leser safety valve factory

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

LESER China offers technical advice and customer support for safety valves in China directly from the manufacturer. The wholly-owned subsidiary covers all areas of a safety valve manufacturer with production (machining, assembly, storage and inspection), order processing, logistics, safety valve consulting, project management, after-sales service and marketing.

LESER sales offices in Tianjin, Beijing and Shanghai as well as sales service in Shenzhen, Xi"an and Wuhan ensure regional customer proximity. LESER partner Sinobright Pesch serves major customers and the province of Xinjiang.

Well-known companies worldwide rely on LESER safety valves. With its sole focus on overpressure protection, the safety valve specialist LESER is one of the international market leaders.

LESER US supplies representatives, distributors, and end customers in North America. This subsidiary provides on-site manufacturer expertise for all your commercial and technical needs. LESER US stocks 7 million USD worth of safety valves and spare parts at its location in Charlotte, North Carolina. This allows LESER US to deliver safety valves and spare parts from the regional warehouse within one week or, in emergencies, on the same day.

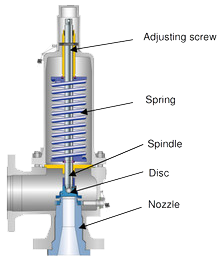

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

With 11.000 kilometers from north to south and 18 countries, the Spanish speaking Latin America is one of the biggest economical regions of the world. Since 2004, LESER build-up a sales and service partner network in this extensive region. Today, LESER is represented in all industries 20 sales and service partners supported by four nativespeaking Sales Market Developers and around. With this network LESER provides local support with technical consulting and short delivery times to the market.

LESER safety valves are produced at the Hohenwestedt plant, which is, with a capacity of 130,000 valves per year, the largest production site for safety valves in Europe. In addition, LESER manufactures in Paithan/India and Tianjin/China for the respective local markets.

Prefabrication and assembly are largely carried out on automated production lines. Through this process, LESER ensures the consistently high quality standard of the products, regardless of whether it is a series component or an individual production of your choice.

LESER US supplies representatives, distributors, and end customers in North America. This subsidiary provides on-site manufacturer expertise for all your commercial and technical needs. LESER US stocks 7 million USD worth of safety valves and spare parts at its location in Charlotte, North Carolina. This allows LESER US to deliver safety valves and spare parts from the regional warehouse within one week or, in emergencies, on the same day.

The primary purpose of a pressure relief valve is to protect life, property and the environment. Pressure relief valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of pressure relief valves differs depending on the main type or loading principle of the valve. The main types of pressure relief valves are spring-loaded, weight-loaded and controlled pressure relief valves.

Regardless of the type or load, pressure relief valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

LESER India is one of the leading manufacturing companies for safety valves in India. The state of the art manufacturing facility is located in Paithan, Aurangabad. The sales and marketing organization headquartered in Mumbai offers powerful and competent service.

The company was established in 1987 as a joint venture between Fainger Engineering, India, and LESER GmbH & Co. KG, Germany to manufacture safety valves with a proven design and technology. Since 2010, the company is a 100% subsidiary of LESER with now more than 1050 employees.

Our modern manufacturing and testing facilities ensure high quality safety valves and a large central stock guarantees short delivery times for valves and spare parts. To date, the more than 3,00,000 LESER India safety valves installed underline the trust the customers have in LESER India.Our safety valves are being used by customers across all major industries like oil & gas, petrochemicals, chemicals, pharmaceuticals, and Original Equipment Manufacturers (OEMs).

Loyalty by transformation. With almost 200 years of experience, LESER ranks among the pioneers of mechanical engineering in Germany. The company started in Germany in 1818 as a brass foundry and developed a product portfolio of components of mechanical equipment and machines during the "industrial revolution".

In 1885 the company developed its first safety valve for the protection of steam boilers. Even at that early date, LESER products were working for the safety of man and the environment. Since the 1970"s LESER has specialized only in safety valves.

LESER India is one of the leading manufacturing companies for safety valves in India. The state of the art manufacturing facility is located in Paithan, Aurangabad. The sales and marketing organization headquartered in Mumbai offers powerful and competent service.

The company was established in 1987 as a joint venture between Fainger Engineering, India, and LESER GmbH & Co. KG, Germany to manufacture safety valves with a proven design and technology. Since 2010, the company is a 100% subsidiary of LESER with now more than 120 employees.

Our modern manufacturing and testing facilities ensure high quality safety valves and a large central stock guarantees short delivery times for valves and spare parts. To date, the more than 150,000 LESER India safety valves installed underline the trust the customers have in LESER India.

Our safety valves are being used by customers across all major industries like oil & gas, petrochemicals, chemicals, pharmaceuticals, and Original Equipment Manufacturers (OEMs).

Fainger LESER is one of the leading manufacturing companies for safety valves in India. The state of the art manufacturing facility is located in Paithan, Aurangabad. The sales and marketing organization headquartered in Mumbai offers powerful and competent service.

The company was established in 1987 as a joint venture between Fainger Engineering, India, and LESER GmbH & Co. KG, Germany to manufacture safety valves with a proven design and technology. Since 2010, Fainger LESER is a 100% subsidiary of LESER with now more than 120 employees.

Our modern manufacturing and testing facilities ensure high quality safety valves and a large central stock guarantees short delivery times for valves and spare parts. To date, the more than 150,000 Fainger LESER safety valves installed underline the trust the customers have in Fainger LESER.

Our safety valves are being used by customers across all major industries like oil & gas, petrochemicals, chemicals, pharmaceuticals, and Original Equipment Manufacturers (OEMs).

8613371530291

8613371530291