safety valve plans for sale

Avoid the headache, hassle and costly repair bills caused by a water or sewer emergency on your property, or an in-home plumbing problem. A single call to Safety Valve takes care of it all.

New to Safety Valve? Enter your address below to check eligibility. Already a customer? Log in to manage your account. You must register first if you haven"t done so.

1-800-223-7019. Work must be done by a Safety Valve referred contractor to be covered sodo NOT call a contractor directly or your claim will not be covered.

To start a claim you must call Safety Valve directly at 1-800-713-1613. Work must be done by a Safety Valve referred contractor to be covered so do NOT call a contractor directly or your claim will not be covered.

All leaking internal clean water pipes (hot or cold), fittings and valves from the point the supply enters the house up to and including the shut-off valve before each fixture

The curb box allows access to the curb valve, and the curb valve is the valve located on your property that can be used to shut off the water in the event of an emergency water line leak.

The Water Line Protection Plan covers from where your water service line connects to your main water valve in your basement to the curb valve located on your property. In some instances, you may also own and be responsible for the water line in the street, which runs from your curb valve on your property to the water main in the street. (We suggest you contact your local water utility for clarification.)

No, the main shut-off valve in your home is not covered under the Water Line Protection Plan. It is the point where the water service line coming into your home ends. We consider the main valve as part of your internal plumbing. If you would like coverage for the main shut-off valve, please review our In-Home Plumbing Protection Plan.

All plans take effect 30 days after the enrollment is processed and payment received, regardless of whether you pay by check, bank account or with a credit card. In some cases, we may need to perform an on-site inspection, so we provide customers with a 30-day window to account for this possibility.

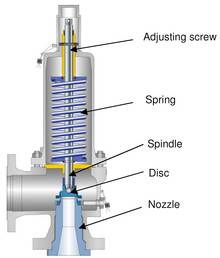

After a boiler has been engineered, built and tested for a given operating pressure there is only one reliable way to prevent operation of the boiler above this design pressure. This is a safety valve. The safety valve should be sized so that a single valve can handle the maximum steam production rate of the boiler and once open prevent boiler pressure to continue to rise. Standard operating procedure for the last century has been to install two safety valves on the boiler, one set 3-5 lbs below the design pressure and one valve set at the design pressure.

The 1st valve listed below is a true adjustable differential pop valve. The differential is adjured through the differential rings lock screw hole, from 3 PSI to whatever the operator desires. The pressure of the valve can be adjusted from 40 to 200 PSI.

The other valves listed are adjustable for release pressure and have a "pop" action: The pressure differential is not adjustable on these valves. If the valves are operated above their nominal pressure, the set-reset differential increases. If operated at lower pressure, the differential decreases to the point of disappearing about 10-15% below nominal pressure.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

Maintaining safe operating conditions can be challenging in deep-set or deepwater, high-pressure/high-temperature (HP/HT) wells. The REACH™ subsurface safety valve from Baker Hughes provides an answer, with fail-safe operation in a wide range of deep-set completions that require low operating pressures due to control system limitations.

REACH safety valves are designed to provide reliable sealing in deep, HP/HT wells. They can be set up to 20,000 ft (6,096 m) below sea level and withstand temperatures up to 400°F (205°C) and pressures up to 20,000 psi (1,379 bar).

REACH safety valves are V1 validated and have undergone the stringent prototype testing per API SPEC 14A, Specification for Subsurface Safety Valve Equipment, Twelfth Edition. Our safety valve specialists have continuously modified the design to accommodate the new V1 validation specifications while progressively exceeding the requirements set forth by API.

REACH valves rely on field-proven, heavy-sprung closure technology to ensure fail-safe-closed operation. Because tubing pressure is isolated from the control system, the valve can open at much lower operating pressures, reducing the cost of umbilicals in some applications.

The valve’s unique activation system requires lower valve operating pressures than previous safety valve designs by eliminating the need to overcome tubing pressure, making the valve ideal for applications with opening pressure limitations including: subsea completions, high-pressure wells, and fields where the rig site and other control facilities may have supply pressure limitations.

REACH valves incorporate several proven features from other safety valve designs, including flapper closure technology, RBT housing thread technology, dynamic seal technology, and debris exclusion geometries—all of which help deliver integrated functionality and dependability.

To ensure long term reliability, the valve is also offered with a reinforced dynamic seal configuration, upgraded dynamic seal materials, internal alignment enhancements, and an enhanced scraper ring to minimize debris. Because the REACH valve does not utilize gas springs, the operating seals and gland do not experience pressure reversals, making them ideal for your critical deepwater HP/HT applications

A pressure safety valve actuated by inlet static pressure and characterized by rapid opening or rapid popping action. This safety valve is tight shut-off and is for safety only. Meets ASME SEC. VIII (Not a Fulflo valve)

A spring loaded pressure relief valve, actuated by the static pressure upstream of the valve. The valve opens normally in proportion to the increase in pressure over the set pressure. (Fulflo)

A pressure relief valve characterized by rapid opening or pop-action in direct proportion to the pressure increase, depending on the application. (Fulflo)

The pressure existing at the outlet of a pressure relief valve, due to the pressure in the discharge system. The pressure can be constant or variable. It is the sum of the superimposed and build-up pressure.

Fulflo was established in 1912 and is celebrating its 100th anniversary. Located in Blanchester, OH, Fulflo was incorporated in 1933 under its present name and trademark. Patents for the original guided piston, direct acting relief valve were obtained in 1935, coinciding with the onset of fluid power systems. The need for providing large flows without excessive bulk was met by the pilot-valve-control relief valve which was patented in 1943.

Fulflo parts and valves are used in oil and gas refineries, are essential to the military, including ships and aircraft carriers, and amusement roller coaster rides.

Safety valves, when properly maintained, can last a long time—upwards of 30 years or more. Much more. Recently, a century-old valve arrived at NASVI for repair. After machining and lapping […]

William Rock III, NASVI Valve Disassembler Since 2001 When a valve arrives at our facility for remanufacturing, William Rock III (Bill) is ready and waiting on the front line. He […]

Bronze, steel and stainless steel safety relief valves for air, gas, steam, liquid and vacuum service that meet ASME Section VIII, ‘UV’; Section I, ‘V’, are National Board certified and […]

When it comes to safety valve experience NASVI employees have a mountain of knowledge. Guess how many years of collective experience these three long-time employees have in this short video. […]

This direct spring-operated pressure relief valve, part of the Series 60 and 80, uses special internals and soft seats for optimum, accurate performance. Of course, we have them in stock. […]

The NASVI team goes the extra step in safety valve quality control. Before we ship any valve, we set and test them to the end user’s specifications. This is an […]

Q: My customer has a 2-inch line. Do I need to sell them a 2-inch safety valve? A: Safety valves should be sized and selected based on the set pressure […]

Not only is Kunkle’s 6252/6254 among their largest valves, also it’s a very sought-after one. You guessed it; we keep several in stock. For general application, it is suitable for […]

Valve manufacturers are not immune from the supply chain issues plaguing most industries right now. It’s predicted that it will take some time for shipping channels to be adjusted. NASVI […]

With supply chain disruptions hitting manufacturers, it’s important to be proactive as we approach heating season. With 35,000 relief and safety valves in stock & same day shipping, our extensive […]

Supply the following information: Example: 1. Quantity of Valves 4 2. Size of Valve Inlet and Outlet 1 ½” x 2” 3. Type, Model or Figure Number 1905FC 4. Manufacturer Consolidated 5. Inlet and […]

If you’re searching for a new Consolidated 1700 Series Maxiflow™ safety valve, or the 2700 and 1900-P1 Series economizer valves, look no further than NASVI. We’re the only company in […]

Did you know that NASVI has 35,000 safety & relief valves ready to ship at a moment’s notice? Or that warehouse is so huge (63,000 square feet!) we have a […]

NASVI pressure tests over 150 valves every day. Watch the process from adjusting the blow down ring to field service guidelines and performing the test pop, to sealing and shipping […]

If your customers are requesting a Kunkle liquid relief valve, model 218, then it’ll come as no surprise to you that not all distributors stock them and the manufacturer’s lead […]

A cracked valve, a broken part. There are always unwelcome surprises during a scheduled or unplanned shut down. Operations need to be back up and running ASAP. Don’t wait 7-10 […]

A No Brainer. Wearing face masks and social distancing is a no brainer. It isn’t pleasant, but you do what you have to do. Selling safety valves is also a […]

If you’re on the hunt for a new Consolidated 1700 Series Maxiflow™ safety valve, or the 2700 and P1 Series economizer valves, look no further than NASVI. We’re the only […]

What’s the purpose of a drip pan elbow? It provides a means to handle condensate from safety valves used in steam applications. Where are drip pan elbows used? The drip […]

When you sell safety valves, your customers are under pressure to get what they need fast. That’s why NASVI stocks the largest selection of Kunkle Valves for a variety of […]

Suggest a NASVI Valve Exchange Program. If your customer has several safety valves in need of repair but can’t afford to shut down for lengthy repairs, there’s an easy solution: […]

Offer remanufactured safety valves and watch sales grow. More companies today have found that it makes sense to rely on remanufactured safety valves. For most industrial uses, remanufactured valves offer […]

Offer NASVI’s quick turnaround on repair and testing services. At NASVI, our repair services are designed to keep: Your customer’s safety and relief valves at peak operating efficiency, and Put […]

You don’t have to be an expert in the field of safety and relief valves to sell them because that’s our job. And we’re only a phone call away. We’ll […]

Today, many companies are finding when maintenance budgets need to be stretched; a safe way to save is to rely on remanufactured safety valves. For most industrial uses, remanufactured valves […]

Increase profits, make our new Repair Facility your first stop. North American’s new Service Center is equipped to handle any safety valve repair. NASVI has the specifications for nearly every […]

Our goal is to make it easy for you to profit from the sales of safety and relief valves. Call us for assistance. We can help you with sales planning, […]

Earlier this year, I shared a little product education on safety valves that can make you look really smart to customers, which usually means more orders for everything you sell. […]

• More than 35,000 valves in 3,100 varieties • Currently set and ship over 200 valves per day • We repair over 40 valves a week with plenty of capabilities […]

Offer North American’s remanufactured safety valves as an alternative and watch your sales grow. Many companies have found that it makes sense to rely on remanufactured safety valves. For most […]

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. In addition to an experienced, skilled staff, NASVI’s Service Center is equipped […]

Our giant inventory and remarkable selection awaits your call. One of the customers recently inquired about the availability of five 4-inch liquid flanged valves. The end user had made a […]

Today, many companies are finding when maintenance budgets need to be stretched; a safe way to save is to rely on remanufactured safety valves. For most industrial uses, remanufactured valves […]

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. And put extra profits in your pocket. North American’s Service Center is […]

Offer NASVI’s quick turnaround on repair and testing services. At NASVI, our repair services are designed to keep: Your customer’s safety and relief valves at peak operating efficiency, and Put […]

For some reason I get asked pretty frequently if I’m a surgeon. Believe me, you don’t want me operating on you. I tell people I’m the Safety Value Doctor because […]

We are moving just a few miles east of our current location. Our plans are to be in place by late summer. When Budgets are Tight, Push the Remanufactured Alternative. […]

Offer NASVI’s quick turn-around on repair and testing services. Over the years, our Service Center has proven popular with maintenance managers. It allows your customer’s plant to have their valves […]

Due to the special nature of the safety valve, after receiving the product, the user needs to get the inspection by the pot inspection. It can be used only after the parameters are qualified. The setting pressure must be set and debugged before leaving our factory according to the user`s actual requirements.Therefore, please be sure to inform us for these pressure parameters requirement after you order, otherwise it will not be shipped.

With our partner specifications archives, six on-site lathes, technical know-how and 35,000 in-stock valves, we’ve got your valve repairs covered. Valves are quickly repaired and set following exact specifications, and if they’re irreparable, chances are we’ve got a replacement in stock.

As soon as mankind was able to boil water to create steam, the necessity of the safety device became evident. As long as 2000 years ago, the Chinese were using cauldrons with hinged lids to allow (relatively) safer production of steam. At the beginning of the 14th century, chemists used conical plugs and later, compressed springs to act as safety devices on pressurised vessels.

Early in the 19th century, boiler explosions on ships and locomotives frequently resulted from faulty safety devices, which led to the development of the first safety relief valves.

In 1848, Charles Retchie invented the accumulation chamber, which increases the compression surface within the safety valve allowing it to open rapidly within a narrow overpressure margin.

Today, most steam users are compelled by local health and safety regulations to ensure that their plant and processes incorporate safety devices and precautions, which ensure that dangerous conditions are prevented.

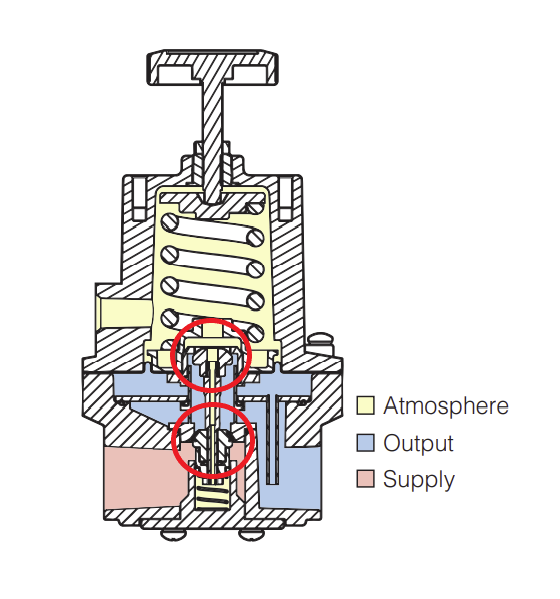

The principle type of device used to prevent overpressure in plant is the safety or safety relief valve. The safety valve operates by releasing a volume of fluid from within the plant when a predetermined maximum pressure is reached, thereby reducing the excess pressure in a safe manner. As the safety valve may be the only remaining device to prevent catastrophic failure under overpressure conditions, it is important that any such device is capable of operating at all times and under all possible conditions.

Safety valves should be installed wherever the maximum allowable working pressure (MAWP) of a system or pressure-containing vessel is likely to be exceeded. In steam systems, safety valves are typically used for boiler overpressure protection and other applications such as downstream of pressure reducing controls. Although their primary role is for safety, safety valves are also used in process operations to prevent product damage due to excess pressure. Pressure excess can be generated in a number of different situations, including:

The terms ‘safety valve’ and ‘safety relief valve’ are generic terms to describe many varieties of pressure relief devices that are designed to prevent excessive internal fluid pressure build-up. A wide range of different valves is available for many different applications and performance criteria.

In most national standards, specific definitions are given for the terms associated with safety and safety relief valves. There are several notable differences between the terminology used in the USA and Europe. One of the most important differences is that a valve referred to as a ‘safety valve’ in Europe is referred to as a ‘safety relief valve’ or ‘pressure relief valve’ in the USA. In addition, the term ‘safety valve’ in the USA generally refers specifically to the full-lift type of safety valve used in Europe.

Pressure relief valve- A spring-loaded pressure relief valve which is designed to open to relieve excess pressure and to reclose and prevent the further flow of fluid after normal conditions have been restored. It is characterised by a rapid-opening ‘pop’ action or by opening in a manner generally proportional to the increase in pressure over the opening pressure. It may be used for either compressible or incompressible fluids, depending on design, adjustment, or application.

Safety valves are primarily used with compressible gases and in particular for steam and air services. However, they can also be used for process type applications where they may be needed to protect the plant or to prevent spoilage of the product being processed.

Relief valve - A pressure relief device actuated by inlet static pressure having a gradual lift generally proportional to the increase in pressure over opening pressure.

Relief valves are commonly used in liquid systems, especially for lower capacities and thermal expansion duty. They can also be used on pumped systems as pressure overspill devices.

Safety relief valve - A pressure relief valve characterised by rapid opening or pop action, or by opening in proportion to the increase in pressure over the opening pressure, depending on the application, and which may be used either for liquid or compressible fluid.

In general, the safety relief valve will perform as a safety valve when used in a compressible gas system, but it will open in proportion to the overpressure when used in liquid systems, as would a relief valve.

Safety valve- A valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored.

8613371530291

8613371530291