homeowner safety valve company manufacturer

Avoid the headache, hassle and costly repair bills caused by a water or sewer emergency on your property, or an in-home plumbing problem. A single call to Safety Valve takes care of it all.

New to Safety Valve? Enter your address below to check eligibility. Already a customer? Log in to manage your account. You must register first if you haven"t done so.

When considering complaint information, please take into account the company"s size and volume of transactions, and understand that the nature of complaints and a firm"s responses to them are often more important than the number of complaints.

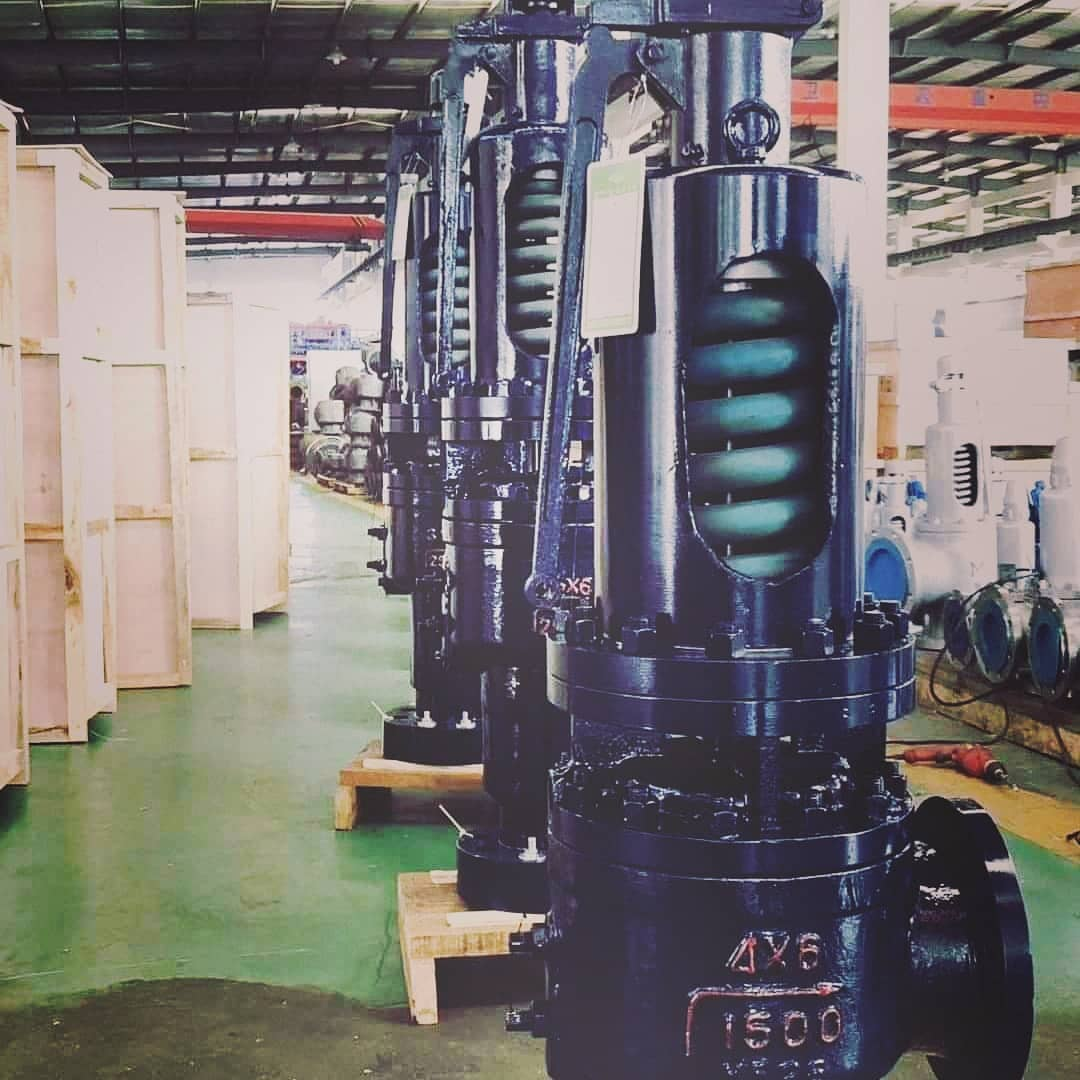

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

It’s a reputation we are proud to have earned from our customers in the United States and around the world. We have earned it with our commitment to consistently provide our customers with prompt, courteous service and the highest quality products. Clack is a leader in the manufacture and distribution of high quality control valves and water treatment components.

While it"s possible to manually shut off your natural gas, the following specialized valves are available that can automatically shut off your service in case of an emergency:

Earthquake natural gas shut-off valve (also known as a seismic natural gas shut-off valve) automatically shuts off your natural gas service when an earthquake of a sufficient magnitude occurs at your home.

An excess-flow valve (EFV) automatically closes and restricts the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter.

If you want to have an earthquake natural gas shut-off installed, or are required to have one by your insurance company or the local Department of Building and Safety, the valve must be installed on your house line.

Under the regulations of the California Public Utilities Commission (CPUC), General Order 112-E, only SoCalGas® or its certified contractors are authorized to operate the natural gas service shut-off valve.

When you hire a qualified professional to install your earthquake valve, you"ll need to make sure that the valve is installed on your house line, not on SoCalGas" facilities. SoCalGas" facilities include all of the pipe fittings installed and maintained by SoCalGas, up to and including the last elbow or tee connecting to your house line. See the diagram below for to see where your house line starts.

All unauthorized valve installations found on SoCalGas" facilities will be removed. In addition, earthquake valves are not permitted in utility curb meter vaults.

If an earthquake or other significant event causes your earthquake shut-off or excess-flow valve to close, you can follow the manufacturer"s instructions for resetting the valve so that natural gas flows again. However, we recommend that you contact a qualified professional or SoCalGas to reset the valve, and to perform a safety check of your natural gas appliances before they are placed back in operation to verify that no natural gas leaks exist, and to re-light your pilot lights.

Remember that following a major emergency it may take many days or even weeks before someone can come to your location. (SoCalGas charges a fee to reset valves and re-light pilot lights when your earthquake shut-off valve has closed due to a non-earthquake occurrence.)

Price: The cost of the valve is going to vary based on the type and size of the valve, as well as the installation requirements and the company installing it.

Choosing a valve: In order to choose the right valve size and manufacturer, contact your local Department of Building and Safety to find out their earthquake valve requirements.

Where to buy a valve: You can purchase an earthquake valve at supply retailers, licensed plumbing contractors, or directly from the valve manufacturer.

Using a contractor: You can hire a qualified professional to install the earthquake or excess-flow valve on your house line. SoCalGas will not install a valve for you.

Effective February 10, 2002, California Public Utility Commission (CPUC) Decision 01-11-068 prohibits installation of an earthquake valve on SoCalGas" facilities. In addition, SoCalGas no longer installs earthquake shut-off valves for its customers, and does not allow any customer owned equipment, including excess-flow valves, be installed on SoCalGas" facilities.

If you have an earthquake valve that was installed by SoCalGas or one of its authorized contractors on or before the February 10, 2002 cutoff date, that is located on SoCalGas" facilities, with proper documentation your installation may be allowed to remain in place. Authorized contractors are those who participated in SoCalGas" earthquake program and were trained by SoCalGas to work on their facilities.

Additional information regarding earthquake valves and natural gas service restoration after a valve activates can be found in Tariff Book, Rule 10, Section G, "Earthquake Valve Service."

An Excess Flow Valve, or EFV, is a safety device installed on natural gas distribution pipelines to automatically close and restrict the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter. These conditions are typically caused by digging or construction but can also be caused by damage to your natural gas meter by a vehicle impact.

NOVI, MI – For both new installation and repair work, professional plumbers and DIY homeowners alike rely on durable and safe fittings, connectors and valves. Since 1946, BrassCraft Manufacturing has been the professional’s choice, becoming a trusted partner in providing a full range of water, gas, faucet and toilet supplies, tubing and more.

“From the wall to the fixture or appliance, our products hook up more water and gas connections than any other brand in the industry,” said Joe Gross, president of BrassCraft Manufacturing. “Ensuring the safety and reliability of these critical connections is a top priority for our customers, and we take that responsibility very seriously. Both professionals and DIY homeowners know they can trust BrassCraft® products to do the job right, every time.”

Today, BrassCraft Manufacturing continues to excel in developing world-class, dependable products like its Speedi Plumb PLUS® polymer braided connectors, along with the Safety+PLUS® excess flow valves and ProCoat® corrosion-resistant gas connectors, which recently won First Place in the 2014 Innovation Awards by Home Improvement Executive. The company has also been at the forefront of the industry in meeting the new no-lead laws with a full range of high-quality compliant products, helping customers to meet government mandates as quickly and efficiently as possible.

“We’ve designed our products to provide the fast, reliable and safe connections professionals demand to help ensure customer satisfaction and reduce call-back repairs,” Gross said. “At the same time, our products give homeowners the ability to buy what the pros buy to make every DIY project a success.”

In addition to providing customers with quality, reliable products, BrassCraft Manufacturing is also committed to investing in the future of the plumbing industry and supporting the next generation of skilled tradesmen and women. The company will award at least 100 $1,500 scholarships this year alone to help plumbing apprentices enrolled in accredited training programs complete their schooling to become journeyman plumbers.

Brasscraft Manufacturing Company, a Masco-owned company, is a leading manufacturer of plumbing products for use in the new construction and repair and remodel markets. Founded in 1946, Brasscraft Manufacturing is headquartered in Novi, Michigan and has manufacturing facilities throughout the continental United States. BrassCraft®. This is our Craft™.

New replacement air compressor pressure safety relief valves. Using the correct one for your application is critical for safety. If you need help picking the right one, please call us for assistance.

A backwater valve (sometimes called a backflow or sewer backup valve) is a valve you can install on your sewer line and is designed to allow water or sewage to flow only one way—out of your house. Sudden heavy rainfall can overwhelm city sewer lines, causing water or sewage to flow back towards your home. A backwater valve prevents sewage from flowing backwards into your house during such events.

They can be installed in the initial new construction or retrofitted into existing homes. Installing during the initial construction is naturally much cheaper, costing around $500. To retrofit a backwater valve, a section of the home’s foundation needs to be removed to access the main sewer line. The cost to retrofit a backwater valve ranges from $2,000 to $5,000.

Backwater valves are required by some municipalities and recommended by others. Some municipalities offer subsidies to assist with the installation of backwater valves—check out the links at the end of this article.

The risk of water backup increases if there is a basement in your home, or if the ground floor is less than 30 cm above street level. If a new home has any fixtures located below street level, The National Plumbing Code requires a backwater valve.

Your home’s sewer system allows water and sewage to flow out of the house. A backwater valve stops water or sewage from flowing into your house should the main sewer line become overloaded.

Inside the valve is a small flap that is normally open, allowing water to exit your home and any sewer gases to vent. There is a small floatation device on each side of the flap. If water or sewage starts to flow backwards into the house, the floaters cause the flap to lift up and close, thus preventing anything from entering your home.

When you retrofit a backwater valve onto your existing home (as opposed to installing it during construction), you’ll need a plumbing permit from your municipality. During installation, a plumber will have to cut a hole in the concrete floor, usually near the floor drain. Then, they’ll dig down to the main sewer line, cut out a portion, and replace it with the new valve.

The valves often have a clear top so you can see if it is operating properly. There’s also a lid that you can remove for cleaning. Without a properly functioning backwater valve, sewage could come into the basement through a floor drain, sinks, tubs, and toilets.

Before you install a backwater valve in your home, talk to your municipal government to find out if any local permits are required, as well as to find out what sort of equipment they recommend.

When it comes time for installation, hire a licensed plumber. They can install the backwater valve and can also obtain any necessary building permits. Municipal governments sometimes maintain lists of pre-approved plumbers.

“People often forget this and cover them with flooring. This stops the ability for inspection and maintenance as well as losing access to the drains for clearing blockages if they occur. Drains can still block and cause a backup even with a backwater valve installed. Underground piping in the basement may require the expected installation location to change.”

Things can get stuck inside the valve, preventing it from closing. Sharp items moving through can also damage the valve. Proper, regular maintenance can catch these issues before there is a serious problem.

Backwater valves are usually easily accessible. They have a clear top, so you should be able to see if water is flowing freely or if anything is stuck. You’ll find plenty instructional videos to help you DIY the maintenance. Or, you can call an expert if the thought of sticking your hand in a sewage pipe is not particularly appealing. If you do attempt to clear a block on your own, be sure to follow all the instructions carefully—especially wearing gloves.

If everything is clear, and the city sewer backs up during a major rainstorm, your backwater valve will close, which is exactly what you want to happen.

When the valve is closed, water can’t flow out of your house either. There is a certain amount of storage space in your plumbing system to account for this. But, you may not want to shower and run your washing machine or dishwasher all at once during a major rainstorm or snowmelt event. Since none of your wastewater will be able to escape with the backwater valve closed, you could wind up flooding your own house.

The WAGS Valve is a brand-name product designed to eliminate the risk of and damage caused by flooding when a hot water heater fails to drain properly. WAGS stands for Water And Gas Safety. Some statistics suggest that a majority of water heaters fail within 7-10 years. While that number seems high in our personal experience, statistically about 5 million tank failures occur every year. Not all of these are catastrophic. However, during these leaks, the water heater keeps refilling and leaking. This creates a damaging cycle that can go on for some time until it is discovered or remedied.

The WAGS valve is designed to shut off the water supply when it detects a water leak. Typically this would come from a hot water heater. In this way, a WAGS valve minimizes water damage and, on the enhanced models, possible gas leakage.

You can easily install a WAGS valve on all styles of water heaters. It’s fully mechanical and requires no external power supply. If a leak occurs, an internal water-soluble fiber element dissolves, releasing a powerful, spring-loaded piston. This immediately shuts down water flow to the tank.

The valve’s action is based on fiber element technology developed for the British Royal Air Force to inflate life jackets automatically. Once activated, the valve shuts off the water and the gas supply.

The device even causes a red pop-up tab to emerge. This lets you know an activation has occurred. You need to replace a WAGS valve once it activates. That may seem like a pain if you sweated it in using copper. Considering it stopped a leak, however, that “pain” may be well worth the hassle and cost of replacing the valve.

The WAGS valve is a very simple, and relatively inexpensive device that could save you tons of money in the event of a water heater leak. It’s definitely something to consider having installed the next time you replace your tank.

Corporation stop—The corporation stop is connected to the water main. This connection is usually made of brass and can be connected to the main with a special tool without shutting off the municipal supply. The valve incorporated in the corporation stop permits the pressure to be maintained in the main while the service to the building is completed.

Curb stop—The curb stop is a similar valve used to isolate the building from the main for repairs, nonpayment, of water bills or flooded basements. Because the corporation stop is usually under the street and it is necessary to break the pavement to reach the valve, the curb stop is used as the isolation valve.

Curb stop box—The curb stop box is an access box to the curb stop for opening and closing the valve. A long-handled wrench is used to reach the valve.

Meter stop—The meter stop is a valve placed on the street side of the water meter to isolate it for installation or maintenance. Many codes require a gate valve on the house side of the meter to shut off water for plumbing repairs. The curb and meter stops can be ruined in a short time if used very frequently.

The water meter is a device used to measure the amount of water used in the house. It is usually the property of the water provider and is a very delicate instrument that should not be abused. In cold climates, the water meter is often inside the home to keep it from freezing. When the meter is located inside the home, the company providing the water must make appointments to read the meter, which often results in higher water costs unless the meter is equipped with a signal that can be observed from the outside. The water meter is not shown in

The supply mains should have a drain valve stop and waste valve to remove water from the system for repairs. These valves should be on the low end of the line or on the end of each fixture riser.

Copper lasts a long time, is durable, and connects well to valves. It should not be installed if the water has a pH of 6.5 or less. Most public utilities supply water at a pH between 7.2 and 8.0. Many utilities that have source water with a pH below 6.5 treat the water to raise the pH. Private well water systems often have a pH below 6.5. When this is the case, installing a treatment system to make the water less acidic is a good idea [5].

Galvanized Steel. Galvanized pipe corrodes rather easily. The typical life of this piping is about 40 years. One of the primary problems with galvanized steel is that, in saturated water, the pipe will become severely restricted by corrosion that eventually fills the pipe completely. Another problem is that the mismatch of metals between the brass valves and the steel results in corrosion. Whenever steel pipe meets copper or brass, the steel pipe will rapidly corrode. Dielectric unions can be used between copper and steel pipes; however, these unions will close off flow in a short time. The problem with dielectric unions is that they break the grounding effect if a live electrical wire comes in contact with a pipe. Some cities require the two pipes to be bonded electrically to maintain the safety of grounded pipes.

A tap-water temperature of 120ºF–130ºF (49ºC–54ºC) is hot enough for washing clothes, bedding, and dishes. Even at 130ºF (54ºC), water takes only a few minutes of constant contact to produce a third-degree burn. Few people bathe at temperatures above 110ºF (43ºC), nor should they. Water heater thermostats should be set at about 120ºF (49ºC) for safety and to save 18% of the energy used at 140ºF (60ºC). Antiscald devices for faucets and showerheads to regulate water temperature can help prevent burns. A plumber should install and calibrate these devices. Most hot water tank installations now require an expansion tank to reduce pressure fluctuations and a heat trap to keep hot water from escaping up pipes.

It is essential that valves be used in a water system to allow the system to be controlled in a safe and efficient manner. The number, type, and size of valves required will depend on the size and complexity of the system. Most valves can be purchased in sizes and types to match the pipe sizes used in water system installations. Listed below are some of the more commonly encountered valves with a description of their basic functions.

Shutoff Valves. Shutoff valves should be installed between the pump and the pressure tank and between the pressure tank and service entry to a building. Globe, gate, and ball valves are common shutoff valves. Gate and ball valves cause less friction loss than do globe valves; ball valves last longer and leak less than do gate valves. Shutoff valves allow servicing of parts of the system without draining the entire system.

Flow-control Valves. Flow-control valves provide uniform flow at varying pressures. They are sometimes needed to regulate or limit the use of water because of limited water flow from low-yielding wells or an inadequate pumping system. They also may be needed with some treatment equipment. These valves are often used to limit flow to a fixture. Orifices, mechanical valves, or diaphragm valves are used to restrict the flow to any one service line or complete system and to assure a minimum flow rate to all outlets.

Relief Valves. Relief valves permit water or air to escape from the system to relieve excess pressure. They are spring-controlled and are usually adjustable to relieve varying pressures, generally above 60 psi. Relief valves should be installed in systems that may develop pressures exceeding the rated limits of the pressure tank or distribution system. Positive displacement and submersible pumps and water heaters can develop these excessive pressures. The relief valve should be installed between the pump and the first shutoff valve and must be capable of discharging the flow rate of the pump. A combined pressure and temperature relief valve is needed on all water heaters. Combination pressure and vacuum relief valves also should be installed to prevent vacuum damage to the system.

Pressure-reducing Valves. A pressure-reducing valve is used to reduce line pressure. On main lines, this allows the use of thinner walled pipe and protects house plumbing. Sometimes these valves are installed on individual services to protect plumbing.

Altitude Valves. Often an altitude valve is installed at the base of a hot water tank to prevent it from overflowing. Altitude valves sense the tank level through a pressure line to the tank. An adjustable spring allows setting the level so that the valve closes and prevents more inflow when the tank becomes full.

Foot Valves. A foot valve is a special type of check valve installed at the end of a suction pipe or below the jet in a well to prevent backflow and loss of prime. The valve should be of good quality and cause little friction loss.

Check Valves. Check valves have a function similar to foot valves. They permit water flow in only one direction through a pipe. A submersible pump may use several check valves. One is located at the top of the pump to prevent backflow from causing back spin of the impellers. Some systems use another check valve and a snifter valve. They will be in the drop pipe or pitless unit in the well casing and allow a weep hole located between the two valves to drain part of the pipe. When the pump is started, it will force the air from the drained part of the pipe into the pressure tank, thus recharging the pressure tank.

Frost-proof Faucets. Frost-proof faucets are installed outside a house with the shutoff valve extending into the heated house to prevent freezing. After each use, the water between the valve and outlet drains, provided the hose is disconnected, so water is not left to freeze.

Frost-proof Hydrants. Frost-proof hydrants make outdoor water service possible during cold weather without the danger of freezing. The shutoff valve is buried below the frost line. To avoid submerging it, which might result in contamination and back siphoning, the stop-and-waste valve must drain freely into a rock bed. These hydrants are sometimes prohibited by local or state health authorities.

A properly installed T&P valve will operate when either the temperature or the pressure becomes too high due to an interruption of the water supply or a faulty thermostat.

A tankless unit has a heating device that is activated by the flow of water when a hot water valve is opened. Once activated, the heater delivers a constant supply of hot water. The output of the heater, however, limits the rate of the heated water flow. Demand water heaters are available in propane (LP), natural gas, or electric models. They come in a variety of sizes for different applications, such as a whole-house water heater, a hot water source for a remote bathroom or hot tub, or as a boiler to provide hot water for a home heating system. They can also be used as a booster for dishwashers, washing machines, and a solar or wood-fired domestic hot water system [7].

Occupational Safety and Health Administration. Safety hazard information bulletin on the use of polyvinyl chloride (PVC) pipe in above ground installations. Washington, DC: Occupational Safety and Health Administration; 1988. http://www.osha.gov/dts/hib/hib_data/hib19880520.htmlExternal.

Homes that are equipped with a gas line that runs from the utility line to the home should have an automatic gas shut-off valve (ASV) (Figure 1), which is a valve that shuts off the flow of gas into a home due to an earthquake or other event that causes a rupture of the gas line, thus reducing the chance of explosion or fires from leaking gas. Shaking or movement of a building or the appliances in the home in the event of an earthquake or other natural disaster can cause damage to the gas piping and appliances, causing the accidental release of natural gas, which can lead to fires or explosions. Structural weaknesses, the absence of appliance anchors, and lack of flexible pipe connectors can all contribute to a greater possibility of gas leaks (Danville 2021).

All homes that have natural gas have a manual shutoff valve located on the gas meter that can be closed using a wrench to stop the flow of natural gas into the home in the event of an emergency (Figure 5). However, the home’s occupants may not be available to close the line in the event of a natural disaster or may not be aware of a rupture of the line due to some other cause such as digging. If an automatic gas shutoff valve is installed on the line, it can stop the flow of gas quickly in the event of an emergency with no human intervention needed, preventing large gas spills from occurring and potentially causing fires or explosions.

There are two types of automatic gas shut-off devices: earthquake-actuated gas shut-off valves (also known as seismic valves) and excess flow valves. The differences between the two valves are summarized in Table 1 and described below. Requirements for shutoff valves for natural gas lines vary by jurisdiction. The requirement typically applies to new building construction and significant alterations or additions to existing buildings (PG&E 2021). Because an earthquake valve is triggered by movement, not an actual line break, while it will prevent gas leakage from the initial quake or aftershocks, it will shut off the gas even if no rupture occurs to the gas line. In contrast, an excess flow valve is triggered by sudden high flow on the line, indicating a leak has occurred; earthquake movement alone won"t trigger it. Utilities note that restoration of utility gas service after an emergency will take time, whether the gas valve has been shut manually or automatically, because the utility may require that its crews inspect the gas meter and equipment to verify there are no leaks in the line, clear active lines of residual gas, restore service to the lines, and relight pilot lights (PG&E 2021).

Stops flow of gas on the service line between the main line and the meter when it detects high gas flow and/or loss of line pressure depending on valve model.

An earthquake-actuated gas shutoff valve (also known as an earthquake valve or a seismic valve) is a simple mechanical device installed just downstream of the meter on the pipe between the meter and the house (Figures 1 and 2). If the valve is subjected to significant movement, a ball or “float” in the valve drops into place to block the flow of gas through the pipe and into the building. If an earthquake does impact the home, gas flow will be stopped by the valve so gas will not continue to flow into the home, where it could potentially leak from any ruptures in the line downstream of the meter and possibly catch fire or explode. Earth movement equivalent to an earthquake registering approximately 5.4 or greater on the Richter scale will activate the locking mechanism. (The Richter scale ranges from 1.5-barely detectable to 9.5-catastrophic; a 5.4 quake could cause considerable damage.) Many utilities require the installer to attach a stabilizing bracket to the piping near the valve to minimize the likelihood that an accidental bump will activate the valve.

Seismic valves can be required by insurance companies or local departments of building and safety in areas prone to seismic activity. Some city, state, and/or county regulations require the installation of seismic valves; some leave this up to the owner’s discretion. Seismic valves are typically located on the homeowner’s side of the meter, on the pipeline leading from the meter into the house, which is usually located in an easily accessed location outside, above ground on the side or front of the house. The seismic valve is located downstream of the utility manual gas shut-off valve, pressure regulator, meter, and the service tee (see Figures 1 and 2).

Seismic valves are purchased by the homeowner and installed by either the homeowner or a licensed plumber or contractor who has been certified to do so. Most utilities do not install seismic valves (for example, SoCalGas 2021). Some utilities offer assistance in purchasing the valves. For example, the City of Berkeley, California, offers free seismic valves to homeowners who complete a training program (City of Berkeley 2018). The City of Malibu, California, requires a plumbing permit to install valves but waives fees for the permit process (City of Malibu). Utilities do not typically allow attachments or connections of any kind on the utility’s piping and equipment before the point where the service tee connects to the gas houseline piping. After installation, the valve must not obstruct any gas operations or utility services in or around their piping, gas service shut-off valves, gas meters, or gas pressure regulating equipment (PG&E 2021).

Seismic valve products should meet the requirements of ASCE 25-97 and ANSI Z21.70-1981 Standards for Seismic Gas Valves. Some locales require that installers use a state-approved model for excess flow gas shut-off valves and earthquake-actuated gas shut-off valves. Seismic valves installed in California should be certified by the California State Architect"s Office as meeting California Standard No. 12-23-1 for Earthquake-Actuated Automatic Gas Shutoff Systems. The State of California’s Division of the State Architect (DSA) oversees the certification of both types of gas shutoff valves as required by the Health and Safety Code and lists approved models on the website of the DSA Gas Shut-off Valves Certification Program. Products used in Los Angeles need to be approved by the City of Los Angeles. Examples of seismic valves approved for use in California are shown in Figures 3 and 4.

Seismic valves will operate to shut off the gas when they sense enough earth movement, whether a line rupture occurs or not. If the gas is shut off by a seismic valve, some utilities specify that the homeowner is not to turn the gas back on themselves but should notify the utility to have a utility representative perform a safety check, restore gas service, and relight appliance pilot lights. For this reason, some utilities do not encourage the installation of seismic shutoff valves for residential service due to the time required to go around and reset all of the valves following an earthquake. Some jurisdictions require excess flow valves instead. Check the applicable jurisdiction for specific requirements in your area (FEMA E-74, 2011).

The valve is manually reset once a safety inspection has been done to verify there are no leaks in the building. Some jurisdictions allow homeowners to reset their own automatic shutoff valves. This is one reason some homeowners prefer to have an earthquake-actuated shutoff valve even if not required to do so by the local building department or their homeowner’s insurance company. In the event of an earthquake, an earthquake-actuated valve will shut off gas flow as soon as significant earth movement is detected without waiting to sense a gas leak. If, after the quake, no leaks are detected, the homeowner may be able to reset the valve or hire a plumber to reset the valve and re-establish gas service. Many homes have both types of valves.

Excess flow valves automatically stop the flow of gas on the service line between the main gas line at the street and the customer"s meter (on the "utility side" of the meter) if excess flow or loss of pressure is detected, indicating a rupture of the gas line (American Gas Association 2011), whether the rupture is caused by an earthquake, or some other natural cause such as a sinkhole or a washout, or damage from digging or drilling equipment, or motor vehicle impact to the meter, or line breakage in the home.

In 2006, Congress mandated the use of excess flow valves on all new or replaced gas distribution lines serving single-family residences (49 CFR 192.383(a)). By the end of 2014, an estimated 9 million excess flow valves were in service and over 800,000 new valves were being installed every year (P&GJ 2016). In a Final Rule published in the Federal Register on October 14, 2016, the Pipeline and Hazardous Materials Safety Administration (PHMSA) made changes to 49 CFR Part 192 to expand the requirement to include multifamily residences and small commercial buildings, and required gas utilities to notify customers who had existing homes without excess flow valves of their right to request installation of one. For new homes, the cost of installation is included in the charge for the new line.

Dates at which utilities began installing excess flow valves for new homes vary by utility, although many pre-date the 2006 Congressional mandate. For example, all homes with gas service built in Oregon after 1993 have an excess flow valve installed by the utility at construction. With an existing home, if you are unsure if an excess flow valve is already installed, contact the gas utility. In existing homes without an excess flow valve, the customer can request that the utility install one, at the homeowner’s expense (Colorado Springs Utilities). The utility or their service contractor will install the excess flow valve on the underground service line pipe running from the street to the meter. Costs vary depending on location and difficulty of the installation, with reported costs ranging from $400 to $7,000. For example, the City of Ellensburg, Washington, estimates $500 to $1000 (City of Ellensburg). TECO Peoples Gas in Florida estimates $1,200 to $1,800 (TECO Peoples Gas). PG&E estimates $2,500 to $6,000 or more, based on the specific site (PG&E 2017).

In an emergency, some utilities tell their homeowners that the gas can be turned off at the main gas service shutoff valve, with the following guidelines (for example, PG&E 2021, SoCalGas 2021).

Locate the main gas shutoff valve. It is typically next to the gas meter. It may be on the side of front of the house, or in a cabinet meter outside of the house, under the house, or underground.

Give the valve a quarter turn in either direction. The valve is closed when the tang (the part of the valve you put the wrench on) is crosswise (perpendicular) to the pipe. See Figures 5 and 6.

Manually turn off the gas shutoff valve at each appliance. For safety, a shut-off valve should be installed at every natural gas appliance. If a leak happens at a specific appliance, the valve allows you to turn off the natural gas at the appliance rather than shutting off the natural gas service line to the whole house. Some valves require a wrench. See Figure 7.

Consult your local utility for guidance. Some utilities advise homeowners not to shut off the gas unless they smell gas, hear gas escaping, see a broken gas line, or suspect a gas leak because, if they do shut off the gas, there may be a considerable delay before the utility can turn the service back on (for example, PG&E).

8613371530291

8613371530291