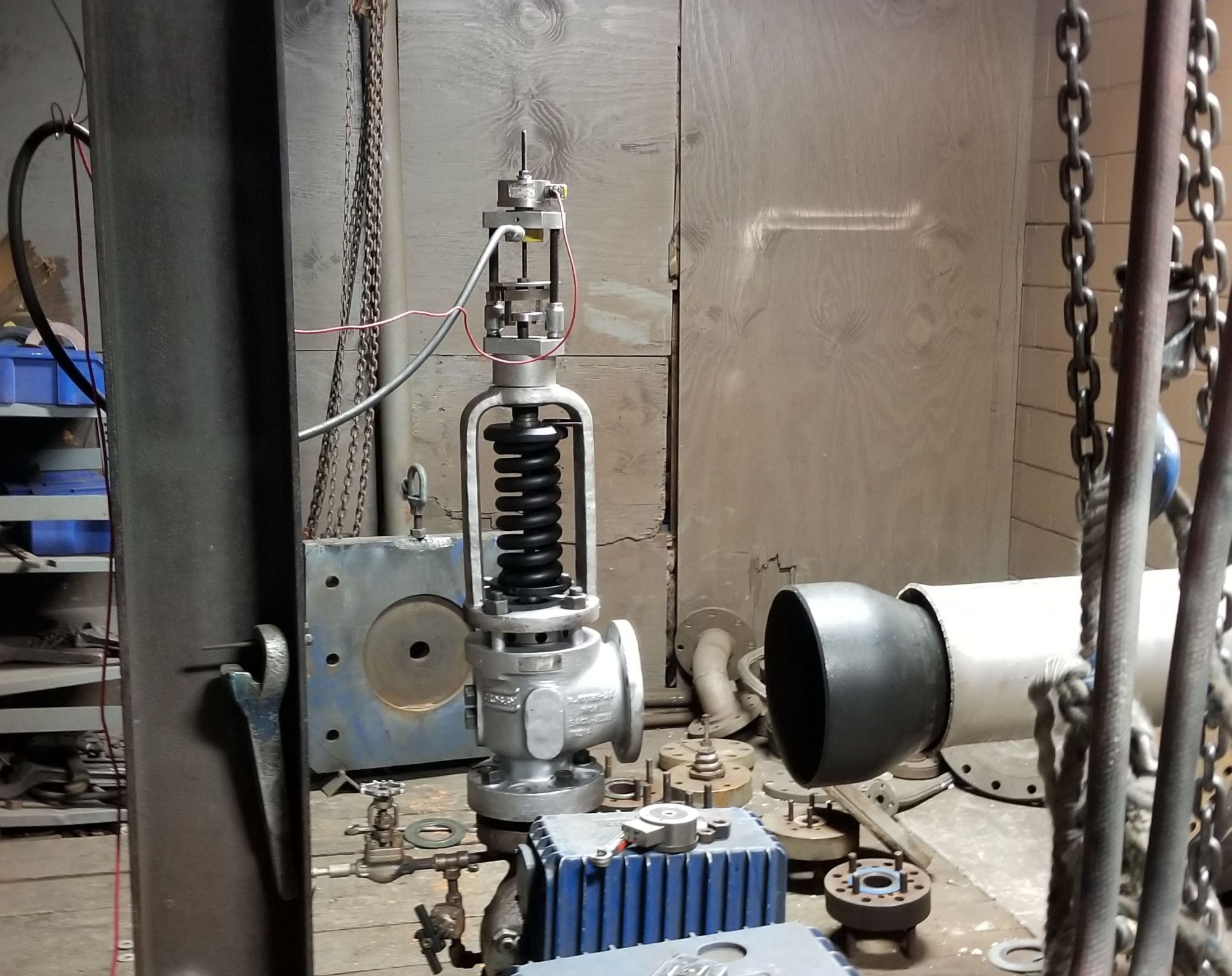

Valsource provides 24/7 repair and testing services in our shop or in the field. Our valve program allows our technicians to repair, remove, install and test your pressure relief and safety relief valves on-site. Using our AVK Electronic Test Vessel Package, our technicians are able to accurately test safety relief valves on-site without removing them from line. The primary function is to verify the set pressure in-line without having to shut down a system or unit. This service is a sure way to guarantee minimal downtime and peak valve performance. If you are preparing to service your boiler, Valsource technicians will come to your site and test each main steam safety valve to determine which valves require service. We will perform the repairs in-house or on-site using our 53’ field machining trailer, install and re-test back to calibrated set points.

If you need the best in valve repair and remanufacturing, Valsource can deliver the right options for your company. We offer rapid response times and emergency repair services available to resolve unplanned outages quickly. Our experienced technicians look forward to working with you to determine the most effective solutions for your valve repair needs.

Vinson understands that complete reliability of all Pressure Relief Devices is essential to protect, not only a plant’s assets, but most importantly all personnel and the environment. Vinson offers both field and in-shop repair services, and is proud to be one of the nation’s leading National Board certified VR & TO Repair Facilities. With certifications on air/gas/liquid and steam service (Section I & VIII), Vinson provides setting, repair and testing services on all manufacturers valves up to 10,000 psi.

Pressure safety valves are designed to protect process piping and equipment in case of an overpressure event. TEAM Valve Solutions inspects, tests, repairs and re-certifies safety valves at 17 service centers across three continents, and in our fleet of mobile facilities, all of which are audited under the jurisdiction of relevant governing bodies.

Our solutions cover all major safety valve brands and support our customers through an inventory of spare parts and loose-assembled valves. In addition, our facilities are audited and governed by the National Board of Boiler and Pressure Vessel Inspectors. Testing, repair, and assembly are performed under license and guidelines of NBIC, and ASME Section I and VIII.

To ensure accurate in-line setpoint verification, TEAM Valve Solutions utilizes Trevitest, the pioneering system for validating safety valve performance in Conventional and Nuclear Power plants, as well as in other industrial process facilities.

Pressure relief valves are safety devices that protect equipment from process overpressure. These valves require regular maintenance and testing to ensure they work properly when you need them.

Quadco LLC is a valve sales and service provider that works with all manufacturers to provide our customers in the Energy, Power and Refining, Chemical and Pharmaceutical, Oil and Gas, and Water industries with custom solutions that best suit their individual needs. We repair all brands and sizes of safety valves and relief valves within our scope. Our trained and certified valve technicians use specialty repair tools, blasting equipment, lathes, polishing equipment, lapping equipment, and qualified test stands to inspect, repair and test your pressure relief valves to international standards and manufacturer specifications.

Offering the best service and convenience, Quadco can test, service, and repair your pressure relief valves in our facilities located throughout the Rocky Mountain Region or with our certified test trailers we can provide field service at your location and can even test your valves in-line (while your process is operating). As in all our service departments, Quadco"s technicians are available 24 hours a day, 365 days a year to ensure that your plant is kept up and running.

Quadco LLC is “VR Certified” by the National Board of Boiler & Pressure Vessels (NBBI) to service, to repair all ASME Section I and VIII Division I safety and safety relief valves (all makes/models of pressure relief valves for liquid service, air service, gas service and steam service). The "VR" stamp that our shop carries covers both high pressure and low pressure safety valves and relief valves. All of our safety valves and relief valves are repaired in accordance with the A.S.M.E and National Board Inspection Codes.

Quadco maintains its own Internal Valve Reporting System which is a custom built maintenance database with traceability for complete historical repairs of valves, replacement parts and repairs

The Flow Component Testing Facilities (FCTF) at SwRI are accredited through the American Petroleum Institute (API) to perform validation testing on both surface and subsurface safety valves. The facilities are also used to perform safety valve testing on other downhole safety valves, riser isolation valves, and wellhead valves. All testing is completed under an API Q1 and ISO 17025 quality management system.

SwRI performs SSSV testing on surface control safety valves (SCSSV) and subsurface control safety valves (SSCSV), subsurface injection safety valves (SSISV), and annular safety valves.Validation Testing – Annex B

SwRI performs testing on various types of valves used as underwater safety valves (USV), surface safety valves (SSV), and boarding shutdown valves (BDSV). This equipment is essential for emergency shutdown of offshore production.

We are National Board certified for repair of safety and relief valves, regardless of manufacturer, media, or pressure class. Certified services are available on-site or at one of our local repair facilities, featuring:

Utilizing state-of the-art diagnostic, measurement, weld repair, and machining equipment, we provide comprehensive valve repair regardless of valve type, pressure class, or manufacturer.

SVI Industrial offers both shop and field diagnostic and control valve repair services. By utilizing “Bench Mark” diagnostic equipment, we can input your control valve’s configuration information, run baseline tests, then provide detailed documentation that will show the valve’s performance. This information can be used to determine if your control valve needs minor instrumentation calibrations or possibly a major overhaul.

We can work independently or with your reliability engineers to establish a database of your safety relief devices throughout your plant. You can count on our experience and knowledge to establish a recommended frequency of safety valve testing and repairs of your safety valves, that meet your corporate requirements and requirements set by your state inspector and insurance auditor based on “best practices” from the National Board.

SVI Industrial holds three “VR” certificates from the National Board of Boiler and Pressure Inspectors authorizing our technicians to repair, set and certify safety pressure valves inline, on our customer’s site and at any of our shop locations for both ASME Section I and VIII code stamped safety valves. Our skilled valve technicians will evaluate the condition of your safety valve, make the proper recommendations and work diligently to get your safety valves tested, repaired and set to the correct specifications and back in-line as quickly as possible in order to minimize interruption of your daily operations.

We are a turnkey service provider with the capability to service, repair or replace your welded in-line steam safety valves, including pipe prep, welding, removal and heat treating. SVI Industrial is your one-stop source for all of your industrial safety valve repair and other maintenance needs.

Allied Valve is the industry leader in valve sales, service, and distribution. Driven by three key principles – safety, reliability, and quality – Allied Valve is a leading supplier of pressure relief valves, control valves, rupture discs, conservation vents, flame arresters, blanket gas regulators, back pressure valves, actuation, and valve services in the upper Midwest. Helping your business meet tight production schedules and reduce downtime with 24/7/365 services delivered on-time, on-site, and in-person, Allied Valve is your trusted partner to keep your business running seamlessly.

Our factory-trained, OEM-certified technicians deliver time-tested solutions that reduce downtime and costs while maintaining the integrity of your safety program. With locations in IA, IL, IN, MN, ND, OH, and WI, our 100+ certified service technicians are at your service. We operate five Consolidated Green Tag Centers, two authorized Kunkle Assemblers plants, and five Masoneilan™ Authorized Repair Center (MARC™), dedicated to providing quality products.

A pressure safety valve (PSV) is a failsafe used to protect people, property and processes from process over pressure. Designed to open immediately to relieve pressure when system pressure reaches a certain level, known as the set pressure, they then close back up to prevent the further release of fluid or gas once normal conditions have been restored. PSVs are essential to the protection of lives and equipment, particularly in the oil & gas, power generation, water/wastewater, aerospace/aviation, steel manufacturing, and chemical/plastics industries. They are purely mechanical so they’re capable of operating at all times and are considered the last resort in preventing catastrophic failure in systems under over pressure conditions.

As the final link in the safety chain, safety valves need frequent testing to ensure they’re in good operating condition and functioning properly. The mechanical parts can stick closed, wear over time and exposure to contaminants and corrosion can affect the resealing or closing of the valve seat after release that could result in a leak. Depending on the industry in which they’re being used, it’s recommended that they’re tested at least every 1-3 years, or more frequently depending on previous inspection history.

PSVs should be tested at their operating pressures and temperatures. A test can be performed "in-situ," while the valve is still in service, but the set pressure is often challenging to create in the field so they’re more commonly removed from the system entirely and taken into a lab/test center for bench testing.

During a conventional PSV test, a technician carefully supplies rising pressure to the valve until it pops (or "cracks"), compares that pressure to the set pressure, and records the results. The goal is to ensure the valve will open and perform its function at the desired set pressure and that the reseal event happens at the desired lower pressure.

To get started you’ll need to connect your PSV, a pressure reference gauge, and an external pressure source. Be sure to follow ASME Section VIII standards for the type of valve being tested.

Step 1: Before you start testing, determine the set pressure of the PSV. Every PSV has a set pressure engraved on the tag riveted onto the body, which is the reading at which the valve should pop open to quickly release pressure. Be sure that the gauge you’re using has the correct measuring range to accommodate the set pressure.

Step 3: Slowly decrease the flow of pressure and record the reseating pressure value, or the pressure point at which the valve closes. If the volume of your pressure source is too low, this will happen instantly and the lower pressure may be difficult to record.

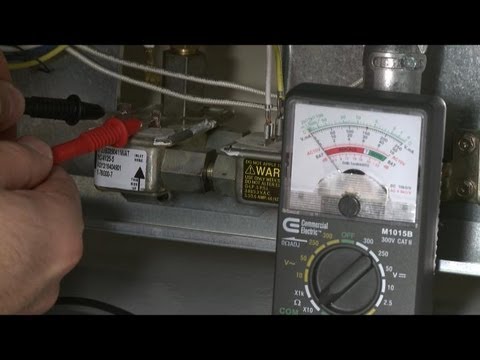

Though the basic PSV testing procedure is relatively easy to perform, results are certified by a technician based on simple observation with little hard data to back it up, and certificates are signed and issued with little to no traceability other than the technician’s word. Even two highly trained technicians observing the same test may record different results, which highlights the inherent potential for human error in this type of standard PSV test.

Accurate testing of PSVs requires extremely precise measurement of the cracking pressure when the valve lifts, and the exact moment when the valve reseats. The FieldLab’s unique PSV/PRV test mode detects the PSV crack pressure and reseat pressure by logging pressure at 200 times per second - far quicker than the logging rate on other devices. It allows the technician to conduct the test and record all of the data directly on the gauge, and then transfer it electronically to a PC where a test report with graphs, customer data, tag data and other required information can be output and shared. It can also perform a leak test and make a judgement of pass or fail based on the ASME standard.

Though the terms Pressure Relief Valve (PRV) and Pressure Safety Valve (PSV) are often used interchangeably, it"s important to understand that PRVs are designed to control pressure in a system. They open gradually in proportion to increasing pressure and are mainly used in fluid or compressed air systems. A PSV is strictly a safety mechanism with no attempt to control the pressure. PSVs open immediately and fully with a "pop action" when the set pressure is reached.

Because of their importance, checking or calibrating valves is critical, but creating a consistent test result is difficult, as two technicians may interpret the analog test gauge differently.

Companies use pressure relief or safety valves to protect equipment from pressure spikes. Because of their importance, checking or calibrating these valves is critical, but creating a consistent test result is difficult, as two technicians may interpret the analog test gauge differently.

Crystal has a solution with its XP2i Digital Pressure Gauge. The XP2i features a special PSV mode designed to test pressure safety and relief valves. Once the valve opens, the XP2i detects the pressure drop and displays the maximum pressure that the gauge ever reached before the drop. This value remains on the display until the technician clears it. Rather than two technicians possibly reporting different values when the analog gauge spikes, with the XP2i both technicians would write the same value, even to a thousandth of a psi.

The XP2i Digital Pressure Gauge features three accuracy levels to choose from, 0.1% of reading, 0.05% of full scale, or 0.02% of full scale. They are available in ranges from vacuum to 15,000 psi and are fully temperature compensated from –10 to 50 C. All versions are ATEX, IECEx, and CSA intrinsically safe, making them ideal for the oil & gas industry and others requiring intrinsic safety. An optional datalogging upgrade allows the XP2i to collect and store up to 32,000 data points and easily download the results to a spreadsheet or protected pdf file.

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for ...

... regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve works to protect any fittings ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

It"s a Safety valve in according with Directives ATEX 20K/34/EU. Technical Norm Fire Prevention 41/256 31/10/2019. d.P.R. 10/520 19/03/1955 and subsequent amendments.

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

V651 Series safety relief valves are produced as safety and relief type. Safety valves are pressure relief elements used to evacuate excessive pressure ...

PVS type slam shut valves are pilot-operated relief valves in which the opening and the closing of the main plug is controlled by a pilot device which is very ...

This range of spring loaded conventional and balanced safety relief valves is specifically designed for overpressure protection of unfired pressure vessel (ASME Section VIII application). ...

The EMERSON BM7 SERIES is a disk slam-shut valve characterized as automatic isolating elements, which are suitable for installation as safety devices in regulating stations. This device has a high operation ...

... control and regulate the gas, air flow to burners and other combustion devices. HMV is a unique safety valve that can be supplied for the requiremen of handling higher ...

Type 50 is a safety valve for universal use. It can be used for nearly any industrial application, e.g. in shipping and pipeline construction, the chemical and petrochemical industries, ...

The RIEGER Safety valve Type SH prevents excessive pressure in steam and gaseous media in plant components and tanks. The set pressure is generally higher than the operating pressure of the system.

... sewage, gas, glycol, diathermic oil, industrial water, steam and other natural and aggressive media, depending on theresistance of materials usedfor the construction ofthe valve.

When it comes to understanding pressure relief valve testing requirements, there’s a lot of information out there, but not all of it seems conclusive. If you’re new to pressure relief valves or are getting started in a new industry, it can be tough to decipher what testing requirements your facility needs to meet.

While we can’t provide the specific testing requirements for every industry, we can offer a few general testing requirements, and point you in the right direction to find the information you need for your facility’s unique testing requirements:

It’s good to keep in mind that every industry and region has unique pressure relief valve testing requirements. Your facility may be required to just bench test pressure relief valves every five years, or you may have to test valves every year, but bench test and repair valves every three to five years. There is a large variance in the testing requirements for pressure relief and safety valves depending on your industry and your region. That said, there are a few general testing requirements we can look at to start with.

The National Board Inspection Code, created by the National Board of Boiler and Pressure Valve Inspectors, makes the following recommendations on the frequency of testing for safety and pressure relief valves, depending on the temperature, psi, and function of your boiler:

High-pressure steam boilers greater than 400 psi should be pressure tested to verify nameplate set pressure every three years, or as determined by operating experience as verified by testing history.

It’s important to remember that these are general pressure valve testing recommendations. For specific requirements, you’ll have to verify your unique jurisdictional and industry code requirements. See the resources below for more information.

The National Board Inspection Code is an industry-recognized name offering quality information on pressure relief valve testing requirements. Here, you’ll find a wealth of information and testing best practices.

The ASME is another organization setting pressure relief valve testing requirements, and offering the necessary training engineers need to test and understand the testing procedures for pressure relief valves. In addition to testing requirements and standards, the ASME offers a variety of online courses on pressure relief valves, from fabrication and proper installation to inspection and repair.

For specific testing standards, it’s best to check with your industry and your regional jurisdiction. Pressure relief valve testing requirements can vary by state or region and are most often industry-specific. Check your industry’s standards, and check local code requirements to ensure your facility is adhering to the most relevant pressure relief valve testing requirements.

When you’re looking for the pressure relief valve testing requirements relevant to your facility, it’s important to understand the different testing methods that are available to you. It’s likely that regardless of your industry if you have safety and pressure relief valves in use at your facility, you’ll have to bench test those valves at least every five years.

In addition to those bench tests, though, you’ll also have to perform manual or on-site pressure relief valve testing. Here’s a quick look at the three most common pressure relief valve testing methods you’ll see when researching pressure relief valve testing requirements:

The most commonly mandated form of pressure relief valve testing, bench testing is unique in that it requires you completely shut down your facility’s system and remove all pressure relief valves. The valves are then transported to a lab where they are tested and repaired as necessary. Tested valves are then re-installed in your system.

Bench testing is the most involved method of pressure relief valve testing, but as this is how valves are tested when they’re manufactured, the industry considers this to be the most thorough testing method.

Inline testing is another accurate pressure relief valve testing method that doesn’t require the removal of valves or facility downtime. With inline safety relief valve testing equipment, a trained technician can test valves in the system to calculate the real setpoint of a valve in the system.

While inline testing cannot take the place of mandated bench testing, it is a more efficient form of testing for other regular testing requirements. Inline pressure relief valve testing is the ideal choice for any required testing that does not have to be bench testing, as it eliminates the need for downtime while still providing exceptionally accurate results.

Some pressure relief valve testing requirements will call for regular manual testing for freedom of operation. This is a basic test that can be done on-site. To complete an operated-in-place test, the test lever on the valve is manually activated. This test functions to ensure that the valve can open and shut tightly, but it does not verify at what pressure the valve opens and shuts. This is a test that may be required quarterly or bi-annually, to ensure the most basic functionality of safety relief valves.

Pressure relief valve testing is necessary for any facility with safety relief and pressure relief valves. For more information about the equipment you need for pressure relief valve testing, the profitability of certain testing methods, and more, head to the AccuTEST blog. There, you’ll find a variety of resources on everything from implementing inline safety relief valve testing to minimizing plant downtime.

If your company requires regular pressure relief valve testing, you might be interested in AccuTEST’s high-tech equipment. Offering inline testing with accurate, repeatable results, our system is the best on the market. See how our equipment works in real-time — schedule a live webinar demo today.

WITT is a manufacturer of Pressure relief valvesor Safety relief valves for technical gases. They are designed to protect against overpressure by discharging pressurized gases and vapors from pipelines, pressure vessels and plant components. Safety relief valves (SRV) are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve (PRV), safety valve, pressure safety valve, overpressure valve, relief valve or blow-off valve.

WITT safety valves are very precise. They are individually preset to open at a predetermined pressure within the range 0.07 to 652 Psi. Their small size and orientation-independent installation allow a wide range of connection options. WITT relief valves also stand out due to their high blow-off flow rates of up to 970m³/h. They can be used within a temperature range of -76° F to +518°F and even with very low pressures.

For maximum safety, WITT undertakes 100 % testing of each safety relief valve before it is delivered. In addition, WITT offers individual testing of eachsafety valveby the TÜV, with their certificate as proof of the correct set pressure.

WITTsafety relief valvesare direct-acting, spring-loaded valves. When the preset opening pressure is reached, a spring-loaded element in the valve gives way and opens, and the pressure is relieved. Once the pressures are equalized, the valve closes automatically and can be reactivated any time the pressure rises again. Depending on the application and the nature of the gas, the safety relief valvescan either discharge to atmosphere, or via a connected blow-off line. The opening pressure of the safety valves is preset by WITT at the factory according to the customer’s requirements.

Safety relief valvesare used in numerous industries and industrial applications where, for example, gases pass through pipelines or where special process vessels have to be filled with gas at a certain pressure.

For most industrial applications using technical gases, brass is usually the standard material of construction of thesafety relief valvebody/housing. For the use of pressure relief valves with aggressive and corrosive gases, the housings are made of high-quality stainless steel (1.4541/AISI 321, 1.4404/AISI 316L, 1.4305/AISI 303 or 1.4571/AISI 316Ti). The use of aluminium as a housing material is also possible.

Depending on the type of gas used and individual customer requirements, various sealing materials and elastomers are available to ensure the safety of your systems under even the most difficult conditions.

WITT pressure relief valves are available with different connections. In addition to the standard versions with the usual internal or external threads, special versions with KF or CF flanges, VCR or UNF threads can also be ordered. Special adapters for connecting the safety relief valve to a blow-off line are also available.

Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous. Generally valves are placed on or near the pump head of the hose, pipe or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves.

This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Like every other type of check valve, relief valves may be constructed from a variety of materials, including PVC, brass, ductile iron, copper, polyethylene, polypropylene, aluminum, steel, stainless steel and rubber. Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas and pressure applications.

8613371530291

8613371530291