subsurface safety valve in stock

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

Maintaining fluid control and well protection is critical in your shallow depth well operations. The SelecT™ subsurface safety valve from Baker Hughes addresses the unique challenges that shallow set safety valves (typically <1,000 ft) endure.

The tubing-retrievable SelecT valve includes an ultra-strong power spring that delivers the high closing forces needed to reliably and consistently close the valve in the presence of paraffin and other produced solids.

The SelecT is engineered to avoid failures due to wireline damage during downhole interventions. The valve’s advanced flapper design prevents damage and ensures that all seal surfaces are protected from wireline contact—even during accidental closure of the valve during wireline operations.

Ensure greater seal integrity with the SelecT valve’s patented advances that include thru-the-flapper self-equalizing system. And the radial punch control fluid communication system eliminates accidental communication associated with linear shifting sleeves.

Baker Hughes’s portfolio of subsurface safety valves deliver reliable performance when it matters the most, providing emergency closure in the event that well control is lost. We offer a full range of valves to suit applications ranging from shallow- to deep-set, and the valves are available in surface- and subsurface-controlled, tubing-retrievable, and wireline-retrievable options. All Baker Hughes valves undergo stringent prototype testing and conform to standards and specifications such as API and ISO, as well as requirements requested for your unique situation.

Safety valves are designed to automatically shut in the flow of a well in the event surface controls fail or surface equipment becomes damaged. They are classified according to the location from which they are controlled – surface or subsurface. In this article, subsurface safety valve types, operating systems, working principle, setting depth, and selection process are presented.

It is advisable, and in most cases mandatory, to have a secondary means of closure for all wells capable of natural flow to the surface. The installation on of a sub-surface safety valve (SSSV) will provide this emergency closure capability.

Operating systems may be either remotely operated on a fail-safe principle from surface (SCSSV) actuated from a control panel located on surface, or will be a subsurface controlled (SSCSV), designed to close automatically when a predetermined flow condition occurs in the well (actuated by the pressure differential/flow velocity across the valve).

In case of SCSSV, a 1/4″ inch stainless steel control line is attached to the outside of the tubing string and installed when the tubing is installed. Depending on the wellhead pressure, it may be necessary to keep as much as 4000 to 5000 psi on the control line to keep the valve open.

The differential type subsurface controlled subsurface safety valve senses pressure drop across a flow bean. There are several variations of the differential type SSCSV. Although they employ different sealing devices, such as a flapper or ball, they all are controlled with a flow bean and spring tension.

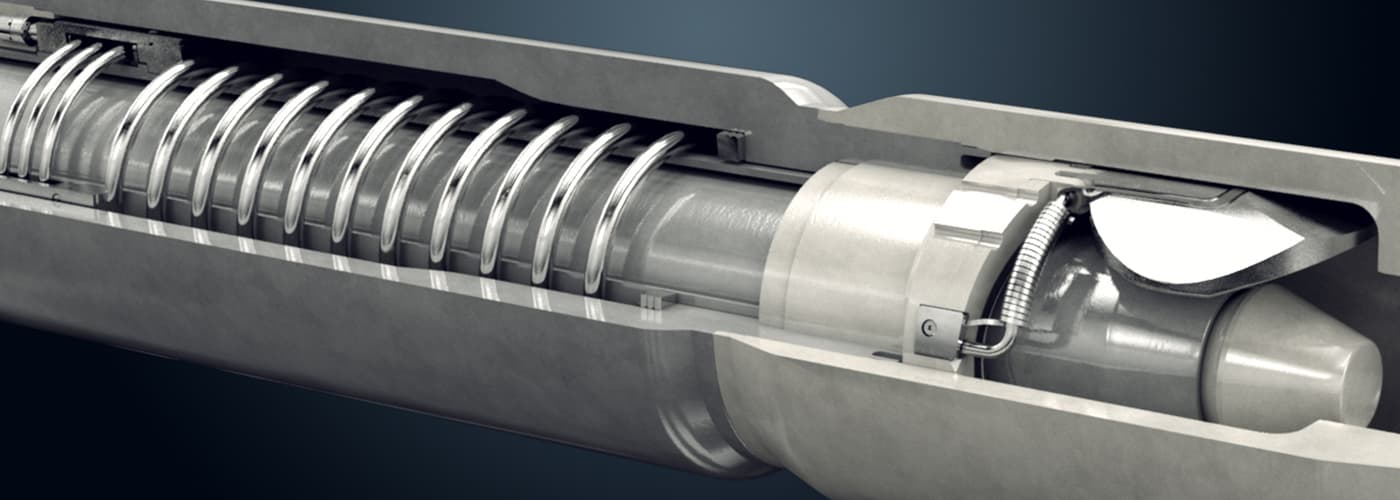

As shown in the following video, when hydraulic pressure is applied down a control line, the hydraulic pressure forces a sleeve within the valve to slide downwards. This movement compresses a large spring and pushes the flapper (in case of flapper type SCSSV) or the ball (in case of ball type SCSSV) downwards to open the valve. When hydraulic pressure is removed, the spring pushes the sleeve back up and causes the flapper (or the ball) to shut. In this way, it is failsafe and will isolate the wellbore in the event of a loss of the wellhead.

The location of the downhole safety valve within the completion is a precisely determined parameter intended to optimise safety. There are arguments against it either being too high or too low in the well and so the final depth is a compromise of all factors. MMS regulations state that the valve must be placed no less than 100′ below the mudline.

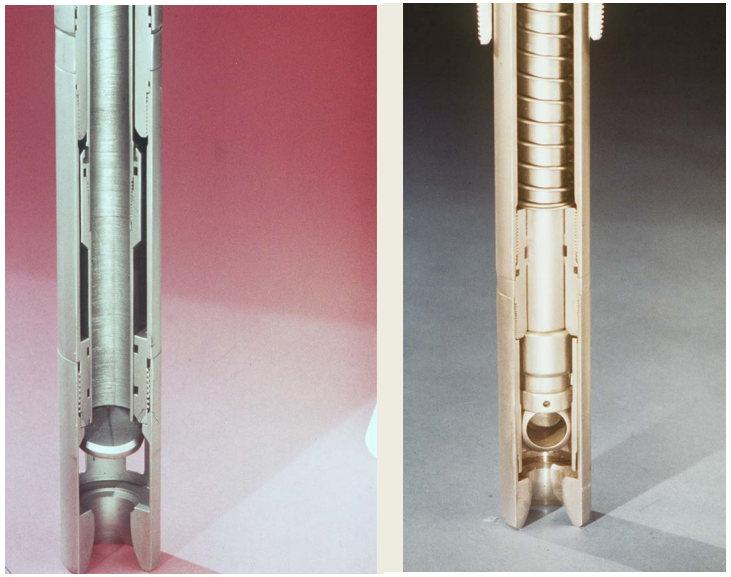

The TH series subsurface safety valves are tubing retrievable surface controlled subsurface safety valves used for high pressure environment. When installed, the safety valve is connected to the surface through the control line. The pressure from surface is transmitted through the control line, acts upon the piston of the safety valve and controls the opening and the closing of the safety valve. This series of products includes self-equalizing and non-equalizing types.

The TSS series subsurface safety valves are tubing retrievable surface controlled subsurface safety valves. Compared with the TS series, the safety valve features super slim outer diameter design. The control line connects the valve to the surface, and the pressurization from surface on the control line controls the opening and closing of the flapper. This series of products includes self-equalizing and non-equalizing types.

Halliburton provides proven, high-performance tubing-retrievable and wireline-retrievable subsurface safety valves (SSSV) designed to reliably shut-in (fail safe) if a catastrophic event occurs, allowing operators to maintain safe operations.

To protect the surface facilities in case of emergency, the wellbore is isolated from surface facilities using a subsurface safety valve (SSSV). Hence such a safety valve needs to be fail safe in order to isolate well bore in any kind of system failure or damage to surface production, control and safety facilities.

A subsurface safety valve is typically a uni-directional flapper valve, directed in such a way that the flappers open downwards when pressure is applied from an upward direction. The flapper can only open in the downward direction. So even if high pressure is applied by the well fluids from a downward direction, a safety valve can remain closed. This makes a subsurface safety valve fail-safe. To open the valve, hydraulic signal is sent from the surface well control panel. This hydraulic pressure is responsible for keeping the flappers of SSSV open and loss of hydraulic pressure result in closing of the valve. Thus wellbore can be isolated in case of system failure or damage to the surface facilities.

The safety device is established in the upper wellbore to administer emergency closure of the bearing conduits in the case of a disaster. Types of subsurface safety valves are surface-controlled and subsurface-controlled. In each case, the safety-valve system is invented to be fail-safe, so that the wellbore is isolated in the event of any system failure or damage to the surface production-control facilities.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale subsurface safety valve on Alibaba.com. When you search for subsurface safety valve and related items, you will be able to find many types of subsurface safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of subsurface safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

As long ago as 1936, accelerated drilling of high pressure oil and gas wells in inland waters near town sites and other dangerous or isolated places required a device to protect wells from uncontrolled flow caused by accident or other damage to surface equipment. To meet this need, many types of safety valves were built and tried, most of them being of the velocity-operated type. These valves were designed to operate by increased velocity, or by the pressure differential across the valve caused by the increased velocity of flow, or by a drop in pressure to a predetermined value, caused by the rupture of some part of the well equipment on the surface. The velocity operated valve is subjected to inherent variables of flowing wells which made it difficult for average operating people to calculate and set the closing rate accurately.

While the velocity-operated valve is suitable for flowing wells producing at reduced rates, it is less suitable in areas where large volumes of flow are permitted. In wells produced at rates at or close to their potential, it is hard to predetermine spring settings to guarantee closure in an emergency.

With the rapid extension of the offshore fields into the shipping lanes of such areas as Lake Maracaibo and the Gulf of Mexico, it became apparent that a safety device should be developed which would not have the disadvantages of the velocity-operated valve.

In Venezuela, work was started on a surface controlled subsurface safety valve which would not be dependent upon the velocity off low to close the valve. As a result of this effort} the ball valve came into being. It is used in many of the oil wells in Lake Maracaibo, Venezuela.

Subsurface safety valves (SSSVs), which are standard and often statutorily required in the oil and gas industry for upper completions, were first developed in the late 1930s. Operators sought to drill more high-pressure wells, often near populated areas or, conversely, offshore or very isolated areas, making the need for a device to protect the wells from uncontrolled flow increasingly apparent. The need was made even more urgent by the fact that the uncontrolled flow could be caused by accident or by damage to the surface equipment, which at the time was quite common.

Modern developments in SSSV design have sought to address the industry’s challenges and the issues that arise in more complex reservoirs and harsher downhole environments through additional testing and research to optimize the valves’ technical specifications. While the basic functionality of the valves has not changed for some time, the standard to which the valves are engineered and manufactured is now shifting, thanks in part to a new partnership between Tejas Research & Engineering and National Oilwell Varco (NOV). It is a partnership bolstered by Tejas’ involvement on the American Petroleum Institute’s (API) 14A standards subcommittee.

Tejas Research & Engineering sprang from the Camco tradition that pioneered many pivotal developments in SSSV design. The R&D and engineering for safety valve products are conducted in Tejas’ HP/HT facility in The Woodlands, Texas, where SSSVs with pressure requirements of 25,000 psi and 260 C (500 F) are designed, tested, qualified and produced.

Tejas’ model TRSV(E) SSSVs are tubing-retrievable, surface- controlled, normally closed devices installed in oil and gas wells to control tubing fl ow. Metal-to-metal seals are used in 100% of Tejas’ tubing-retrievable product line, which has products that are rated to 10,000 psig and are suitable for temperatures up to 176 C (349 F) at moderate setting depths. Higher temperature/pressure/setting depths/slimline diameters are available for custom order. The TRSSSV series are API-14A V1 certified and adaptable to any standard or premium tubing thread. The system features a large fullbore, where the inside diameter (ID) is equivalent or greater tubing than the tubing ID to which the SSSV is attached. Additionally, it has either flat flappers (2⅜ in. to 3½ in.) or curved flappers (4½ in. to 7 in.) and a single rod piston featuring nonelastomeric dynamic seals. The TRSSSV is available in either equalizing or nonequalizing trims. The valve is controlled hydraulically with a ¼-in. control line in the well’s annulus, enabling valve closure during an emergency shutdown.

The new safety valve builds upon lessons learned in valve design over Tejas Research & Engineering’s entire history. Previous valves have achieved significant milestones— including one design that has more than 8,000 valves in use without a single failure or degradation in performance. Completions have evolved since those early designs, and new valves need to withstand significantly higher temperatures, working pressures and setting depths as well as accommodate different diameters. The new valve product line meets the rigorous quality standards outlined in API Specification 14A and tested beyond the specifications in Revision 12, including Annex H, which specifically addresses the verification and validation requirements for use in HP/HT environments.

An evolution in safety valve standards means the industry can be more confident that well control incidents will not occur. As regulations continue to change and become stricter, it is imperative that safety valves maintain their rigorous quality and durability while being able to handle even more challenging well environments.

Subsurface Safety Valve TRSSSV is a kind of tubing retrievable safety valve which is controlled at the surface. It directly connects to the tubing string. There is a hydraulic control line connecting to the safety valve from the ground. While a certain amount of pressure is supplied through this control line to the safety valve, the valve remains open; while the pressure is released, the safety valve will close and the tubing pass is closed at the same time.

We"ve partnered with Tejas Research & Engineering, a respected expert in safety valve development with nearly two decades of experience, to commercialize a new line of subsurface safety valves (SSSVs). The new valves meet the rigorous standards set forth in API Specification 14A and are tested beyond the HPHT specifications of Annex H, drawing upon a legacy of engineering experience while recognizing the need for an evolution in quality and reliability.

The new surface-controlled, tubing-retrievable SSSVs are rated for working pressures up to 10,000 psi (68 948 kPa) and temperatures up to 300°F (149°C). The valves use a non-elastomeric, single-piston actuator, optional self-equalizing flapper, and metal-to-metal flapper closure seal to provide 100% well containment when closed. Our 2⅞-in. safety valves are available now, and additional sizes are forthcoming.

8613371530291

8613371530291