safety valve plans manufacturer

Avoid the headache, hassle and costly repair bills caused by a water or sewer emergency on your property, or an in-home plumbing problem. A single call to Safety Valve takes care of it all.

New to Safety Valve? Enter your address below to check eligibility. Already a customer? Log in to manage your account. You must register first if you haven"t done so.

To start a claim you must call Safety Valve directly at 1-800-713-1613. Work must be done by a Safety Valve referred contractor to be covered so do NOT call a contractor directly or your claim will not be covered.

The curb box allows access to the curb valve, and the curb valve is the valve located on your property that can be used to shut off the water in the event of an emergency water line leak.

The Water Line Protection Plan covers from where your water service line connects to your main water valve in your basement to the curb valve located on your property. In some instances, you may also own and be responsible for the water line in the street, which runs from your curb valve on your property to the water main in the street. (We suggest you contact your local water utility for clarification.)

No, the main shut-off valve in your home is not covered under the Water Line Protection Plan. It is the point where the water service line coming into your home ends. We consider the main valve as part of your internal plumbing. If you would like coverage for the main shut-off valve, please review our In-Home Plumbing Protection Plan.

All plans take effect 30 days after the enrollment is processed and payment received, regardless of whether you pay by check, bank account or with a credit card. In some cases, we may need to perform an on-site inspection, so we provide customers with a 30-day window to account for this possibility.

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

Aquarion refused to be ignored, sending a big white van to pay me a visit. They really stepped it up from the white door tag. This time, the dog alerted me to the vehicular presence in the driveway, and that is where I met my fate. I perp-walked out to the technician feeling rather guilty. After a boots-on-the-ground consultation, I was asked a question that no one in New Canaan is prepared to answer in the affirmative: Do you have water line safety valve insurance?

Ummm, no. You mean those silly letters that I throw away every month and say, “Ha, what sucker buys safety valve insurance?” It was made very clear why the insurance is worth the investment and it was painful. All of the sudden, I had become the New Canaan version of Diane Keaton’s character from “Baby Boom,” and was quite literally, drowning in homeownership hell.

That said, I was quoted up to $10,000 if my leak hide-and-seek project was major. This was not what I had bargained for when I threw away all of those safety valve insurance mailers.

This page lists the ApprovedPressure and Safety Relief ValveManufacturers (vendors), also provides inspection and test advice to thePressure and Safety Relief Valvepurchasers buying from vendors, suppliers and distributors.

Service Sentinel℠ is not an active program at this time. With the acquisition of New England Service Company (NESC) by Aquarion Water Company (AWC), Service Sentinel has been merged into an entity called Safety Valve. Safety Valve is very similar to Service Sentinel, although there are some minor differences which can be explored online at www.safetyvalveplans.com. Safety Valve is a well-respected company that has partnerships with municipalities as large as New Britain, CT and Waterbury, CT. In addition, partnerships that Service Sentinel maintained with certain local water companies are being maintained, meaning that you will be able to rely on Safety Valve to provide the same standard of care and responsiveness that our customers have come to expect from Service Sentinel.

Furthermore, Safety Valve provides customers with several plans that Service Sentinel was not able to offer. In addition to water line coverage and a water and sewer line combo plan, Safety Valve offers both sewer line only coverage, as well as an in-home plumbing plan which can save you considerable time and resources in fixing broken pipes or clogged drains inside of your home or place of business.

Again, please visit www.safetyvalveplans.com for more details, and to enroll or renew existing coverage. Additional information can be found by calling 860-747-1665 (NESC) or 800-713-1613 (Safety Valve).

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

For centuries, safety relief valves have served as a vital line of protection against excessive overpressure that – left unaddressed – can cause considerable damage to industrial processes including equipment failure and process upset, along with secondary hazards arising from an uncontrolled release of pressurized fluid.

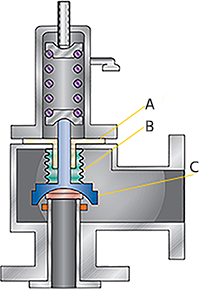

These essential safety devices are designed to automatically open when the force exerted by the pressure reaches a setpoint to rapidly discharge the fluids. Once the overpressurization has dissipated, the valve recloses, conserving the remaining fluid.

In developing codes and standards, the industry has largely standardized around the 90-degree flow path design outlined by the American Petroleum Institute (API). This standardized approach requires a drop in pressure inside the valve before it discharges fluid from the exit nozzle.

To ensure proper performance, the orifice diameter at the inlet side is smaller than the nominal valve size, with an outlet diameter that is larger than both. A two by three-inch traditional API configuration safety relief valve will be designed with either a 0.785” diameter H orifice or a 1.287” diameter J orifice at its inlet and a three-inch outlet, for example.

While it may be convenient for the purposes of standardization, other approaches to safety relief valve design are possible while meeting industry codes and standards such as those published by The American Society Of Mechanical Engineers (ASME), said Geof Brazier, Managing Director, BS&B Safety Systems, Custom Engineered Products Division.

So, BS&B had a novel idea: what if the safety relief valve was an inline device, with outlet and inlet connections that were the same size and an inlet orifice diameter to match the inlet connection?

“With an inline design, the flow moves in a straight line and doesn’t have to change direction,” said Brazier. “The design allows for a certain amount of flow expansion, but we don’t have nearly the same level of turbulence inside the valve, which increases the capacity of the device,” said Brazier.

By having the inlet diameter match the nominal size of the valve, there is more flow [capacity]. The valve can also be more compact, lighter in weight and requires smaller size and therefore less expensive piping. The result is simplified installation and a lower total cost of investment.

To address the need for increased flow, BS&B has introduced the IDV Safety Valve, a self-reclosing safety pressure relief valve that functions the same as a traditional safety relief valve but with an inline configuration rather than the traditional angle body configuration.

The inline configuration allows for up to 3 times the capacity of a conventional valve. The smaller the nominal size, the greater the capacity benefit from the IDV Safety Valve.

This new technology enables customers to achieve the same overall outcome as a traditional valve. The increased capacity allows engineers and operators to optimize their pressure safety systems and, in many applications, reduce the piping configuration (line size) by one or more nominal sizes.

The IDV Safety Valve is compact and lightweight and can be installed using ANSI/ASME B 16.5 and international flange connections. Mounting can be either horizontal or vertical, adding to the flexibility of application for this design.

The valve can be combined with an optional integrated rupture disk at the inlet and/or outlet. The combination of a rupture disk device with a safety relief valve has many benefits arising from valve isolation to the normal process conditions including optimal leak tightness, increased operating pressure, extended valve life and reduced valve maintenance.

The IDV has already been installed in over 10,000 processes worldwide, making it an established alternative to the safety relief valve that meets the same codes and standards.

Dante Valve is a full-service manufacturer, distributor and VR™ certified repair facility of valves and related products for the industrial and military markets.

We manufacture military specification Danco pressure relief valves; we distribute Kunkle relief valves and TRAC regulating, reducing, and temperature regulating valves, fittings and flanges; we also provide CNC machining services.

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

Also known as pressure relief valves (PRV), pressure safety valves (PSV), and safety valves, these systems act as a safety measure. They relieve excess pressure from equipment failure, process upset, or fire by opening an auxiliary passage to divert the fluid (liquid, gas, steam or air) away from the pressure vessel. Once the pressure in the vessel is released and the danger is over the relief valve closes itself. Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous.

Generally valves are placed on or near the pump head of the hose, pipe, or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves. This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial, and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas, and pressure applications.

Safety relief valves often serve as the point-of-protection against potentially dangerous circumstances, so it is important that they be dependable. Baker Hughes provides various valve styles, sizes, options and configurations for multiple industries and applications.

Baker Hughes continues to pursue quality and pro-active approach through regular collaboration with our customers and by staying actively involved in the development of regulatory compliance standards. We configure, engineer, and manufacture safety relief valves that adhere to industry regulations and global and regional standards while helping meet our customers’ evolving needs.

Not sure which valve you need for your application?Download ValSpeQ (Mooney regulators & Becker valves) or ValvStream™ (Masoneilan and Consolidated valves) to size, select and generate proposal documentation for your valves.

Consolidated Green Tag Centers (GTC) from Baker Hughes Energy comprise one of the broadest OEM service networks in the industry. With more than 80 facilities located in more than 30 countries worldwide, the GTCNet™ network provides the aftermarket support you need. Our GTC customers receive responsive and effective service through OEM-certified repairs, innovative valve diagnostics from ValvKeep™- valve management and maintenance software, and the EVT-Pro, an electronic valve testing device. Each GTC location is staffed with highly qualified technicians, specifically trained and certified to deliver exceptional product support and technical expertise.

Outgrowing from subcontractor business, renovateol manufacturing system of high-pressure gas safety valves integrating all processes from design and manufacture to inspection. We took the first step as a manufacturer specialized in safety valves.

Accredited as an authorized safety valve manufacturer (Test: MA, Manufacture: MB, Accreditation No.: 159-19) by Minister of International Trade and Industry (MITI) - under (The 1st) Append. 42 Chem. No.637.

8613371530291

8613371530291